Magnetic tile adhering clamp for direct-current motor

A technology of DC motor and magnetic tile is applied in the field of fixture for magnetic tile bonding of DC motor, which can solve the problems of difficult bonding of magnetic tiles and incomplete positioning of magnetic tiles, so as to increase length and dimension, ensure positioning accuracy, and reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

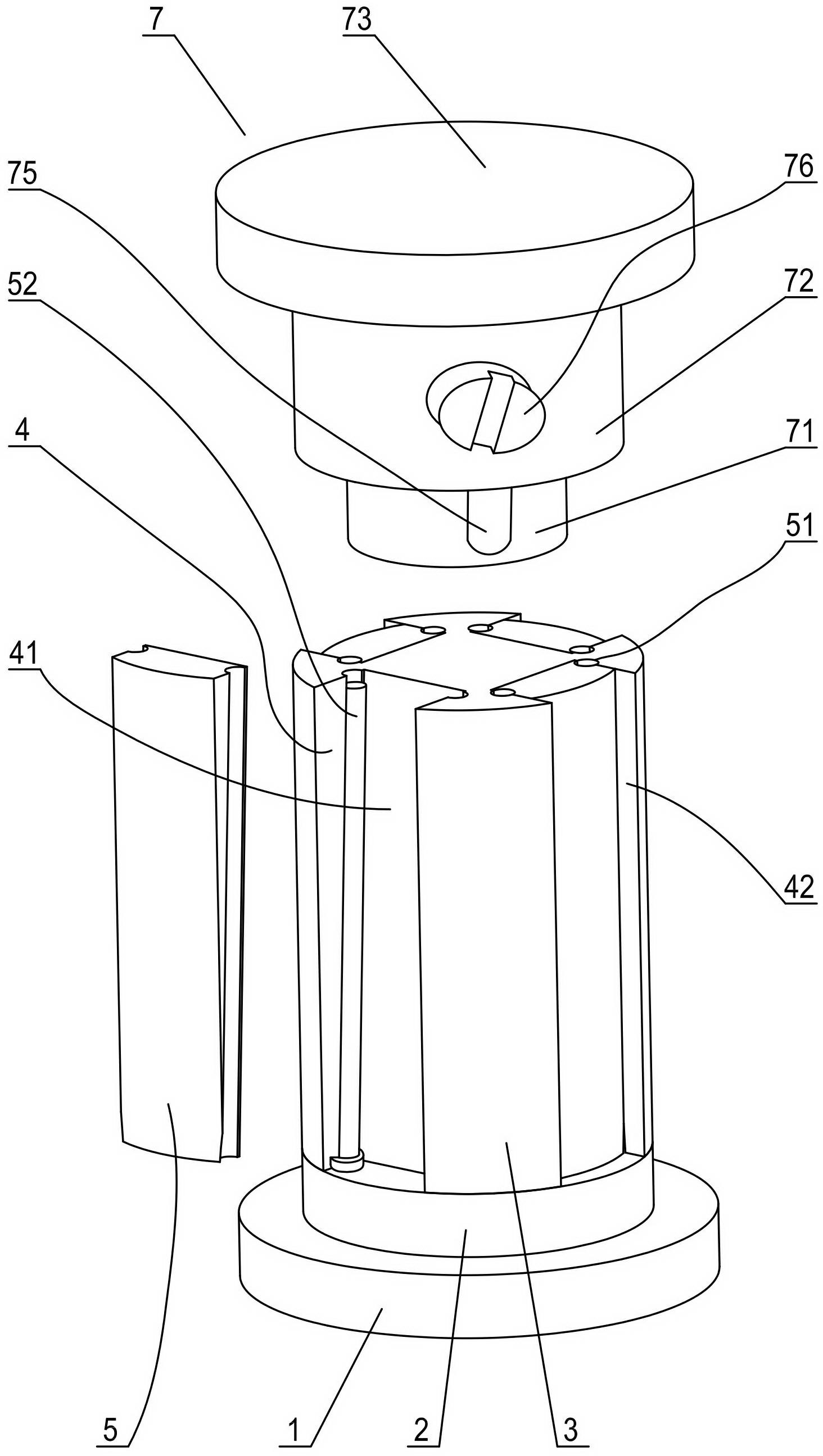

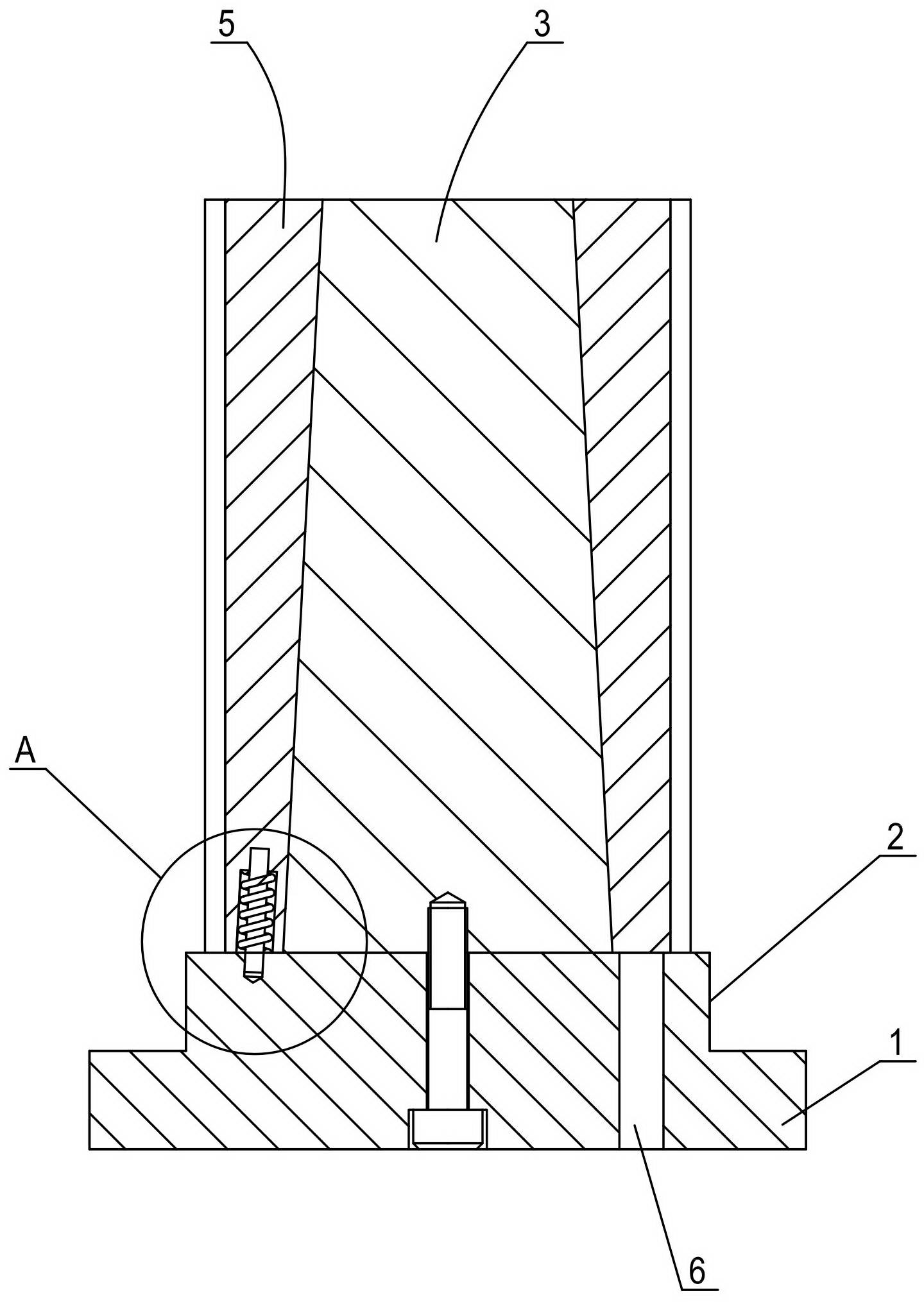

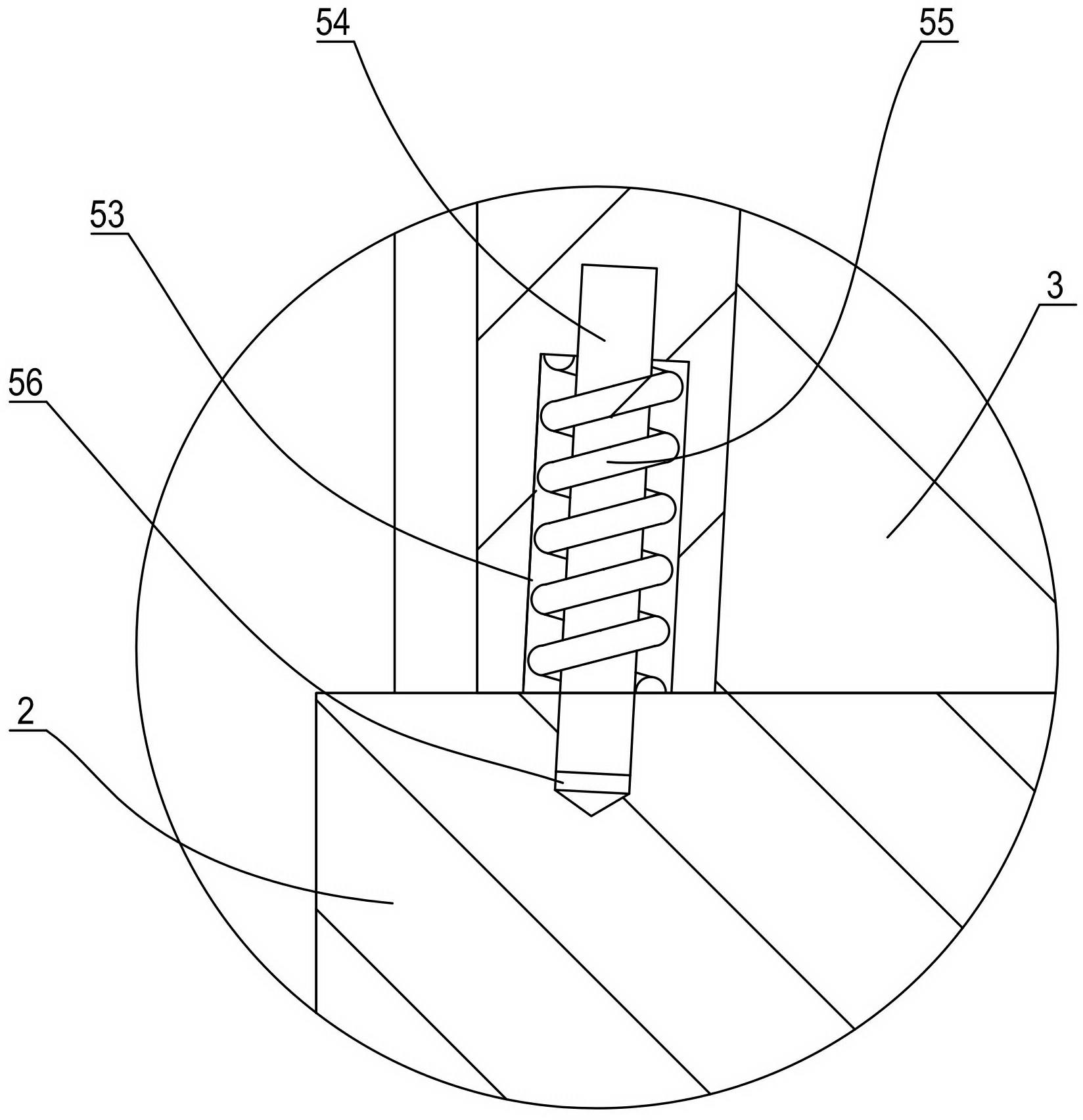

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] like figure 1 In the shown embodiment, a magnetic tile bonding fixture for a DC motor includes a disc-shaped base 1, a cylindrical pad 2 formed integrally on the upper surface of the base, and the diameter of the pad is the same as that of the DC motor casing The inner diameter of the fuselage is compatible, and the height of the heightening column can be determined according to the position of the magnetic tile on the fuselage of the DC motor casing. A positioning cylinder 3 with a split structure is provided on the upper surface of the heightening column, which is the same as the heightening column. The outer diameter of the positioning cylinder is also compatible with the inner diameter of the DC motor body, and the height of the positioning cylinder is comparable to that of the magnetic tile after splicing. The total length is 5 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com