Patents

Literature

62results about How to "Increase the length dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

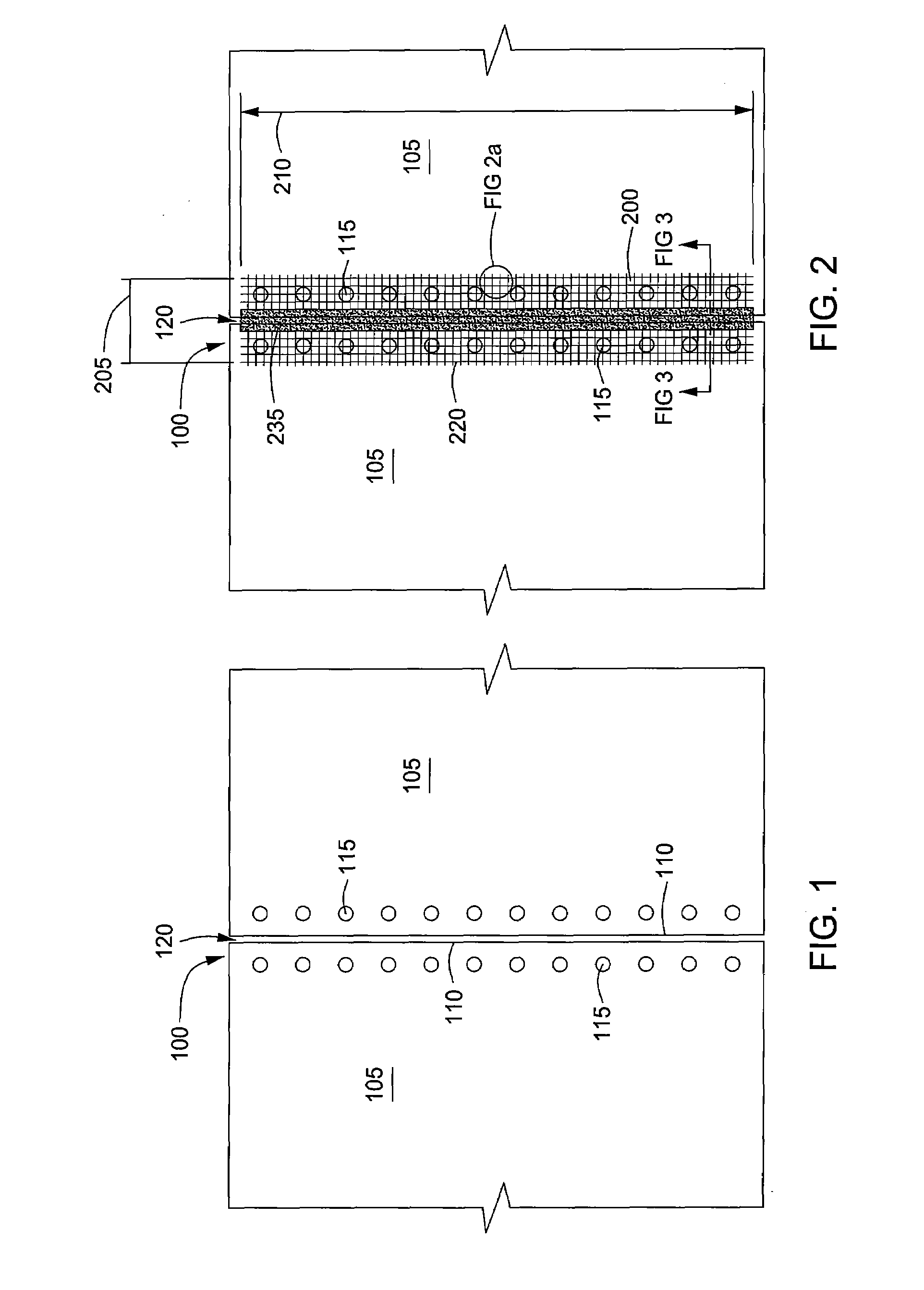

Tape

InactiveUS20070199271A1Improve the immunityResistant to pulling forceCovering/liningsFilm/foil adhesivesUltimate tensile strengthElectrical and Electronics engineering

Owner:LITTLE W FR

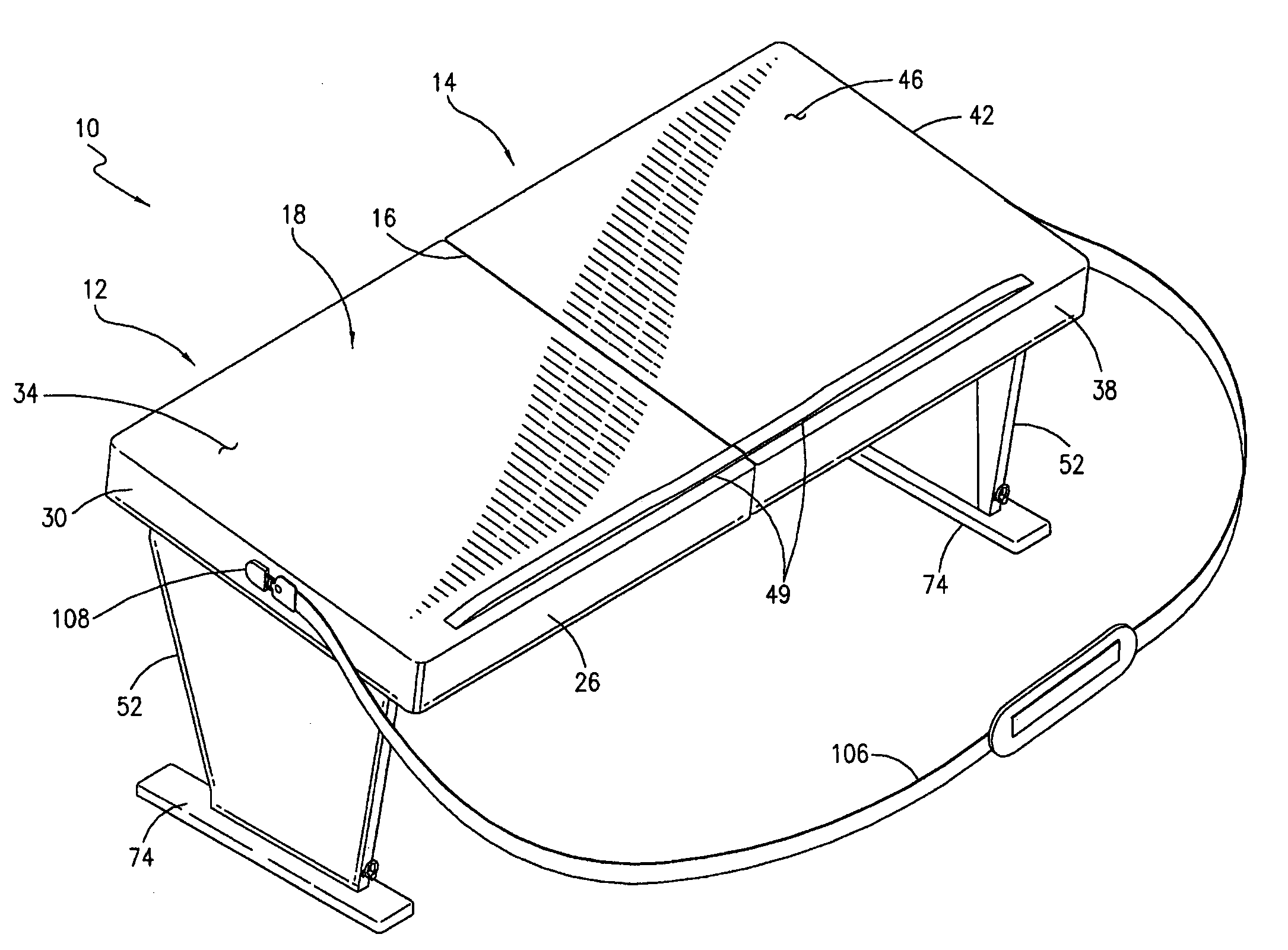

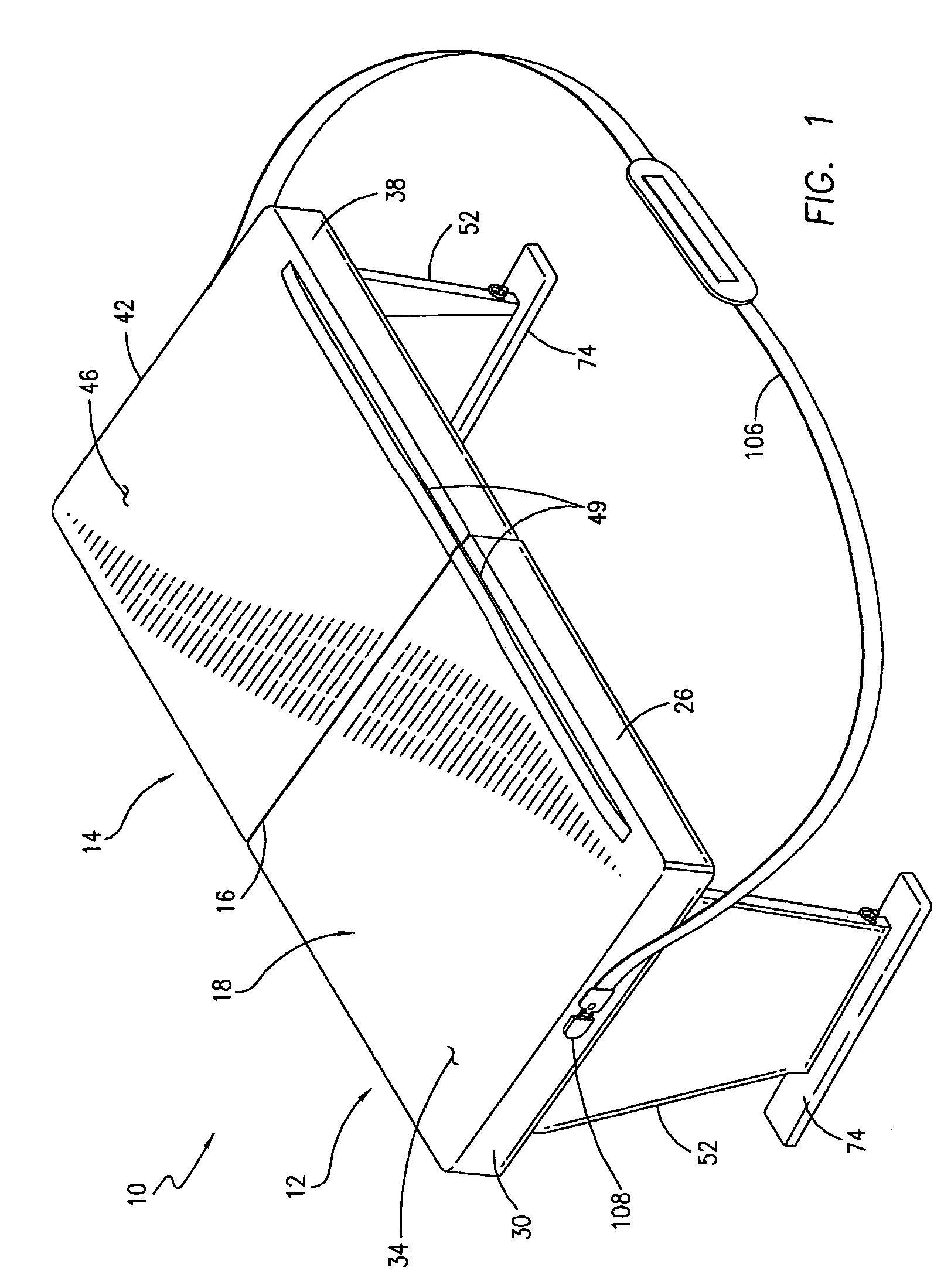

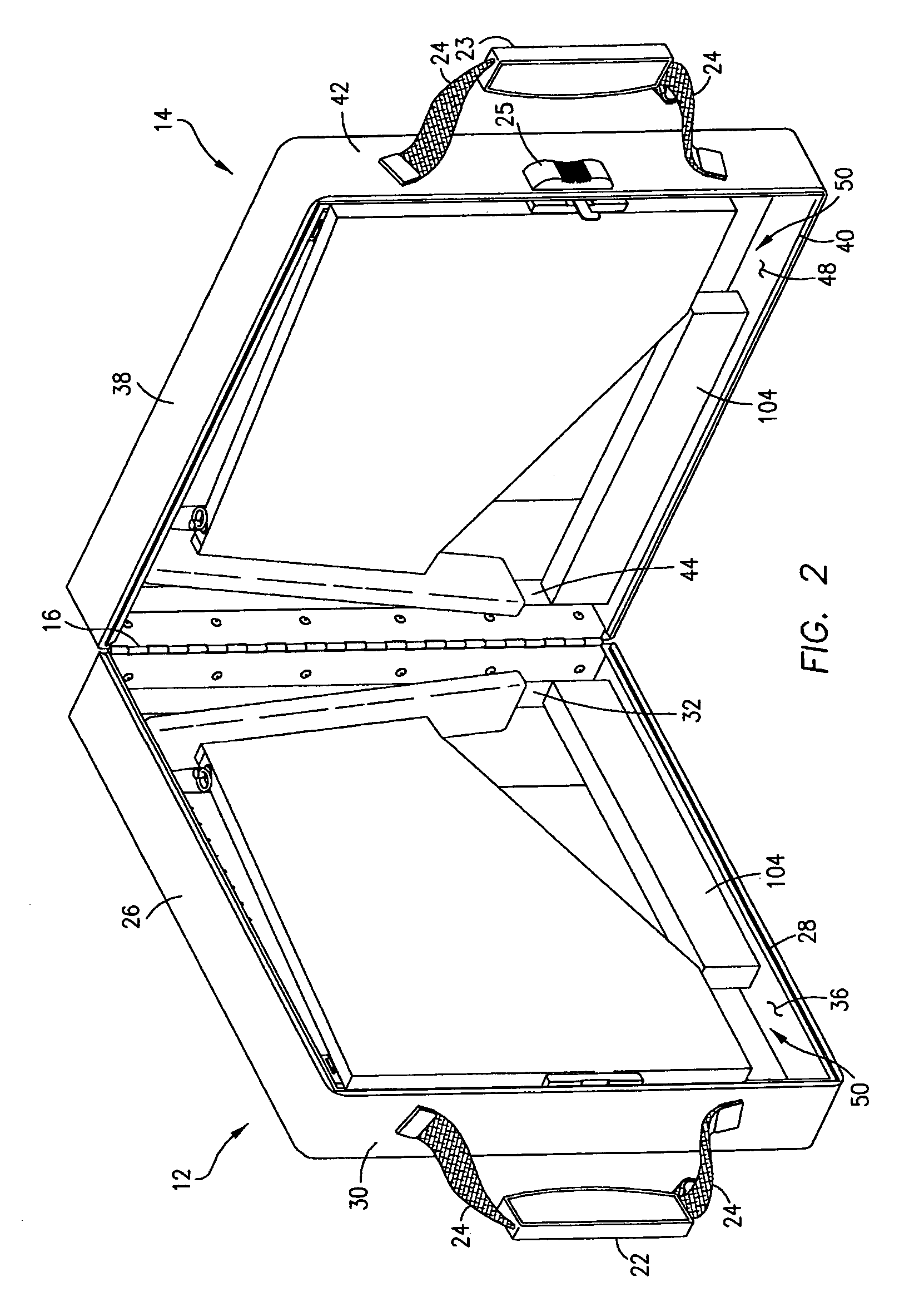

Portable table for a laptop computer

InactiveUS7252040B2Increase the length dimensionBed-tablesFoldable tablesEngineeringElectrical and Electronics engineering

This invention is directed to a portable table which is formed in two half sections movable between a folded position where they form a brief case and an unfolded position in which the half sections abut one another to define a planar table top capable of supporting a laptop computer, notebook and the like. The table top has a pair of legs which are adjustable both in the vertical and lateral directions.

Owner:INTELLECTUAL VENTURES II

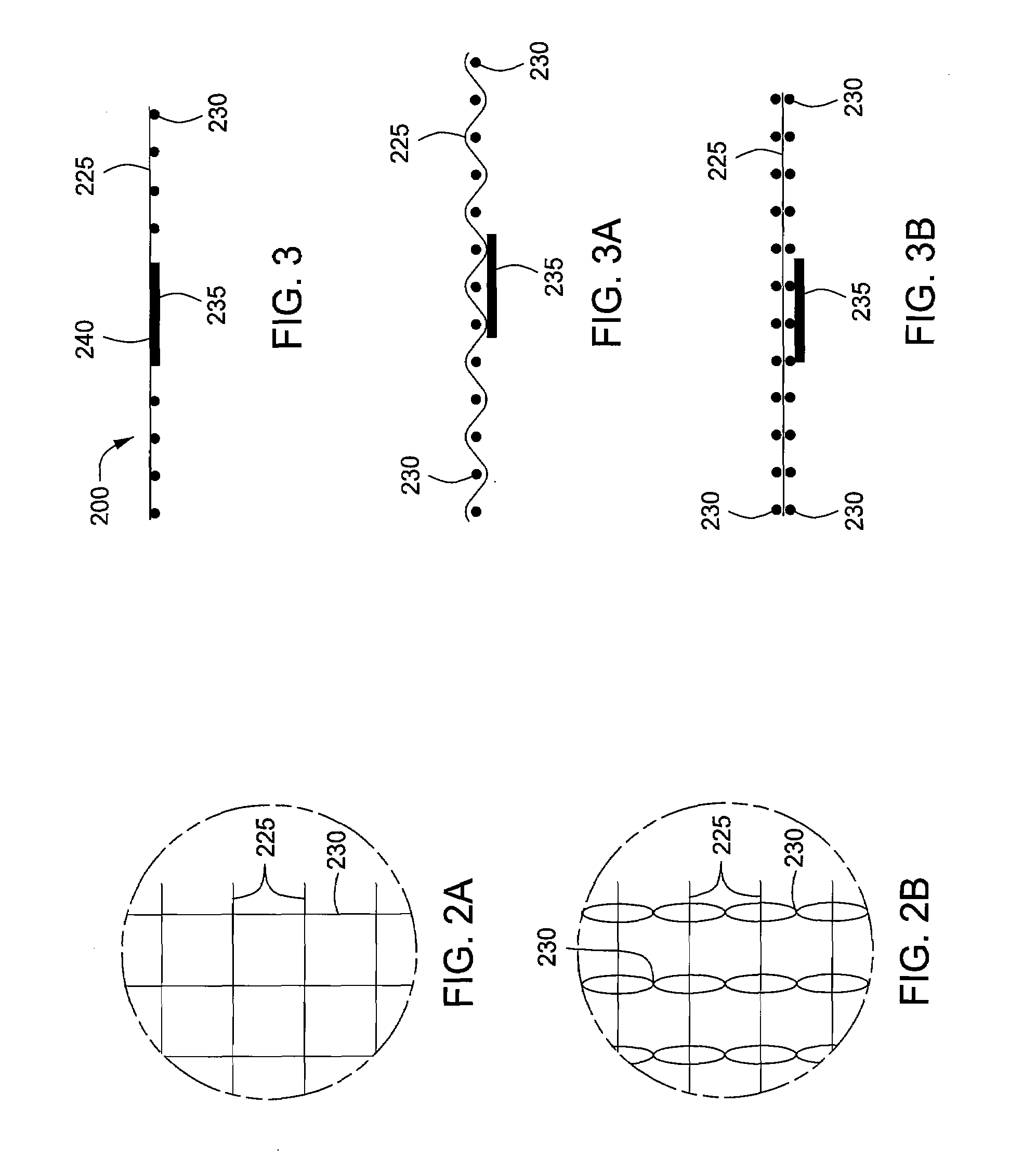

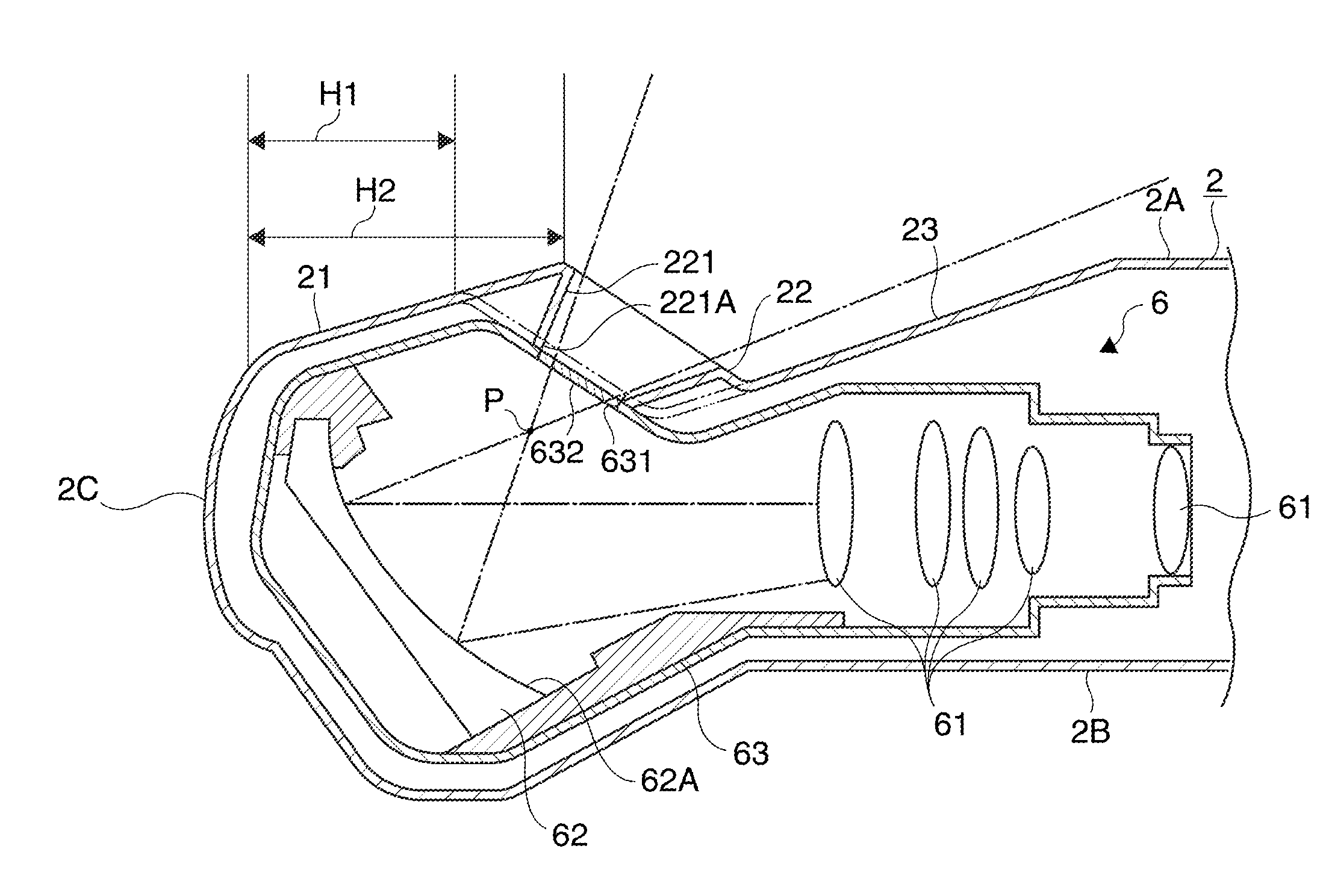

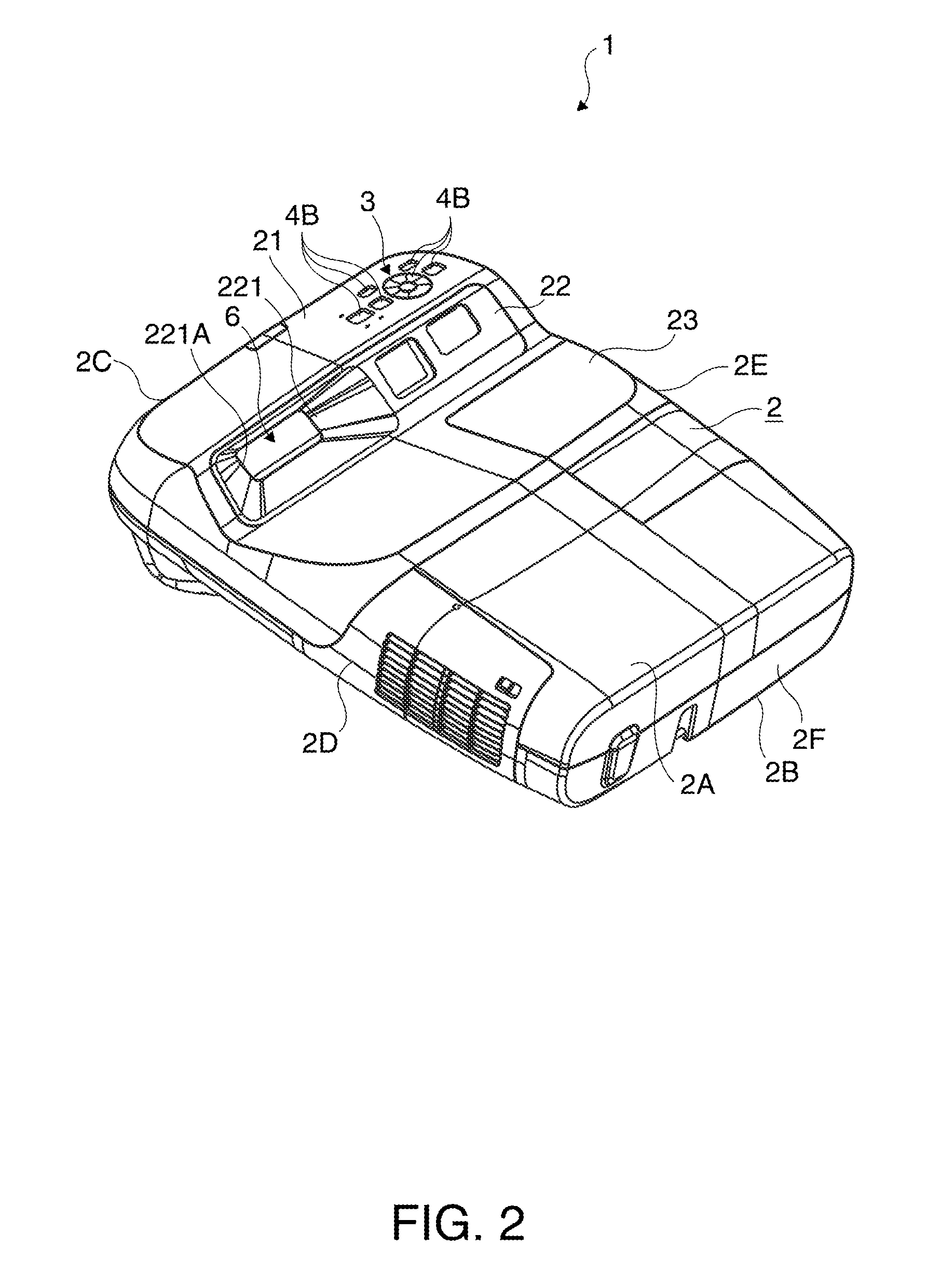

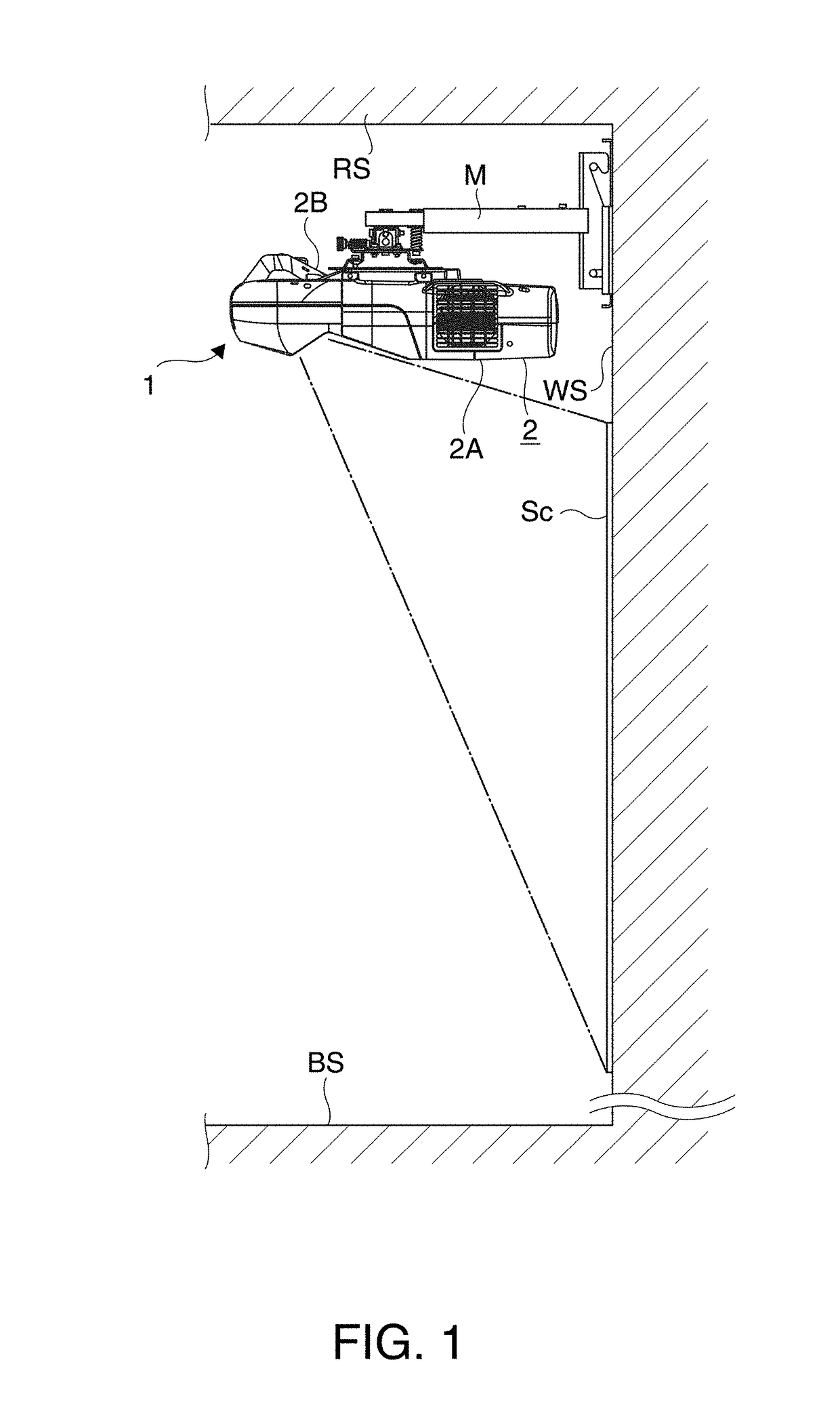

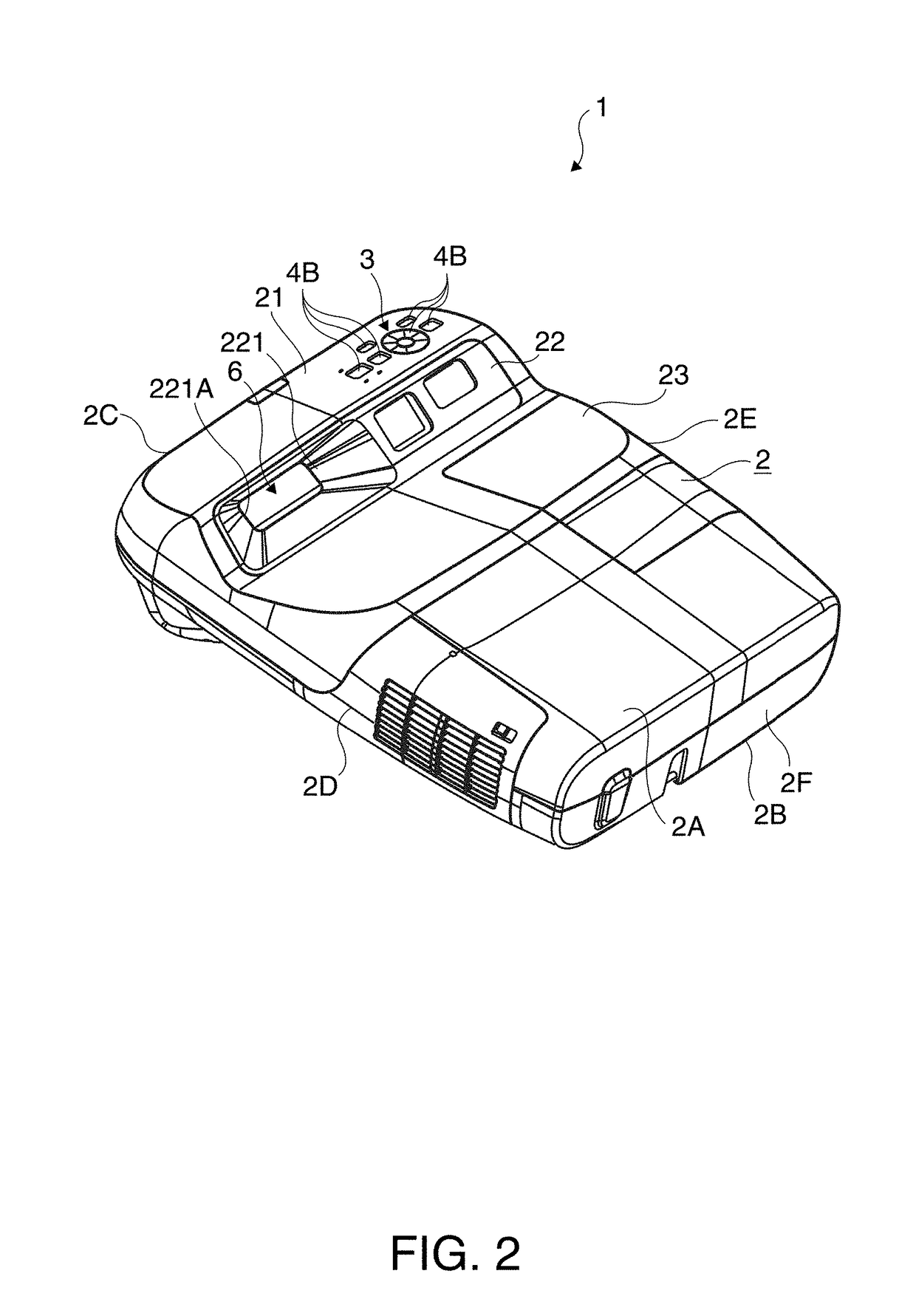

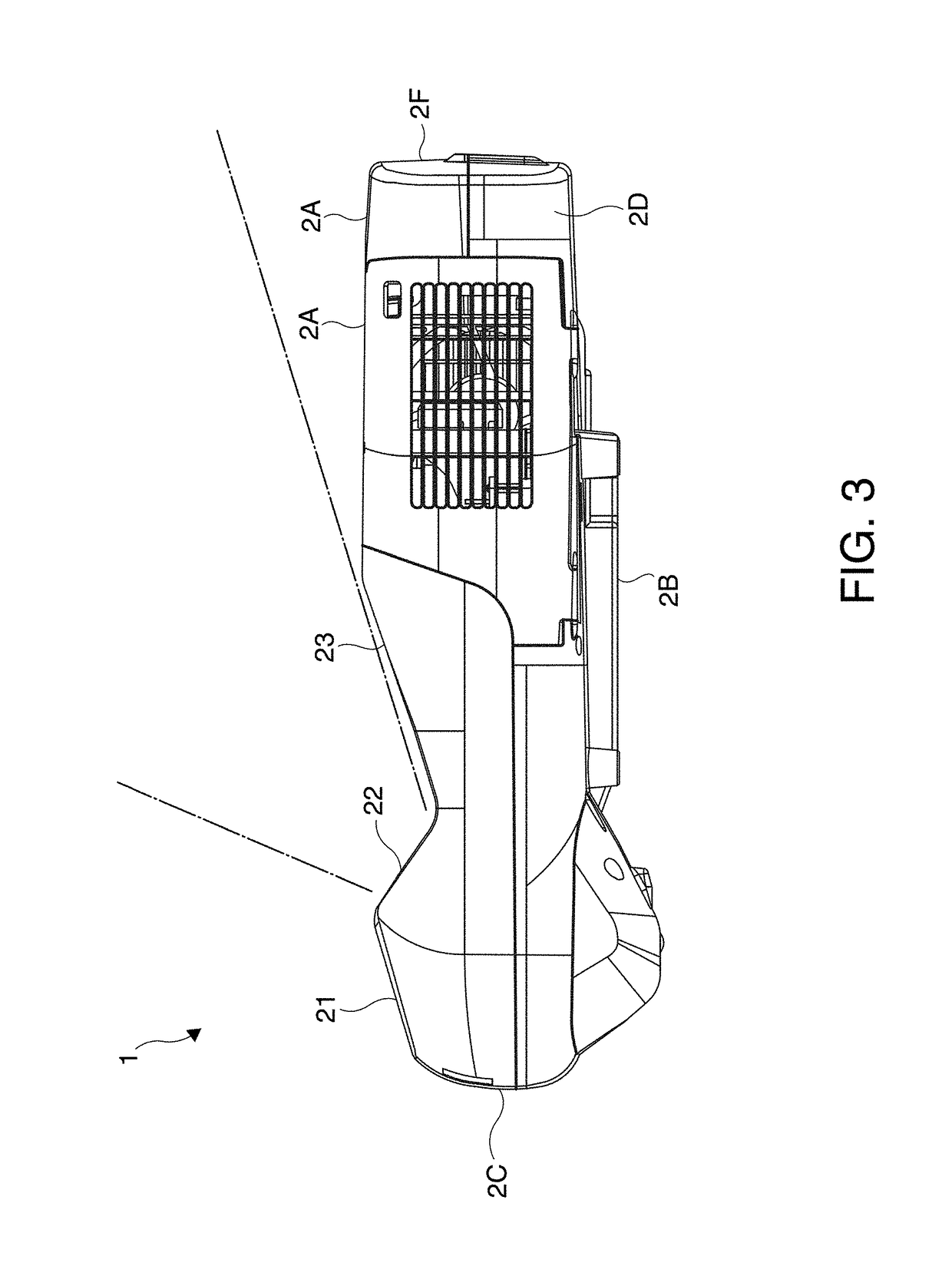

Projector

ActiveUS20100321644A1Increase the length dimensionEasy disposalProjectorsColor television detailsComputer graphics (images)Projector

A projector includes: an exterior housing configuring an exterior; a projection optical device which projects an image toward a projection surface; and a plurality of operation buttons which, being disposed in such a way as to be exposed to the outside of the exterior housing, an image opening for allowing the image projected from the projection optical device to pass through is formed in one sidewall, among sidewalls configuring the exterior housing, which intersects in a vertical direction, the projection optical device includes a reflecting mirror which reflects the image, and projects it through the image opening, and the plurality of operation buttons are disposed on a side of the one sidewall farther from the projection surface than the image opening.

Owner:SEIKO EPSON CORP

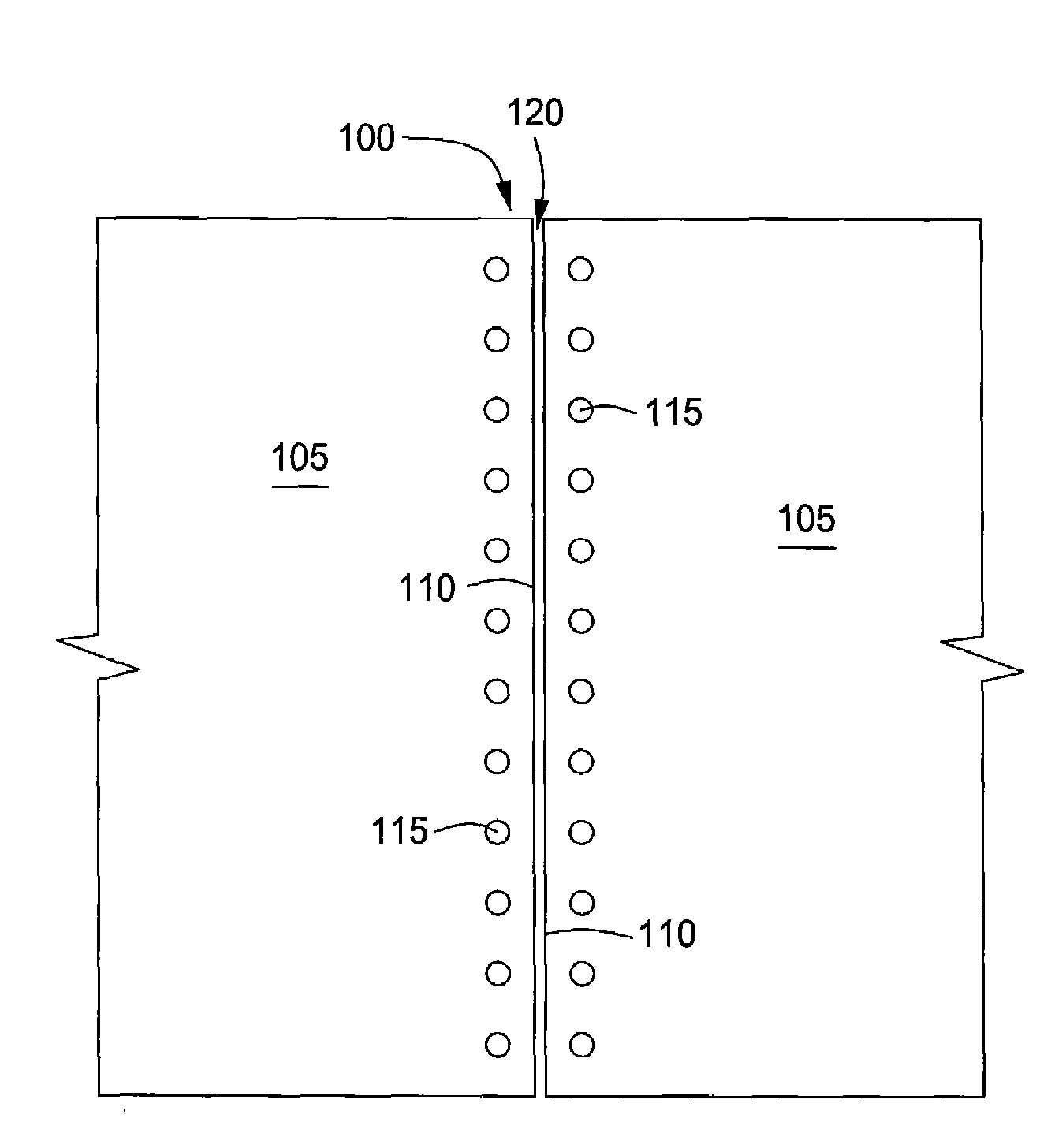

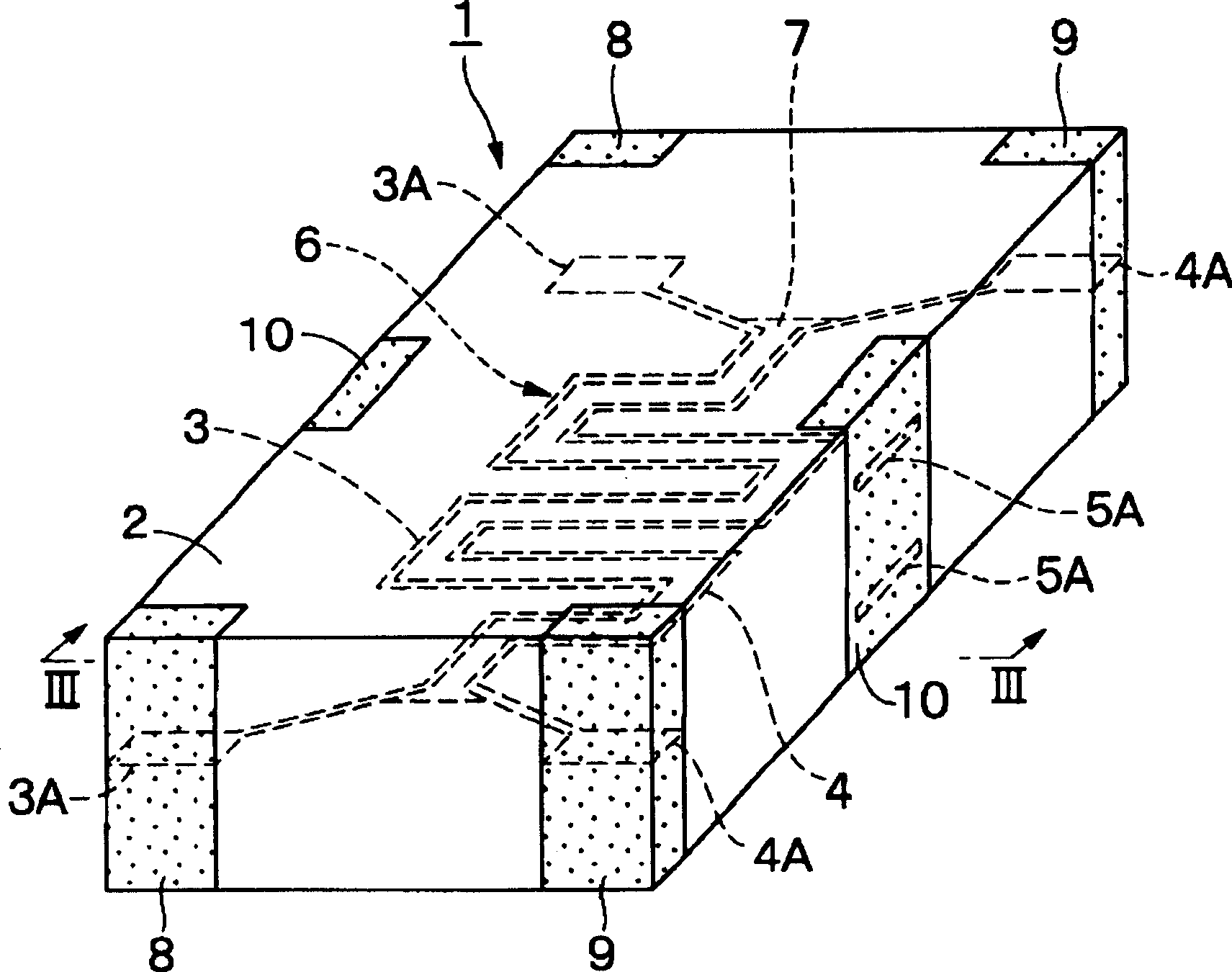

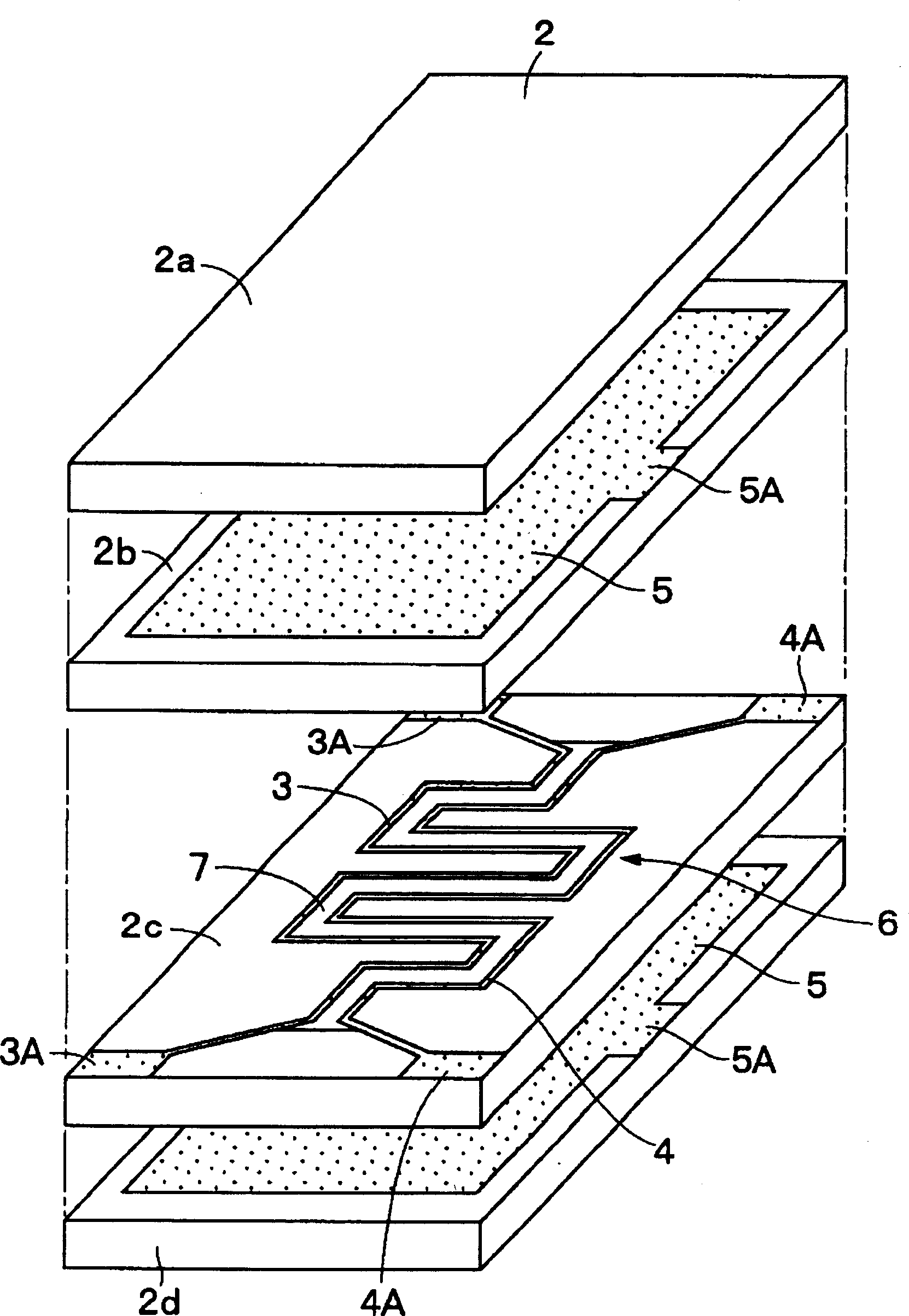

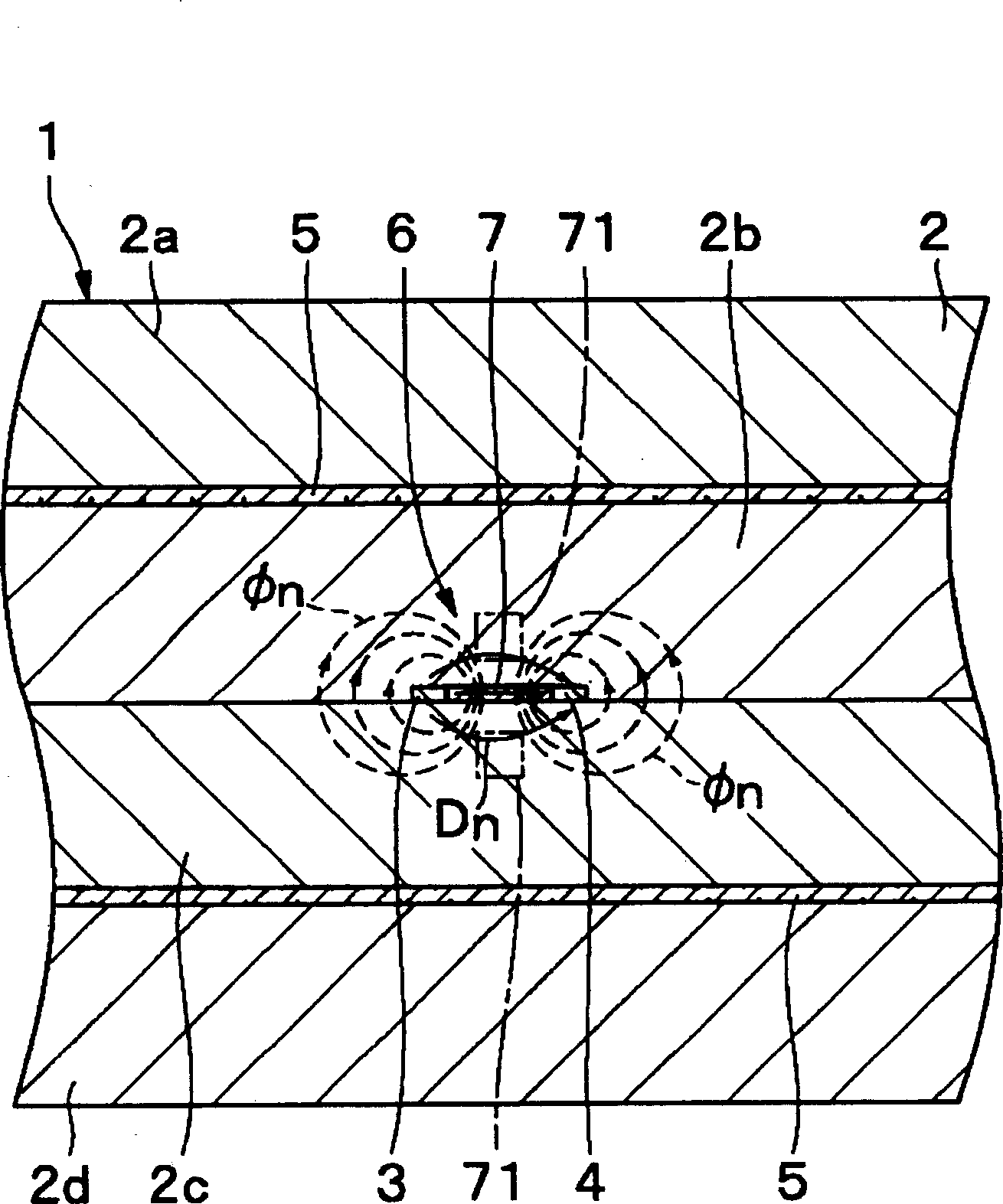

Noise filter

InactiveCN1485863AIncrease the length dimensionImprove the attenuation effectMultiple-port networksWaveguide type devicesDielectricNormal mode

Owner:MURATA MFG CO LTD

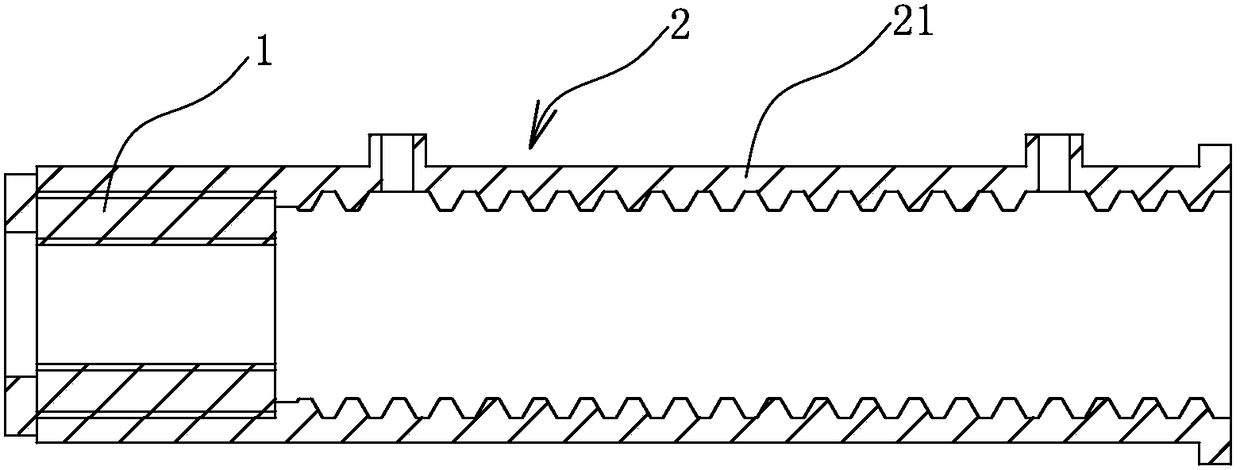

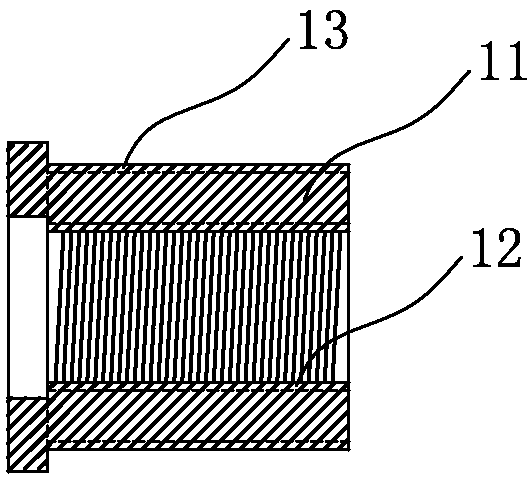

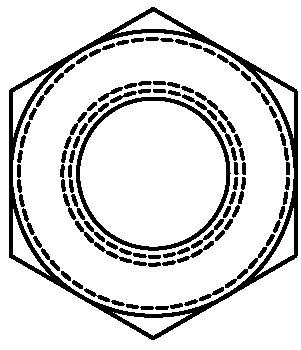

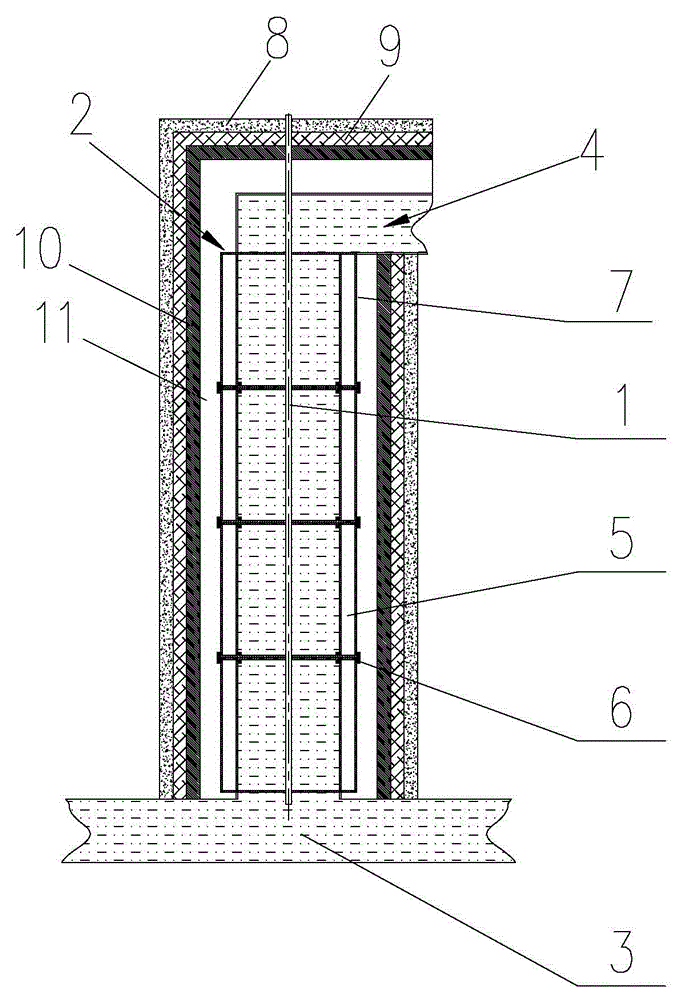

Semi-grouting sleeve assembly of precast beam steel connection of cast-in-place beam column joints and application thereof

The invention discloses a semi-grouting sleeve assembly of a precast beam steel connection of cast-in-place beam column joints and an application thereof. The semi-grouting sleeve assembly comprises asemi-grouting sleeve and an integral nut bolt, wherein the integral nut bolt is connected with the semi-grouting sleeve. The semi-grouting sleeve comprises a straight cylindrical body, one end of thestraight cylindrical body is a threaded end provided with an internal thread, the other end is a grouting end, and the outer end opening of the grouting end is used to insert a horizontally longitudinal rebar of a prefabricated laminated beam. The integral nut bolt includes a body and internal and external threads disposed on the body. The internal threads are used to connect a thread with one end of the horizontally longitudinal rebar of another prefabricated beam. The semi-grouting sleeve assembly replaces an existing full-grouting sleeve with a precast beam steel connection, the length andweight are reduced by nearly half, and the sleeve price is reduced. When the beam steel used for cast-in-place beam column joints are connected, the requirements on the length of a column section arealso correspondingly reduced, thereby avoiding the increase of the length dimension of the column section and the cost is low.

Owner:浙江省建筑科学设计研究院建筑设计所

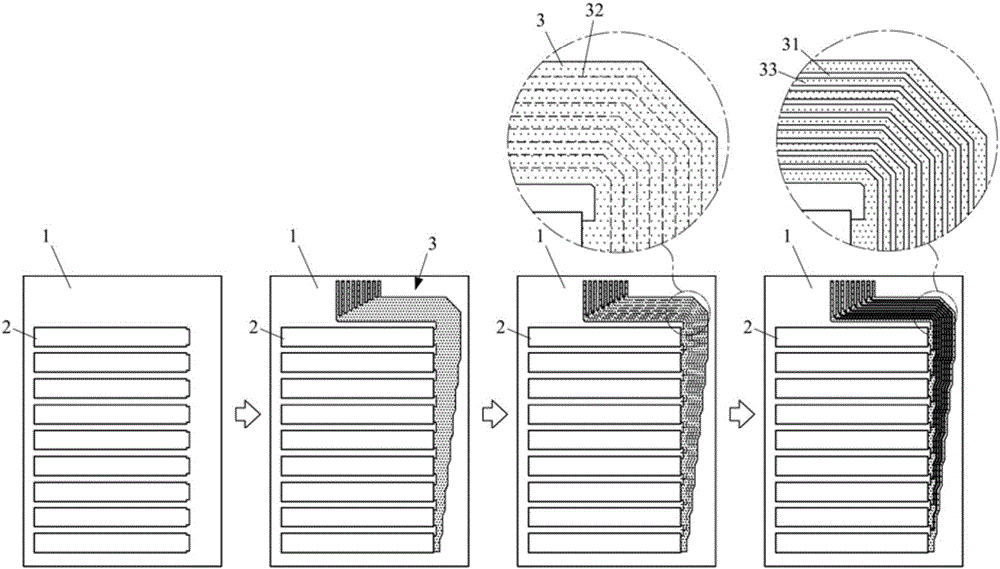

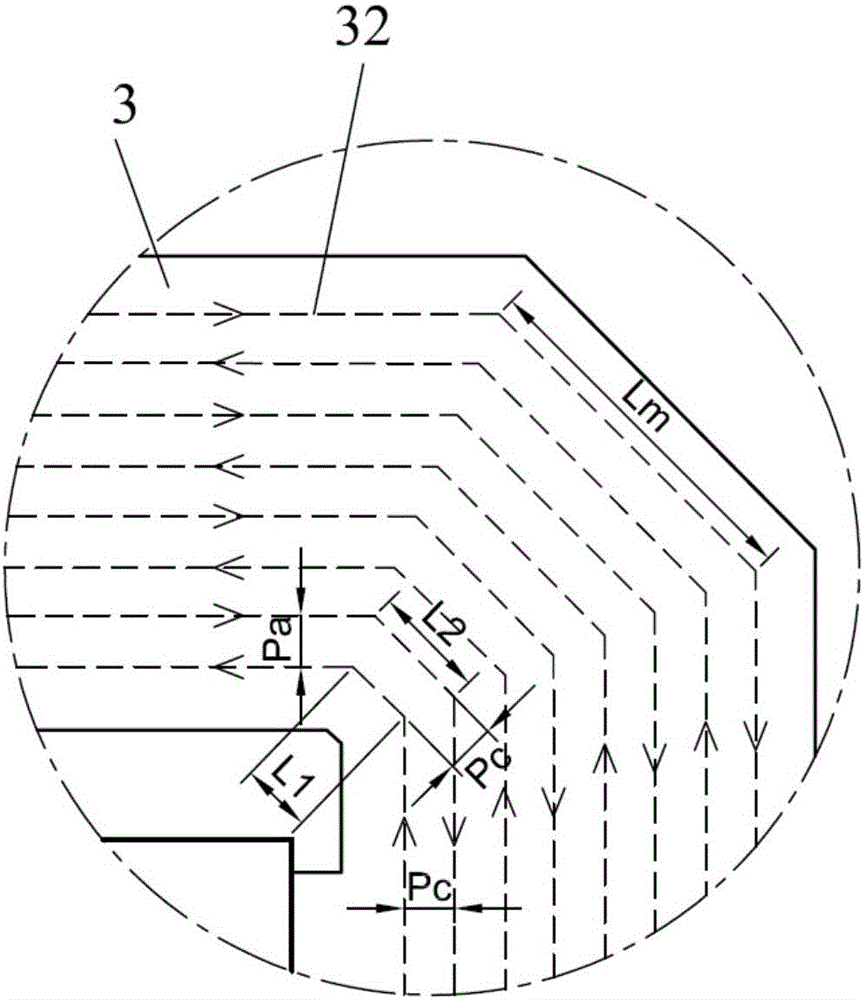

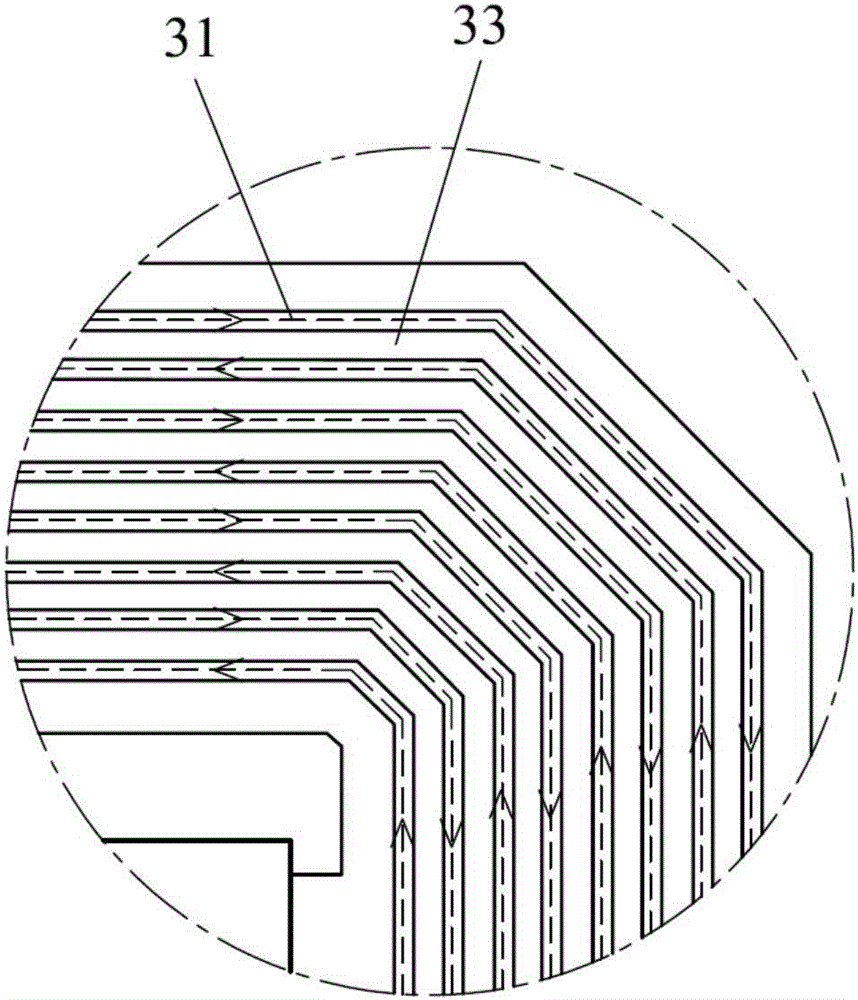

Silicon bar cutting technology

ActiveCN111361027AEasy to manufactureIncrease the length dimensionFinal product manufactureSemiconductor/solid-state device manufacturingEngineering physicsSilicon chip

The invention discloses a silicon bar cutting technology. The silicon bar cutting technology comprises the following steps that firstly, silicon bar square forming is conducted, and a center silicon block and four edge materials which extend in the same direction with a silicon bar are cut; the four edge materials are cut into a first small silicon block, a second small silicon block and a third small silicon block which extend in the same direction with the silicon bar; the length of the cross sections of the first small silicon block and the third small silicon block is 1 / 2 of the width of the cross section of the center silicon block; the length of the cross section of the second small silicon block is the same with the width of the cross section of the center silicon block; and slicingis conducted on the center silicon block, the first small silicon block, the second small silicon block and the third small silicon block, and the slicing direction is parallel to the silicon bar extending direction. The slicing direction is parallel to the silicon bar extending direction, and therefore the length size of a silicon wafer obtained through slicing cannot be limited by the diameterof the silicon bar, and a rectangular silicon wafer with the large length size is easily prepared; and by means of the silicon bar cutting technology, two kinds of silicon wafers different in width specification can be cut, the silicon bar utilization rate can be increased, and the silicon wafer production cost is reduced.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

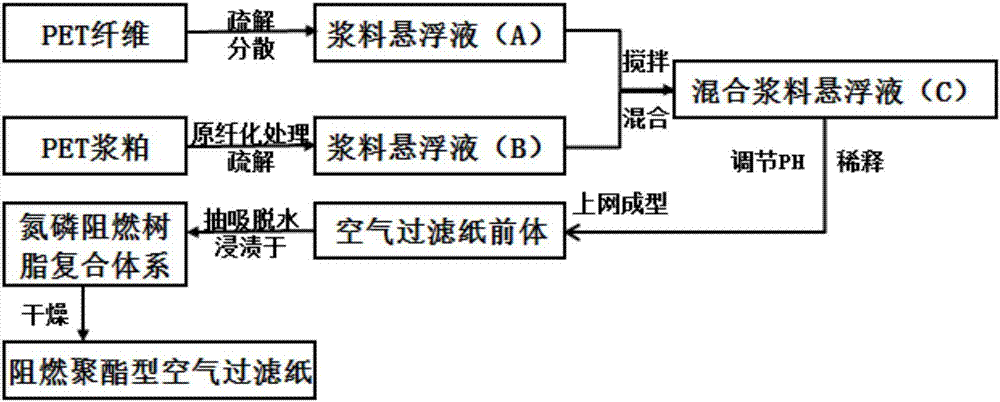

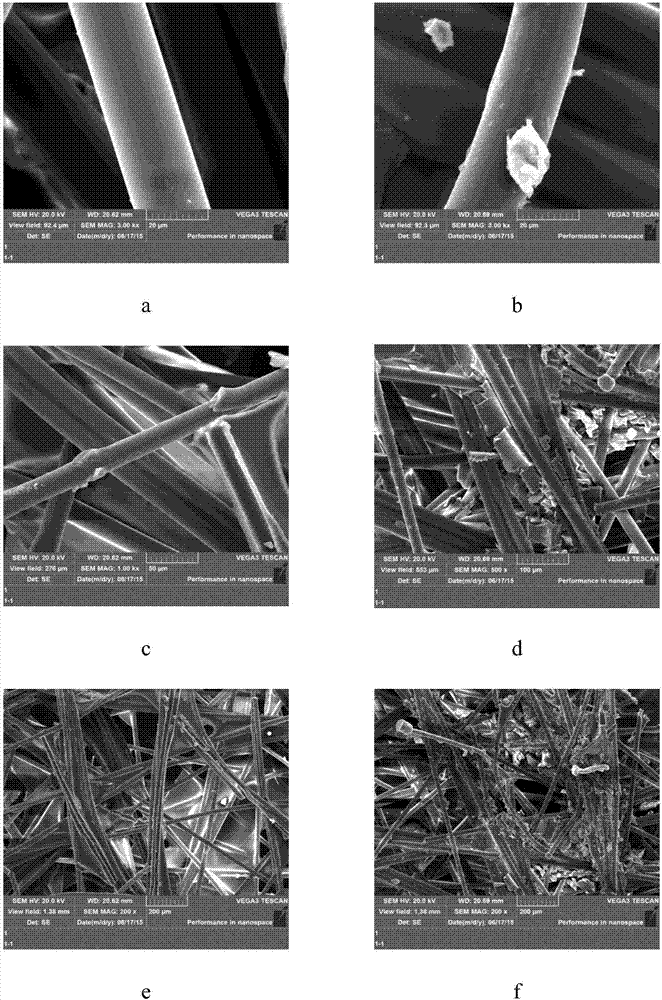

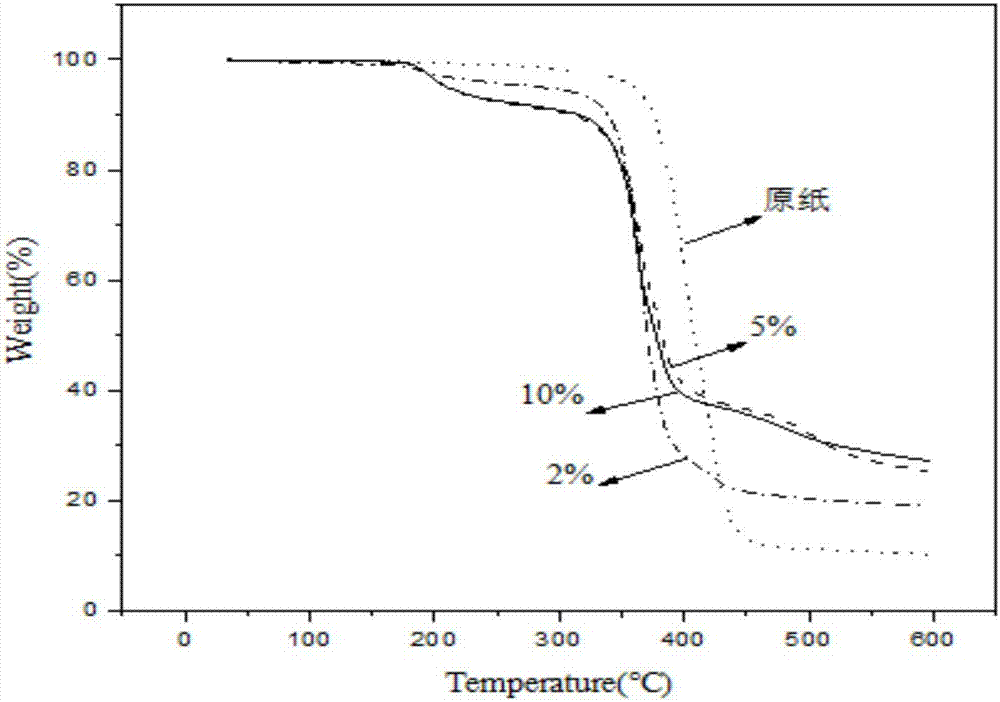

Flame-retardant polyester-type air filtering paper and preparation method thereof

ActiveCN107190550AGood heat settingHigh breaking strength and modulus of elasticityPaper coatingPaper/cardboardPolyesterResin composite

The invention discloses flame-retardant polyester-type air filtering paper and a preparation method thereof. The preparation method of the flame-retardant polyester-type air filtering paper includes the steps that PET fibers are adopted and a structure similar to plant fibers is built by PET pulp. The average length of the PET fibers is relatively long, the PET fibers can be used as skeleton materials of the paper, the average length of the PET pulp is short, through fibrillation treatment, fine fibers adhering to the surface of the PET pulp serve as padding materials, meanwhile, acrylic resin of mixed steeping liquid serves as adhesive, accordingly, the fine fibers and the PET fibers are interwoven to form a small and compact mesh structure, and filter accuracy is improved. On the other hand, raw filtering paper is soaked in a nitrogen and phosphorus flame-retardant resin composite system, nitrogen and phosphorus flame retardants have synergistic effects, the flame retardance efficiency is high, and meanwhile the acrylic resin is used as a glue solution and forms a flame-retardant protective screen on the paper surface. The addition amount of the flame retardants is reduced, the durable and efficient flame-retardant performance is ensured, not only is the production cost reduced but also the comprehensive property of the paper is improved at the same time.

Owner:陕西科达智特新材料有限公司

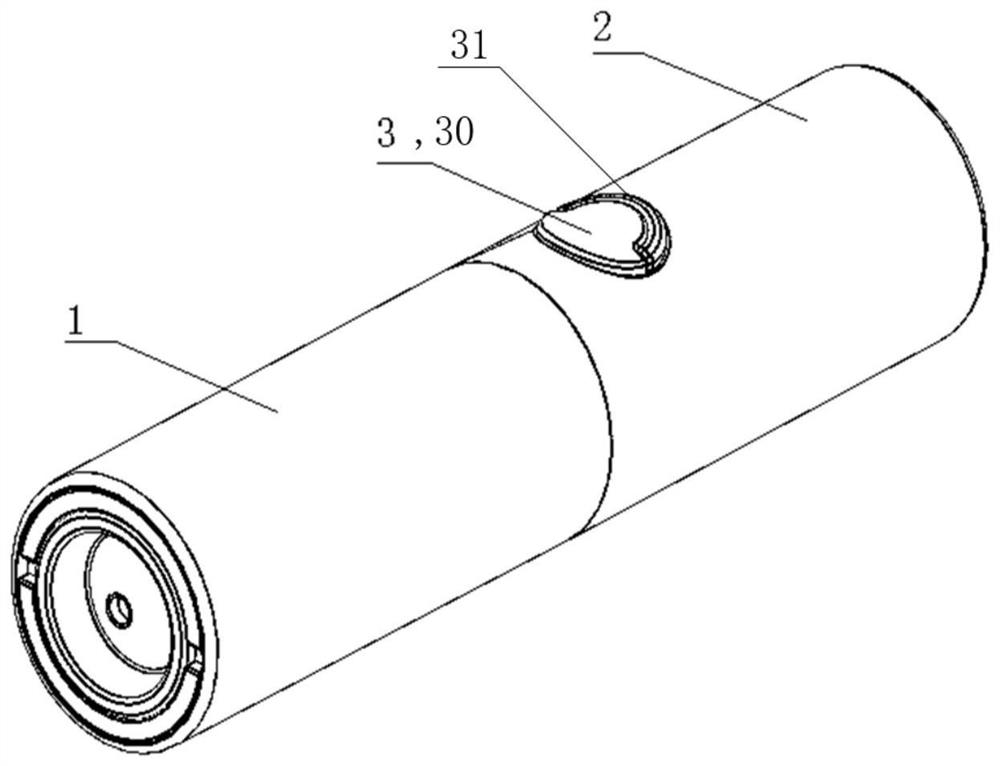

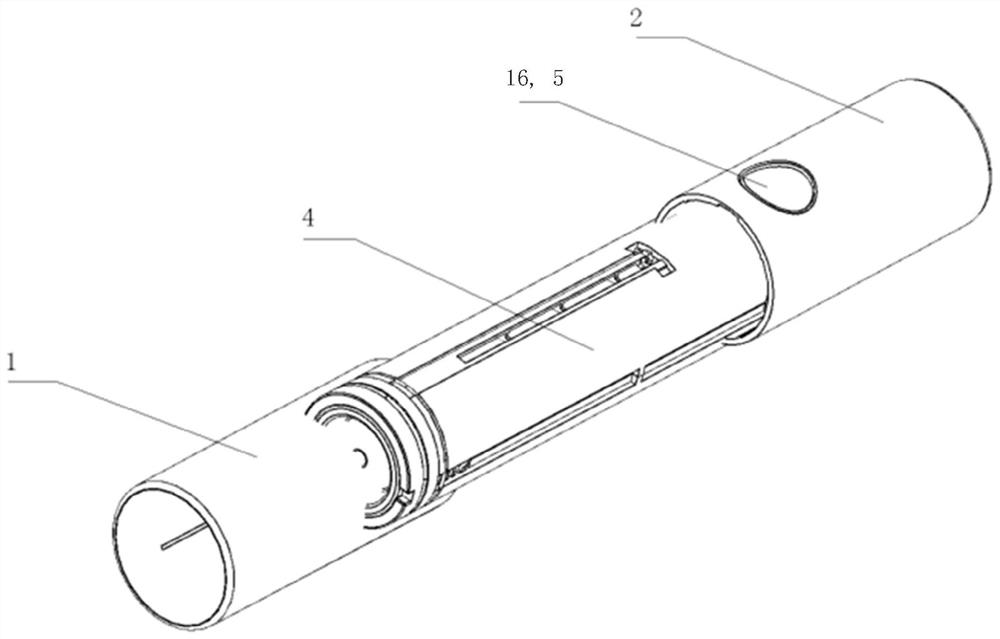

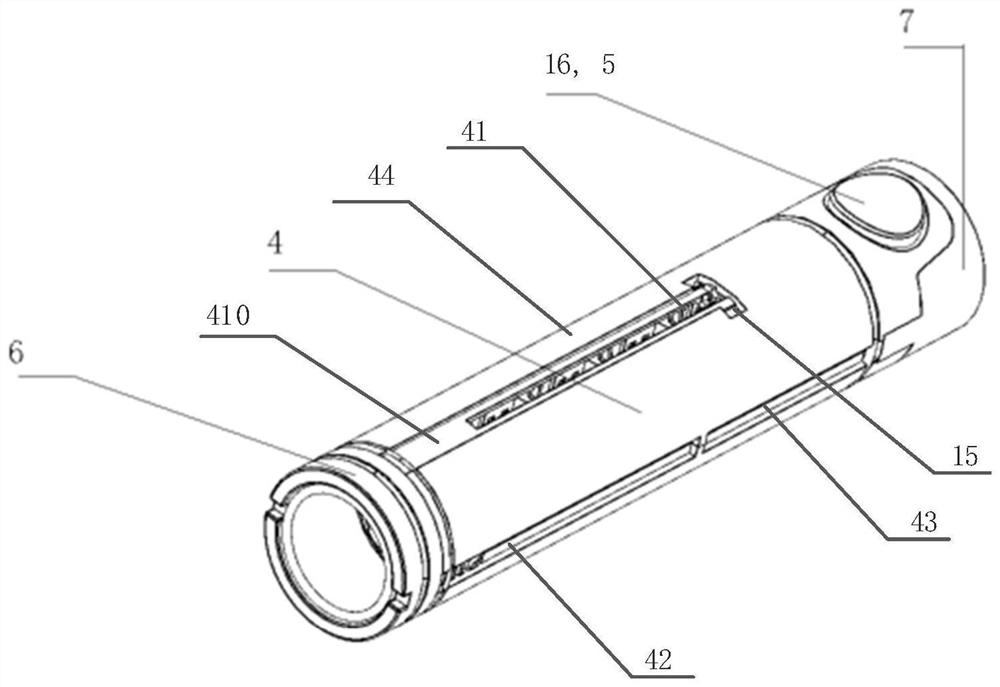

Portable aerosol fire extinguisher

The invention discloses a portable aerosol fire extinguisher which comprises an inner barrel for containing a fire extinguishing agent and further comprises a middle barrel, a front outer barrel, a rear outer barrel, a starting mechanism and a safety mechanism. The inner barrel is contained in the middle barrel, the front outer barrel is installed on the front portion of the middle barrel, the rear outer barrel is installed on the rear portion of the middle barrel, and the front outer barrel and the rear outer barrel both can slide front and back along the middle barrel. When the front outer barrel is located at a rear limiting position and the rear outer barrel is located at a front limiting position, the safety mechanism is installed on the middle barrel through a first clamping part and connected with the front outer barrel and the rear outer barrel through a first connecting part and a second connecting part to prevent the front outer barrel and the rear outer barrel from sliding respectively. The fire extinguisher provided by the invention has a safe and reliable function of preventing misoperation, and also can effectively avoid the injury to a user caused by a high-temperature working condition during use.

Owner:李双庆

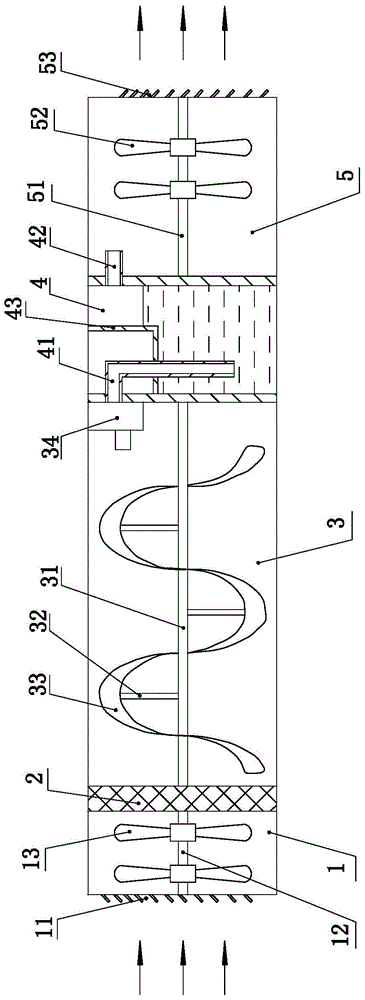

A water filter type air purification device

ActiveCN103990347BFully purifiedIncrease the length dimensionCombination devicesGlass fiberWater filter

The invention discloses a water-filter type air purifying device and relates to the technical field of air purifying, which is used for realizing purifying of indoor air with high efficiency to solve a problem that indoor air pollution is severe, and solving problems that the existing purifying device is high in maintenance charge and small in range of application. The water-filter type air filtering device provided by the invention is integrated with a glass fiber filter layer, an active carbon adsorbing layer and water-filter purifying by utilizing characteristic that aldehyde substances are easy to dissolve in water according to the current situation that the existing air purifying device is low in power and high in maintenance charge, so that dust, smell and formaldehyde are effectively removed, and therefore, the water-filter type air purifying device has the advantages of strong air purifying ability, lasting and stable effect, no secondary environmental pollution, low maintenance charge, wide application range and the like, and is simple and convenient to operate.

Owner:STATE GRID CORP OF CHINA +1

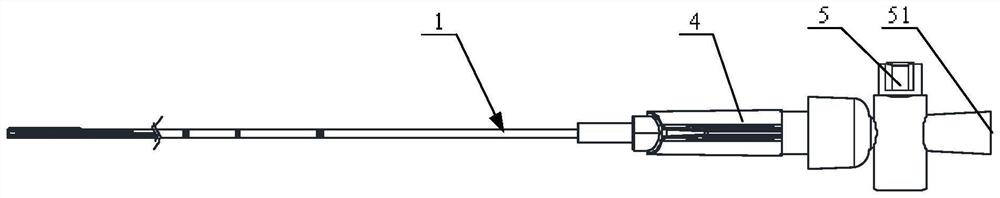

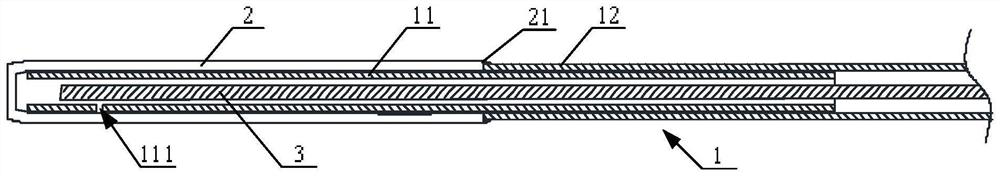

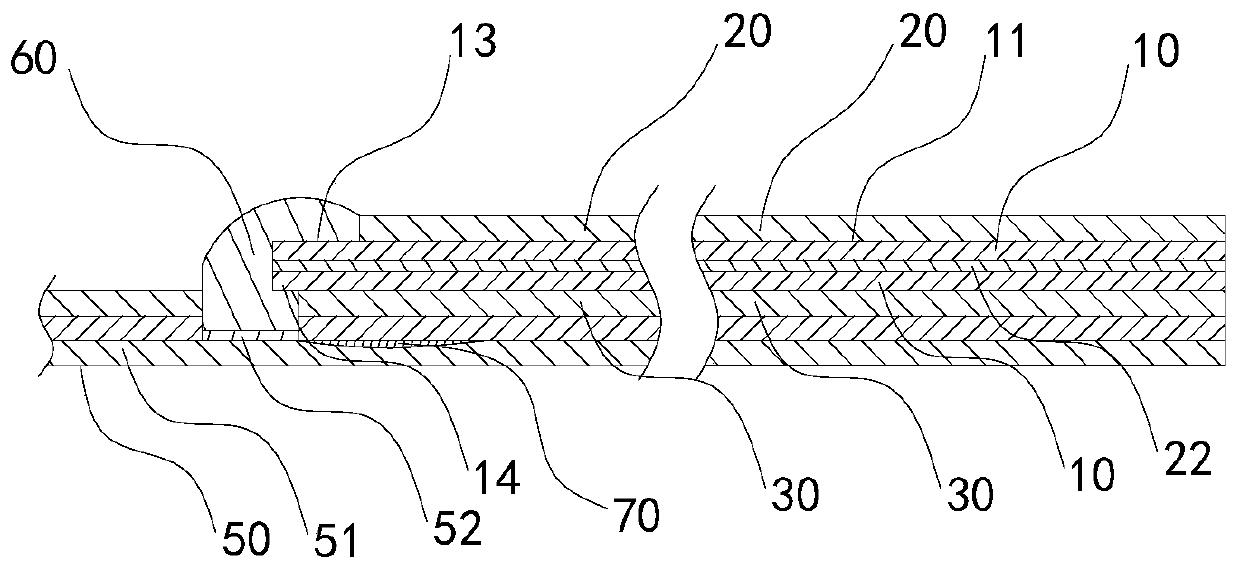

Sacculus and device for removing calculus under choledochoscope

PendingCN114259278AIncrease the length dimensionGood expansion effectBalloon catheterSurgeryEngineeringBalloon catheter

The invention provides a calculus removing balloon and device under a choledochoscope, and relates to the technical field of medical equipment. The calculus removing balloon under the choledochoscope comprises a balloon catheter and a balloon body; the balloon body is provided with an opening end, the opening end is in sealed connection with the outer surface of the balloon catheter, and an expansion cavity is formed between the balloon body and the outer surface of the balloon catheter; the end face of the balloon catheter is located in the expansion cavity, and the balloon catheter is used for discharging gas or liquid in the gas-liquid device into the expansion cavity. According to the calculus removing balloon under the choledochoscope, due to the fact that only one opening end of the balloon body is connected with the outer surface of the balloon catheter in the sealed mode, in the balloon body expansion process, the end face of the balloon catheter is located in the expansion cavity, the end, away from the opening end, of the expansion cavity is not limited, and the balloon body can adjust the expansion direction of itself; therefore, the problem that a conventional balloon catheter is eccentric is effectively avoided. In addition, the balloon body can have a larger length size, and the expansion effect is better.

Owner:MICRO TECH (NANJING) CO LTD +1

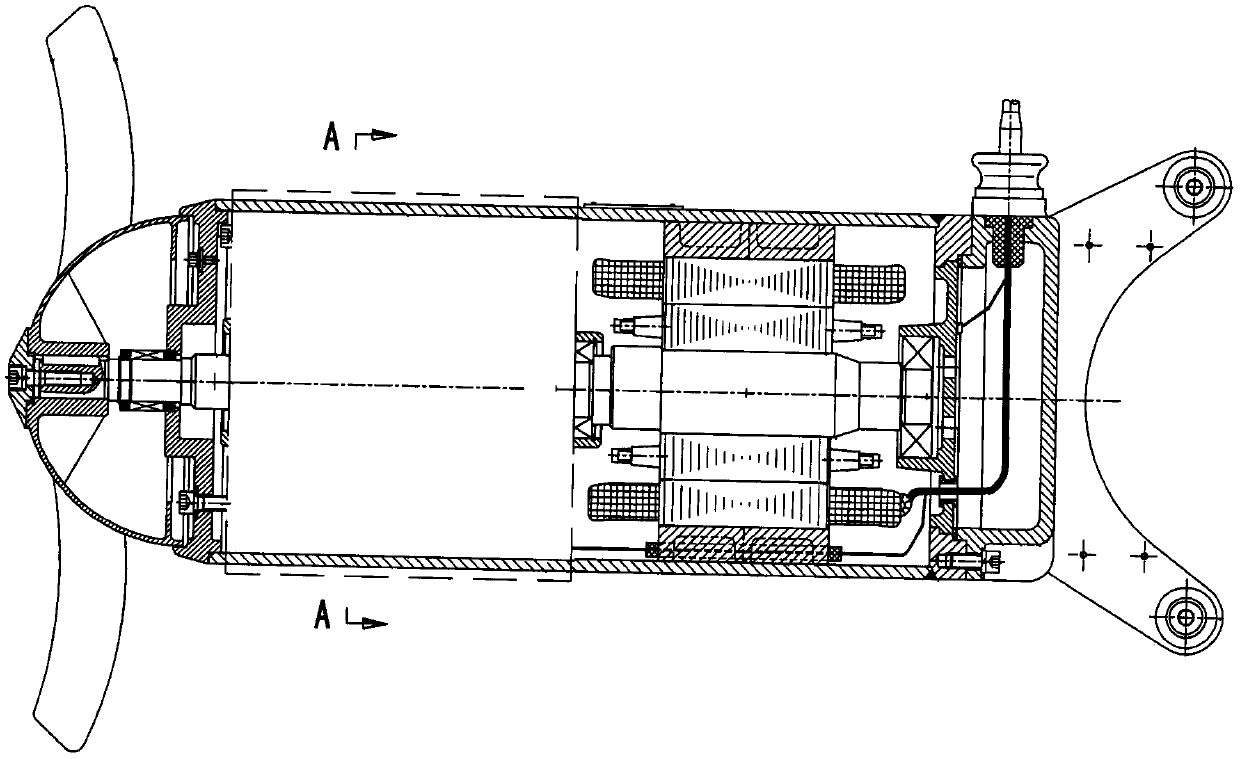

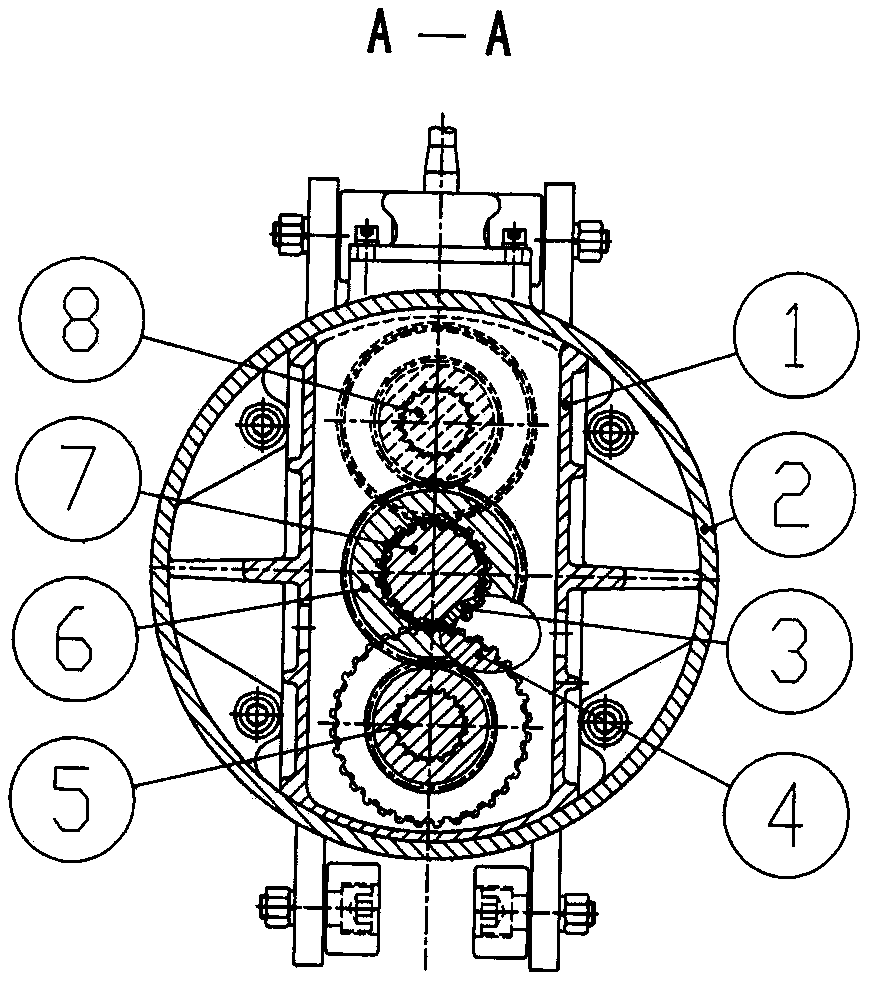

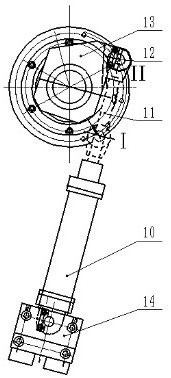

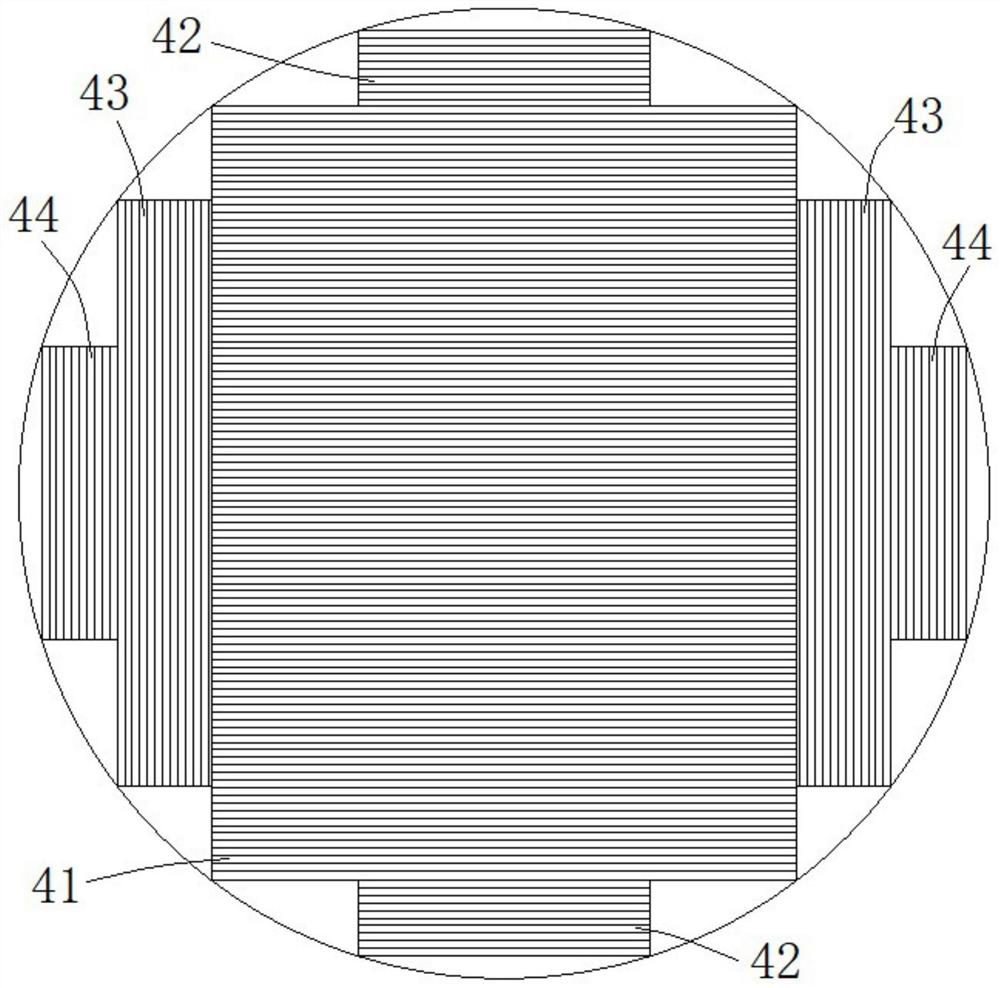

Gear reducer capable of being installed in submersible mixer shell

PendingCN110657198AReduce product weightIncrease the length dimensionToothed gearingsMechanical energy handlingGear driveElectric machine

The invention aims to design a traditional submersible mixer originally adopting a multi-P (such as 6P, 8P and 12P) motor direct-connection type driving structure into 4P motor drive by improving a product structure. A gear reducer is additionally arranged in a submersible mixer shell, the advantages that a 4P motor has good comprehensive performance and the transmission efficiency of a helical gear can reach 99% are utilized, and meanwhile, the mechanical principle of gear reduction and torque increasing is utilized, so that the rotation speed of an impeller on an output shaft reaches to be basically the same with the rotation speed of an impeller of the direct-connection type traditional submersible mixer of 12P, 8P and 6P after the 4P motor drives the gear reducer, and a novel submersible mixer with a power saving function and a novel structure is designed through mechanical-electrical integration combination.

Owner:黄林

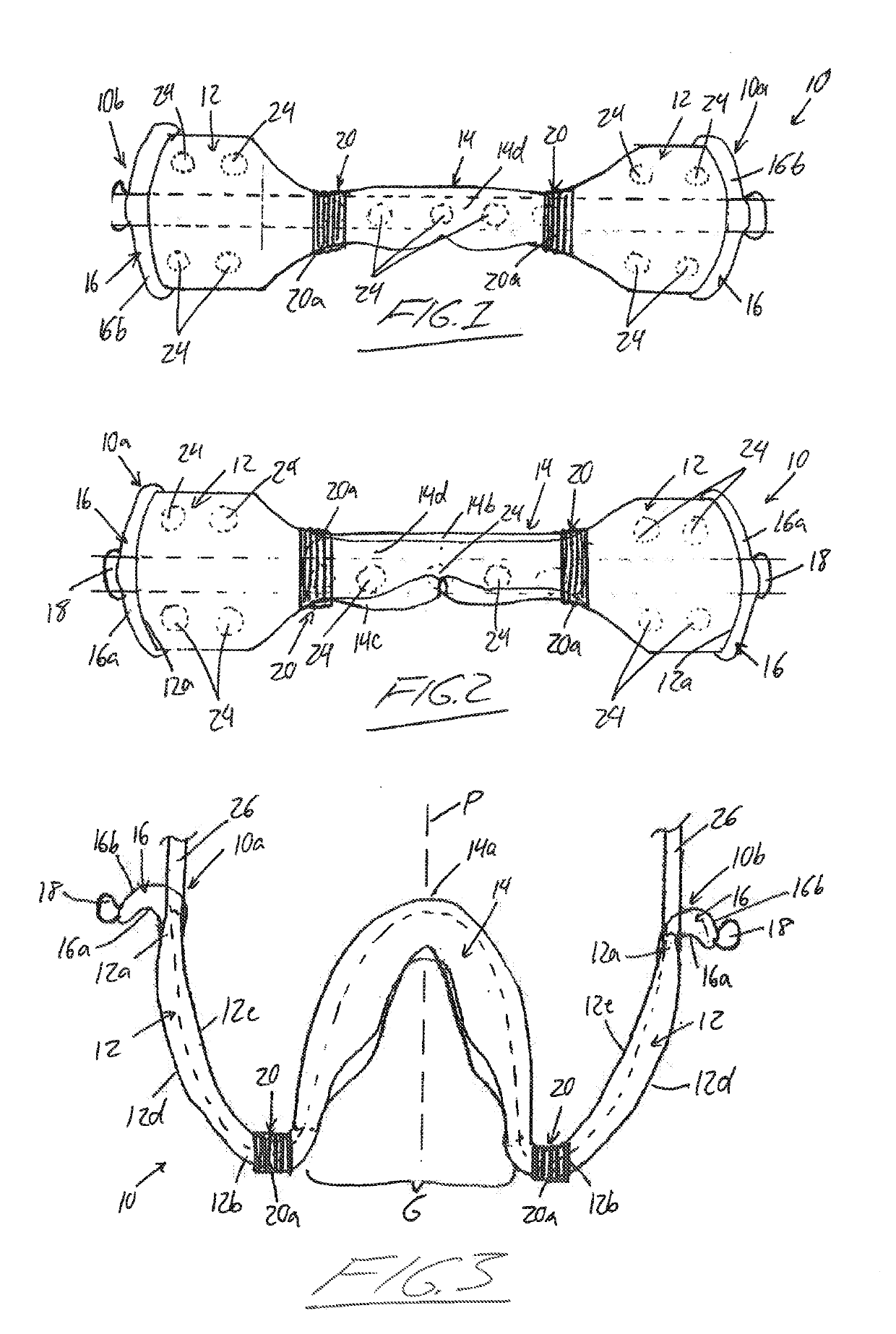

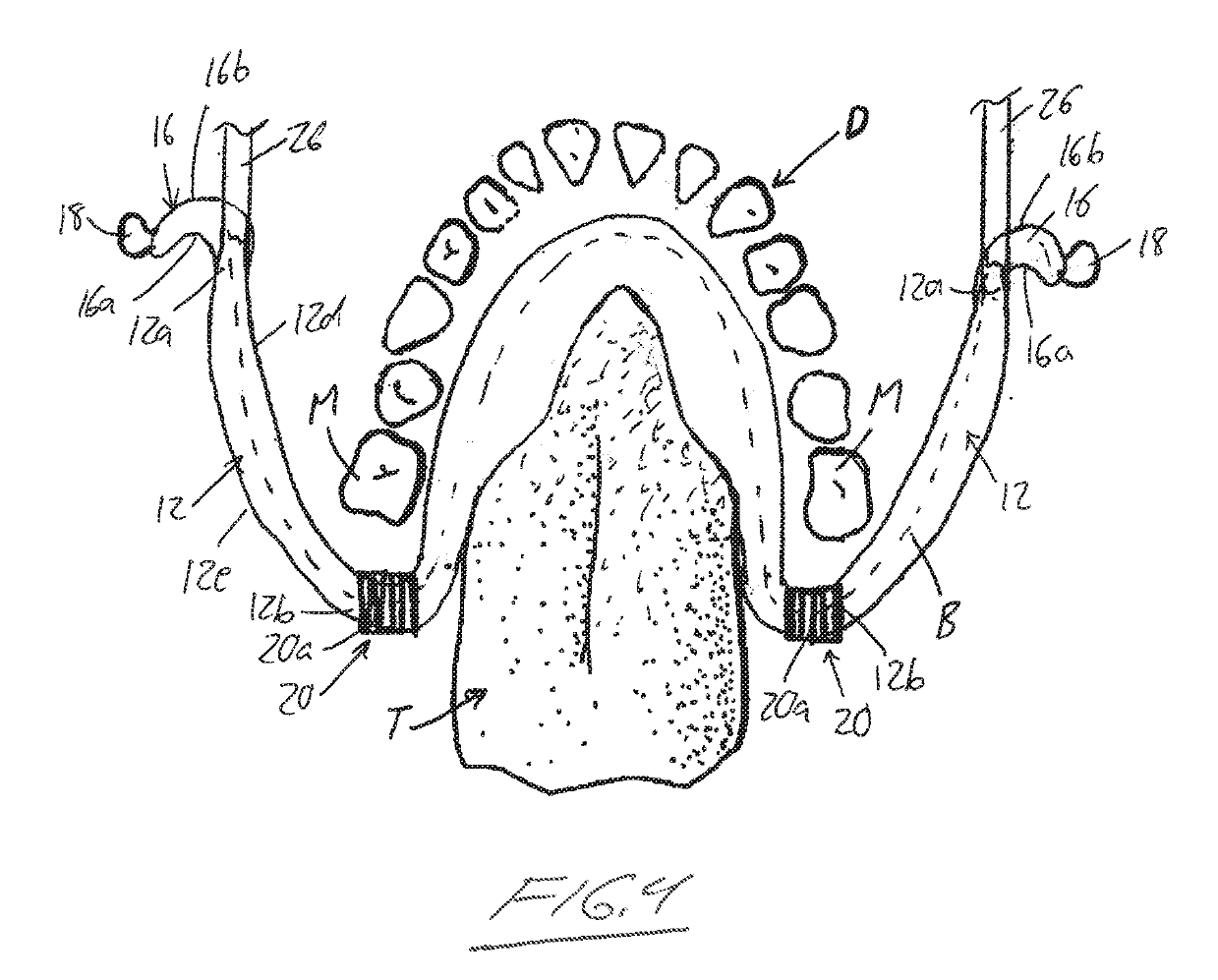

Intra-Oral Appliance for Field Isolation and Moisture Control

ActiveUS20190167383A1Increase the length dimensionIncrease effective lengthDental splintsSaliva removersBuccal mucosaCheek

An intra-oral simultaneous bilateral inter arch isolation appliance features a generally W-shaped body having first and second cheek retractor wings, and first and second transitions respectively joining the cheek retractor wings to a tongue crib of generally U-shaped configuration with an open posterior end. In a patient worn position, each cheek retractor wing runs buccally along a respective half of a patient's dental arches to retract and isolate buccal mucosa, while the transitions curve posteriorly around the rear molars between the maxillary tuberosity and retromolar pad to carry the tongue crib inside the dental arches, where it shields and isolates the tongue. Commissure cradles at anterior ends of the cheek retractor wings hook around the patient's oral commissures at terminal ends of the appliance. Inner passageways within the body accommodate fluid extraction and / or light transmission through the appliance.

Owner:CHANA RANDEEP +1

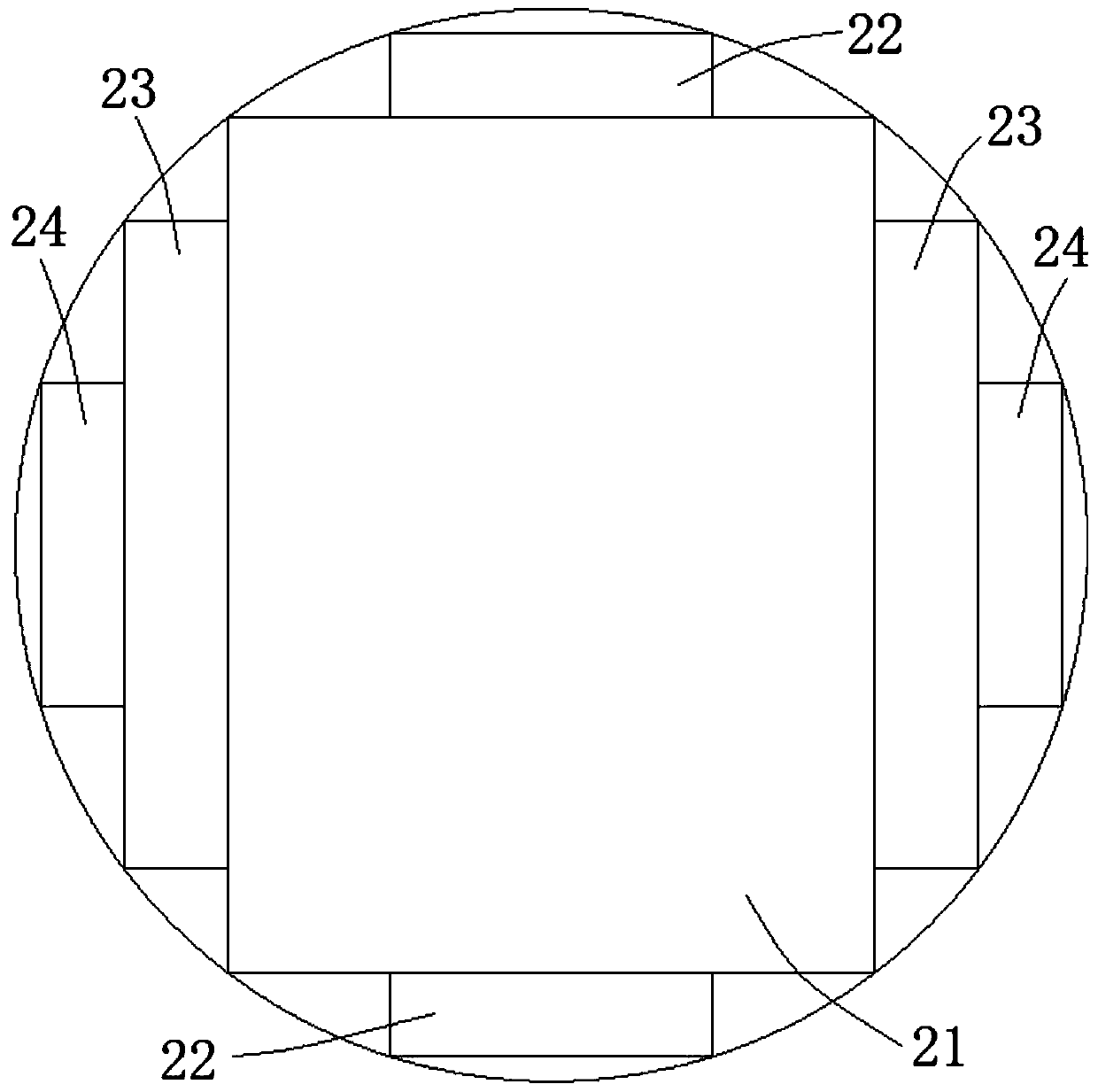

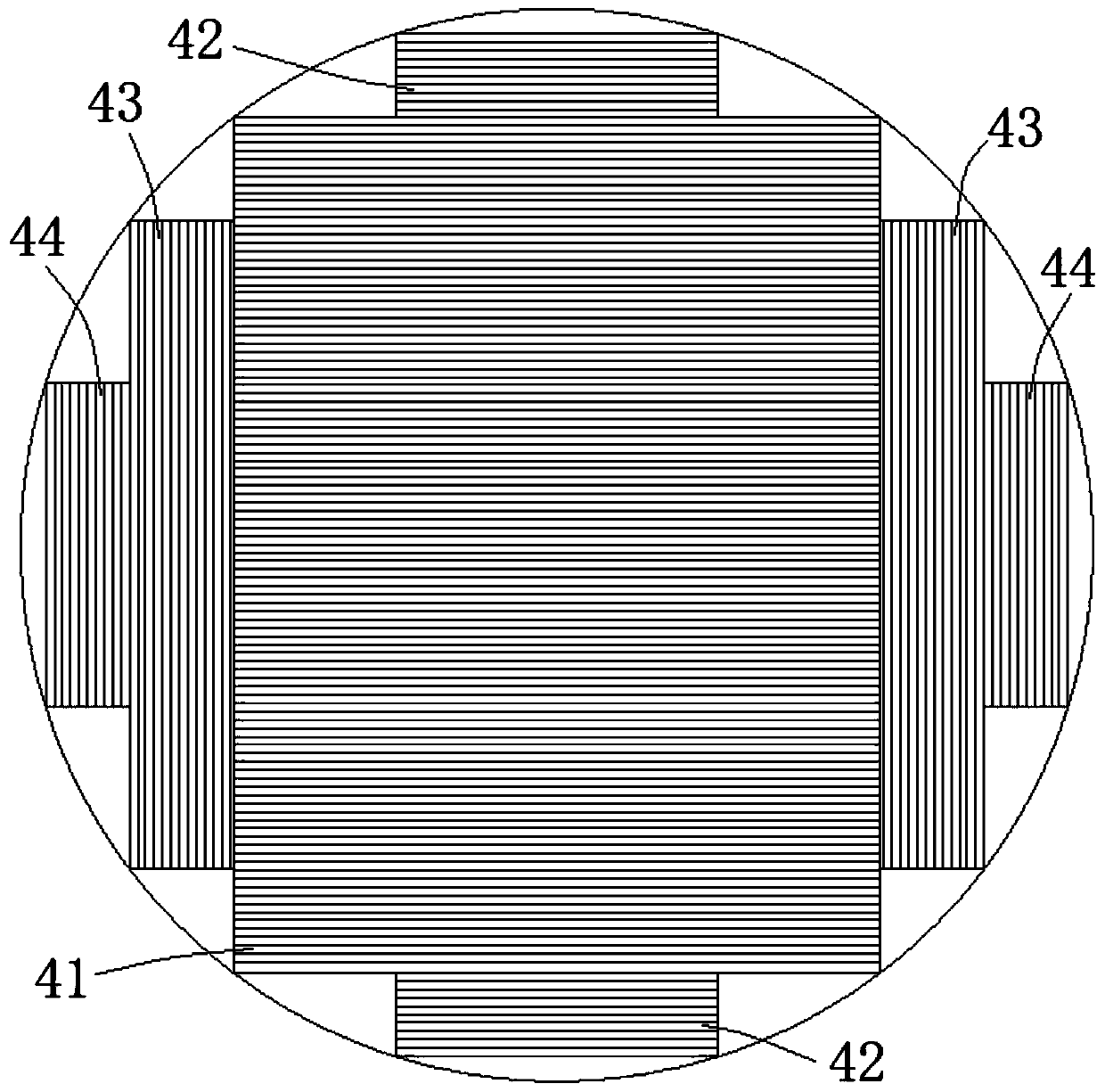

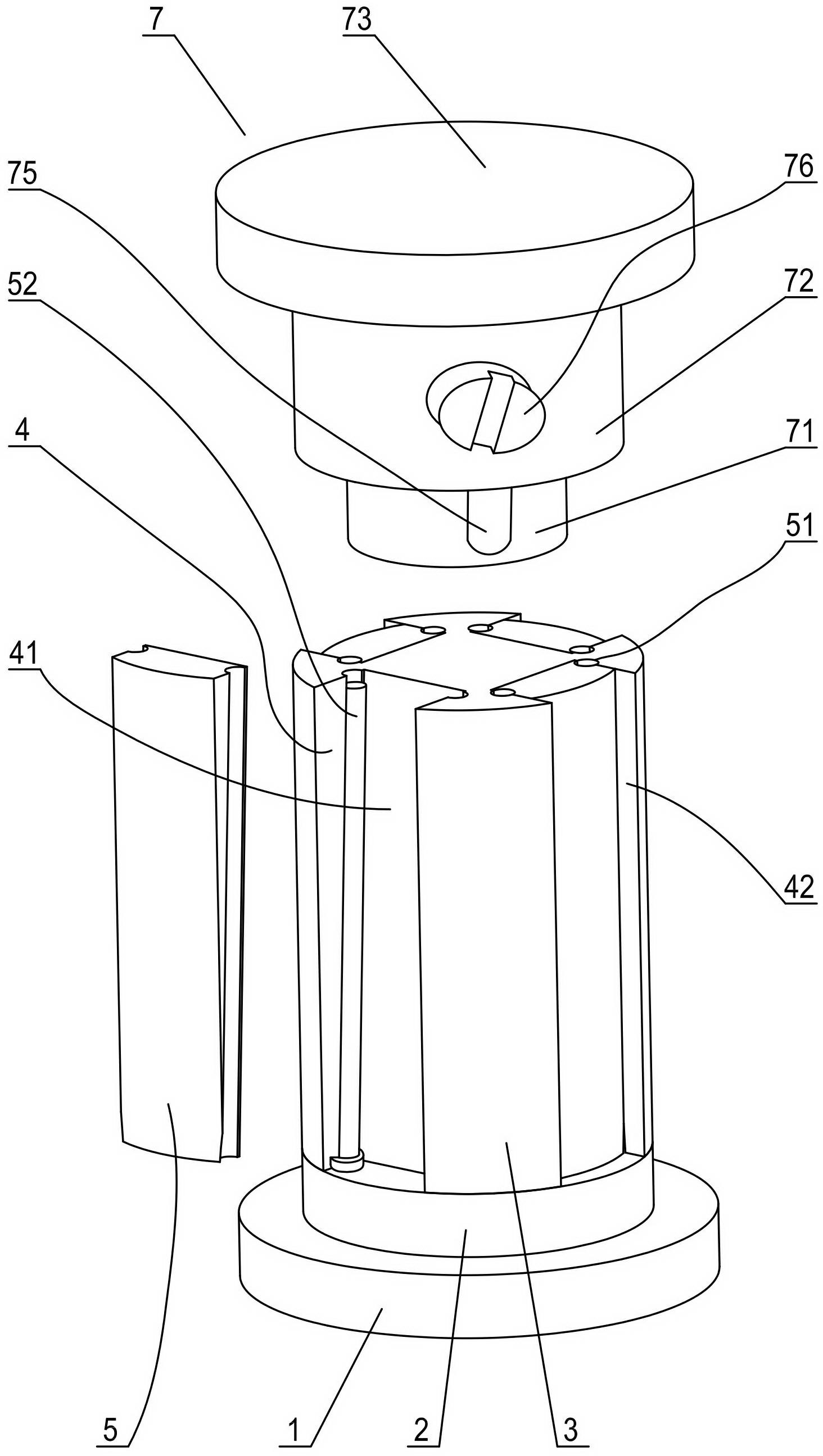

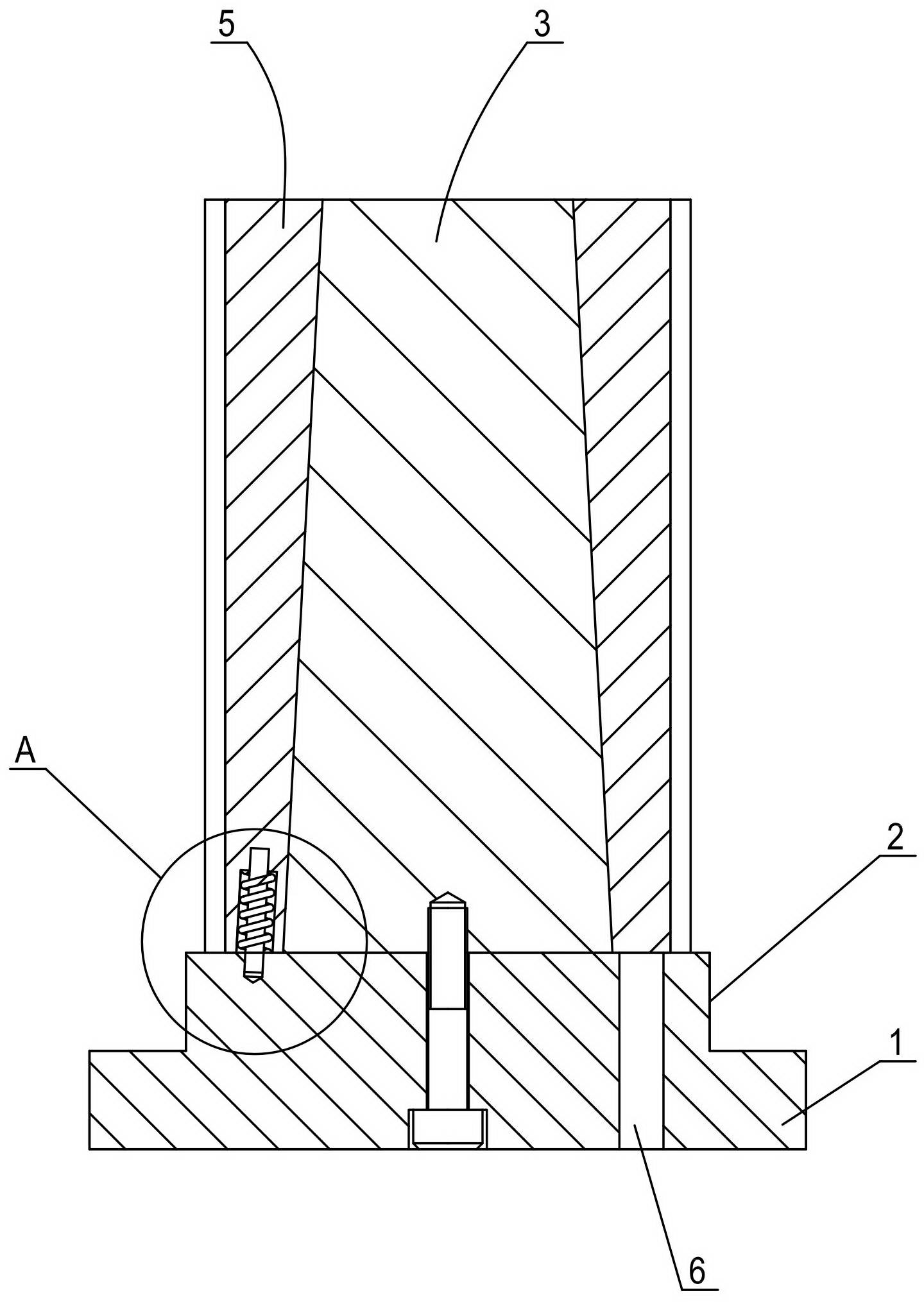

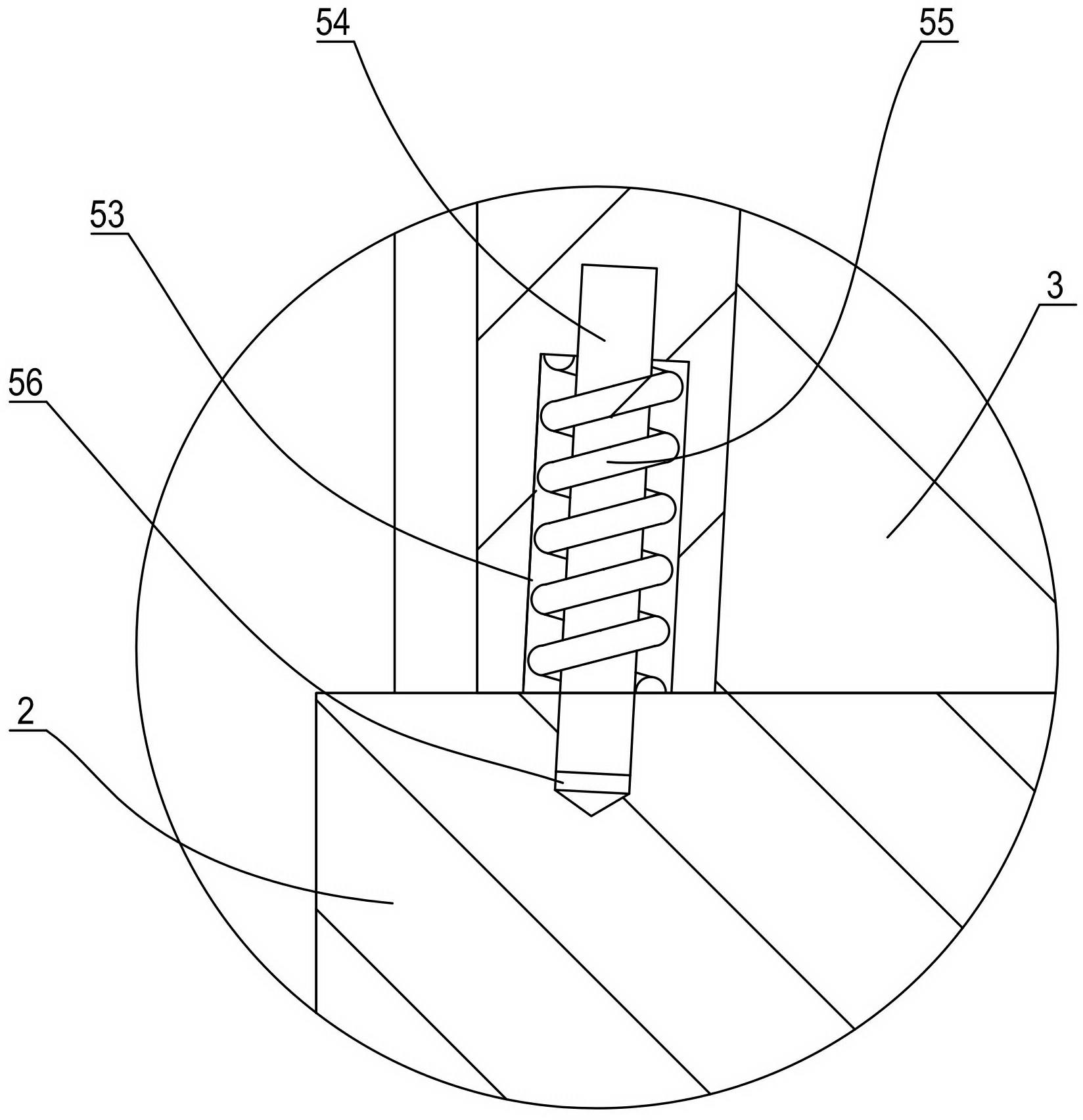

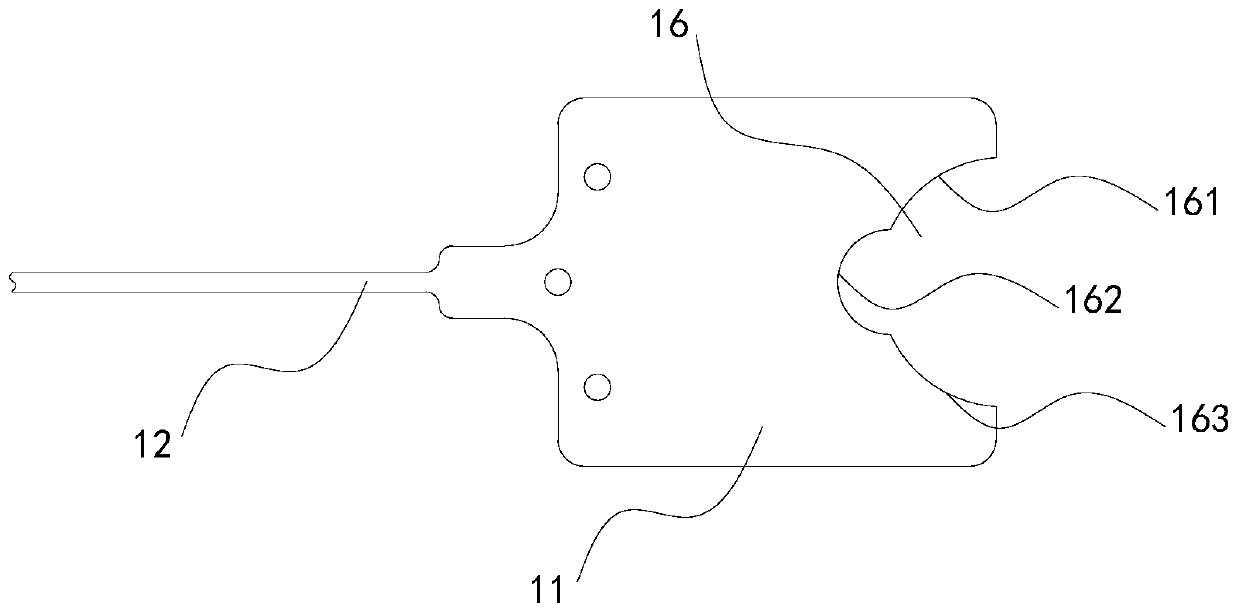

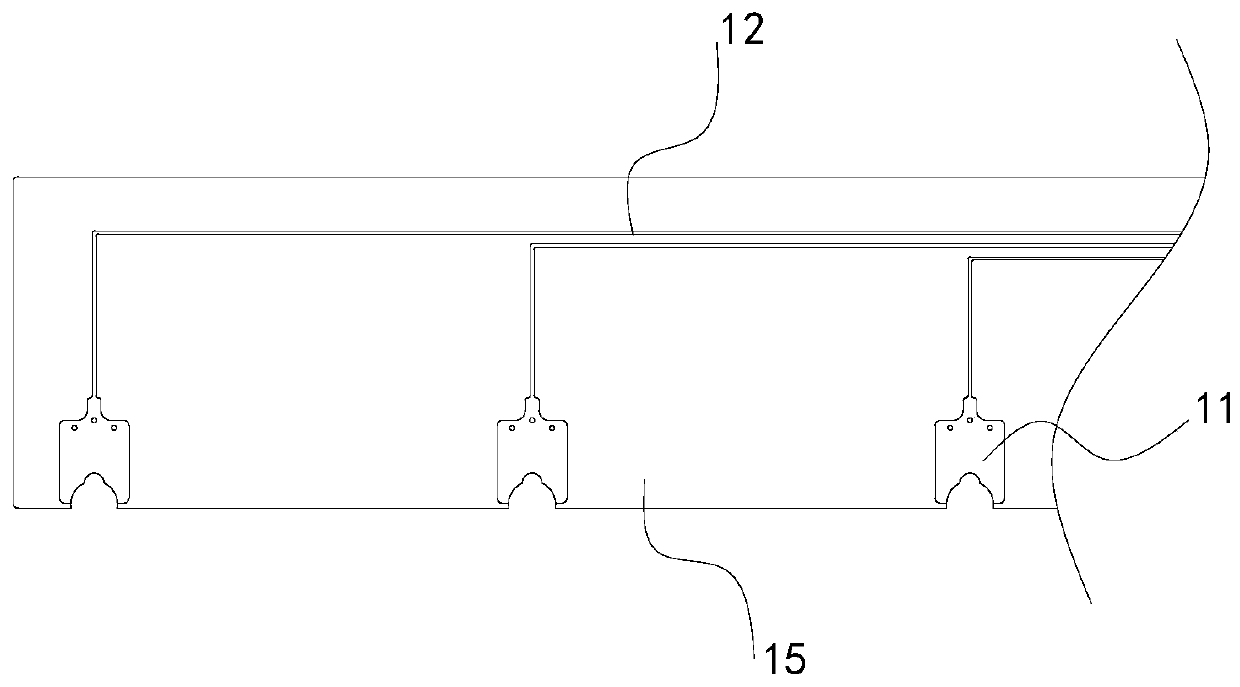

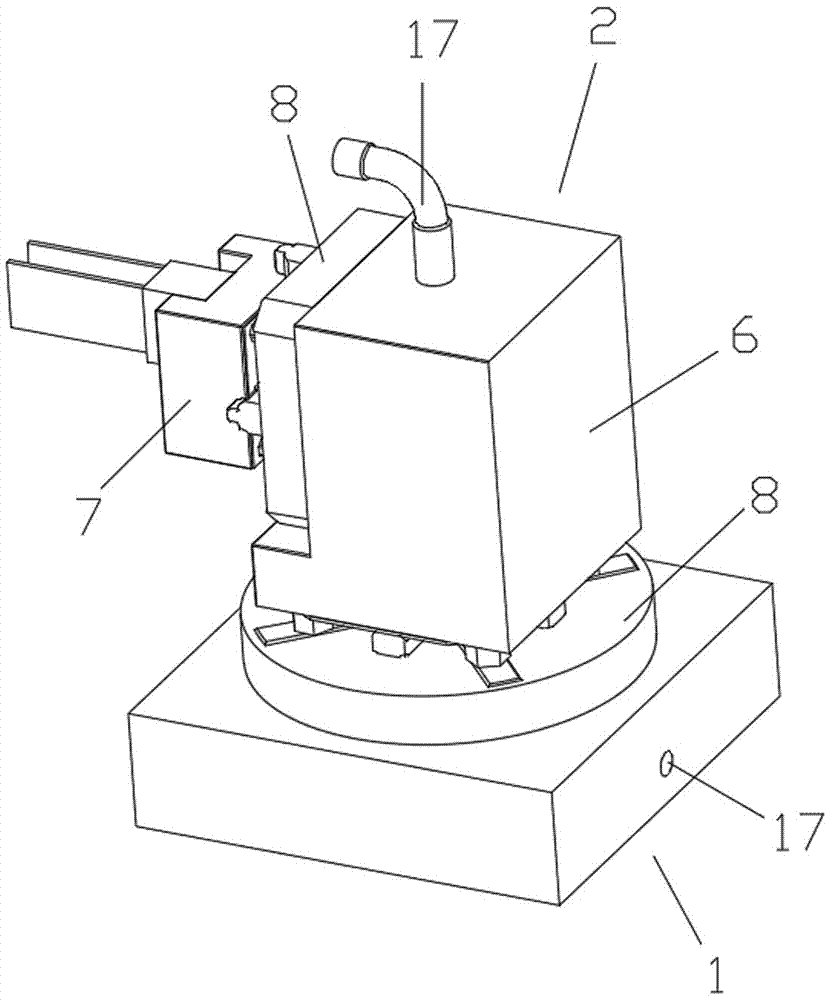

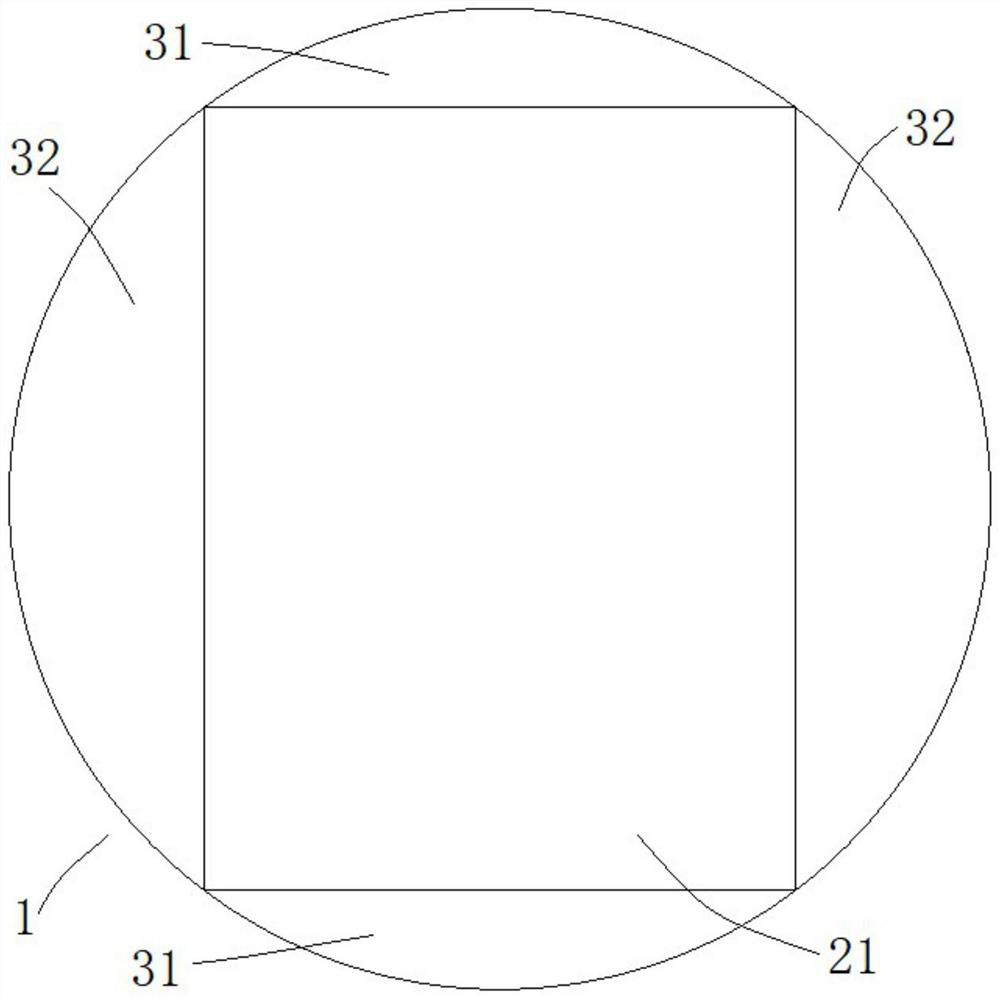

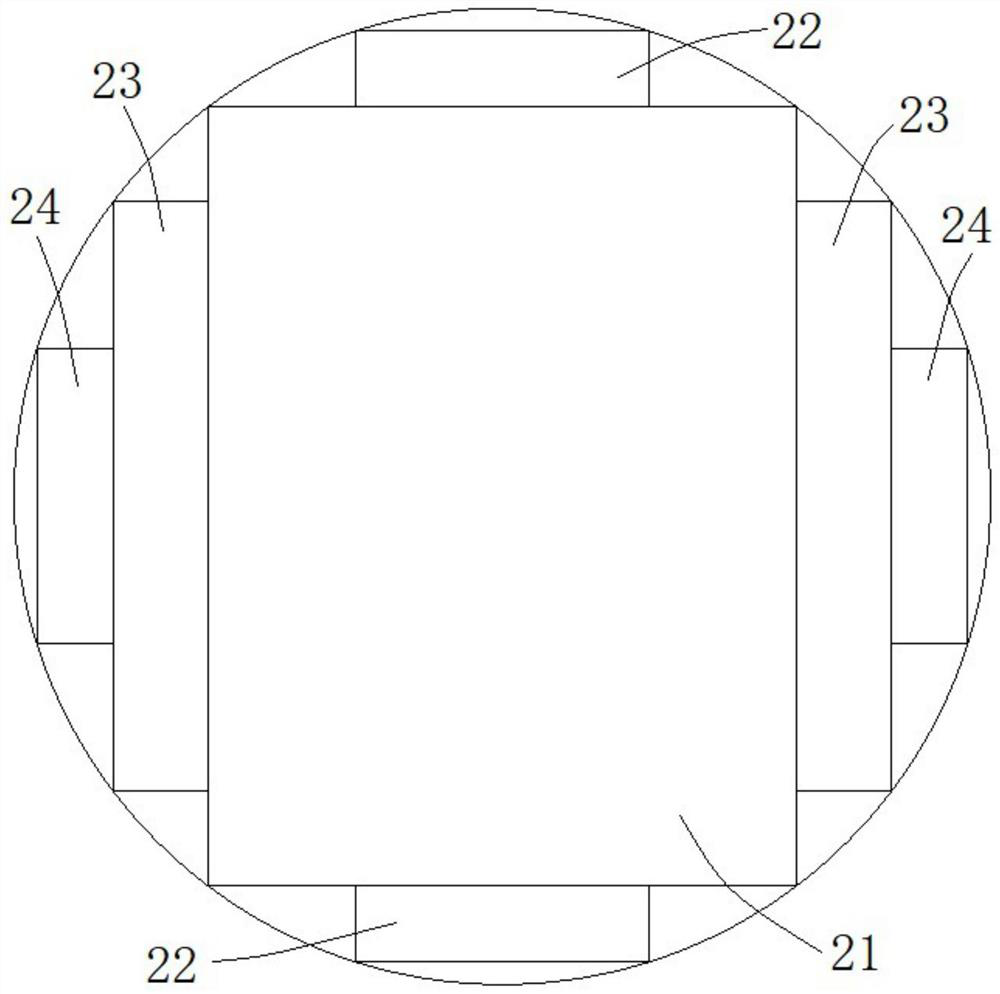

Magnetic tile adhering clamp for direct-current motor

InactiveCN102684401AGuaranteed positioning accuracyIncrease the length dimensionManufacturing stator/rotor bodiesManufacturing cost reductionCurrent meter

The invention discloses a magnetic tile adhering clamp for a direct-current motor. The magnetic tile adhering clamp comprises a base, and an elevated column with the diameter matched with the inner diameter of a body of the direct-current motor is arranged on the upper surface of the base. The elevated column is provided with a positioning cylinder which is of a split structure, the outer diameter of the positioning cylinder is matched with the inner diameter of the body of the direct-current motor, an even number of U-shaped through grooves extending from the position of the upper end face to one side of the positioning cylinder are equally arranged on the outer side face of the positioning cylinder, sliding blocks are arranged in the U-shaped through grooves, sliding guiding structures are arranged between the sliding blocks and the U-shaped through grooves, the outer side faces of the sliding blocks are cambered surfaces matched with the inner side faces of magnetic tiles, the outer side face of each sliding block and the left side face and the right side face of each U-shaped through groove jointly form one magnetic tile positioning groove, and the inner side bottom surfaces of the U-shaped through grooves attached to the sliding blocks are locking slopes inclined outwards from top to bottom. The magnetic tile adhering clamp can guarantee positioning accuracy of the magnetic tiles in adhesion, and is favorable for increasing length dimensions of the magnetic tiles through splicing structures so as to manufacture the direct-current motor with large torque. The guiding structures of the clamp are simplified, thereby being favorable for reduction of manufacturing cost.

Owner:宁波市北仑恒峰电机制造有限公司

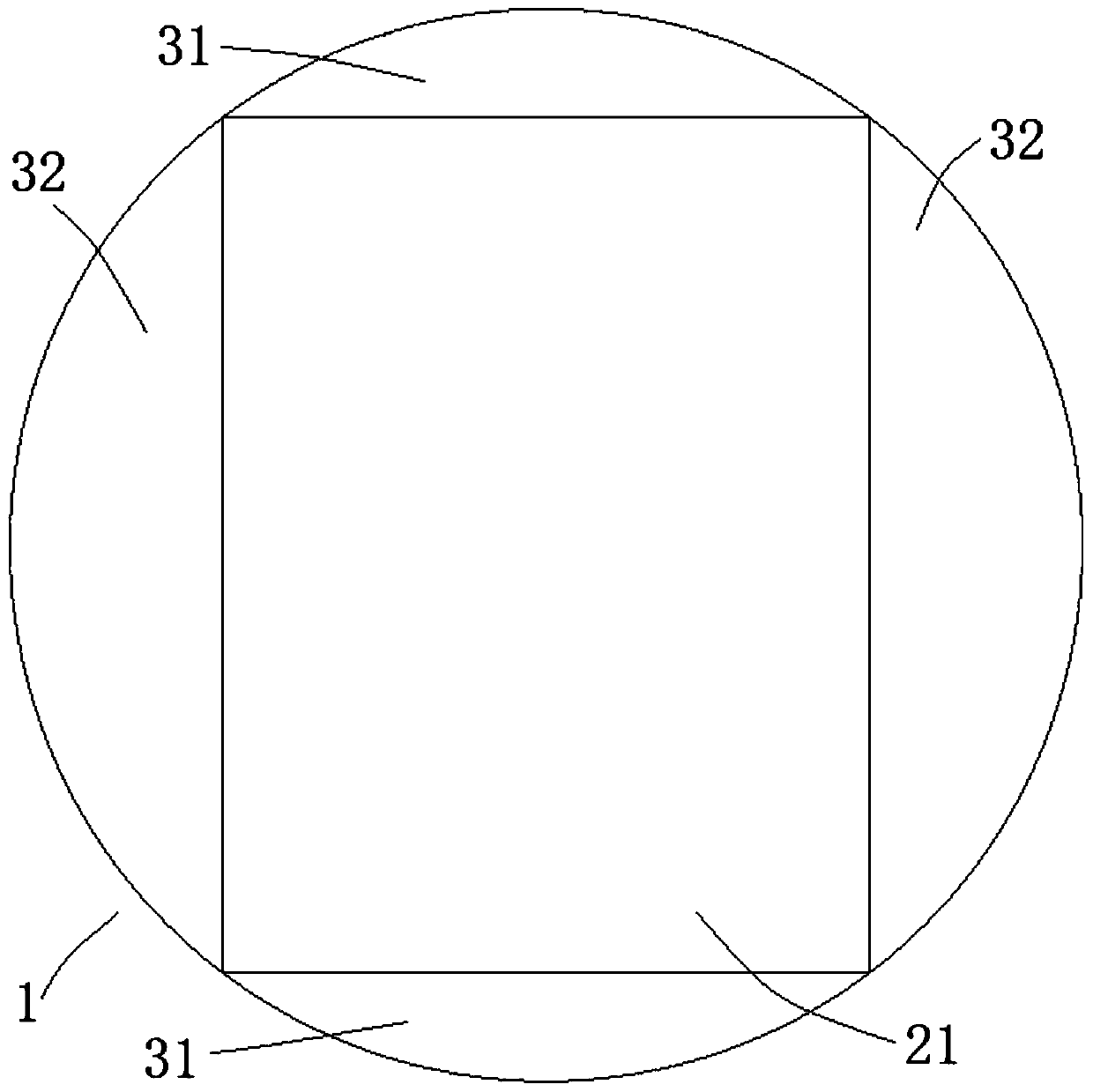

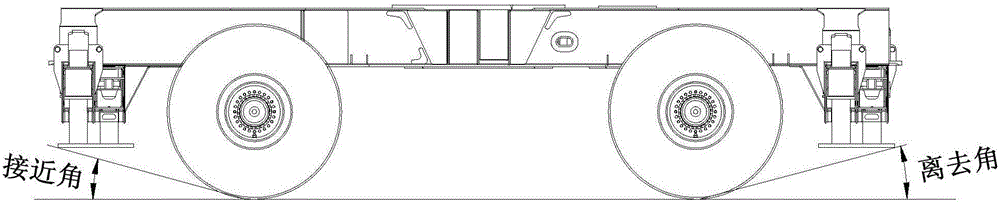

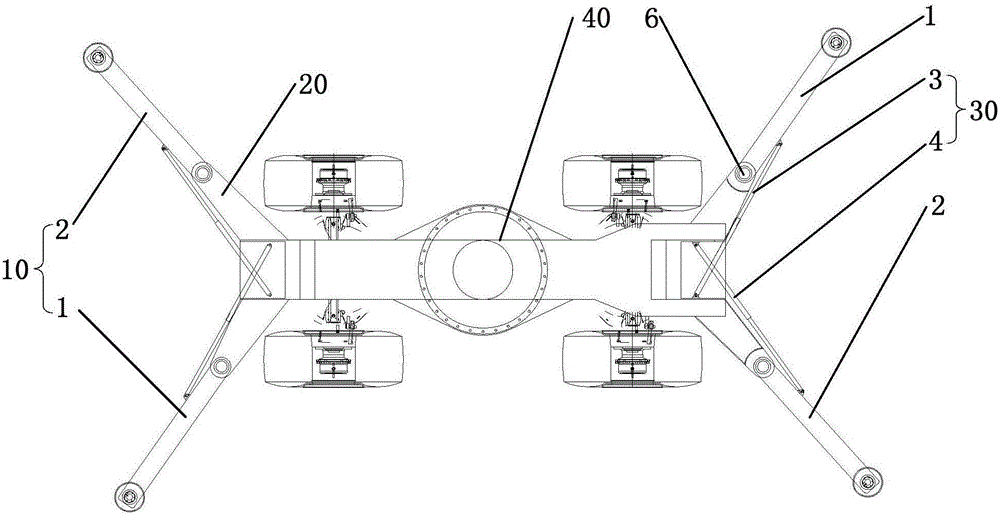

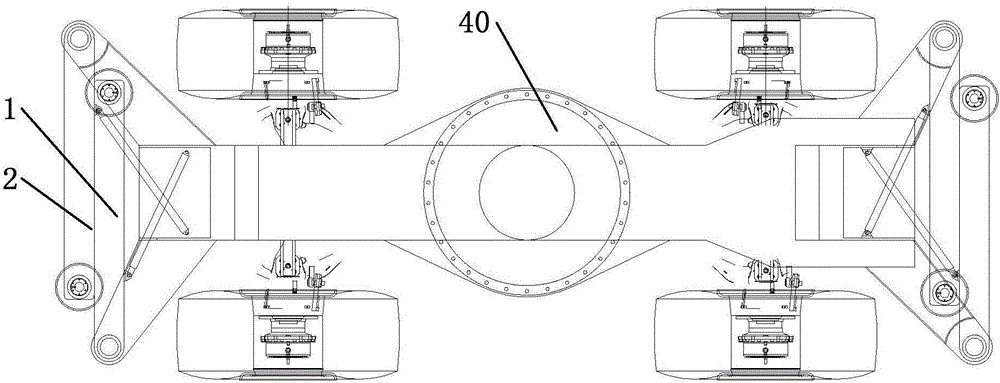

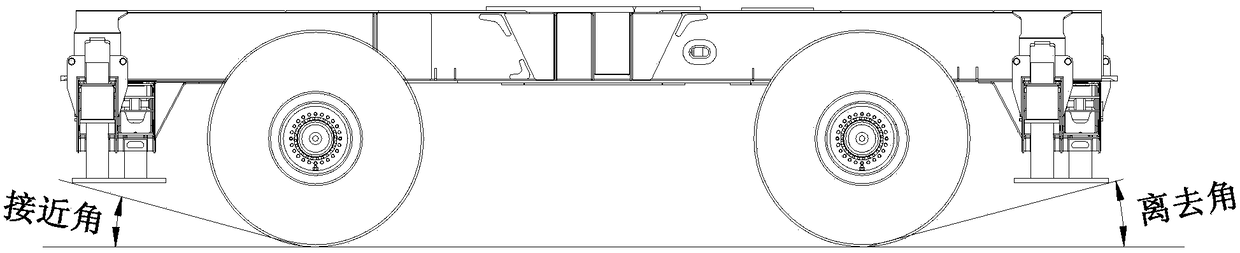

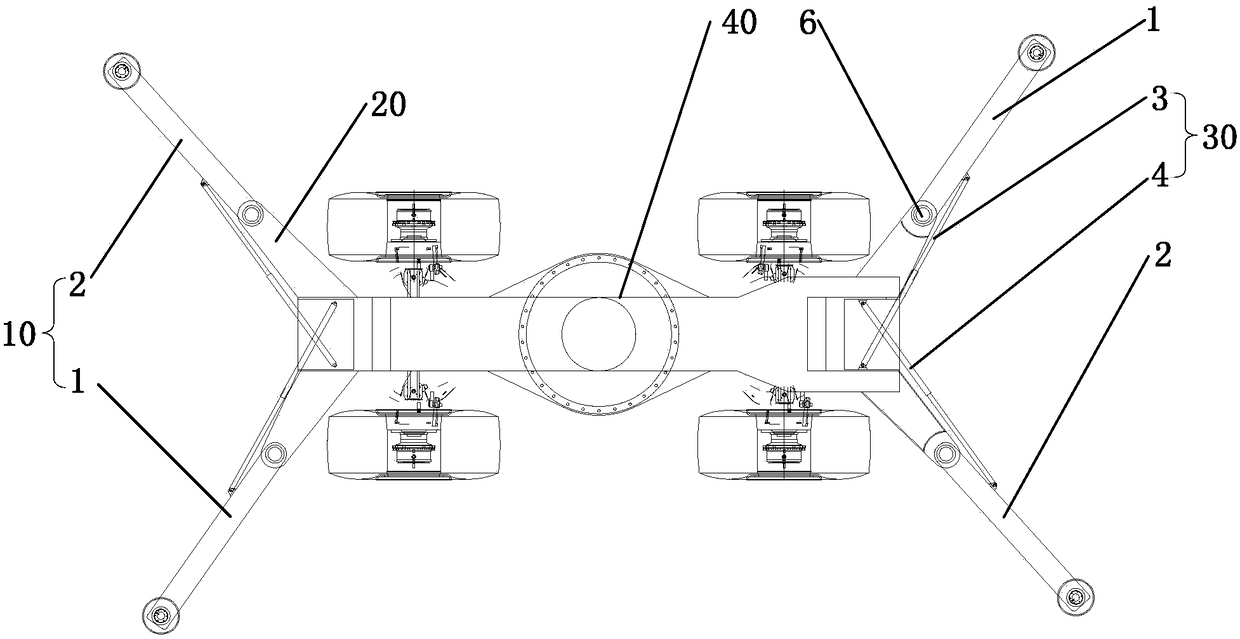

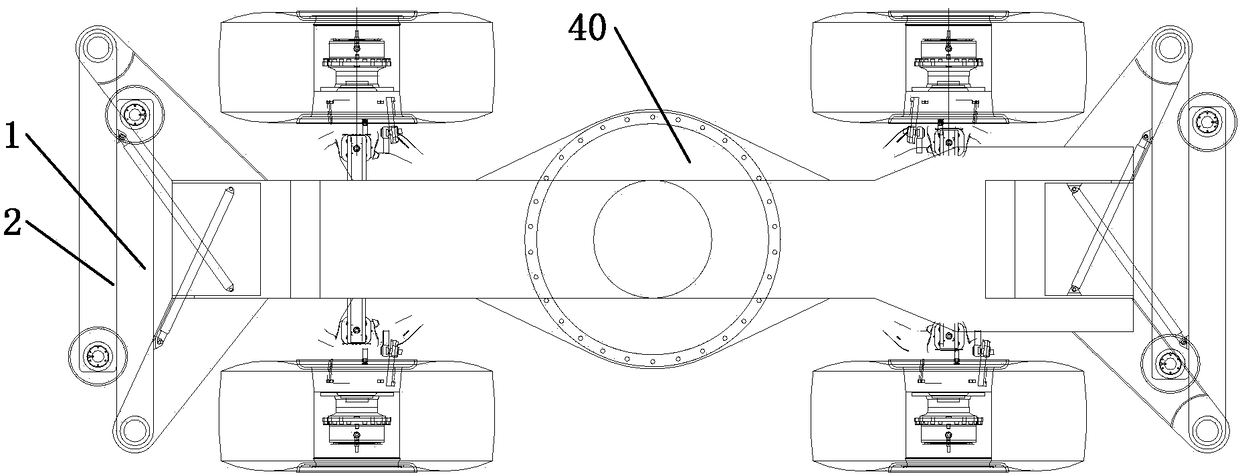

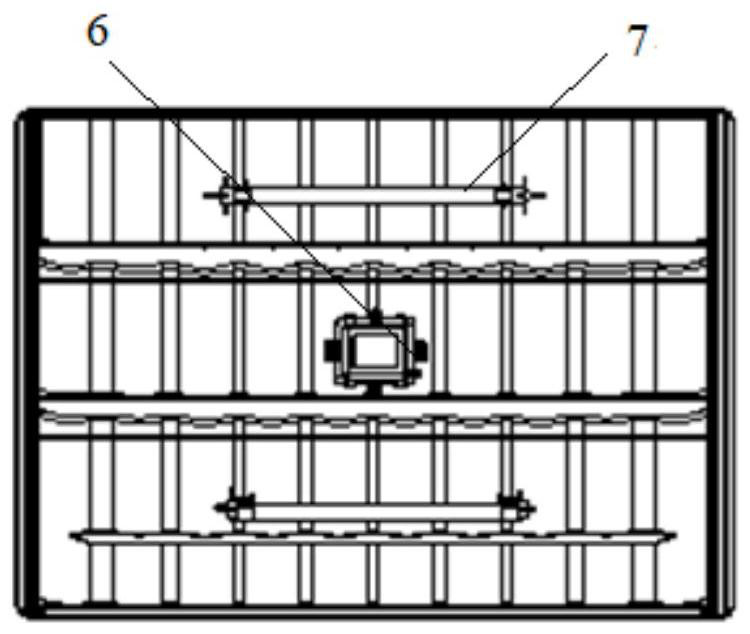

Frame structure and crane

The invention discloses a frame structure and a crane, relates to the field of engineering machinery, and is used for optimizing a structure of a traditional frame body. The frame structure comprises a frame body and support leg structures; the support leg structures are arranged at the end parts of the length direction of the frame body, and are rotationally or slidingly connected with the frame body; the support leg structures are located in an extending state; and the length directions of the support leg structures form acute angles with the length direction and the width direction of the frame body, so that the total length of the frame structure is larger than the length of the frame body, and the total width of the frame structure is larger than the width of the frame body. Under the precondition of not changing the size of the frame body, the length and the width sizes of the frame structure can be synchronously increased, so that the span of the crane is increased; and the weights of the support leg structures are far lower than the weight of the frame body in the prior art corresponding to the same span, so that the lifting weight can be increased when the span is increased.

Owner:XUZHOU HEAVY MASCH CO LTD

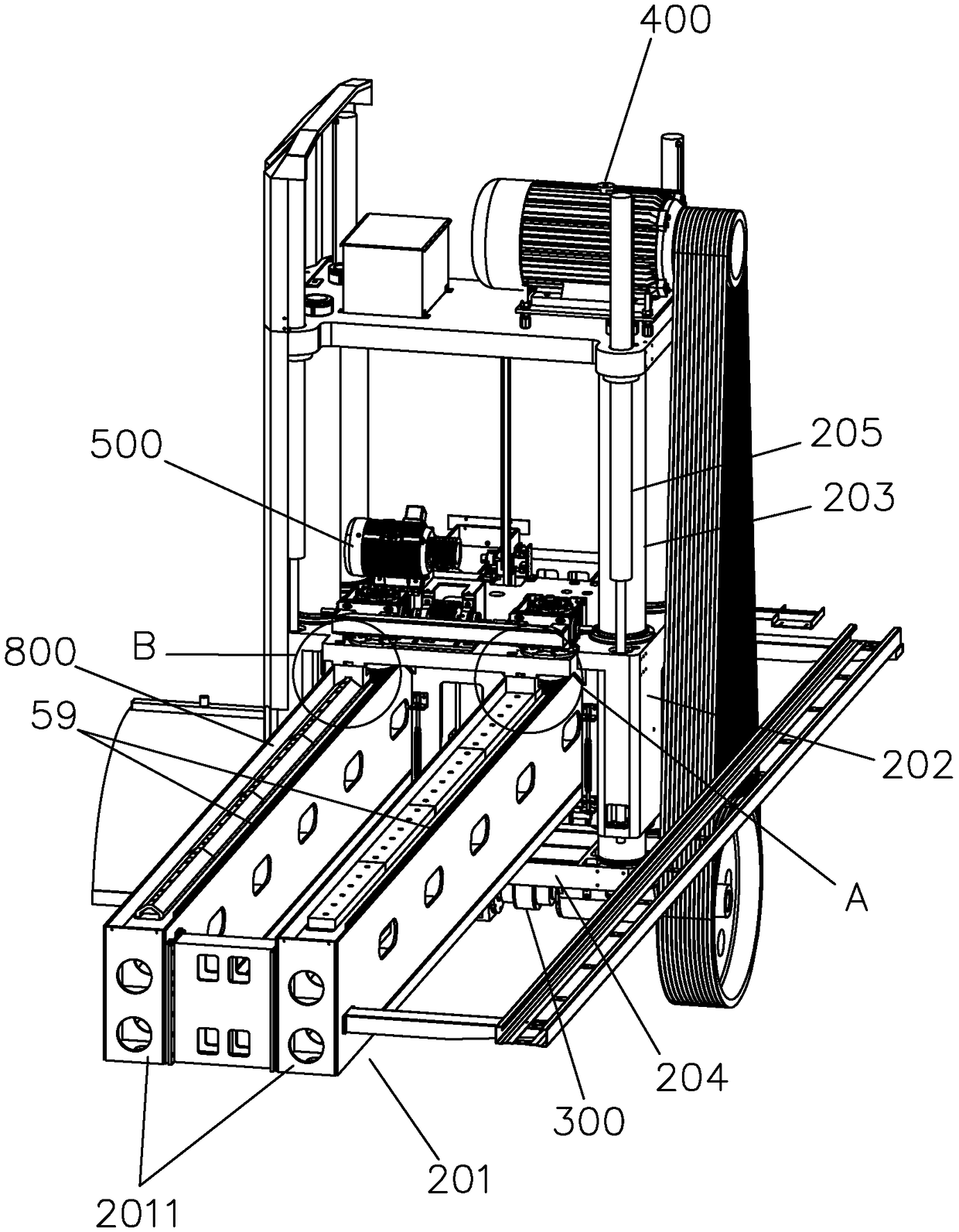

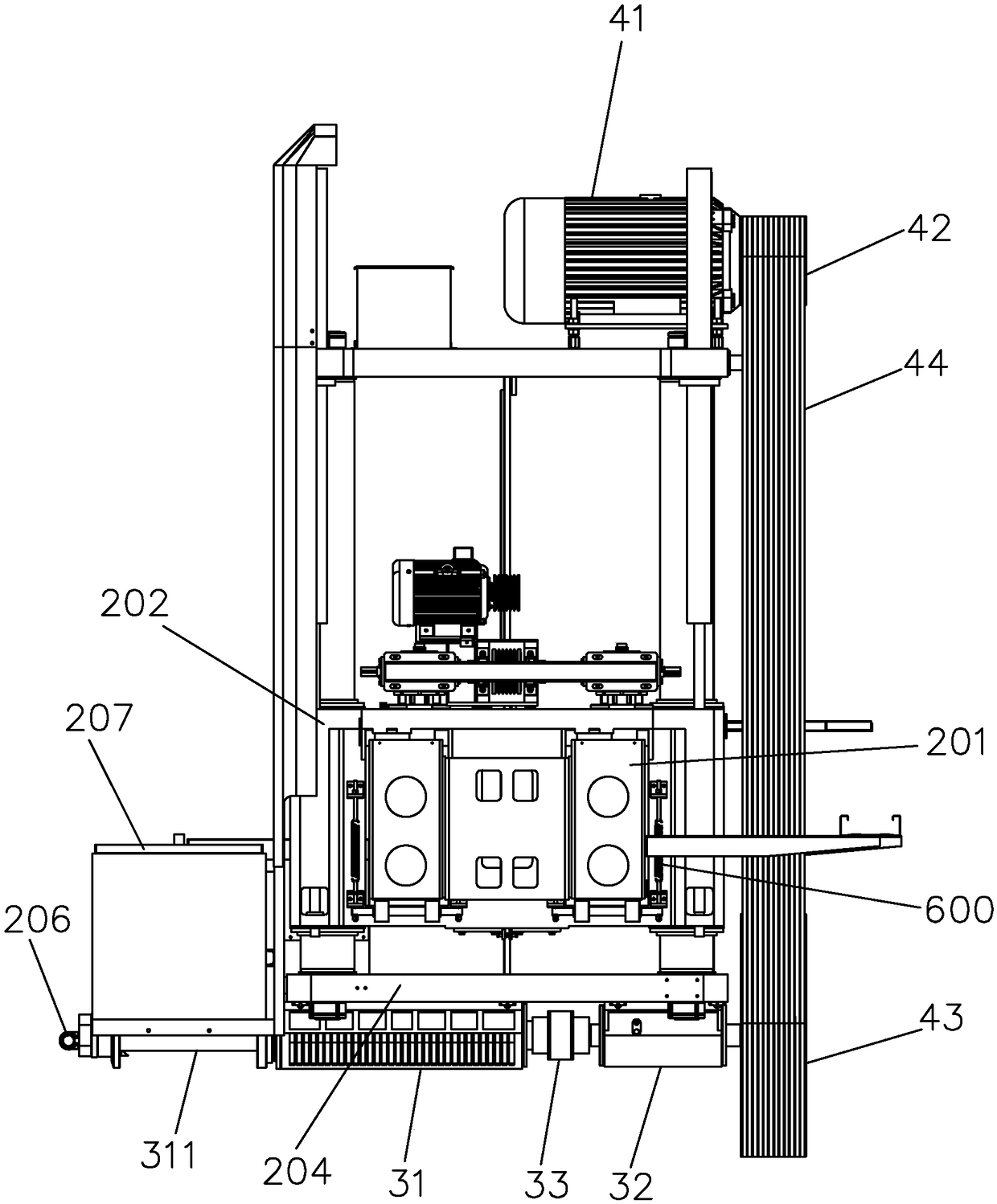

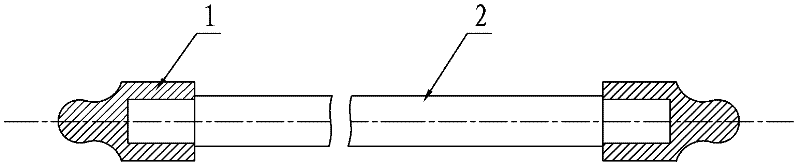

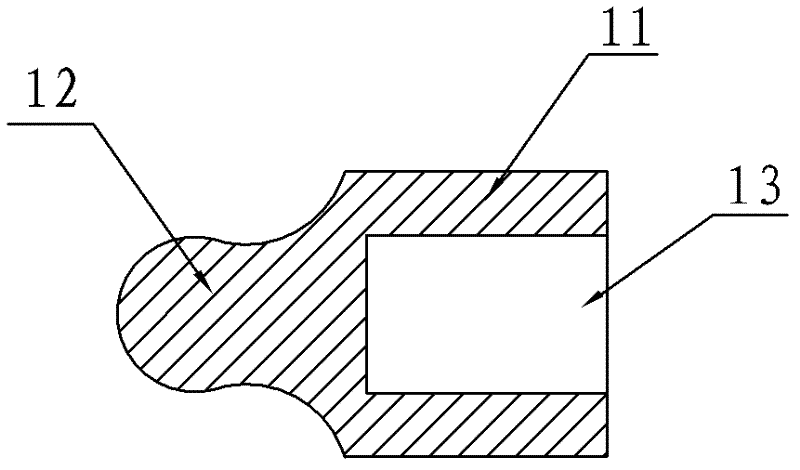

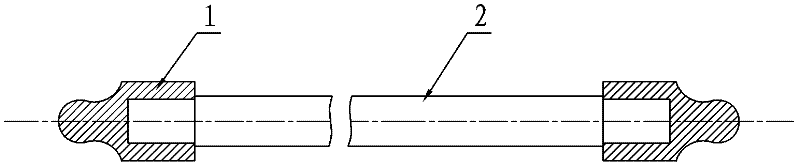

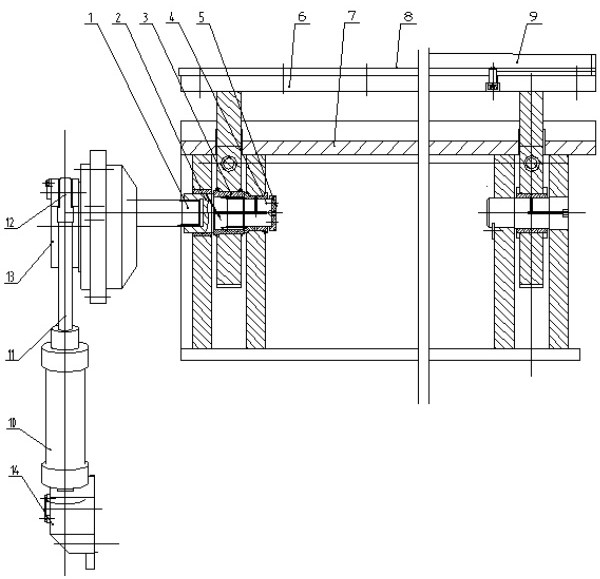

Coupling widened-type stone cutting machine

PendingCN108789879AIncrease the length dimensionImprove practicalityWorking accessoriesStone-like material working toolsSTONE CUTTERCoupling

The invention discloses a coupling widened-type stone cutting machine, comprising a middle frame, a lower beam slab, a lifting column set, a saw blade coupling assembly and a saw blade driving mechanism. The lifting column set is arranged in a manner of vertically penetrating through the middle frame movably; the lower end part of the lifting column set is fixedly connected with the lower beam slab; a lifting driving mechanism is arranged between the lifting column set and the middle frame; the saw blade coupling assembly comprises a spindle box, a transmission box and a coupling; the spindlebox and the transmission box extend coaxially and are arranged in line on the bottom face of the lower beam slab side by side, and the spindle box and the transmission box are integrally connected inmanner of transmission through the coupling; a spindle part extending out of the side face of the middle frame extends on the outer end of the spindle box, and the spindle part is provided with a plurality of saw blades; and a transmission shaft part extending out the side face of the middle frame extends on the outer end of the transmission box, and the transmission shaft part and the saw blade driving mechanism are in transmission connection. The stone cutting machine disclosed by the invention is capable of cutting a wide-size (2.3m wide) square stock, and huge practicability, convenience and high efficiency are brought to actual stone mining and processing.

Owner:QUANZHOU HAIENDE ELECTROMECHANICAL TECH DEV

Flexible circuit board, capacitive screen and processing method of flexible circuit board

ActiveCN109757031AImprove conductivityIncrease contactElectrical connection printed elementsInput/output processes for data processingFlexible circuitsEngineering

The invention discloses a flexible circuit board, a capacitive screen and a processing method of the flexible circuit board. The flexible circuit board comprises a base layer and a conductive layer, wherein the conductive layer is attached to the base layer, the conductive layer is at least provided with a conductive sheet and a conductive wire, the conductive sheet and the conductive wire are electrically connected with each other, the conductive sheet is positioned on the conductive connection side, the conductive sheet is provided with a first abdication gap, and the opening width of the first abdication gap gradually decreases from the outside to the inside. According to the scheme of the invention, the conductive connection structure is stable, the problems of poor contact and bindingopen circuit of the flexible circuit board can be solved, the process flow time for processing the conductive sheet is short, the drilling operation is convenient, and the structure is more stable and reliable.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

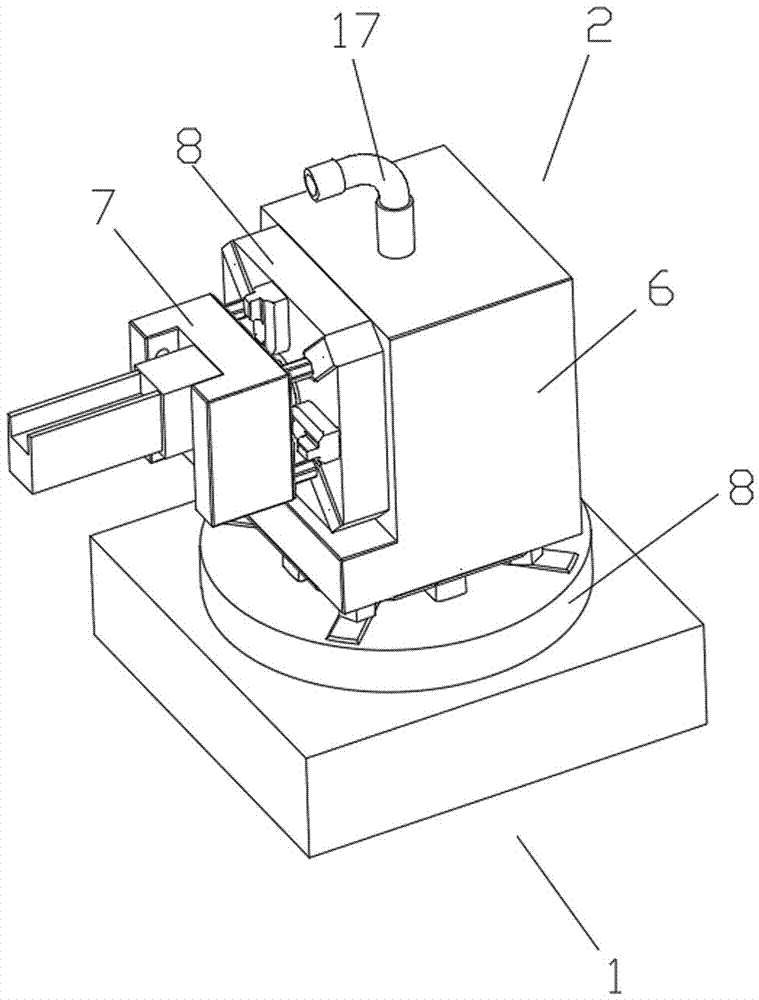

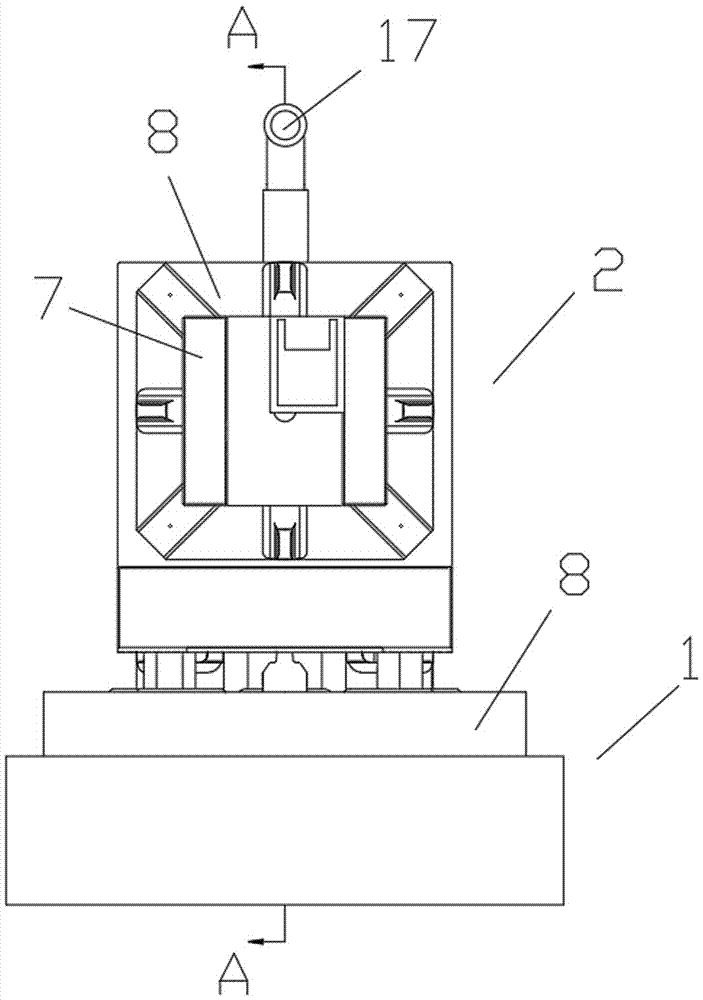

Electrode side milling clamp

PendingCN108000193AIncrease the length dimensionPrecise clampingPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention relates to an electrode side milling clamp according to the technical scheme. The electrode side milling clamp comprises a lower clamping and positioning mechanism which is vertically arranged and an upper clamping and positioning mechanism which is transversely arranged. The upper clamping and positioning mechanism and the lower clamping and positioning mechanism both comprise locking mechanisms, positioning mechanisms and blind rivets. The upper clamping and positioning mechanism is vertically connected to the lower clamping and positioning mechanism through a connecting base.The blind rivet and the positioning mechanism of the upper clamping and positioning mechanism are transversely connected with a clamp body used for clamping workpieces. The electrode side milling clamp is accurate, rapid, stable and reliable in clamping. Compared with a traditional mode that the long edges of an electrode are vertically milled and can be limited by the height direction dimensionsof a machine tool, the electrode side milling clamp can transversely machine the electrode, and thus the length dimensions of the electrode can be greatly increased.

Owner:HUANGYAN XINGTAI PLASTIC MOLD

Projector having reflecting mirror disposed within housing and operation buttons disposed on sidewall of the housing

ActiveUS10151969B2Easy to operateOptimizationProjectorsPicture reproducers using projection devicesComputer scienceProjector

A projector includes: an exterior housing configuring an exterior; a projection optical device which projects an image toward a projection surface; and a plurality of operation buttons which, being disposed in such a way as to be exposed to the outside of the exterior housing, an image opening for allowing the image projected from the projection optical device to pass through is formed in one sidewall, among sidewalls configuring the exterior housing, which intersects in a vertical direction, the projection optical device includes a reflecting mirror which reflects the image, and projects it through the image opening, and the plurality of operation buttons are disposed on a side of the one sidewall farther from the projection surface than the image opening.

Owner:SEIKO EPSON CORP

Air-conditioner air inlet

InactiveCN101718463AIncrease the length dimensionEasy to turn adjustmentLighting and heating apparatusSpace heating and ventilation detailsEngineeringGravitation

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

Laser etching circuit structure of touch panel

ActiveCN106383620AIncrease the length dimensionInput/output processes for data processingSilver pasteLaser etching

The invention discloses a laser etching circuit structure of a touch panel. The laser etching circuit structure of the touch panel comprises a plurality of laser etching line bodies and a plurality of screen-printed silver paste lines. The laser etching line bodies include first line bodies, second line bodies and third line bodies. The central paths of the two first line bodies are spaced by a first width; the central paths of the two second line bodies are spaced by a second width; the third line bodies are connected with one ends of the first line bodies and one ends of the second line bodies; the central paths of the two third line bodies are spaced by a third width; and each screen-printed silver paste line is located between the two laser etching line bodies. The third line bodies are same in length dimension, the first width and the second width are same in length dimension, and the length dimension of the third width is greater than that of the first width. Through the structure, the shortcoming of excessively small thickness or line breakage of the screen-printed silver paste lines (routing lines) caused by inconsistent line widths of the routing lines due to excessively small line spacing of the routing lines or relatively quick laser etching in a fabrication process can be improved.

Owner:INTERFACE TECH CHENGDU CO LTD +2

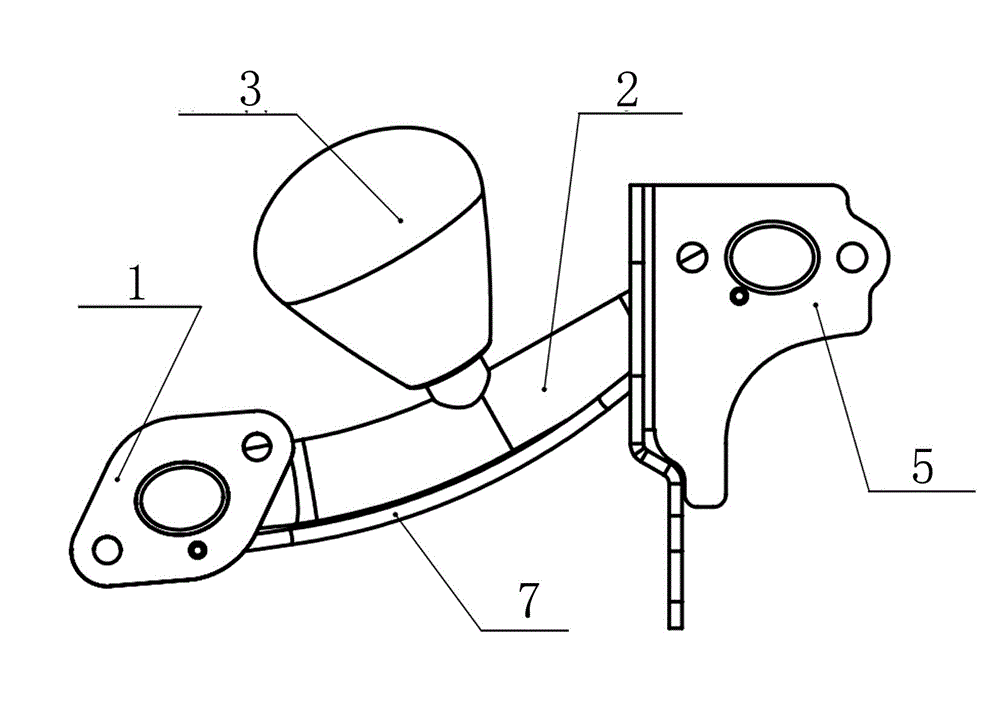

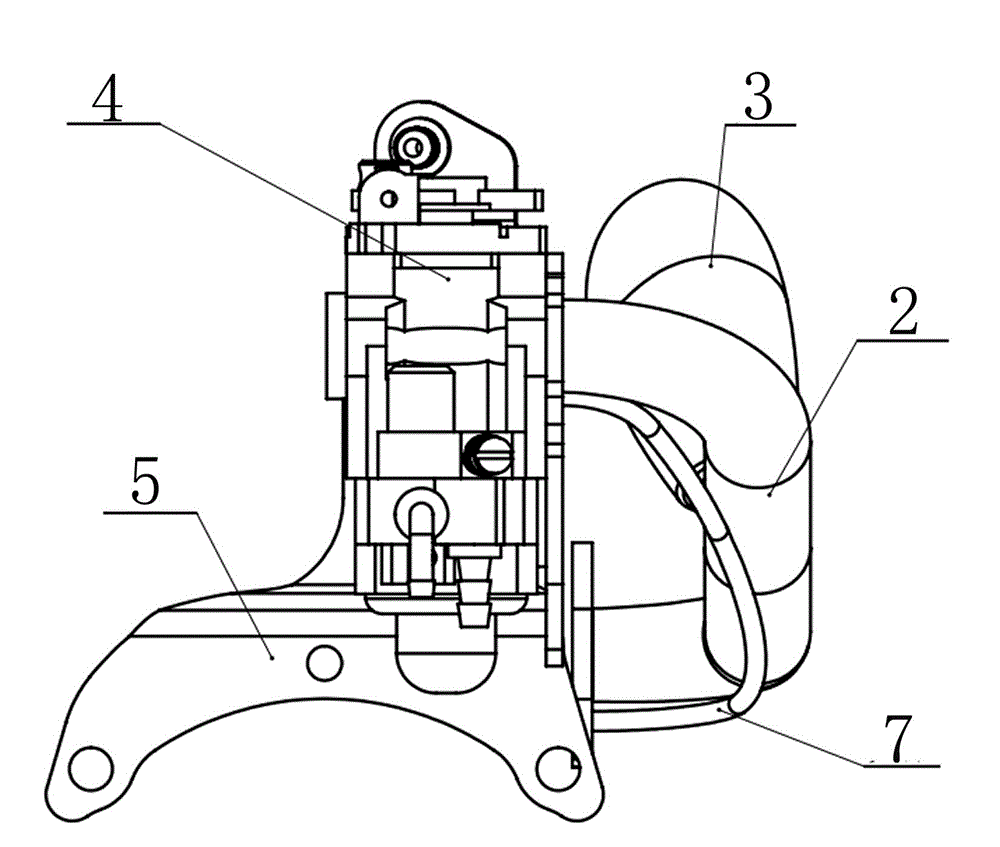

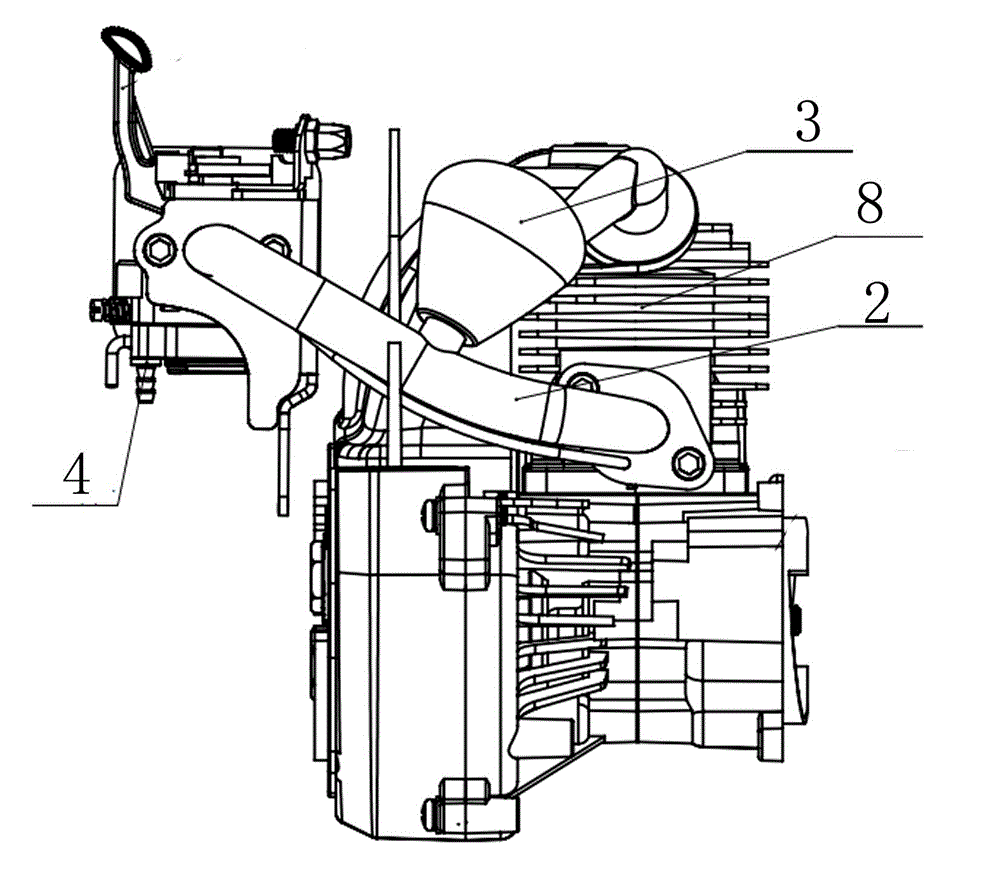

Air inlet system of small gasoline engine classes

InactiveCN103912419AFuel consumption regulationOptimal functional statusMachines/enginesAir cleaners for fuelAir filterDistillation

The invention provides an air inlet system of small gasoline engine classes. The air inlet system is composed of an inlet pipe flange, an inlet pipe, an air storage bag, a carburetor, a carburetor support, an air filter and a negative pressure pipe. The air inlet pipe flange is arranged on the air inlet pipe and is fixedly connected with an air inlet of an engine cylinder, the other end of the air inlet pipe is connected with the carburetor which is fixedly connected with a gearbox through the carburetor support, and the air filter and the carburetor are arranged side by side and is away from the engine cylinder. The air inlet system has the advantages that since the length dimension of the air inlet pipe is increased and the mounting position and direction of the air filter and the carburetor are changed, the air filter and the carburetor are away from the engine cylinder, heat of air inflow to power is reduced, the temperature of gasoline is always controlled within a distillation range point, fuel consumption, power and rotation speed of the engine can be effectively regulated and controlled, and the like.

Owner:YONGKANG JIAHONG TOOLS MFR

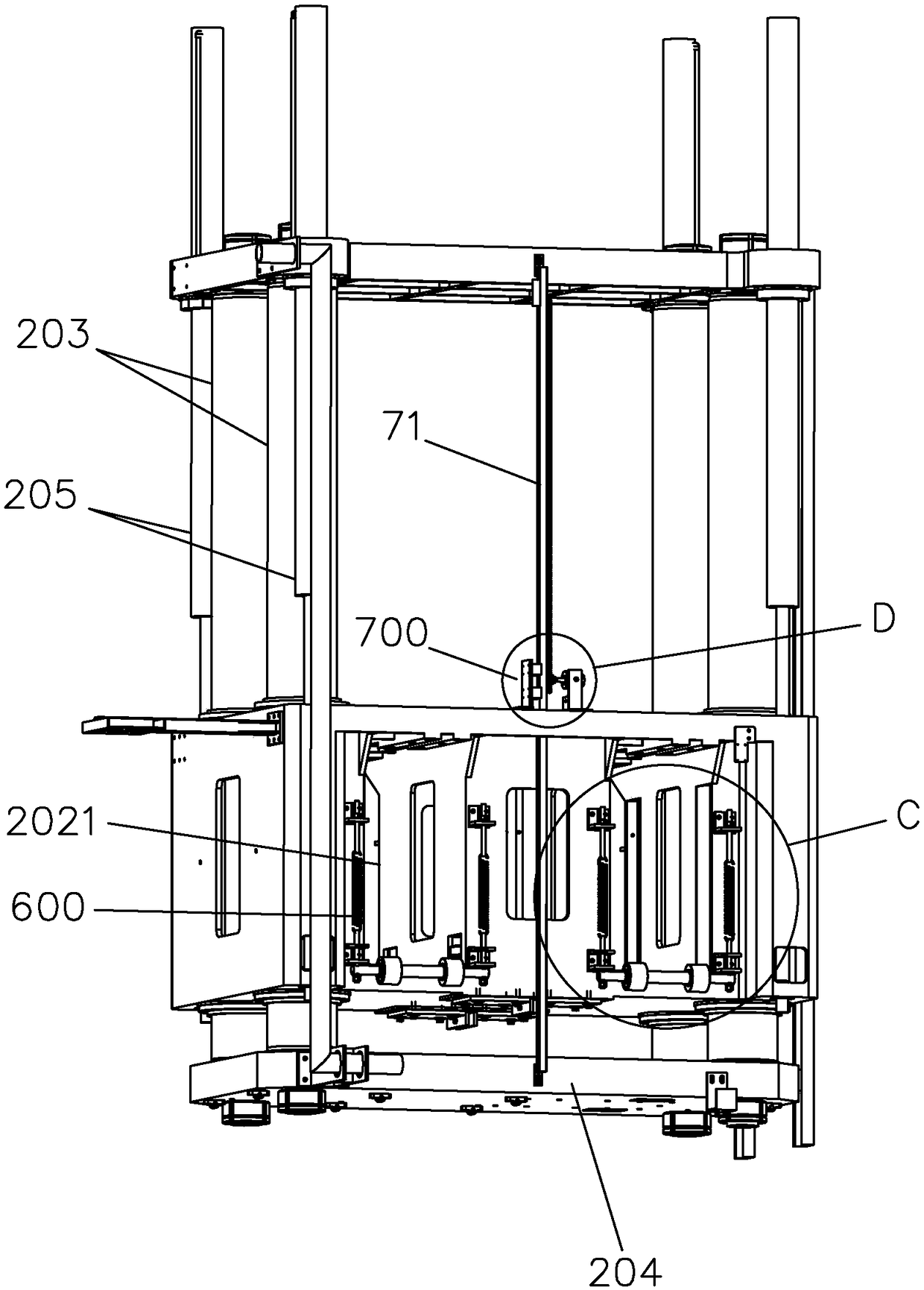

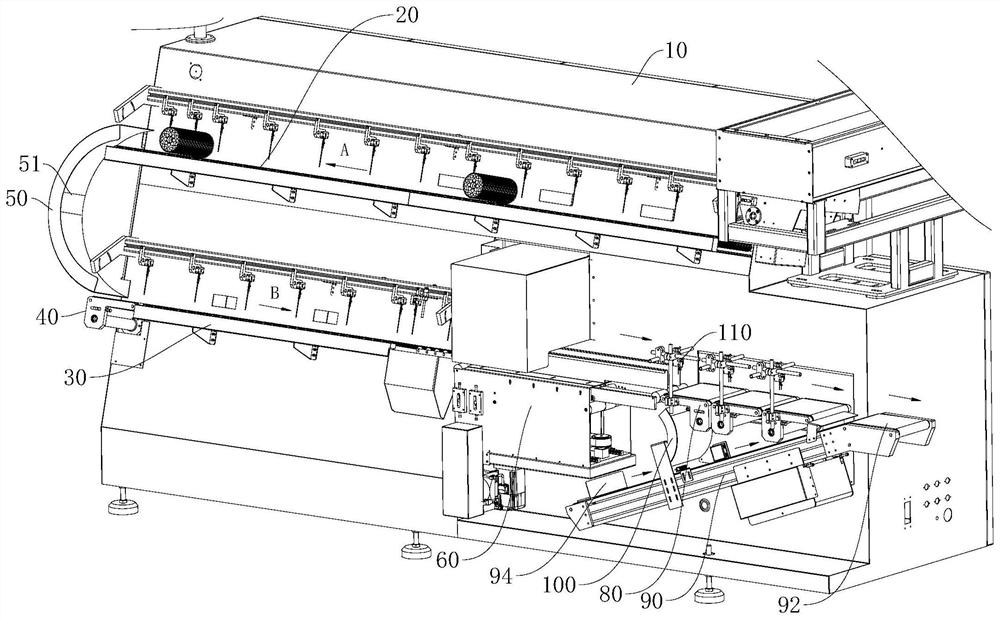

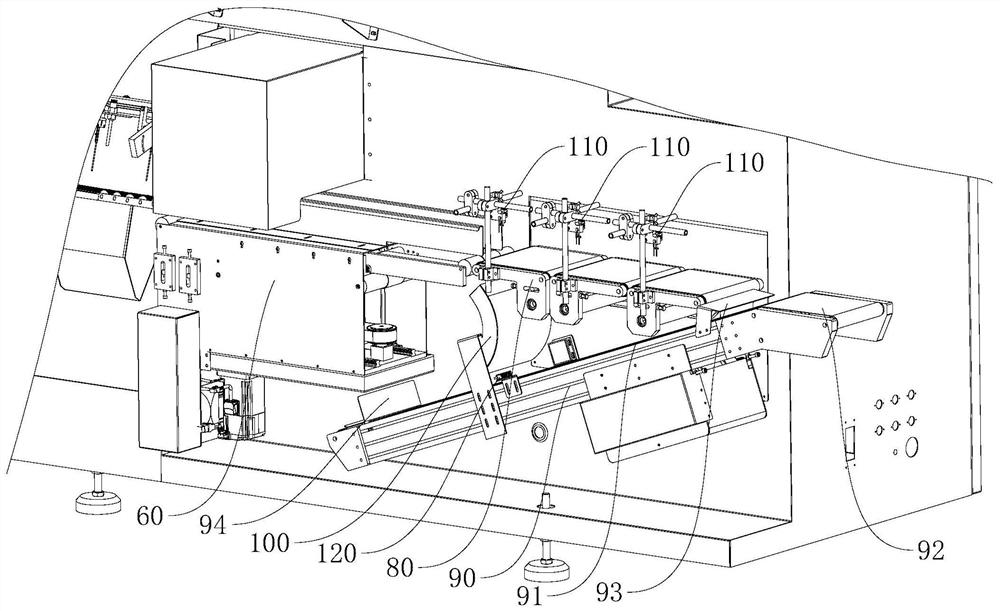

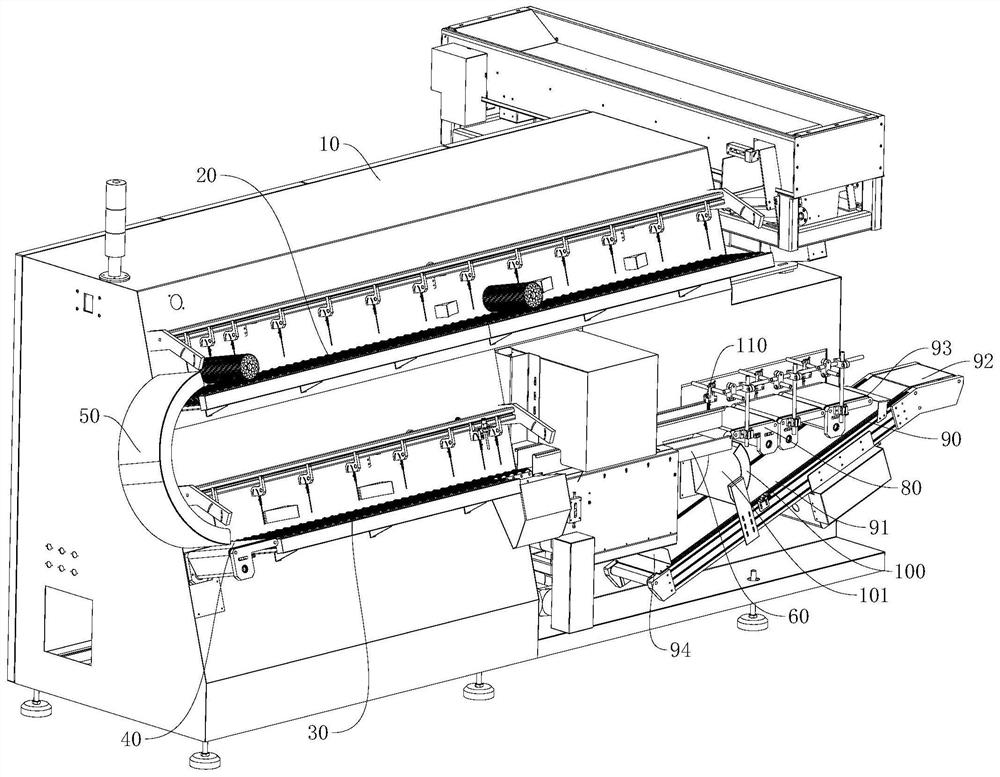

Material finishing machine

PendingCN113734517AIncrease the length dimensionCompact structureConveyorsControl devices for conveyorsEngineeringVisual detection

The invention discloses a material finishing machine which comprises a machine body. The machine body is provided with a material conveying device and a material turnover device; the material conveying device comprises a first conveying device for conveying materials in the first direction and a second conveying device for conveying materials in the second direction; the first conveying device and the second conveying device are arranged from top to bottom; the first direction is opposite to the second direction; the material turnover device comprises a third conveying device, a visual detection device used for detecting whether the materials passing through the third conveying device are in a set state or not, a fourth conveying device, a transfer structure and a fifth conveying device; the front end of the third conveying device is movably arranged; and the front end of the third conveying device can move to be a distance away from the rear end of the fourth conveying device and form a material outlet when the visual detection device detects that the materials are not in the set state; the transfer structure is provided with a guide surface; and the guide surface is used for guiding the materials conveyed out of the material outlet to be turned over to enable the materials to be in the set state. The structure of the material finishing machine is more compact, simpler and more practical.

Owner:安狄包装技术(广东)有限公司

Frame structure and crane

The invention discloses a frame structure and a crane, relates to the field of engineering machinery, and is used for optimizing a structure of a traditional frame body. The frame structure comprises a frame body and support leg structures; the support leg structures are arranged at the end parts of the length direction of the frame body, and are rotationally or slidingly connected with the frame body; the support leg structures are located in an extending state; and the length directions of the support leg structures form acute angles with the length direction and the width direction of the frame body, so that the total length of the frame structure is larger than the length of the frame body, and the total width of the frame structure is larger than the width of the frame body. Under the precondition of not changing the size of the frame body, the length and the width sizes of the frame structure can be synchronously increased, so that the span of the crane is increased; and the weights of the support leg structures are far lower than the weight of the frame body in the prior art corresponding to the same span, so that the lifting weight can be increased when the span is increased.

Owner:XUZHOU HEAVY MASCH CO LTD

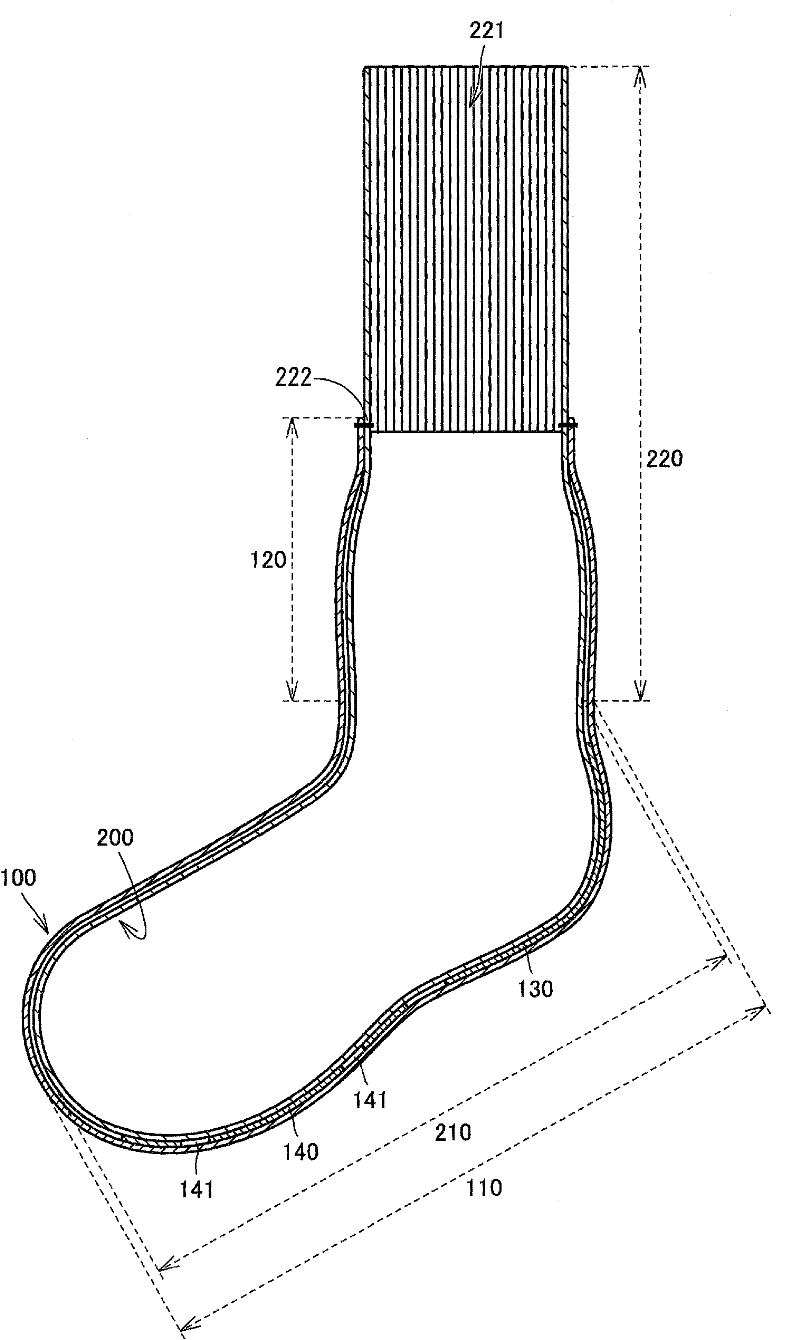

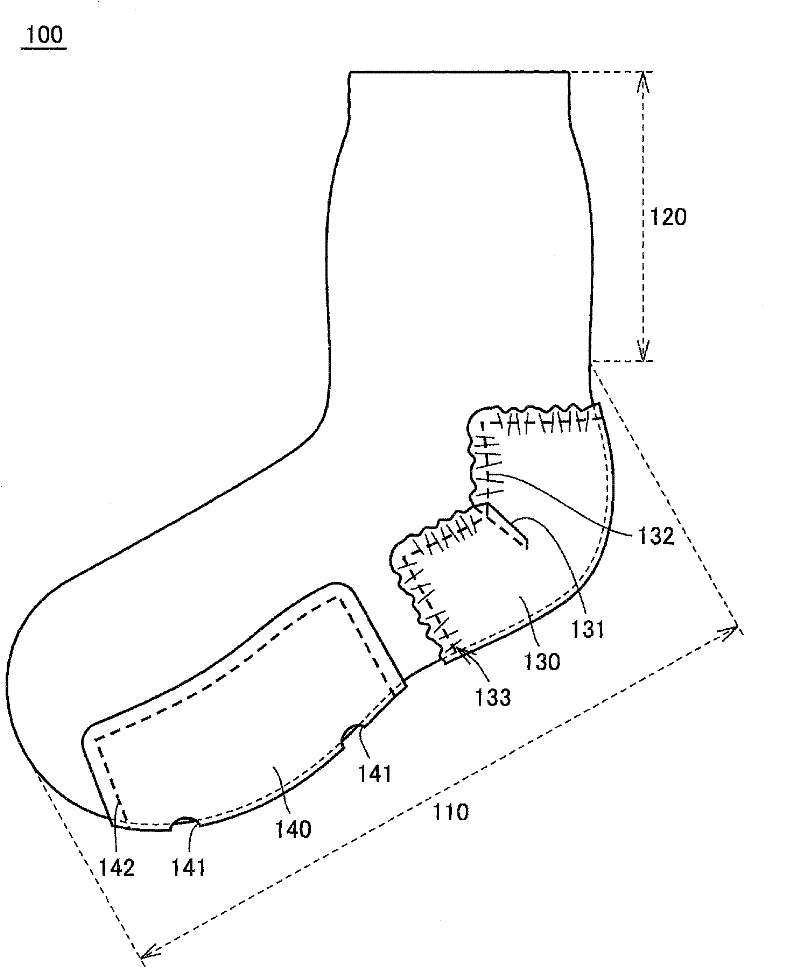

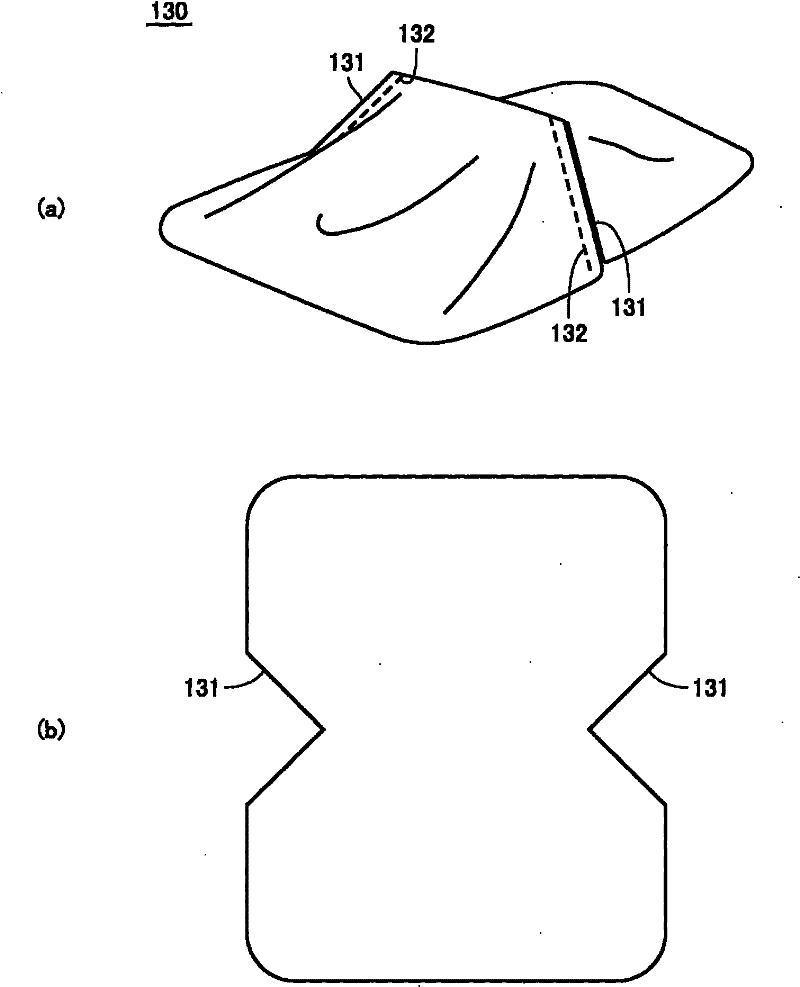

Sock

The invention aims to provide a sock, which can increase the length of the leg part and easily achieve a decrease in fastening force of the sock opening part. The sock comprises an external layer (100) having a foot part (110) and a leg part (120); and an internal layer (200) inserted in the external layer (100) and having a foot part (210) and a leg part (220). Non-permeable sheet materials (130, 140) are sewn on the heel part of the foot part (110) of the external layer (100) and the internal surface of the sole part. The length of the leg part (220) of the internal layer (200) is larger than that of the leg part (120) of the external layer. The sock opening part (221) having retractility in the radius direction is equipped on the upper end part of the internal layer (200). The upper end of the leg part (120) of the external layer (100) is sewn on the external circumference of the leg part (220) of the internal layer (200).

Owner:TAIYO KNIT

Method of Raising Oil Temperature at the Outlet of Oil Well and Structure of Oil Well

InactiveCN103161428BSimple structureIncrease oil temperatureDrilling rodsInsulationEvaporationOil temperature

The invention discloses a method for improving oil temperature at an outlet of an oil well and a corresponding oil well structure. The method for improving the oil temperature at the outlet of the oil well and the corresponding oil well structure are characterized in that a plurality of gravity-type sleeve-shaped heat pipes are connected into a whole and used as oil pipes so that crude oil passes through the centers of the gravity-type sleeve-shaped heat pipes and are pumped out of the oil well. Airtight spaces between pipe walls of the gravity-type sleeve-shaped heat pipes are filled with working media and are vacuumized. The lower portion of each gravity-type sleeve-shaped heat pipe is a heat pipe evaporation segment, and the upper portion of each gravity-type sleeve-shaped heat pipe is a heat pipe condensation segment. Heat passing through the bottom ends of the gravity-type sleeve-shaped heat pipes is uploaded step by step, and then the crude oil passing through the centers of the gravity-type sleeve-shaped heat pipes continuously carries out heat exchange with pipe walls so that the viscosity of the crude oil can be reduced and the crude oil can not become thick. Consequently, the temperature of the crude oil in the gravity-type sleeve-shaped heat pipes nearest to oil outlets can meet the requirement for the thickening-preventing oil outlet temperature. The method for improving the oil temperature at the outlet of the oil well and the corresponding oil well structure have the advantages of being energy-saving, simple, easy to realize and capable of substantially reducing oil extraction cost.

Owner:NANJING UNIV OF TECH

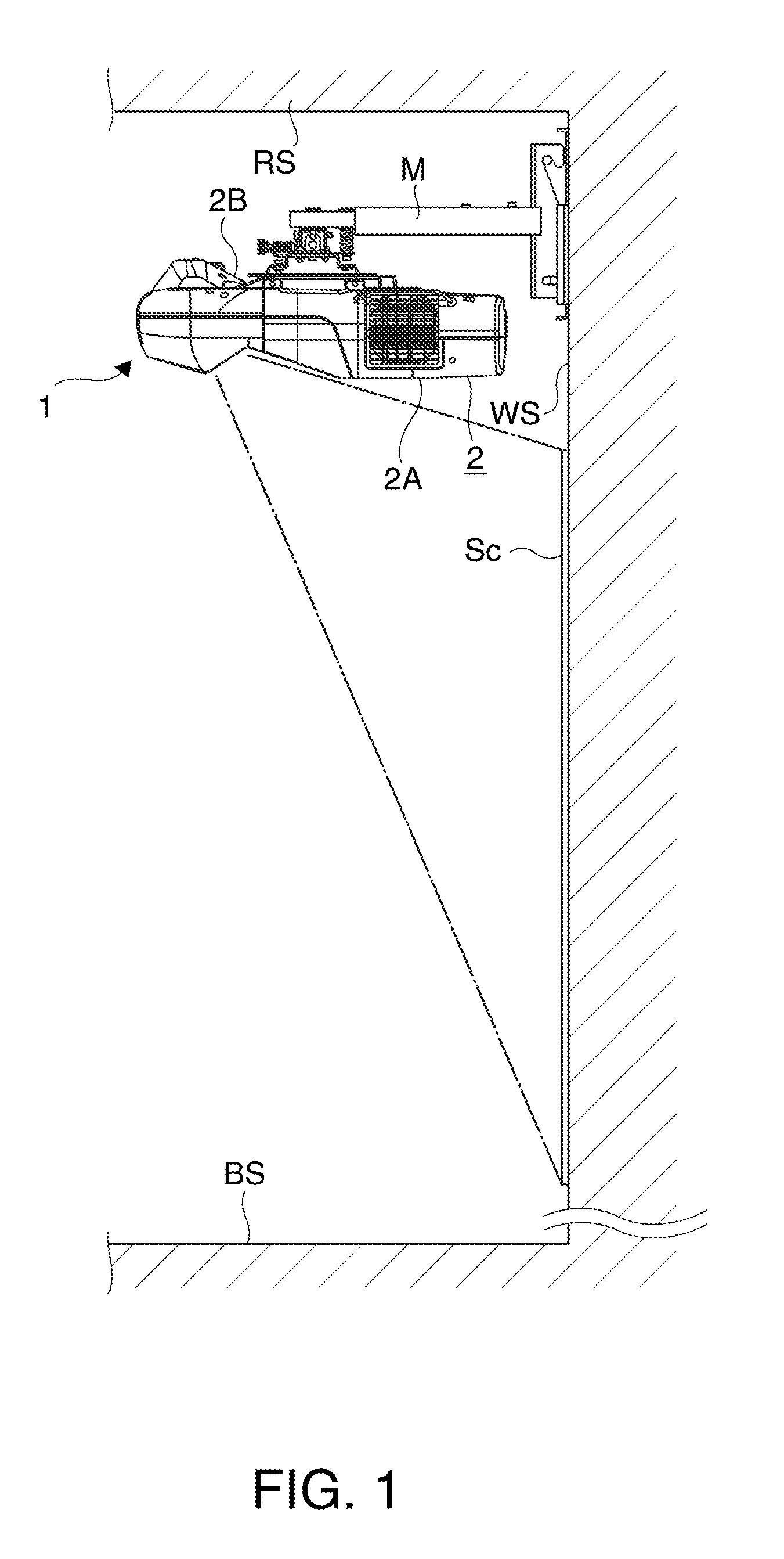

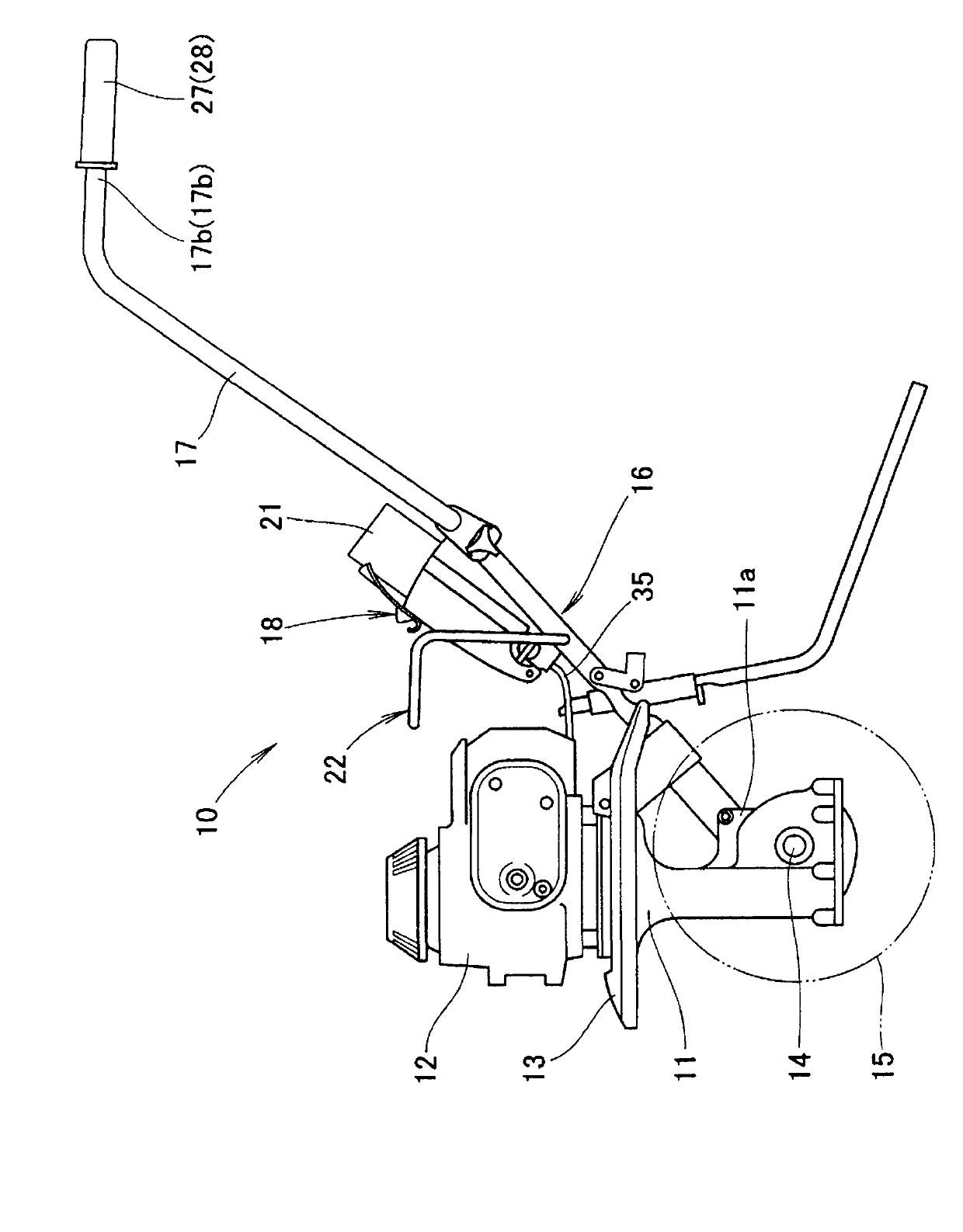

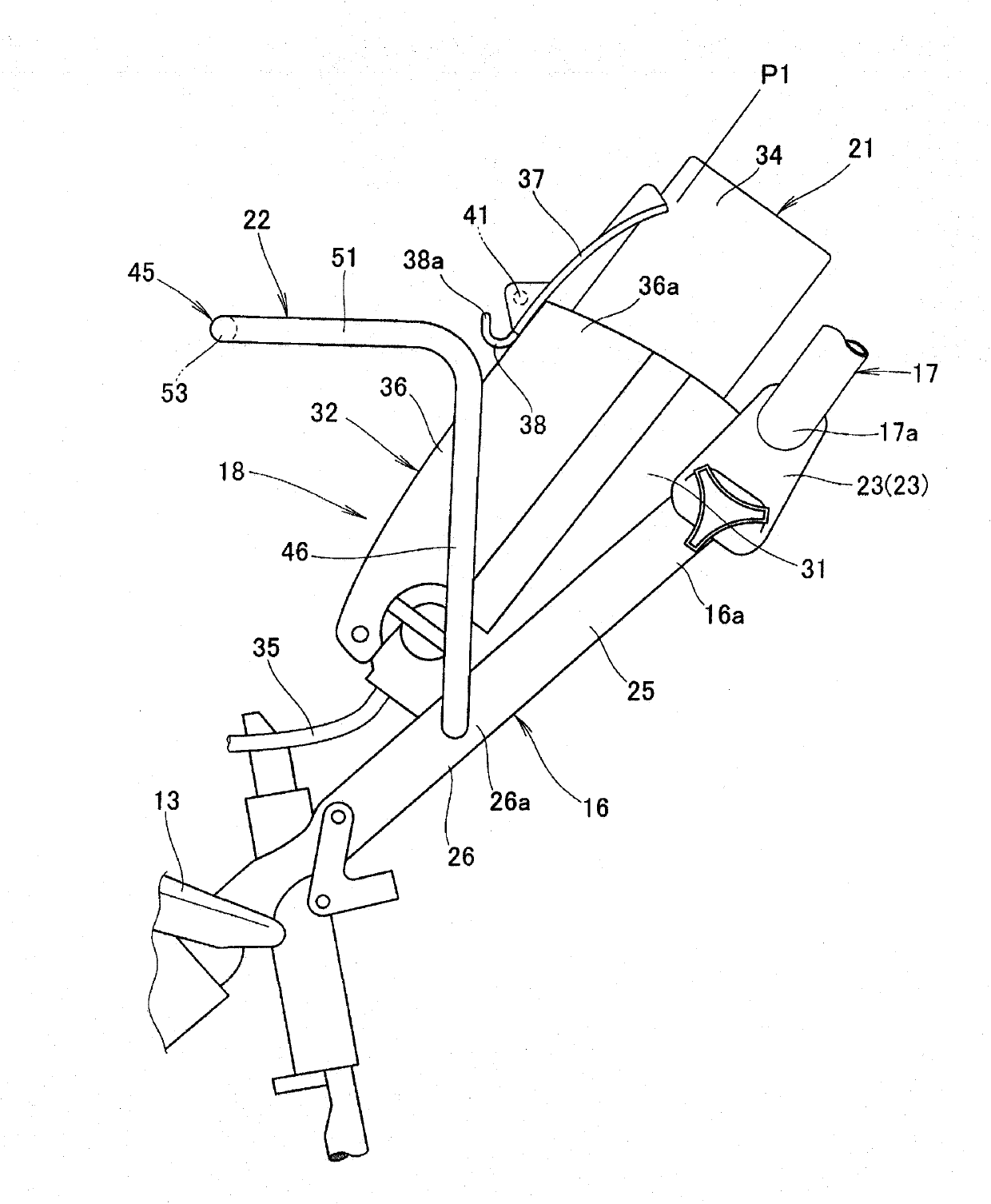

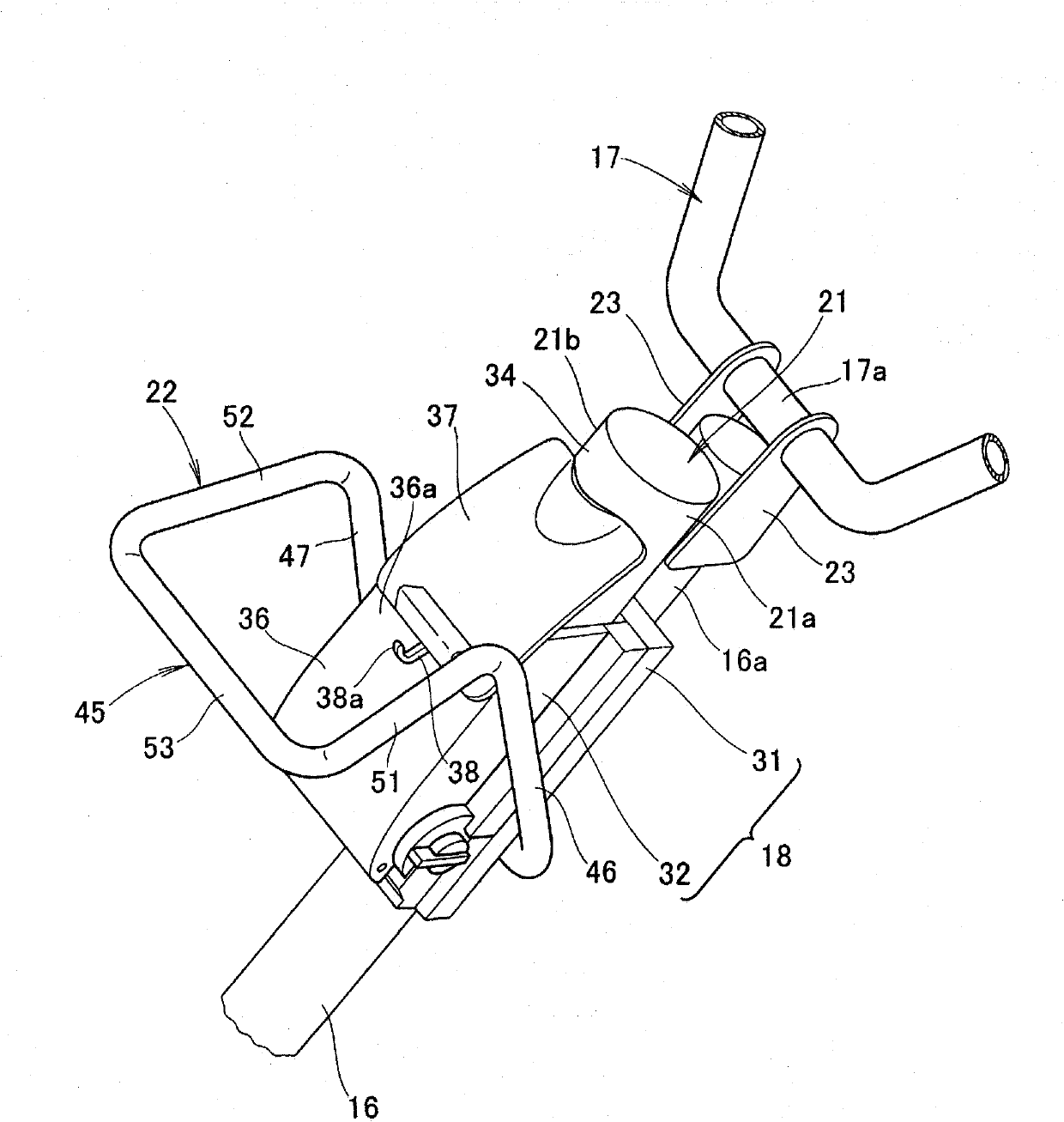

Walking-type working machine

InactiveCN102014606AIncrease the length dimensionImprove handlingVessel mounting detailsContainer filling methodsEngineeringGas engine

A walking-type working machine in which a gas-container housing section (cassette-type gas container) and a carry handle are mounted to a handle post. The walking-type working machine (10) is provided with a cassette-type gas container (21) mounted to a handle post (16), which rises upward and rearward from a rear section (11a) of a working machine body (11), so as to be oriented in the longitudinal direction of the handle post. A gas engine (12) is driven by fuel in the cassette-type gas container (21). The walking-type working machine is provided with a carry handle (22) for carrying the machine. The carry handle (22) is mounted to the handle post and is formed so as to surround the cassette-type gas container. The carry handle has a grip (45).

Owner:HONDA MOTOR CO LTD

Valve push rod for bimetallic single cylinder diesel

InactiveCN102364064APut an end to the relative "short" situationShorten the axial lengthValve arrangementsMachines/enginesSteel ballUltimate tensile strength

The invention discloses a valve push rod for a bimetallic single cylinder diesel, which comprises steel abrasion-resistant ball seats and an aluminum alloy rod body, wherein the steel abrasion-resistant ball seats are arranged at two ends of the aluminum alloy rod body. Because the conventional steel valve push rod is designed into a structure consisting of the aluminum alloy rod body and the steel abrasion-resistant ball seats, the hardness of the steel abrasion-resistant ball seats can be improved and the properties of high strength and good abrasion resistance of the steel abrasion-resistant ball seats are met by the conventional thermal treatment technology, and the aluminum alloy rod body and an aluminum alloy machine body are in the same deformation; because the valve push rod is long, and the axial length of a steel ball to be ground is low, so that the deformation of the whole valve push rod can be consistent with that of the aluminum alloy machine body, and the valve push rod is prevented from being relatively 'shortened' due to different expansion coefficients of the aluminum alloy machine body and the steel valve push rod; and the valve push rod is an indispensable key part in the process of replacing a cast iron machine body for the aluminum alloy machine body for the diesel.

Owner:江苏鑫田柴油机有限公司

Metal plate longitudinal rolling shearing machine super-long scrap edge automatic reversing discharging device

ActiveCN111745211ARealize liftingRealize reverse dischargeShearing machinesMetal working apparatusStructural engineeringMaterial transport

The invention provides a metal plate longitudinal rolling shearing machine super-long scrap edge automatic reversing discharging device. The initial position of a baffle in an automatic overturning discharging device is flush with a plate, an air cylinder telescopic rod conducts linear telescopic motion, the air cylinder telescopic rod stretches out and draws back once, the discharging device completes one-time reversing motion, and the cut super-long plate can fall into a discharging chute below after being reversed by a reversing device. According to the discharging chute device at the lowerend, an upper chute and a lower chute are connected, material transportation is facilitated, and automatic discharging is achieved through relevant angle setting. The phenomenon that cut scrap edgesdroop due to self gravity in the feeding process is effectively avoided, lifting of the scrap edges of the plate is achieved, meanwhile, limitation on the length of the cut scrap edges of the plate isgreatly reduced, shearing and reverse discharging of the scrap edges of the super-long plate are achieved, super-long material supporting, reverse discharging and material collecting devices are integrated, and the working efficiency is greatly improved while the product quality is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

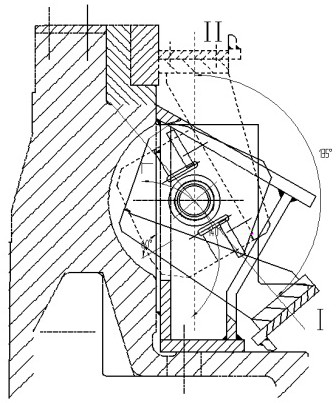

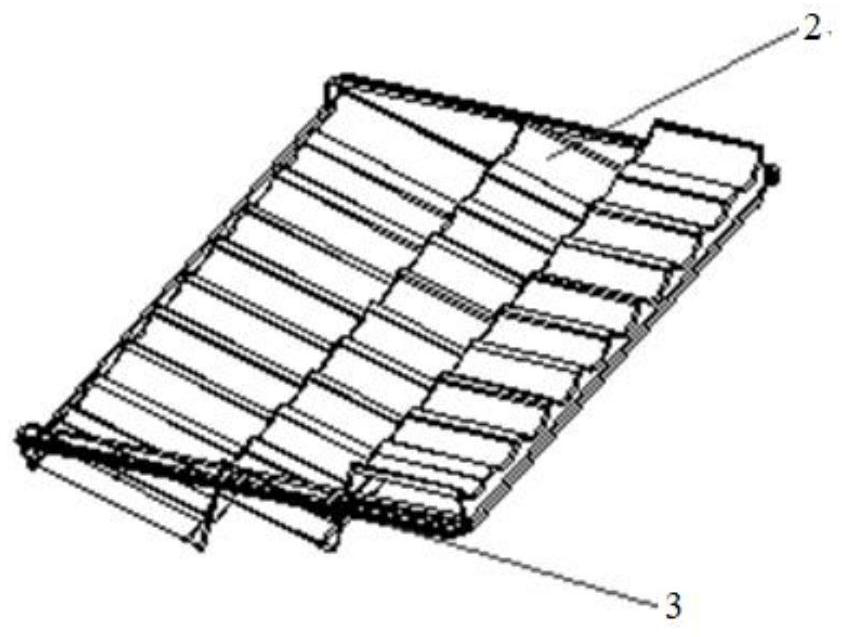

Shelves and retail cabinets including the same

ActiveCN108937361BImprove space utilizationControl footprintShow cabinetsEngineeringMechanical engineering

The invention relates to the technical field of article placing assemblies, and provides a placing shelf and a retail cabinet comprising the placing shelf. The placing shelf is provided with a plurality of rows of placing plates from the front to the back, the height of the placing plate in the rear row is larger than that of the placing plate in the front row for every two adjacent placing plates, and the included angle between the placing plate in the rear row and the horizontal plane is smaller than the included angle between the placing plate in the front row and the horizontal plane. Since one layer of the placing shelf is provided with a plurality of rows of placing plates from the front to the back, while the space utilization rate is increased, the articles can be conveniently arranged classifiedly, so that the articles are placed neatly to bring a good experience and visual effect to a user. Since the height of the placing plate in the rear row is larger than that of the placing plate in the front row for every two adjacent placing plates, goods on the placing plate in the front row do not block the goods on the placing plate in the rear row, so that the observation of thegoods on the placing shelf is facilitated. In addition, the included angle between the placing plate in the rear row and the horizontal plane is smaller than the included angle between the placing plate in the front row and the horizontal plane, so that space occupied by the placing shelf can be controlled to further improve the space utilization of the placing shelf while the pick and place of the goods is facilitated.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

Silicon rod cutting process

ActiveCN111361027BEasy to manufactureIncrease the length dimensionFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon chip

The invention discloses a silicon rod cutting process, comprising the following steps: square the silicon rod, and cut out: a central silicon block and four side skins extending in the same direction as the silicon rod; The silicon rods extend in the same direction: the first small silicon block, the second small silicon block and the third small silicon block; the cross-sectional length of the first small silicon block and the third small silicon block is half of the cross-sectional width of the central silicon block One; the cross-sectional length of the second small silicon block is the same as the cross-sectional width of the central silicon block; the central silicon block, the first small silicon block, the second small silicon block, and the third small silicon block are sliced, and the slicing direction is the same as that of the silicon rod The direction of extension is parallel. The slicing direction of the present invention is parallel to the extension direction of the silicon rod, so the length and dimension of the obtained silicon wafer can not be limited by the diameter of the silicon rod, and it is easy to prepare a rectangular silicon wafer with a large length and size, and the present invention can cut out two kinds of width specifications of the silicon wafer. Chips can improve the utilization rate of silicon rods and reduce the production cost of silicon wafers.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com