Walking-type working machine

A working machine and walking-type technology, which is applied to farming machines, agricultural machinery and tools, agriculture, etc., and can solve problems such as obstacles in the storage part of the gas tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

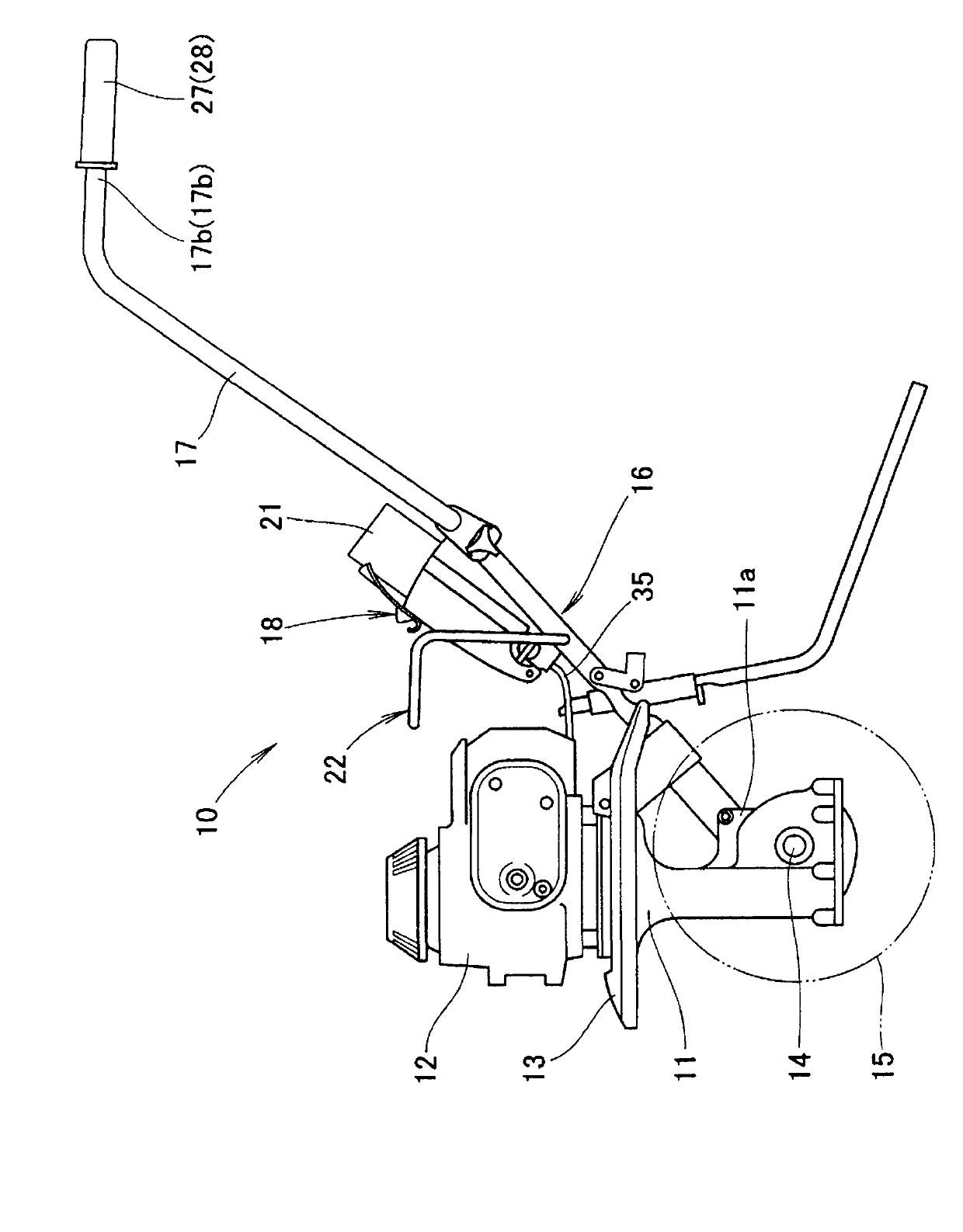

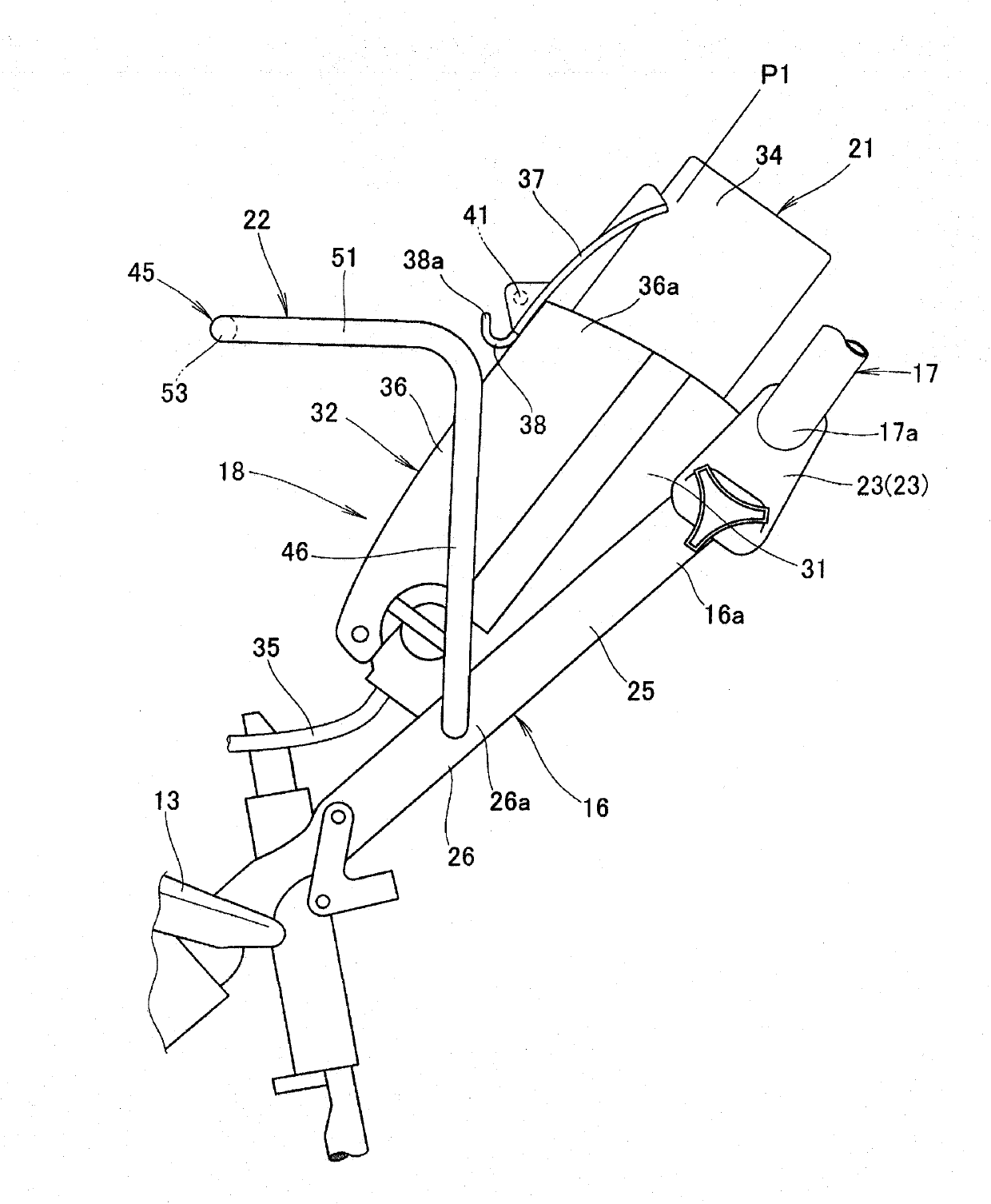

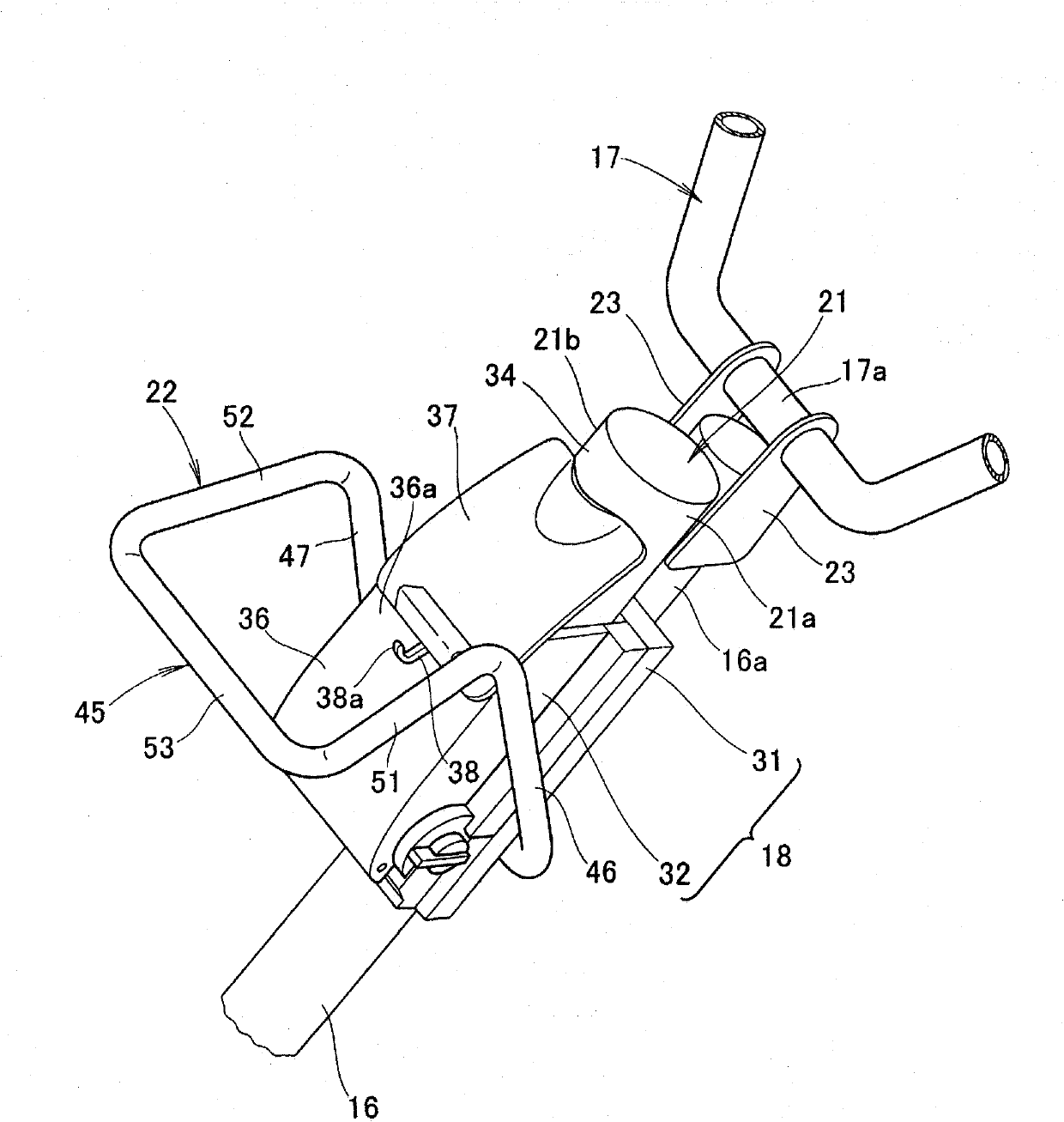

[0028] In this embodiment, a walking type rotary cultivator is shown as an example of a walking type working machine, but the walking type working machine is not limited to this.

[0029] figure 1 The illustrated walk-behind working machine 10 includes: a gas engine 12 mounted on the upper end of a rotary cultivator main body (working machine main body) 11; Below; a plurality of rotary tiller claws 15, these rotary tiller claws 15 are arranged below the fender 13 via the rotary tiller shaft 14; handle pillar 16, the handle pillar 16 is arranged on the rear part 11a of the rotary tiller main body 11; the operating handle 17, the operating handle 17 is arranged on the handle pillar 16; the gas tank storage part (gas tank holding part) 18, the gas tank storage part 18 is arranged on the handle pillar 16; the box-type gas tank 21, the box-type gas tank 21 is accommodated on the gas tank storage part 18;

[0030] This walk-behind operating machine 10 is a walk-behind rotary culti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com