Valve push rod for bimetallic single cylinder diesel

A diesel engine and bimetal technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as power drop, speed fluctuation, automatic shutdown, etc., and achieve the effect of good wear resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

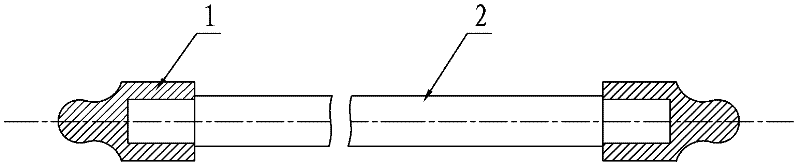

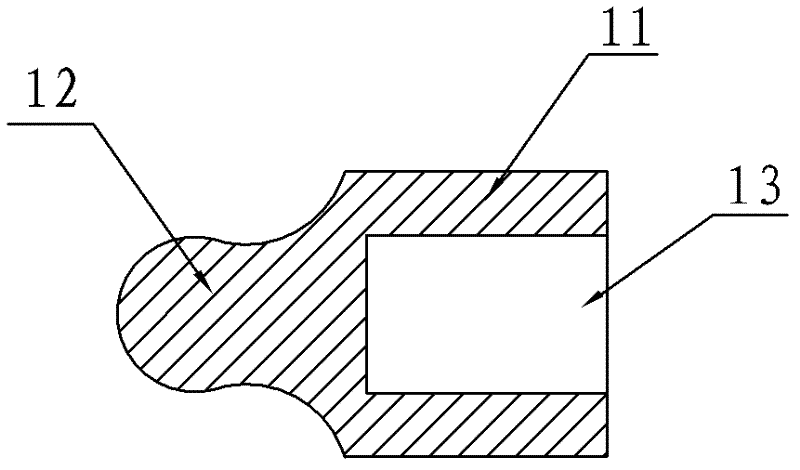

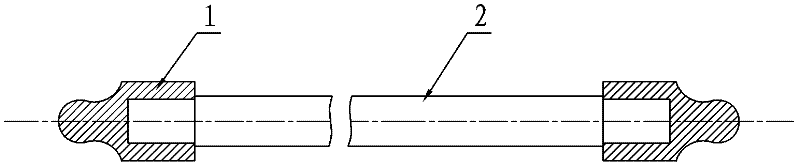

[0016] figure 1 and figure 2 It is a schematic diagram of the structure of the valve push rod used in the model 176 single-cylinder diesel engine. The body of the diesel engine is an aluminum alloy body. The valve push rod is a bimetal structure. The rod body 2 is assembled. The steel wear-resistant ball head seat 1 is composed of a connecting sleeve 11 and a wear-resistant ball head 12. An assembly hole 13 is provided in the center of the connecting sleeve 11. The steel wear-resistant ball head seat 1 is assembled The hole 13 is set on both ends of the aluminum alloy rod body 2, and the fit between the assembly hole 13 on the steel wear-resistant ball head seat 1 and the two ends of the aluminum alloy rod body 2 is an interference fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com