Metal plate longitudinal rolling shearing machine super-long scrap edge automatic reversing discharging device

A technology of longitudinal rolling and discharge device, which is applied in the direction of shearing device, attachment of shearing machine, metal processing, etc. It can solve the problems of shortening the service life of the belt, aggravating the wear of the belt, and high cutting frequency, so as to improve product quality, The effect of reducing the feeding speed and reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

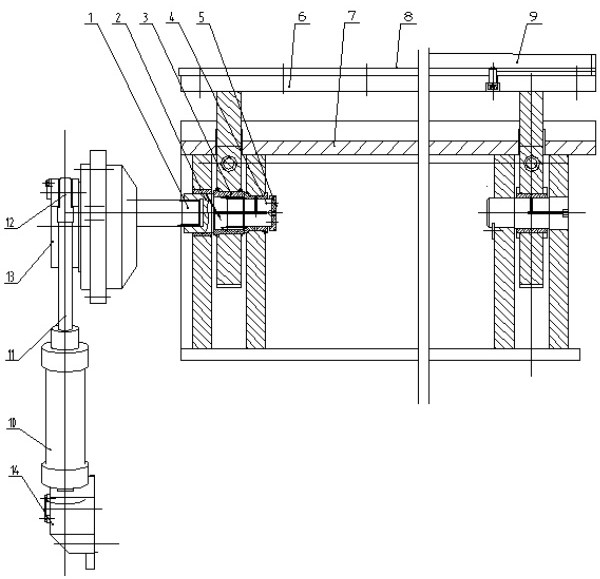

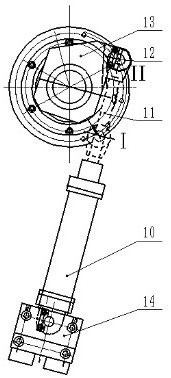

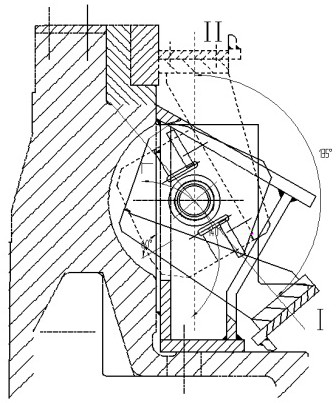

[0022] Such as figure 1 , 2 Shown is the platform of the super-long broken edge automatic reverse discharge device of the rolling shear machine, the cylinder 10 is fixed on the cylinder support seat 14, the cylinder telescopic rod 11 on the cylinder 10 performs telescopic movement, and the cylinder telescopic rod 11 connects with the ball hinge 12 The flywheel 13 is connected, and the linear expansion and contraction motion of the cylinder expansion rod 11 is converted into a rotary motion. The left gear shaft 1 is fixed by the left bushing 2 at the right end of the rotating flywheel structure, and the right gear shaft 3 is driven to rotate through the gear transmission, and the right gear shaft 3 is mounted on the right end. Baffle plate structure 5 is arranged, and the wear-resisting plate 8 that places sheet material edge is connected with the upper end of gear transmission device as the platform of placing sheet material edge, and platform side is broken edge chute 6, fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com