Method of Raising Oil Temperature at the Outlet of Oil Well and Structure of Oil Well

An outlet, oil well technology, applied in wellbore/well components, drilling equipment, earth-moving drilling, etc., can solve the problems of high energy consumption, complex wellhead equipment, etc., and achieve long service life, convenient manufacturing and installation, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

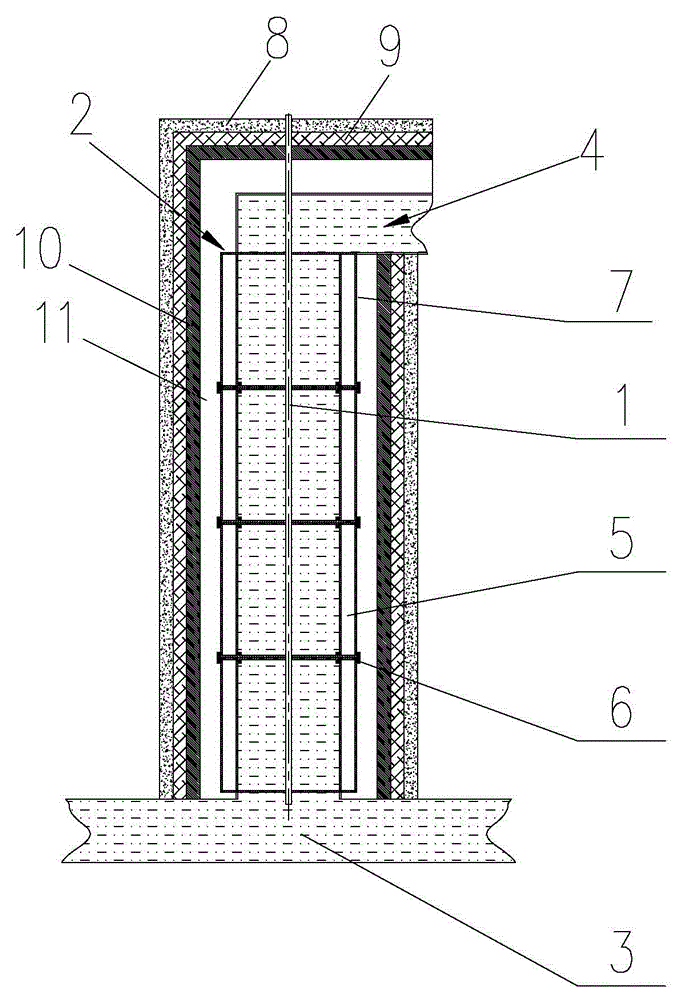

[0025] Such as figure 1 shown.

[0026] A method for increasing the oil temperature at the outlet of an oil well, the key of which is to connect several gravity-type casing-shaped heat pipes into one as an oil pipe, so that crude oil is drawn out of the oil-oil pipe through the center of each gravity-type casing-shaped heat pipe, The working medium is injected into the closed pipe wall gap of the gravity casing heat pipe and vacuumized. The lower part of each gravity casing is the evaporation section of the heat pipe, and the upper part is the condensation section of the heat pipe. , for each gravity-type sleeve-shaped heat pipe, the inner surface of the lower part is in the hot fluid area, and the inner surface of the upper part is in the cold fluid area. Since the heat pipe has the characteristic that it can work normally under a small temperature difference between the cold and hot fluids, and The heat of the lower hot crude oil can be transferred upwards to the upper cold...

Embodiment 2

[0033] Such as figure 1 shown.

[0034] An oil well structure that can increase the oil temperature at the outlet of the oil well, it includes a sucker rod 1 and an oil pipe 2, and the installation method and structure of the oil pipe 2 in the oil well are the same as the prior art, such as figure 1As shown, the entire oil well is composed of the outermost concrete layer 8, insulation layer 9 and casing 10, the insulation layer 9 is located between the concrete layer 8 and the casing 10, the oil pipe 2 is located in the casing 10, and the oil pipe 2 and the casing There is a gap 11 between 10, in the gap 11 there will be various debris (such as water, oil, soil, gravel, etc.) to form a layer of debris, the existence of the gap 11 is also convenient for the maintenance and replacement of the oil pipe 2, the sucker rod The upper end of 1 passes through the casing, insulation layer and concrete layer and moves up and down in the oil pipe 2 under the drive of the power device, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com