Sock

A sock and outer layer technology, applied in socks, pantyhose, apparel, etc., can solve the problems of high cost, reduced fastening force, complicated knitting structure of the sock opening, etc., and achieves low cost and reduced fastening force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

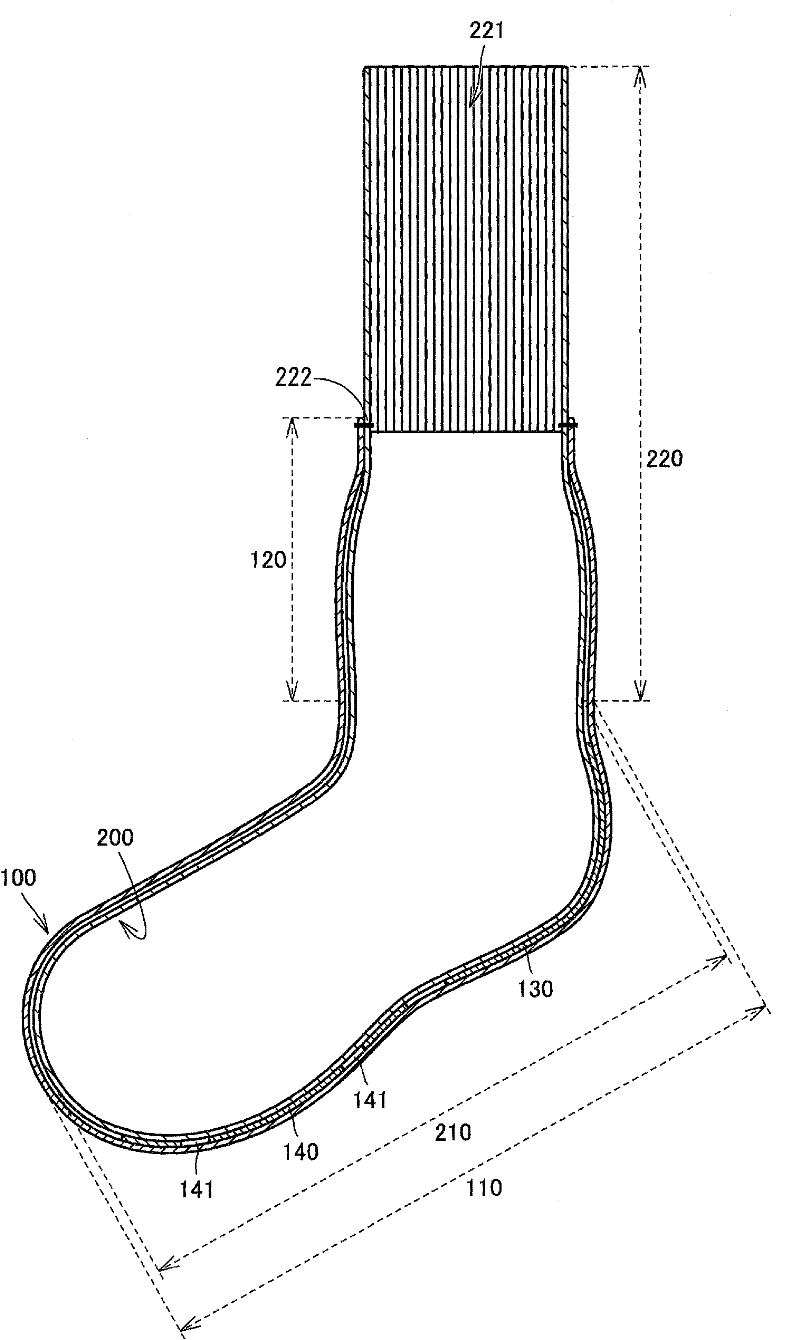

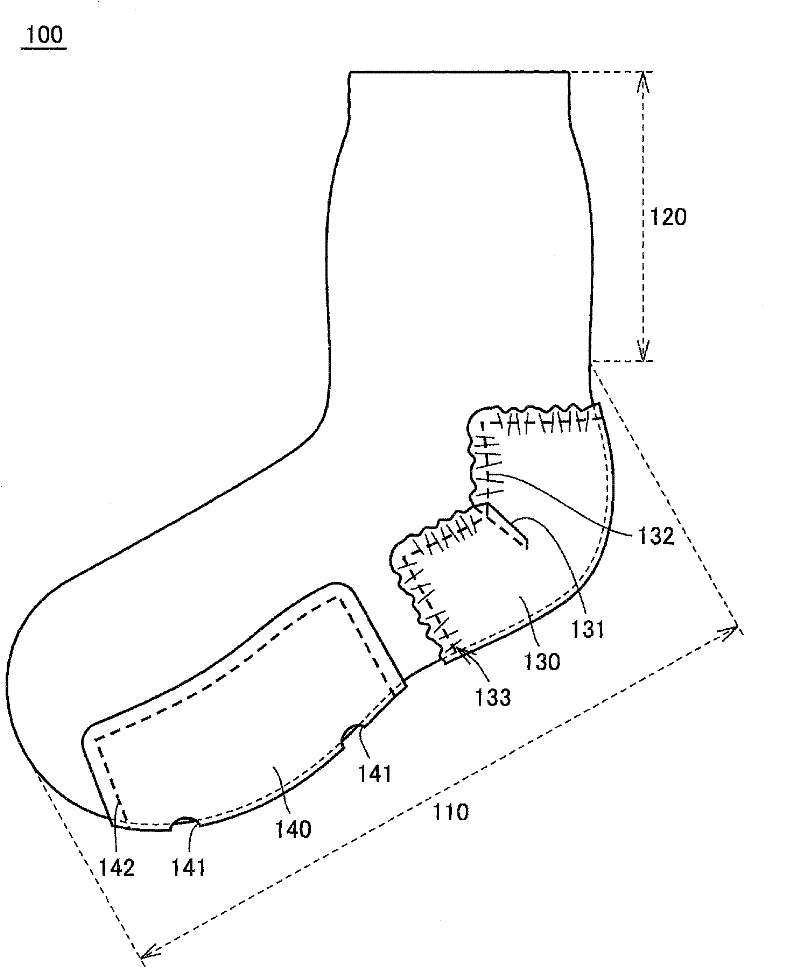

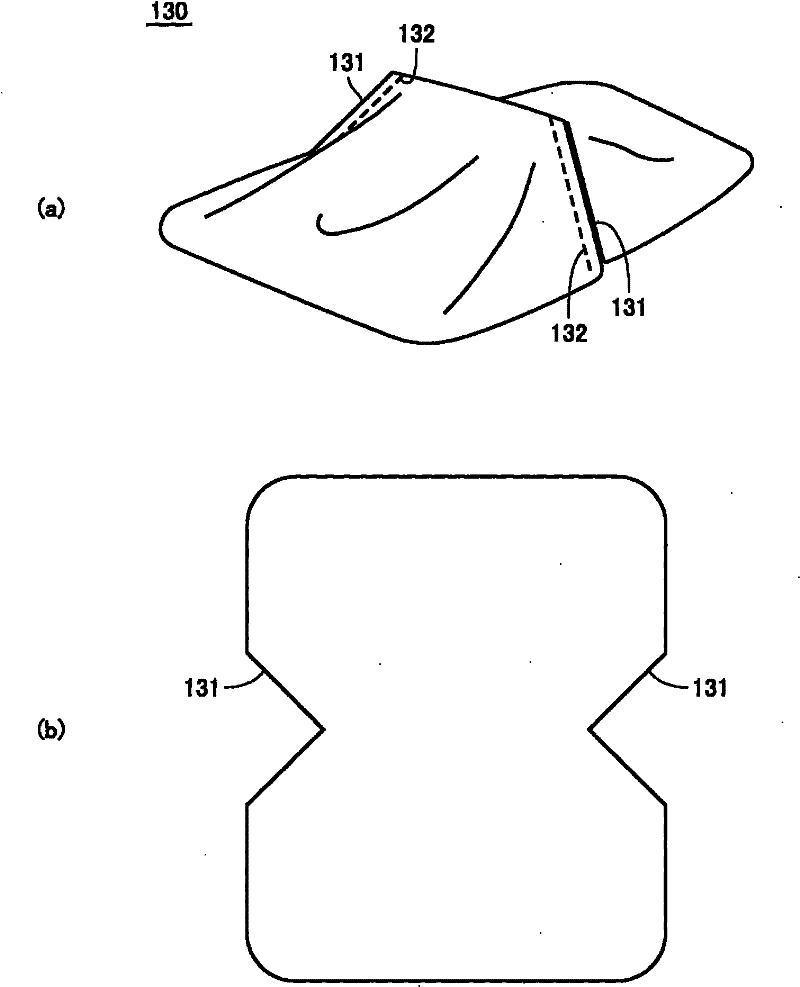

[0022] Refer to the following Figure 1 ~ Figure 4 The sock of embodiment of this invention is demonstrated. figure 1 The sock shown has an outer sock 100 and an inner sock 200 inserted inside the outer sock 100 . Each part is described in detail below.

[0023] like figure 1 As shown, inner sock 200 has foot portion 210 and leg portion 220 . The leg portion 210 is a cylindrical body with a closed front end, and is a portion into which a user's foot is inserted. The leg part 220 is a cylindrical body continuing from the foot part 210, and is a part into which the user's ankle to knee is inserted. A sock opening 221 is provided at the upper end of the leg portion 220 . The part of the inner layer socks 200 other than the sock opening 221 uses a 70-denier double-ply thread (Twin One) and a 30 / 70 polyurethane elastic thread, and uses the same knitting method as a known sock with 200 needle holes of 3.5 inches. method weaving. The portion of the inner layer sock 200 other t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com