Material finishing machine

A technology for sorting machines and materials, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of unreasonable layout of material conveying devices, complex structure of material turning devices, and oversized overall material sorting machines. The effect of convenient and efficient operation, high work reliability and operation stability, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments. It should be noted that, on the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

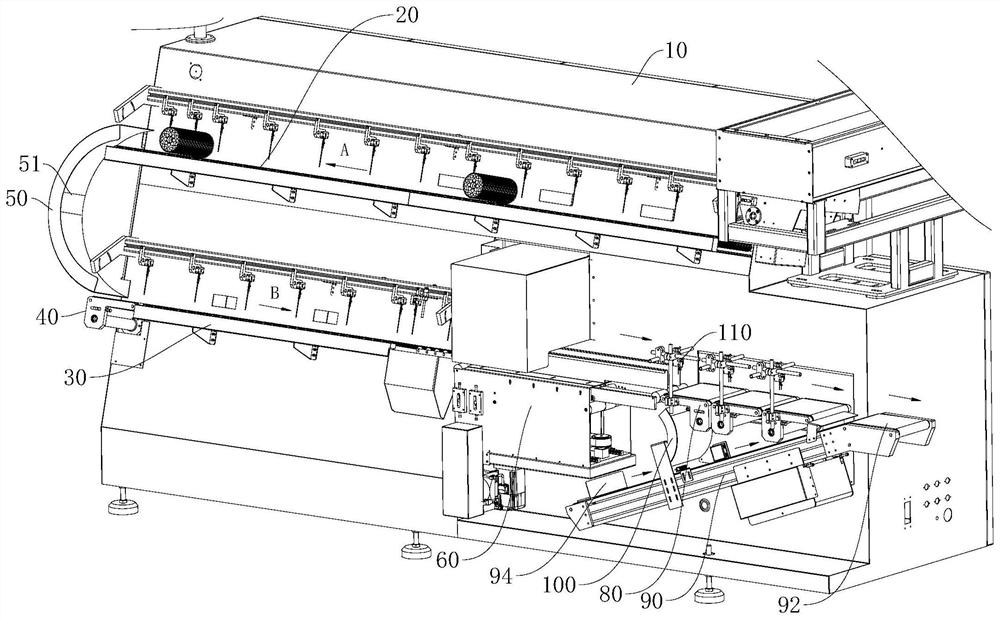

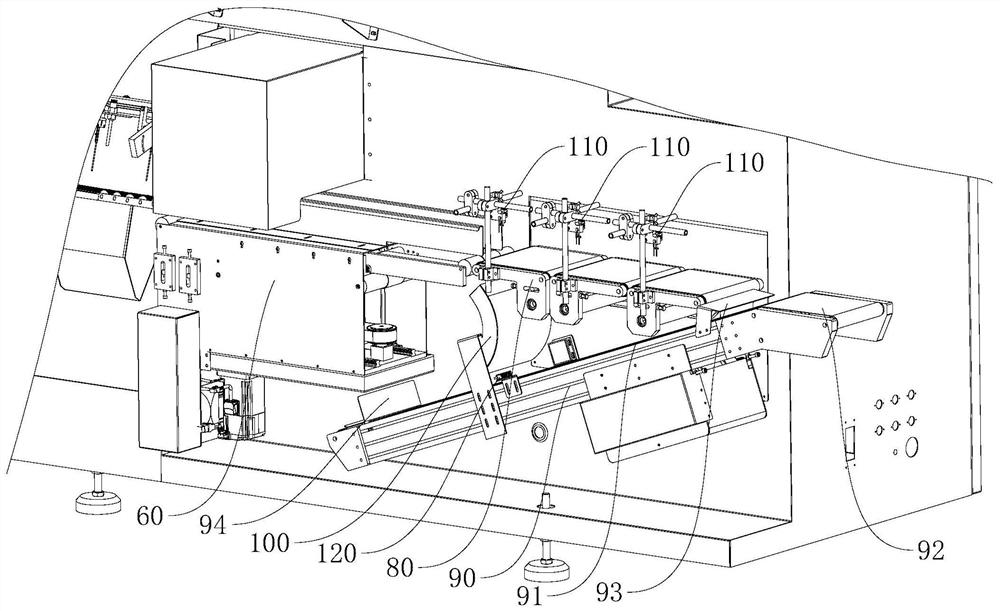

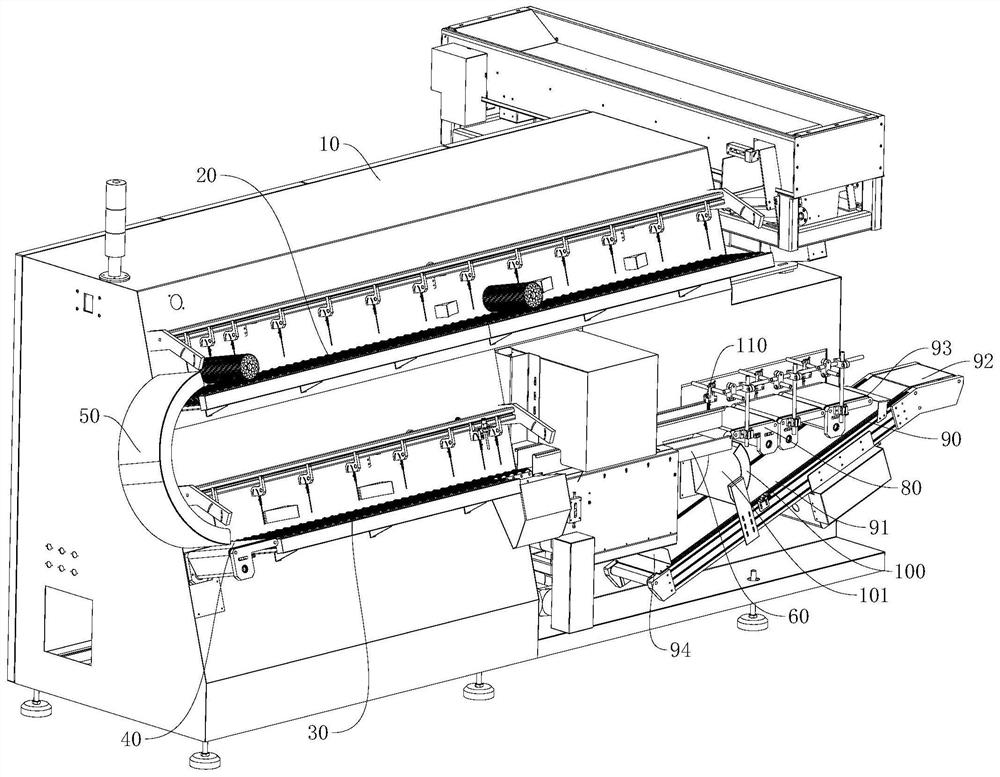

[0040] see Figure 1-Figure 5 , shows a kind of material sorting machine of a preferred embodiment of the present invention, comprises body 10, is provided with on body 10:

[0041] The material conveying device includes a device for moving along the first direction (i.e. figure 1 A direction in) the first conveying device 20 for conveying materials from the back to the front and for moving along the second direction (that is, figure 2 In B direction) the second conveying device 30 that conveys the material conveyed from the front end of the first conveying device 20 from the back to the front, the first conveying device 20 and the second conveying device 30 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com