Air inlet system of small gasoline engine classes

A small gasoline engine and intake system technology, applied in the field of intake system, can solve the problems of large engine size, short intake pipe length, falling off, etc., to improve firmness and durability, ensure operation stability, and strong power output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

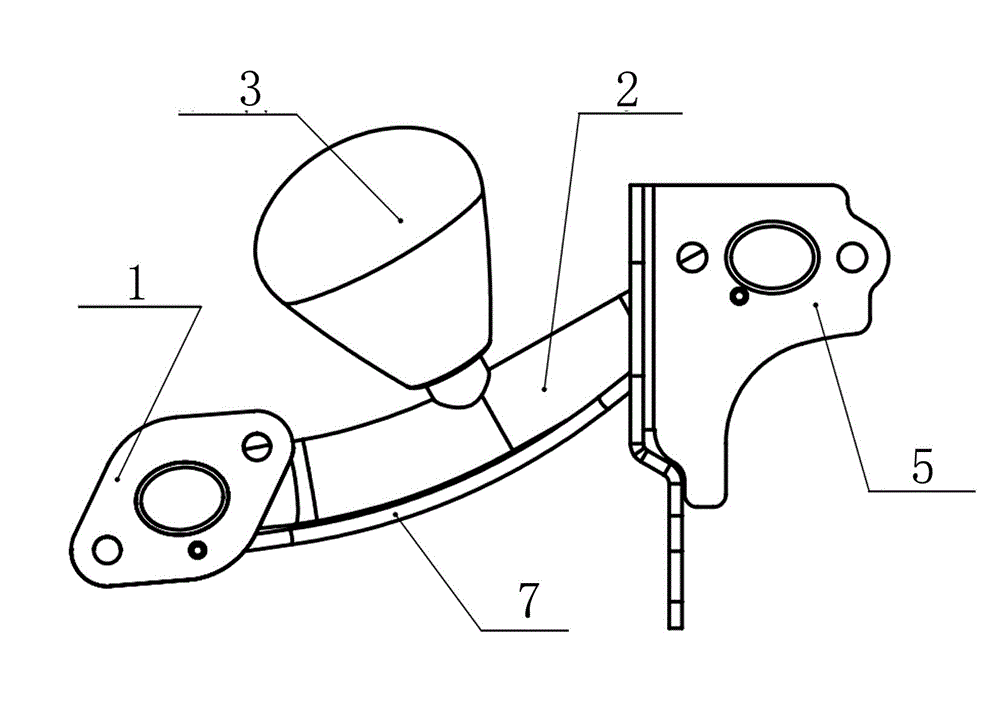

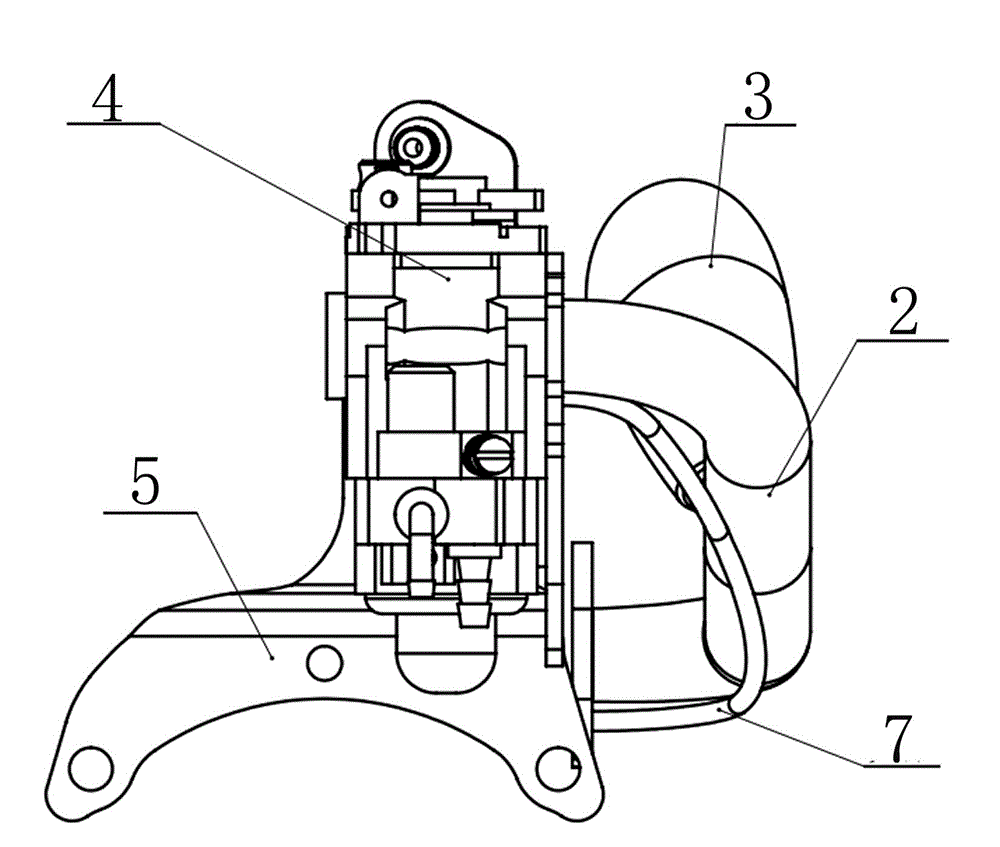

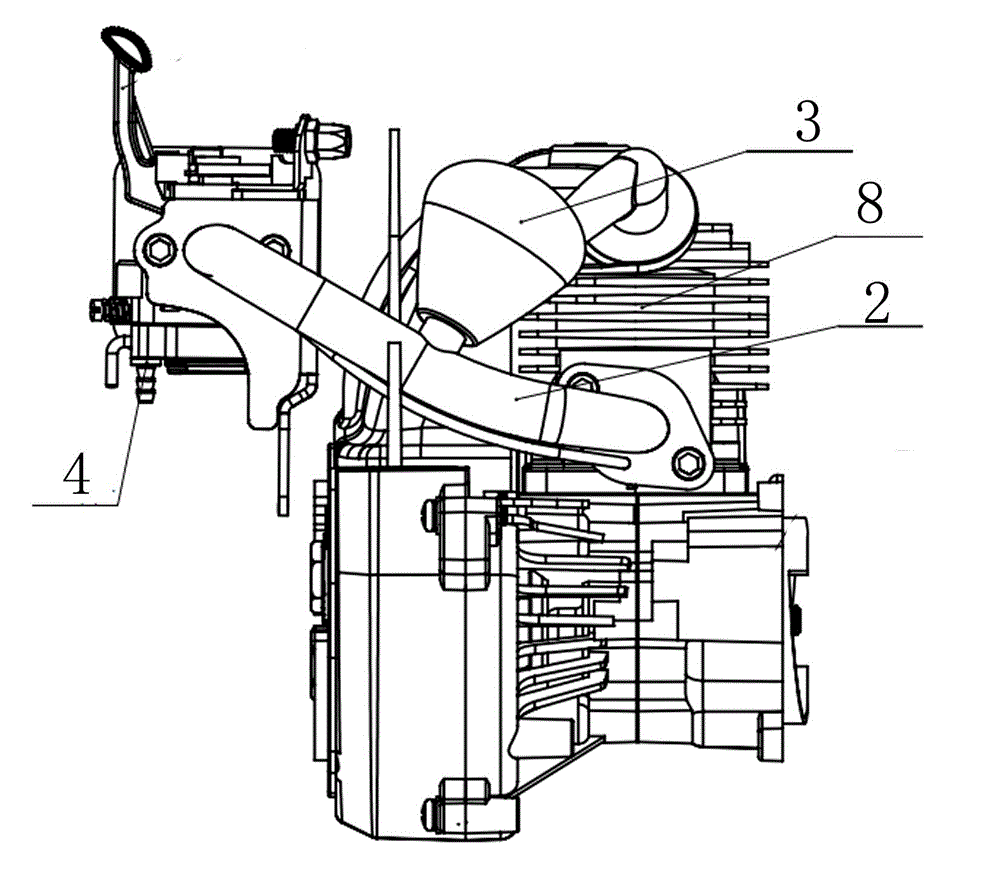

[0019] The air intake system of the small gasoline engine of the present invention is one of the main mechanisms of the small gasoline engine. Air cleaner 6, negative pressure pipe 7 etc. are formed.

[0020] The intake pipe 2 is provided with an intake pipe flange 1, the intake pipe flange 1 is fixedly connected with the engine cylinder air inlet, the other end of the intake pipe 2 is connected with the carburetor 4, and the carburetor 4 is connected by the carburetor bracket 5 and the The gear box is fixedly connected, and the air filter 6 and the carburetor 4 are arranged side by side and away from the engine cylinder 8 .

[0021] An air storage bag 3 is provided in the middle of the intake pipe 2, and a negative pressure pipe 7 is provided between the intake pipe flange 1 and the carburetor bracket 5.

[0022] The air intake system of the small gasoline engine of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com