Coupling widened-type stone cutting machine

A technology of cutting machine and shaft coupling, which is applied in the field of coupling widened stone cutting machine, can solve the problems that affect production efficiency, production cost, inconvenience, multi-slice stone cutting machine cannot perform direct slicing operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with specific embodiment, this case is described in further detail.

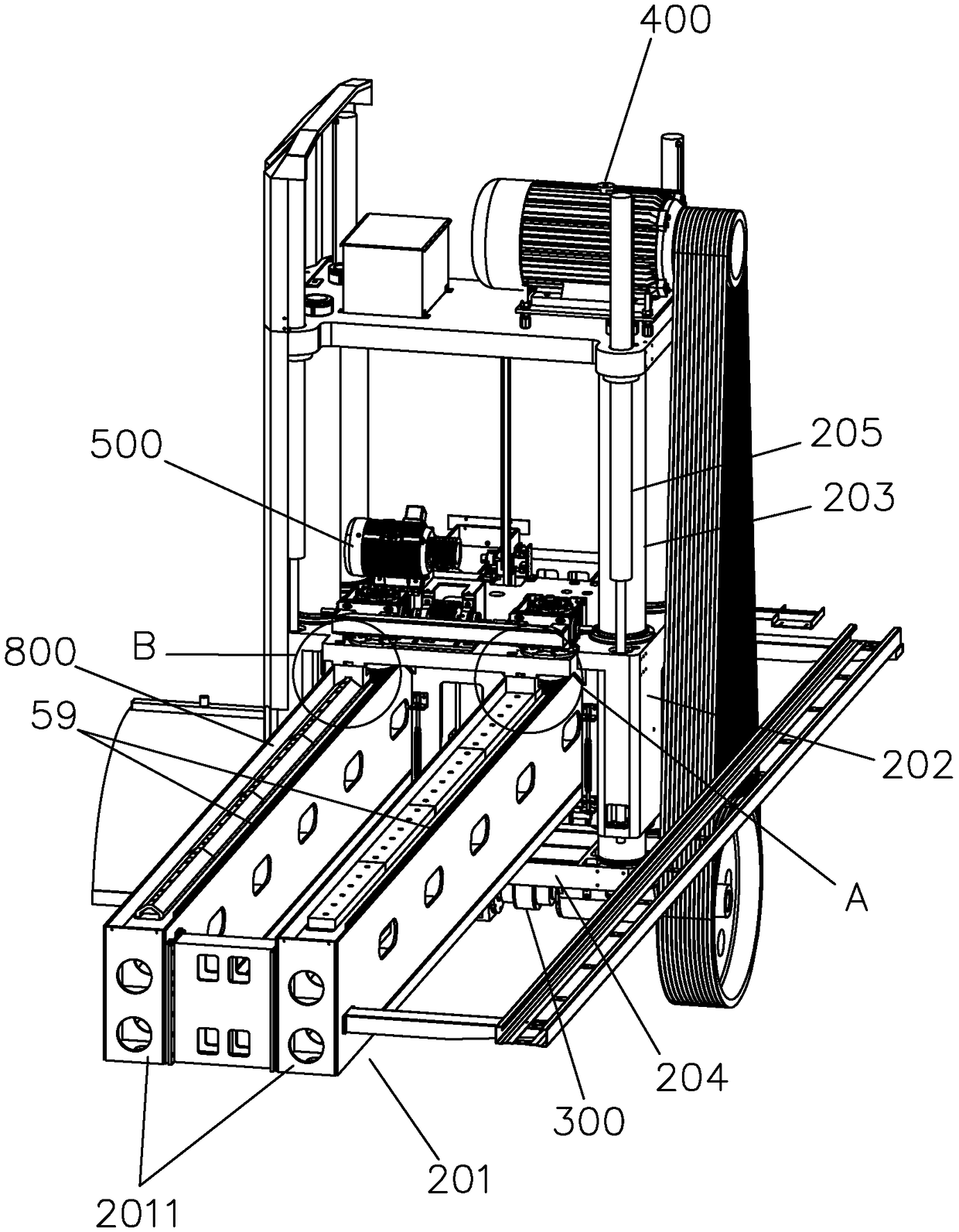

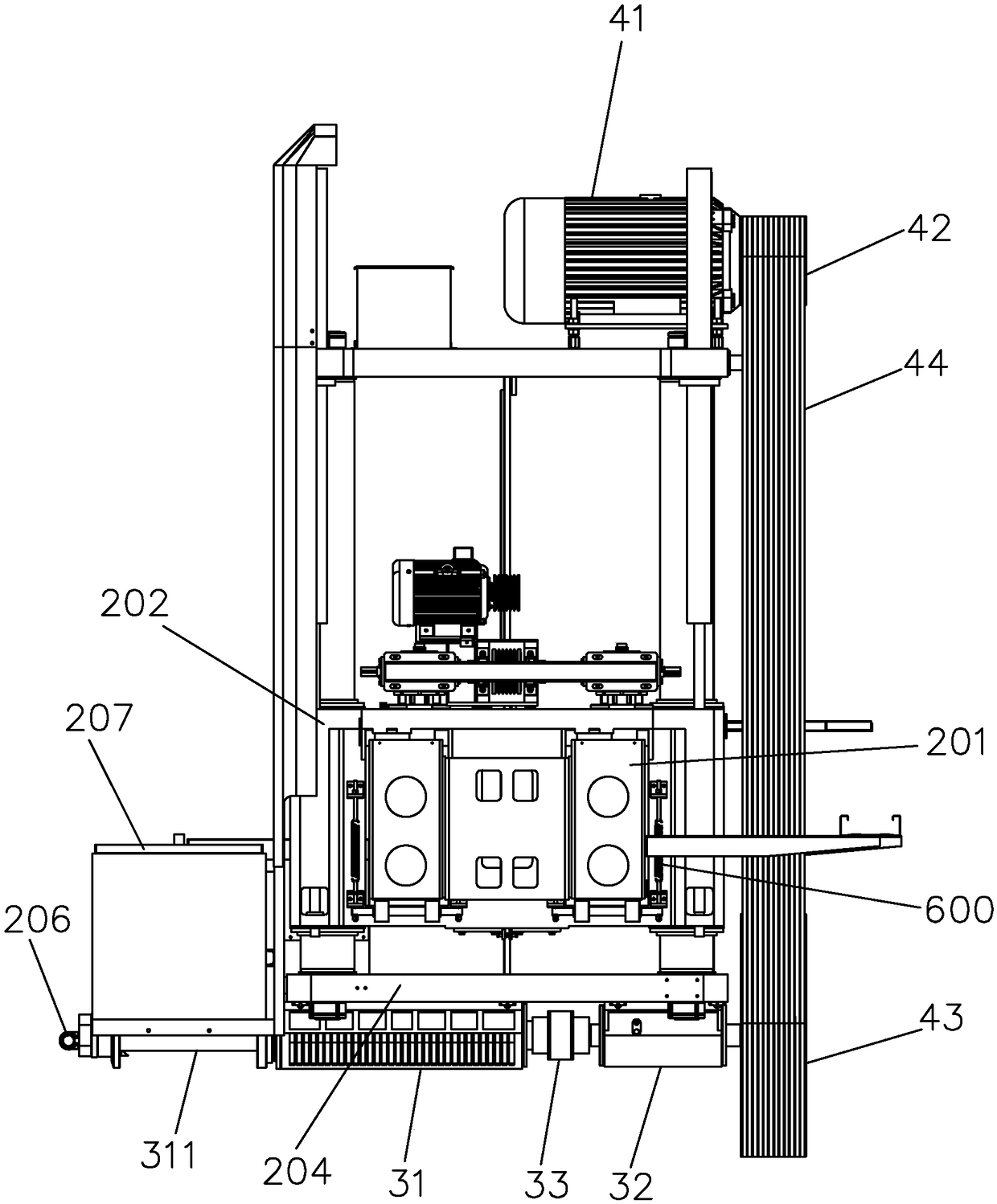

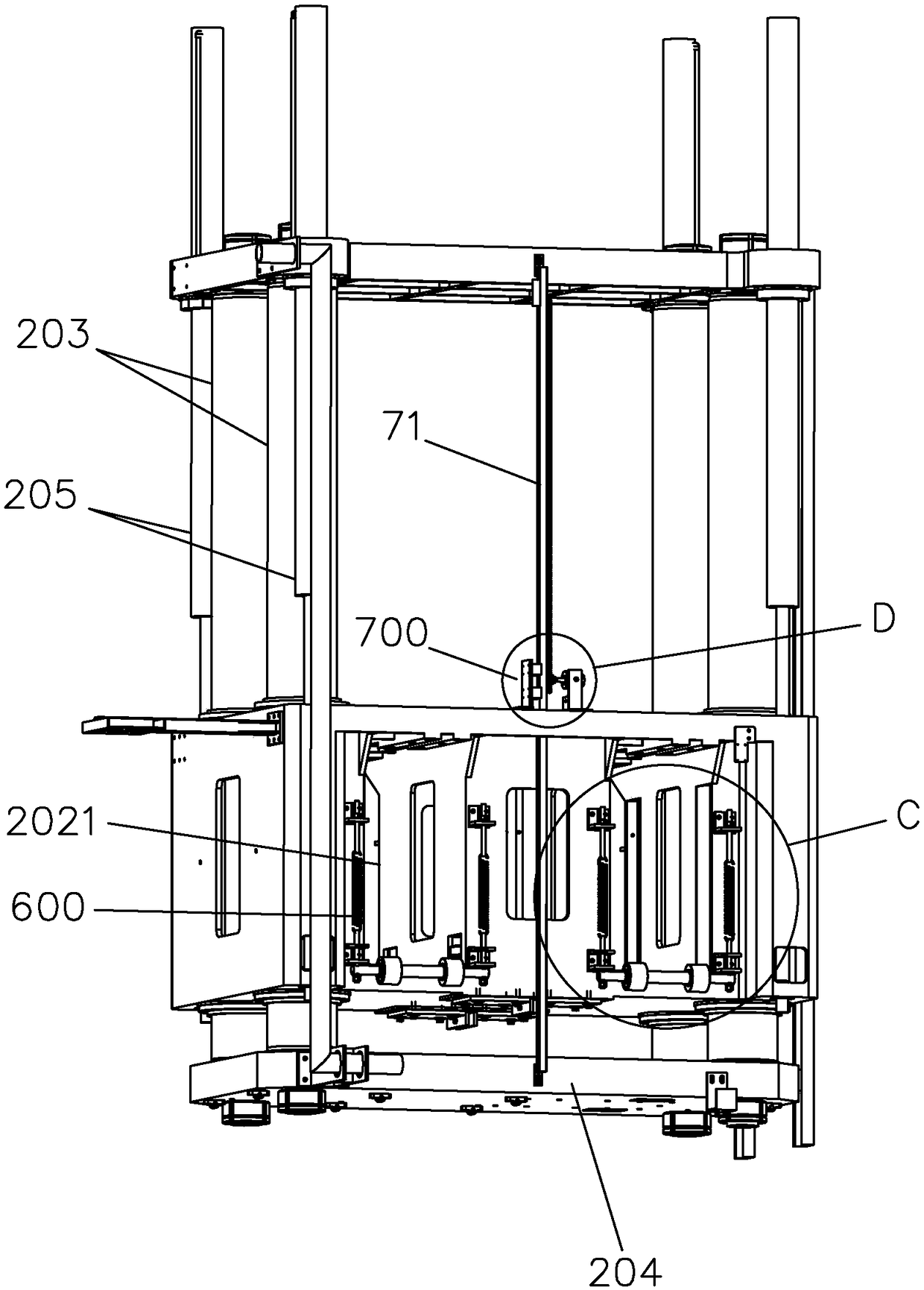

[0047] This case involves a coupling widening stone cutting machine, such as Figure 1-8 As shown, it includes a middle frame 202 , a lifting column group 203 , a lower beam plate 204 , a saw blade coupling assembly 300 and a saw blade driving mechanism 400 .

[0048] The lifting column group 203 is arranged vertically through the middle frame 202 , specifically, the lifting column group 203 is provided with four lifting columns, and the four lifting columns are arranged vertically through the four corners of the middle frame 202 . The lower ends of the four lifting columns are fixedly connected to the lower beam plate 204, and the lifting driving mechanism 205 is arranged between the lifting column group 203 and the middle frame 202 to drive the lifting column group 203 to move up and down relative to the middle frame 202. Preferably, the lifting drive mechanism 205 has four gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com