Gear reducer capable of being installed in submersible mixer shell

A technology of gear reducer and submersible mixer, applied in the direction of gear transmission, belt/chain/gear, electromechanical device, etc., can solve the problem of high power consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be clearly and completely described below in conjunction with the embodiments and the accompanying drawings.

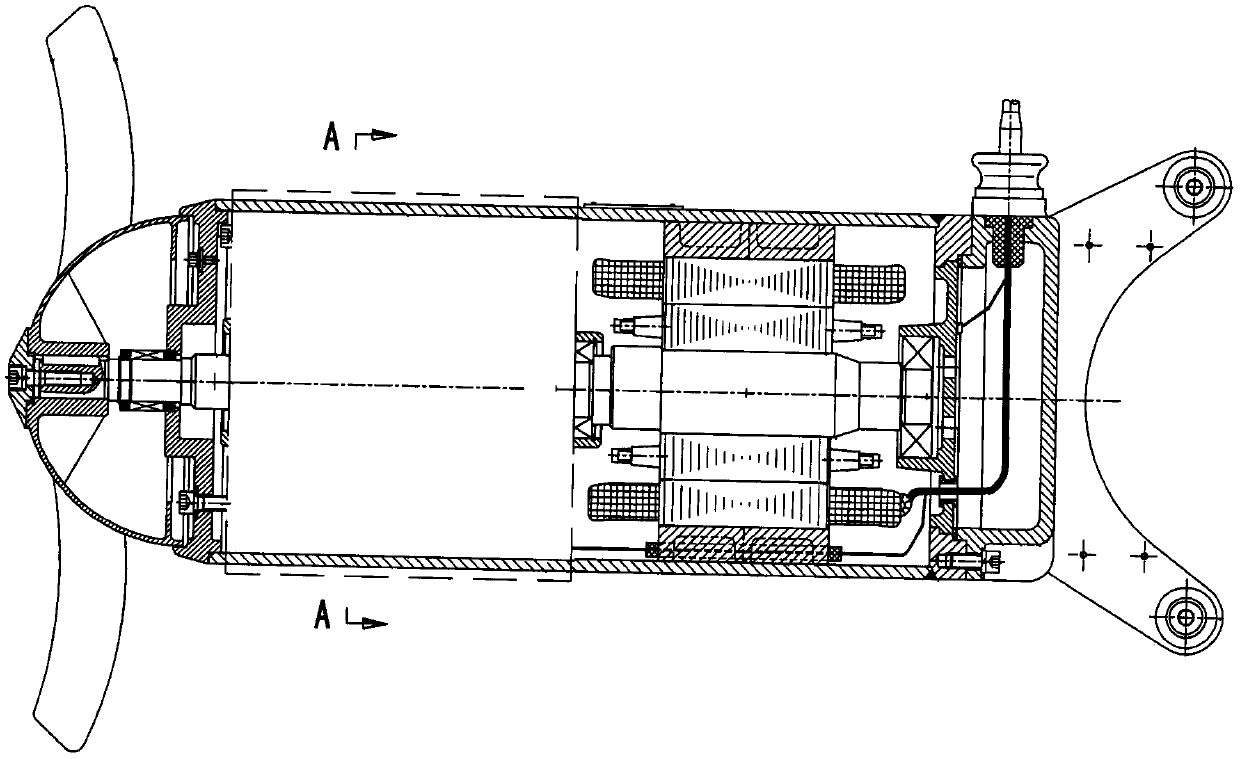

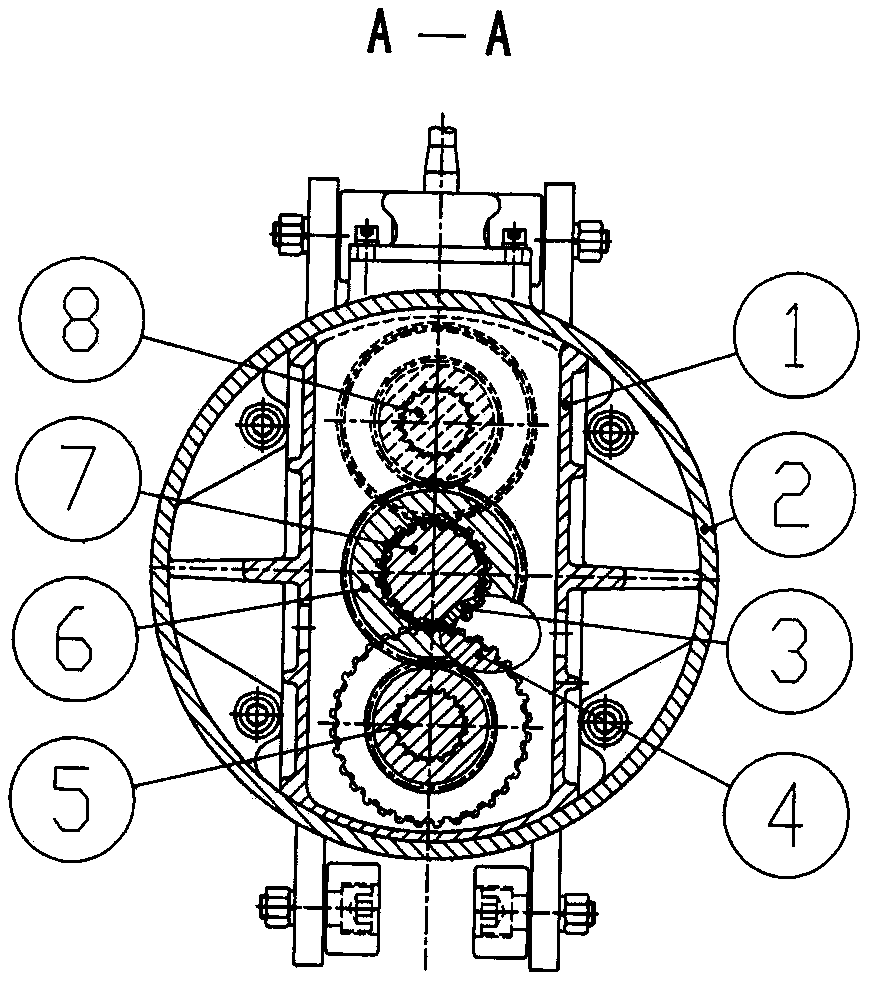

[0010] A gear reducer that can be installed in the shell of a submersible mixer is characterized in that the transmission structure of the gear reducer is a three-axis type; the input shaft and the output shaft are on the same axis; and the parallel shaft helical gears perform two-stage reduction.

[0011] The gear reducer box ① is made of aluminum alloy. The lower side of the box chamber and the rear box room are closed, and there are windows for installing gears and bearings on the upper side of the box body; three sets of holes parallel to the axis are arranged on the front wall, middle wall, and rear wall of the box body, and the three sets of axes One set of axes in the center of the cylinder is coaxial with the center line of the cylindrical box, and the other two sets are the intermediate shafts arranged eccentrically and symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com