S-shaped harrow cutter

A technology of rake blade and blade body, applied in the field of S-type rake blade, can solve the problems of short life, easy cracking, unsatisfactory mechanical performance index and fatigue strength, etc., and achieves improved fatigue strength, reduced product weight, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and the embodiments thereof.

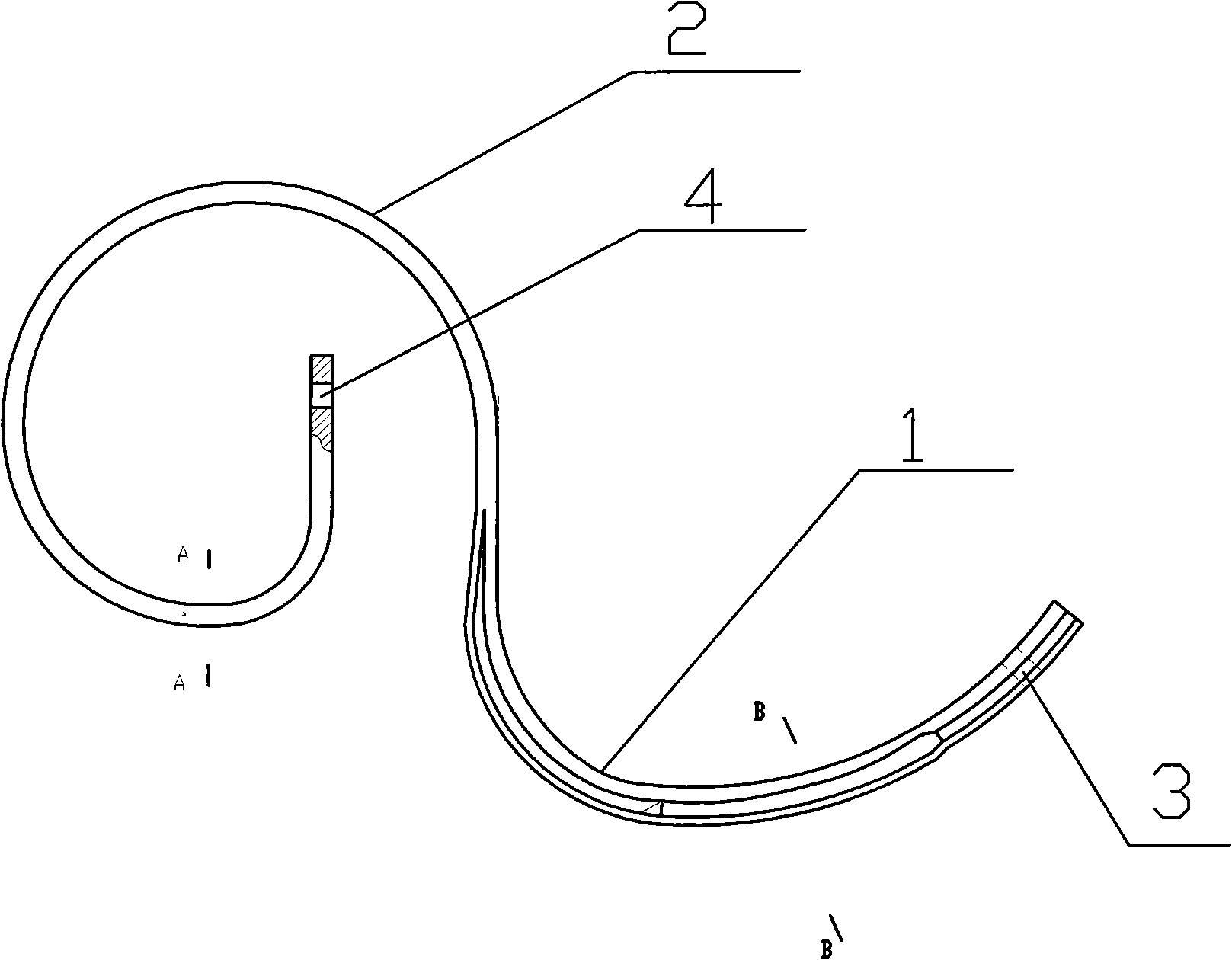

[0011] like figure 1 , an S-shaped rake knife, including a knife body, the knife body is an inverted S-shaped structure, the knife body includes a main blade 1 and a secondary blade 2, the main blade is a structure that bends upward along the axis on both sides; the secondary blade is helical The structure is elliptical in cross section. The main blade is provided with a plow point mounting hole 3 . The S-type rake is connected together with the plow point by bolts through the plow point installation hole 3, and is fixed on the agricultural machine frame to realize loosening and weeding operations on cultivated land.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com