Flame-retardant polyester-type air filtering paper and preparation method thereof

A technology of air filter paper and flame retardant polyester, applied in the direction of filter paper, separation method, filtration and separation, etc., to achieve the effects of enhanced bonding, increased specific surface area, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

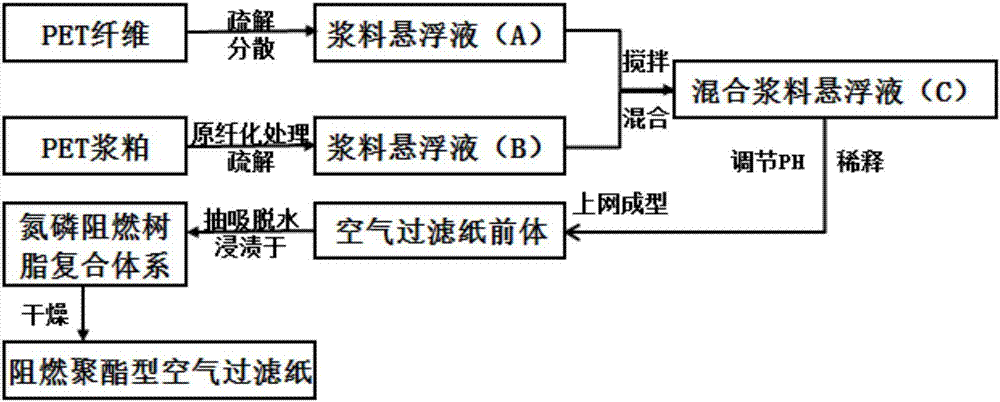

[0031] see figure 1 , a preparation method of flame-retardant polyester air filter paper, comprising the following steps:

[0032] Step 1: Dispersing and dispersing PET fibers with a length of 5-10 mm to prepare slurry suspension A;

[0033] Step 2: Fibrillation treatment of PET pulp with a length of 0.3-1 mm, de-fibrillation and dispersion to obtain a slurry suspension B, the beating degree of the PET pulp is 35-50° SR. Since PET pulp is different from plant fibers, the intermolecular strength mainly depends on physical bonding rather than hydrogen bonding, so the specific surface area of pulp is an important factor affecting the strength, so the pulp fibrillation treatment is used to increase the surface distribution. Silk broomization to increase the specific surface area;

[0034] Step 3: Mix the absolute dry fiber amount in the pulp suspension A prepared in step 1 with the absolute dry fiber amount in the pulp suspension B prepared in step 2 at a mass ratio (30-50): (...

Embodiment 1

[0045] Step 1: Dispersing and dispersing PET fibers with a length of 5-10 mm to prepare slurry suspension A;

[0046] Step 2: Fibrillating PET pulp with a length of 0.3 to 1 mm and dissolving and dispersing to obtain pulp suspension B, the beating degree of PET pulp is 35°SR;

[0047] Step 3: Mix the absolute dry fiber amount in the pulp suspension A prepared in step 1 with the absolute dry fiber amount in the pulp suspension B prepared in step 2 at a mass ratio of 6:11 to obtain a mixed pulp suspension C, And dilute the mass concentration of the mixed slurry suspension C to 0.1% in the mixing tank, and adjust the pH to 5-6, and at the same time use the agitator to stir the different components to fully mix and evenly disperse, the stirring time is 10min, and the stirring speed is controlled at 300rpm;

[0048] Step 4: Send the mixed pulp suspension C prepared in Step 3 to an inclined wire paper machine to make a wet paper. Suction and dehydrate the wet paper so that the moi...

Embodiment 2

[0052] Step 1: Dispersing and dispersing PET fibers with a length of 5-10 mm to prepare slurry suspension A;

[0053] Step 2: Fibrillation and dispersion of PET pulp with a length of 0.3-1 mm to obtain pulp suspension B, with a beating degree of PET pulp of 45°SR;

[0054] Step 3: Mix the absolute dry fiber amount in the pulp suspension A prepared in step 1 with the absolute dry fiber amount in the pulp suspension B prepared in step 2 at a mass ratio of 1:1 to obtain a mixed pulp suspension C, Dilute the mass concentration of the mixed slurry suspension C in the mixing tank to 0.2%, and adjust the pH to 5-6. At the same time, use a stirrer to stir the different components to fully mix and evenly disperse. The stirring time is 15min, and the stirring speed is controlled at 500rpm;

[0055] Step 4: Send the mixed pulp suspension C prepared in Step 3 to an inclined wire paper machine to make a wet paper. Suction and dehydrate the wet paper so that the moisture content is less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Length dimension | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com