Frame structure and crane

A frame structure and frame technology, applied in cranes and other directions, can solve the problems of reduced hoisting weight, increased crane weight, reduced tire load capacity, etc. effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

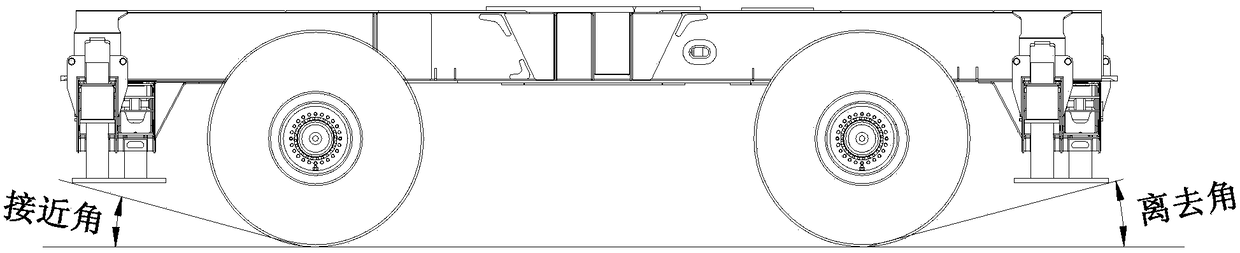

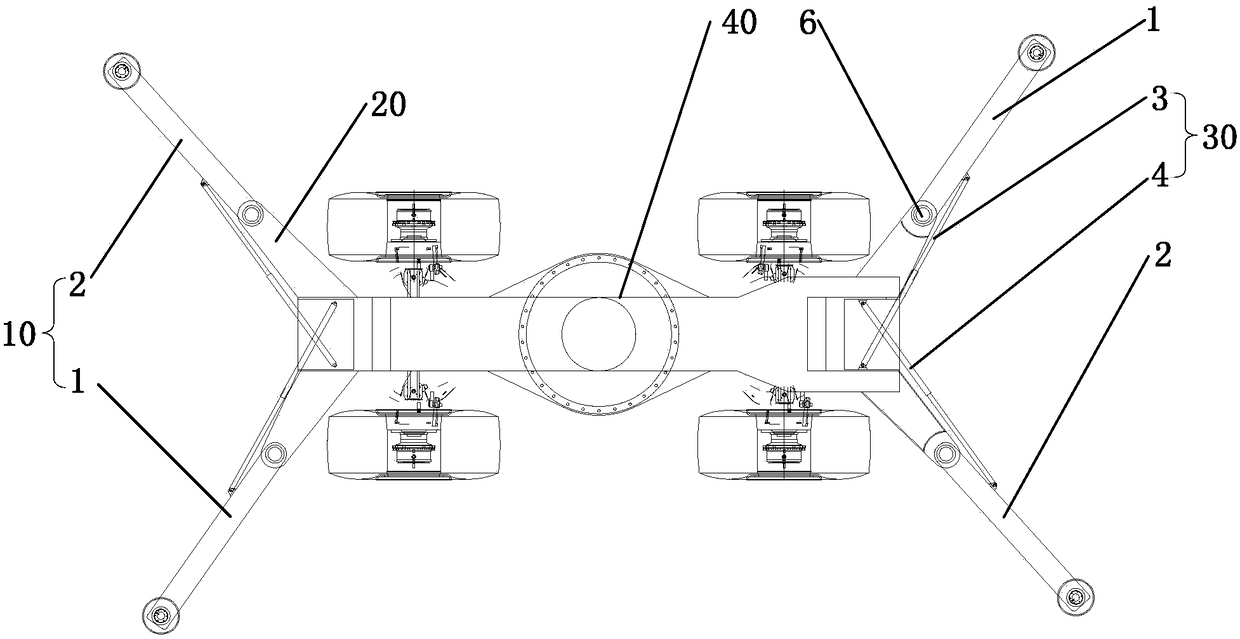

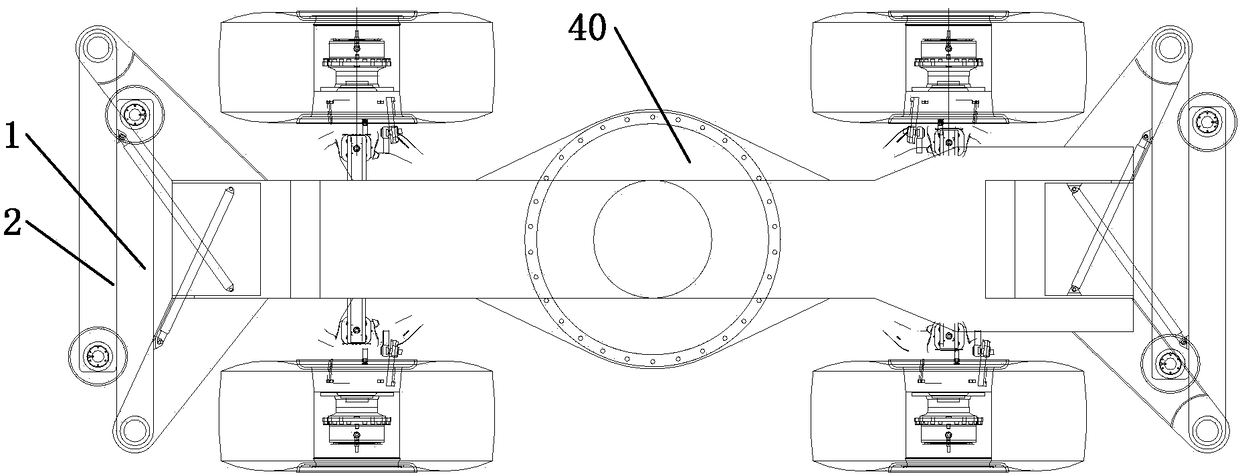

[0028] Combine below Figure 2 to Figure 7 The technical solution provided by the present invention is described in more detail.

[0029] Explanation of names or terms involved in this article.

[0030] Crane: A piece of equipment used to lift heavy loads, mounted on a mobile chassis.

[0031] Frame main body: the main load-bearing structure of the crane, which is used to place and fix other parts.

[0032] see figure 2 , the embodiment of the present invention provides a frame structure, including a frame body 40 and an outrigger structure 10 . The outrigger structure 10 is disposed at the end of the frame body 40 in the longitudinal direction, and the outrigger structure 10 is rotatably connected or slidably connected to the frame body 40 . When the outrigger structure 10 is in the extended state, the outrigger structure 10 is located outside the frame body 40, and the length direction of the outrigger structure 10 forms an acute angle with the length direction and widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com