Patents

Literature

70results about How to "Increase width size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

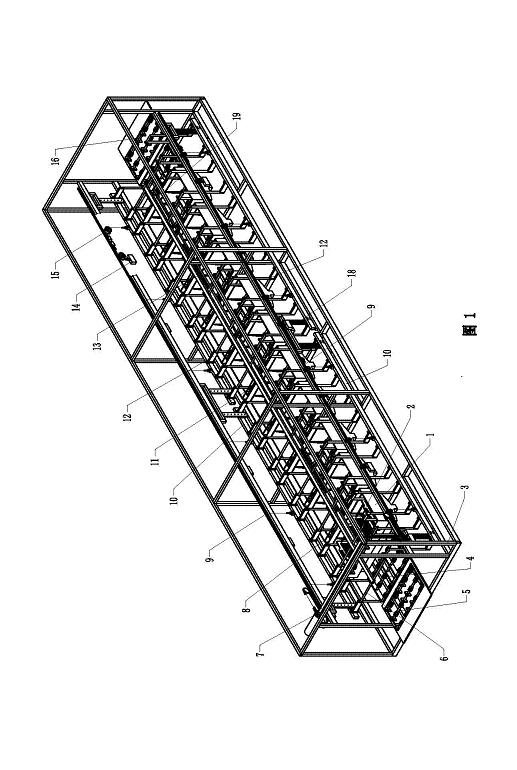

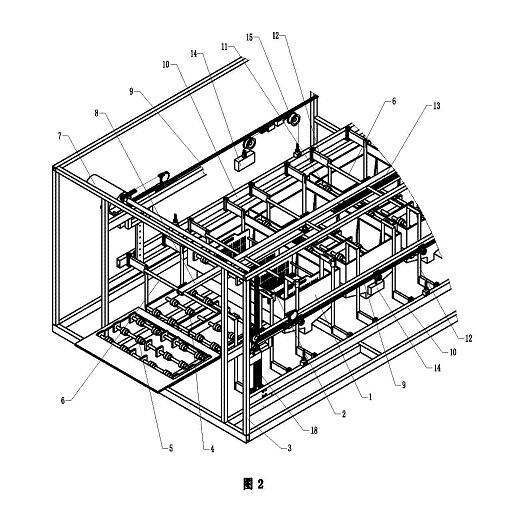

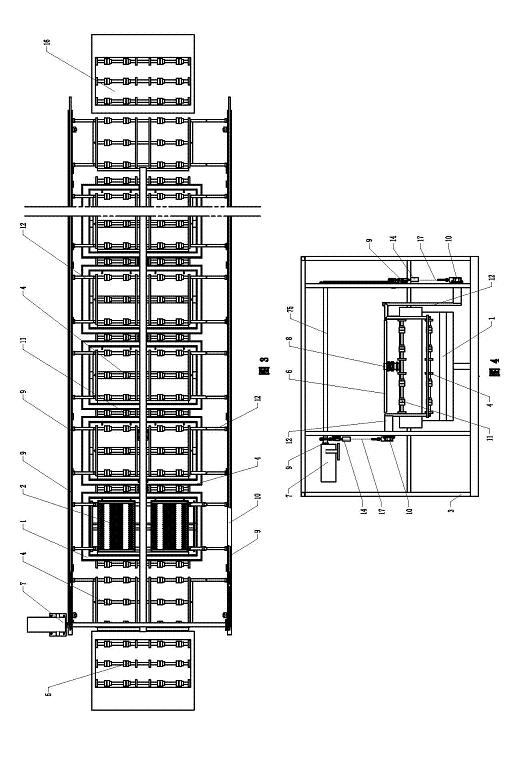

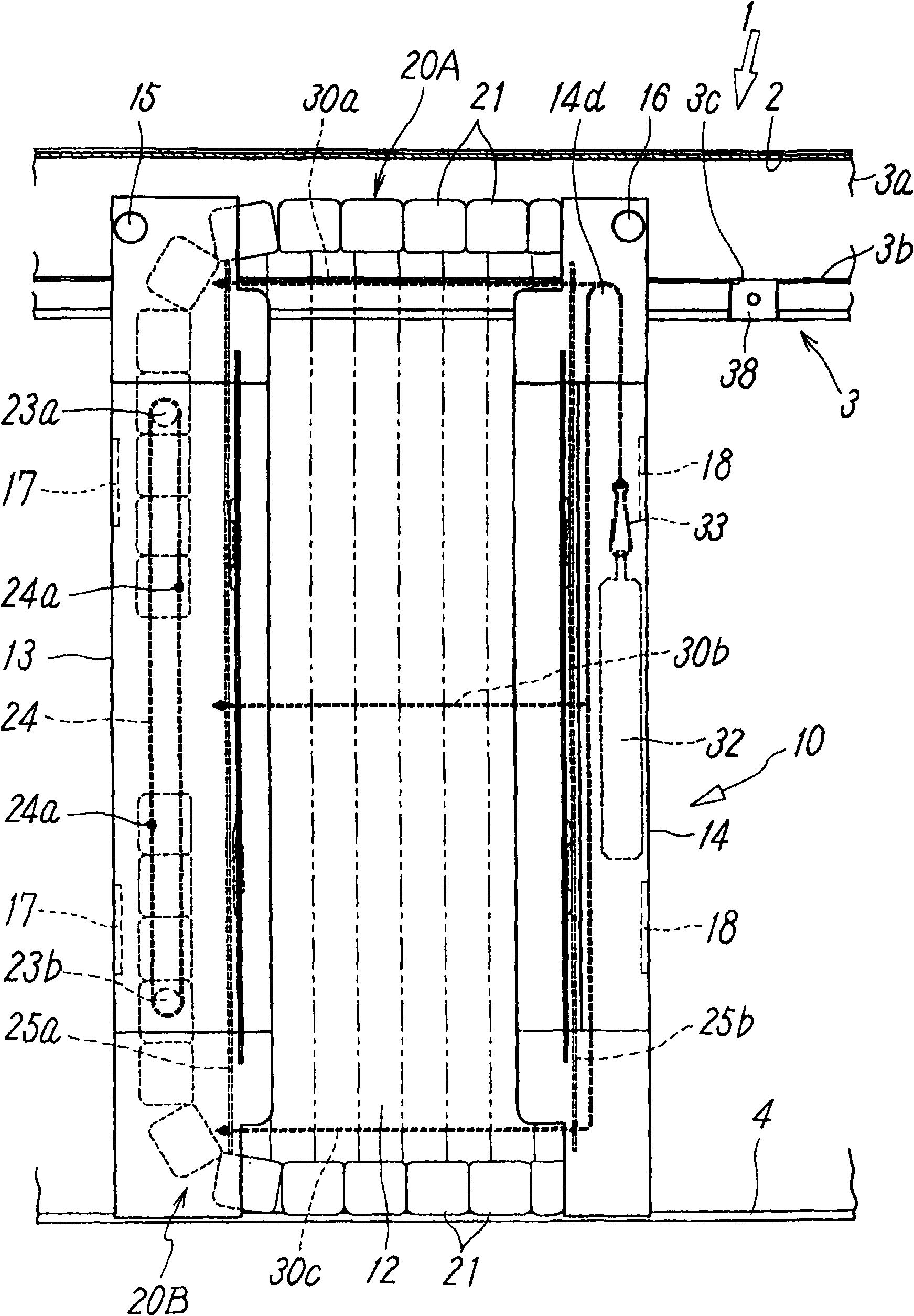

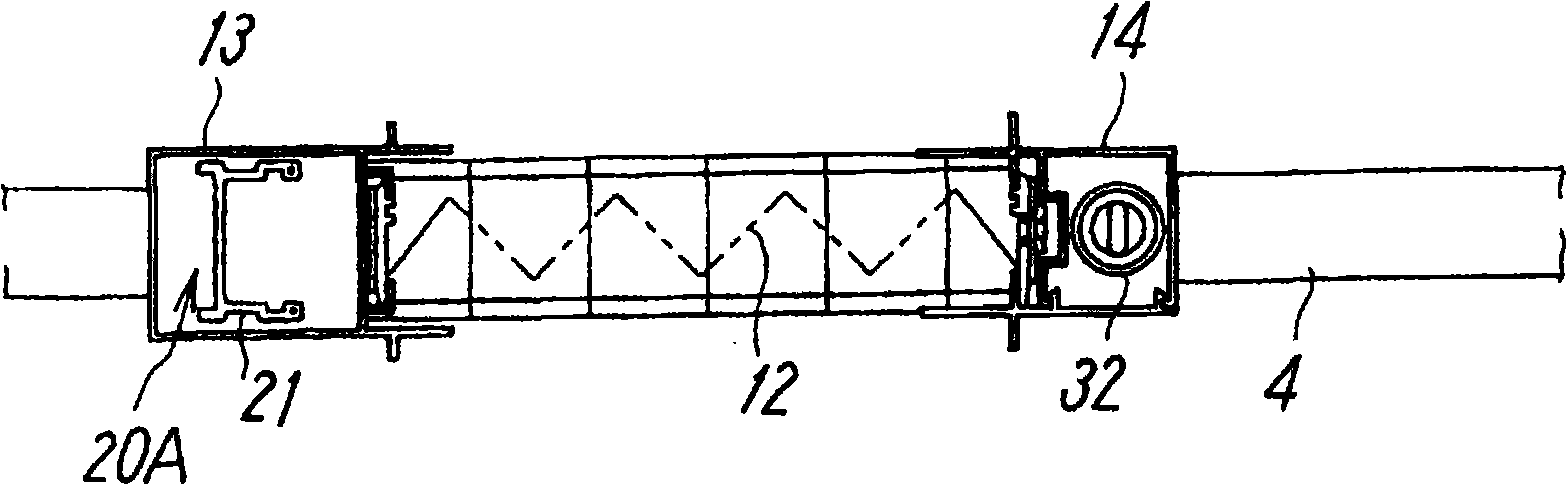

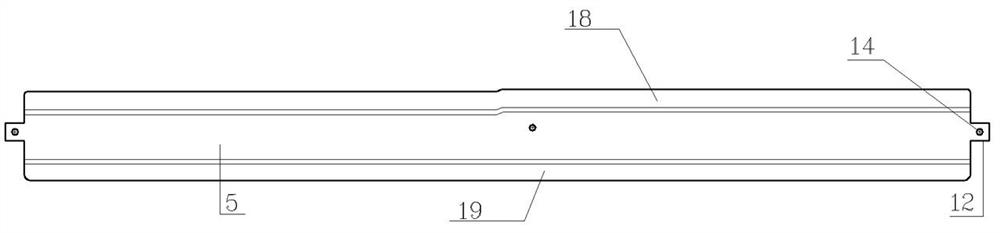

Cleaning machine with supporting and thrusting mechanism

InactiveCN102671883AAvoid recontaminationIncrease width sizeCleaning using liquidsCarrying capacityEngineering

The invention discloses a cleaning machine with a supporting and thrusting mechanism, which comprises a rack and a plurality of cleaning tanks, wherein a lifting bracket used for supporting material baskets is arranged in each cleaning tank; at least one side edge of each lifting bracket is connected with a lifting cross beam through a bracket connecting rod; a lifting driving mechanism mounted on the rack can drive the lifting brackets to be lifted to and fro in the vertical direction through the lifting cross beam; horizontal material basket push rods used for horizontally pushing the material baskets to move are further arranged above the cleaning tanks and are driven by a horizontal driving mechanism; fixed brackets are fixedly arranged between adjacent cleaning tanks; upper bearing surfaces of the fixed brackets are positioned in the same bearing plane as bearing surfaces of the lifting brackets lifted to high positions; and the bearing plane is higher than tank openings of the cleaning tanks. The cleaning machine has the advantages of stability and reasonableness in structure and great carrying capacity; and particularly, a cleaning and conveying path of the cleaning machine is reasonable, the effective cleaning time is long and the work efficiency is high.

Owner:SHANGHAI SNA ELECTRONICS TECH DONGTAI

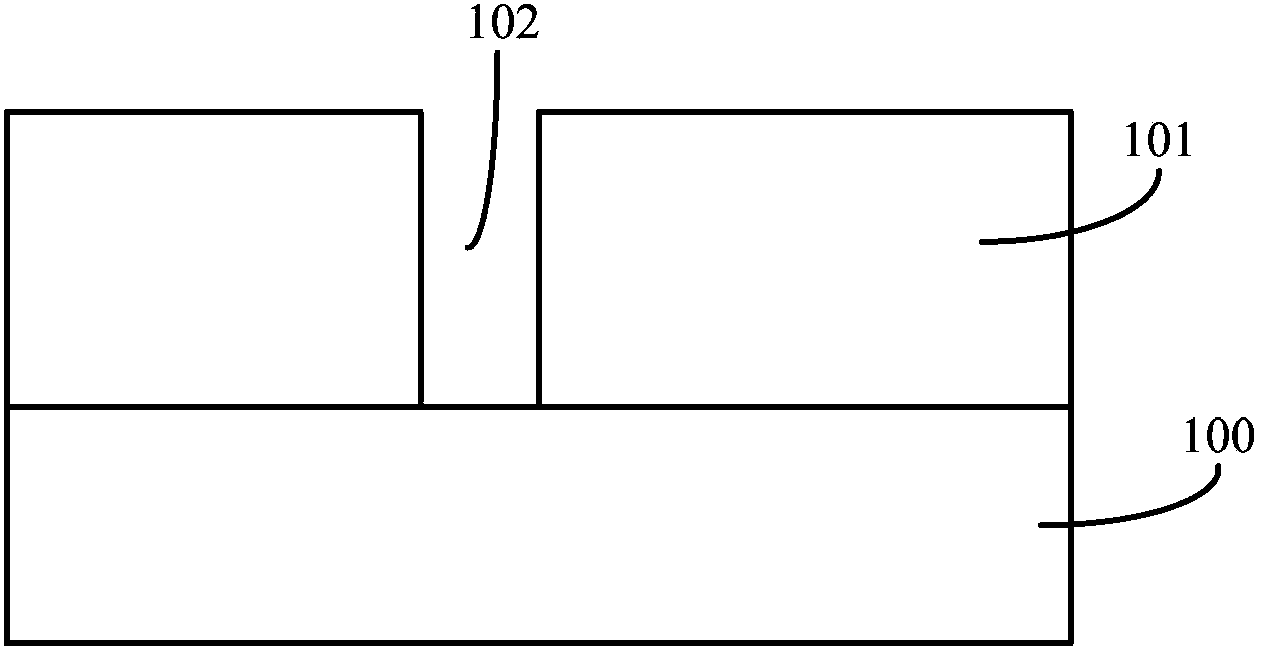

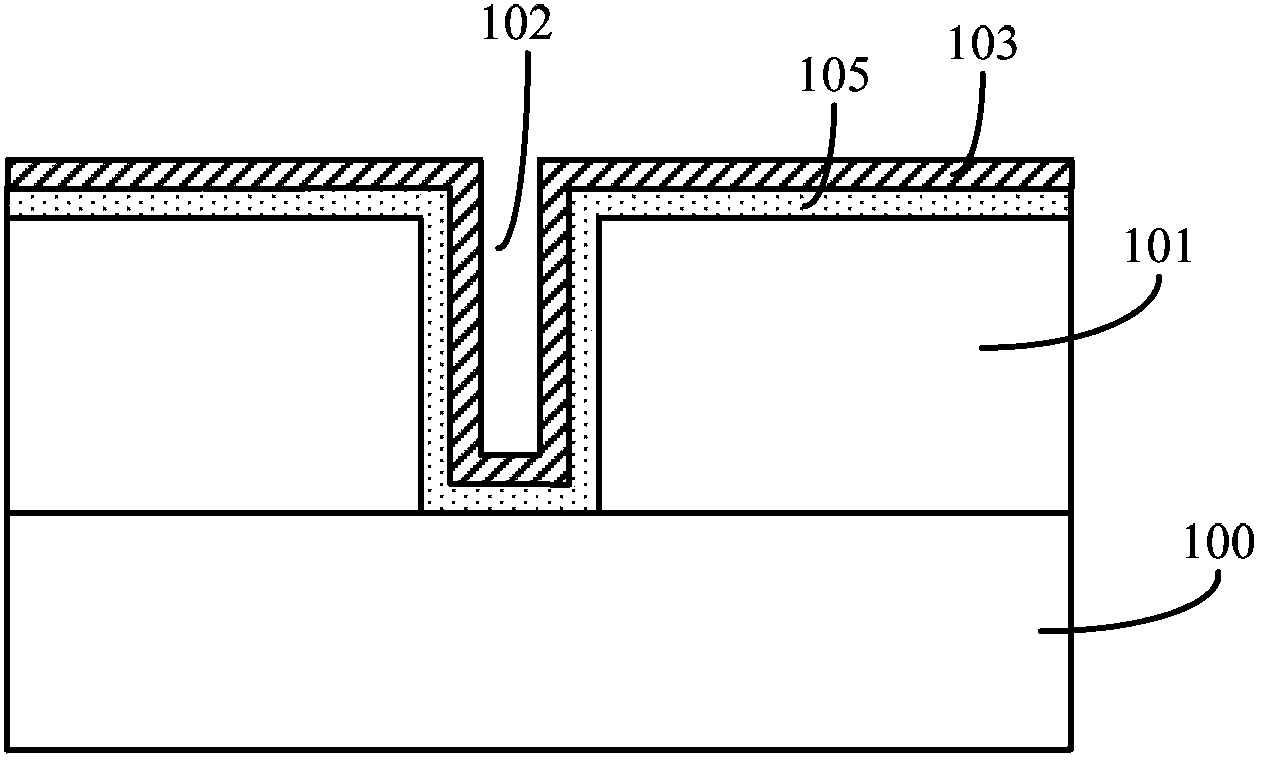

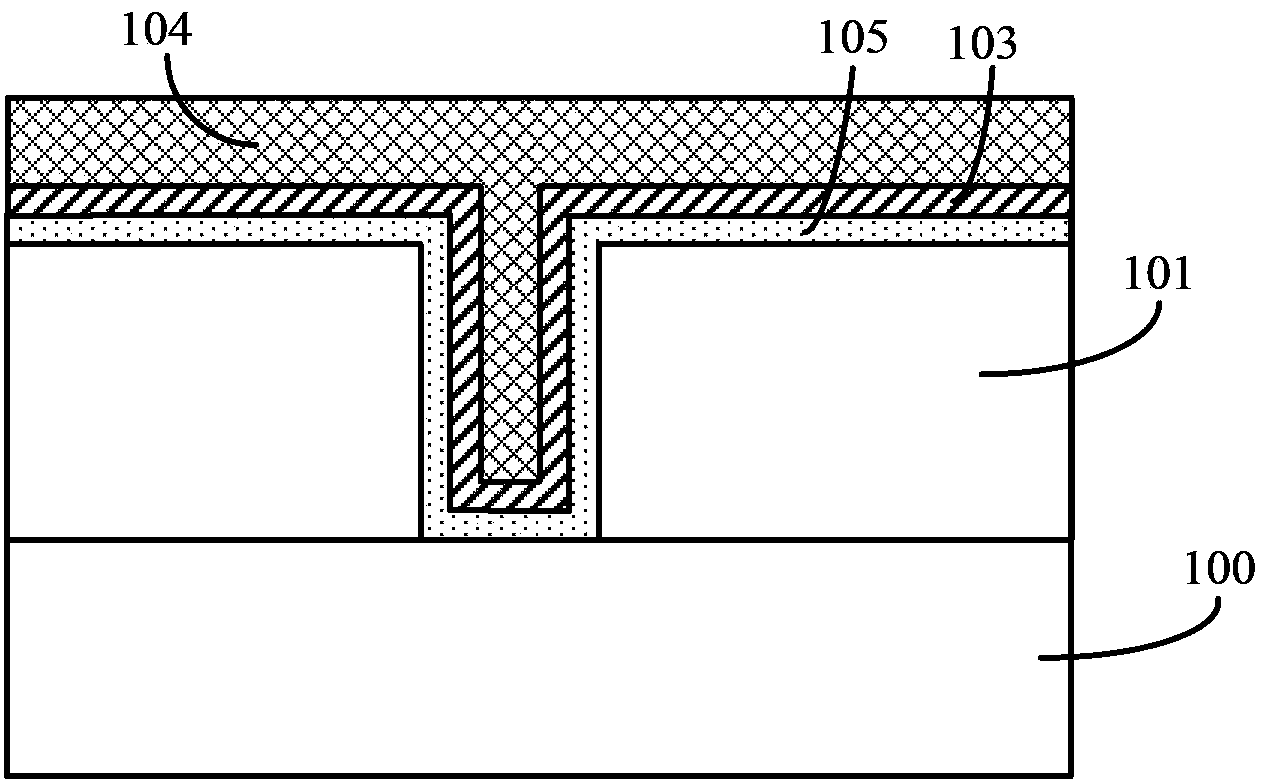

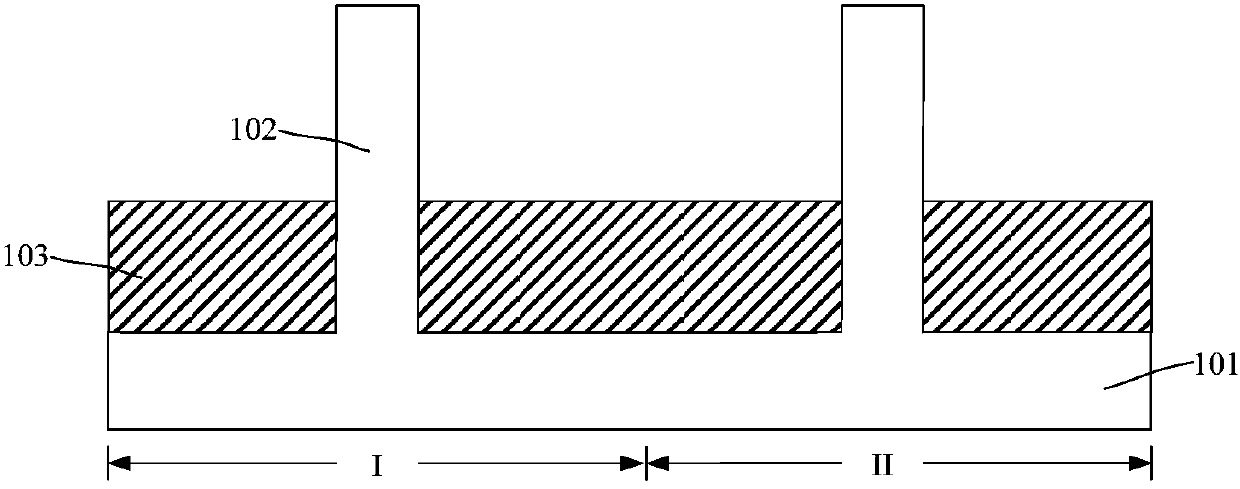

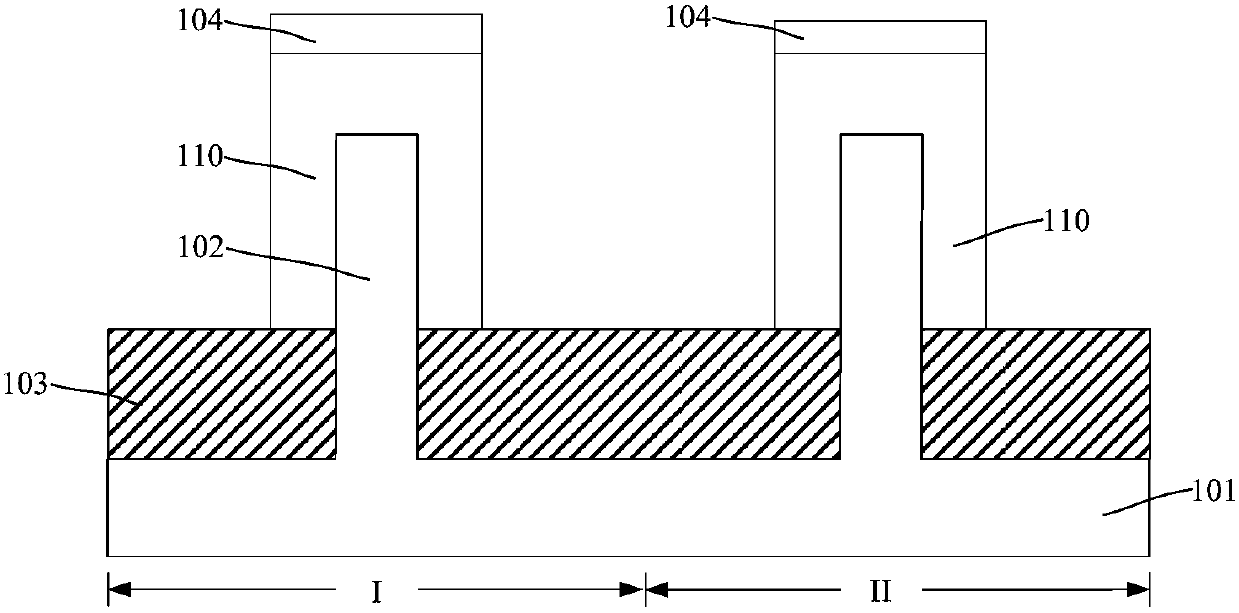

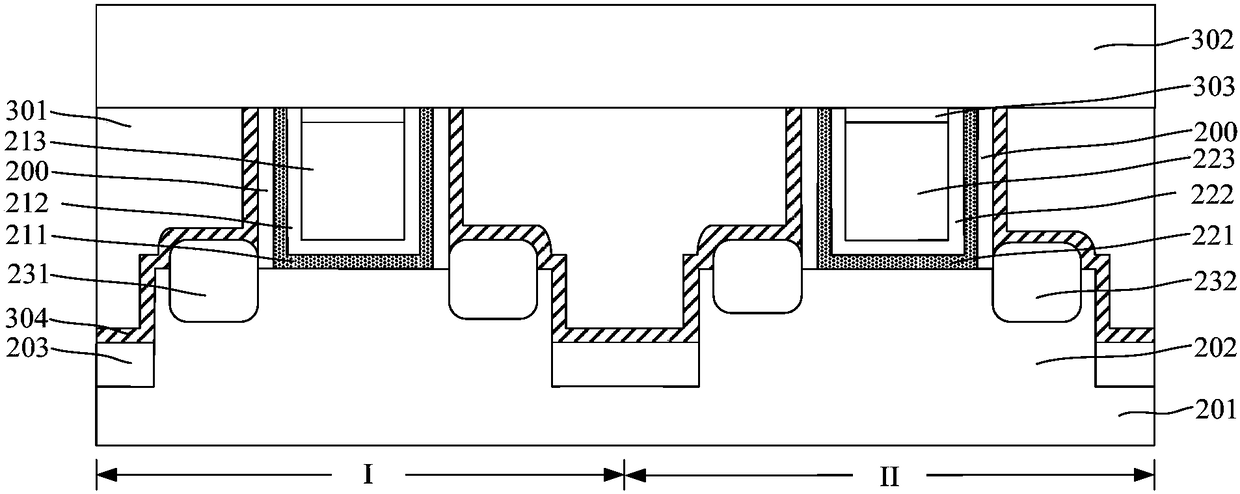

Forming method of electric conduction structure

ActiveCN104124201AImprove performanceIncrease width sizeSemiconductor/solid-state device manufacturingOptoelectronicsDielectric layer

A forming method of an electric conduction structure comprises providing a substrate, wherein the surface of the substrate is provided with a dielectric layer and the dielectric layer is provided with an opening; forming seed layers on surfaces of the lateral wall and the bottom of the opening; implanting modified ions into partial seed layer on the lateral wall surface which is close to the top of the opening through the iron implantation technology; utilizing the thermal annealing technology after the iron implantation technology to enable the partial seed layer with the modified irons being implanted to form into a sacrificial layer, wherein materials of the sacrificial layer and the seed layer are different; removing the sacrificial layer; forming an electric conducting layer in the opening after the sacrificial layer is removed, wherein the opening is full of the electric conducting layer. The formed electric conducting layer is free of gaps internally and good in quality.

Owner:SEMICON MFG INT (SHANGHAI) CORP

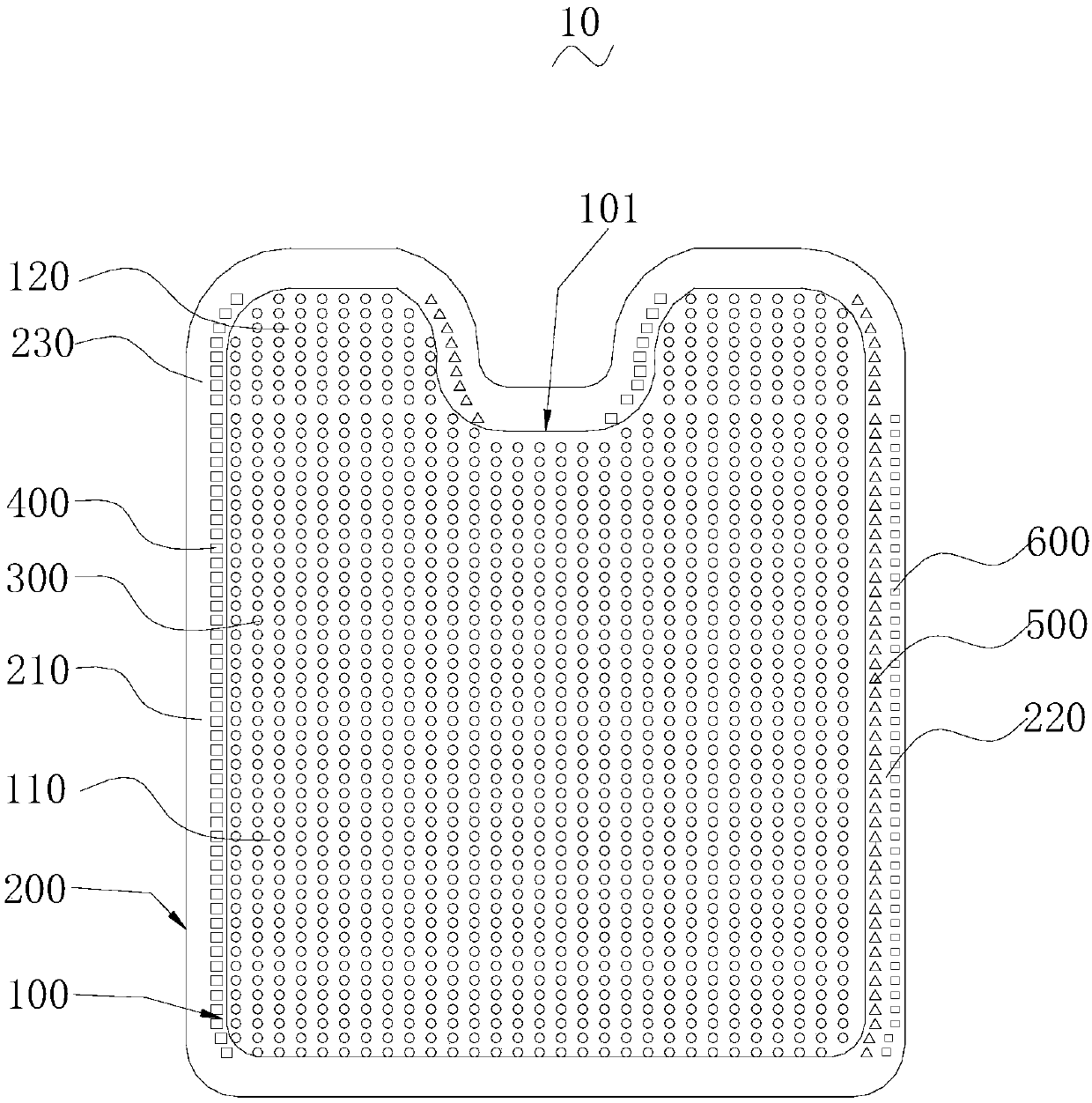

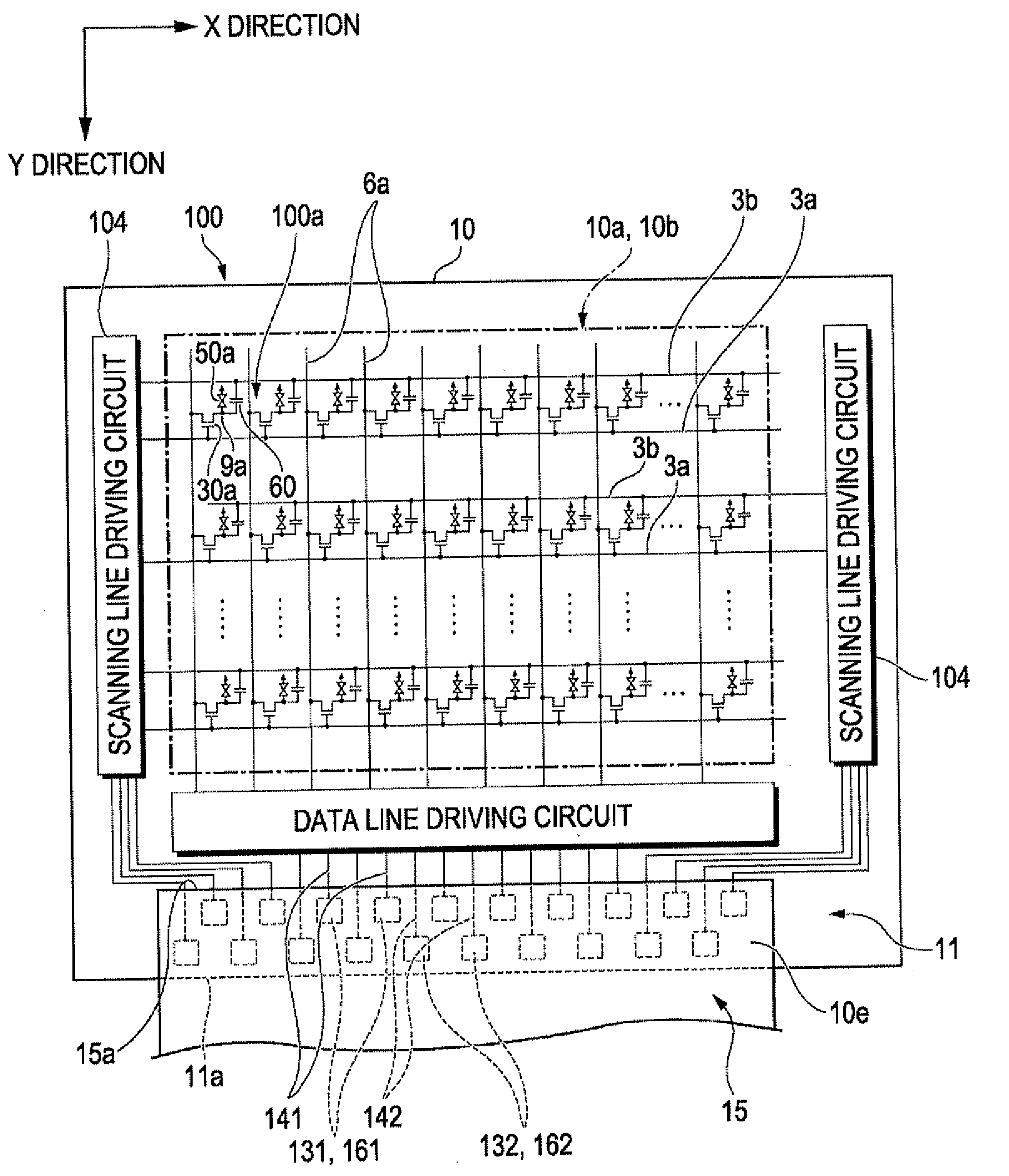

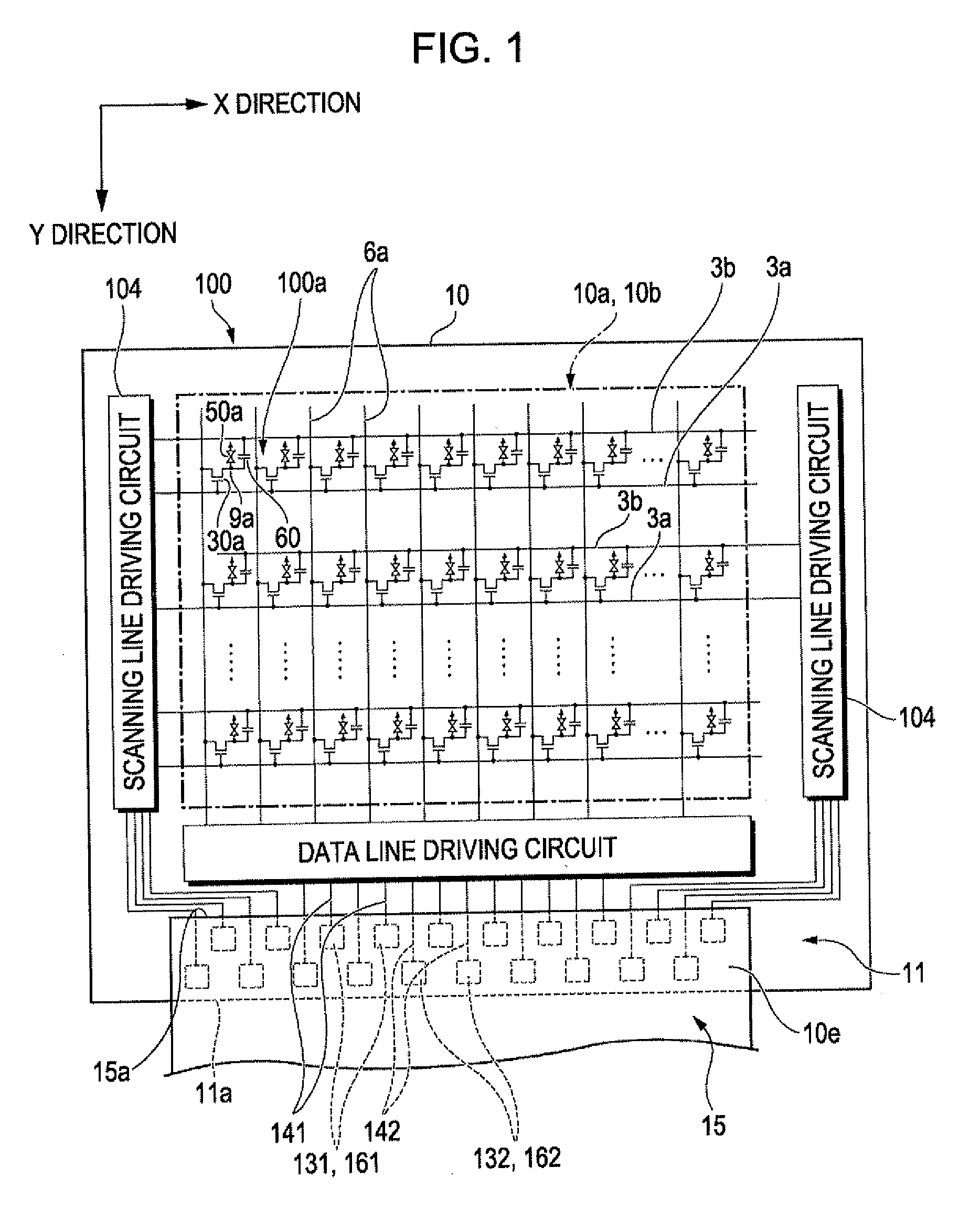

Array substrate and display device

ActiveCN107731151AIncrease width sizeShow normalyStatic indicating devicesImage resolutionDisplay device

The invention discloses an array substrate and a display device. The array substrate comprises a display area and a non-display area, wherein the display area comprises a first sub display area and aplurality of second sub display areas; the non-display area comprises a first sub non-display area, a second sub non-display area and a plurality of third sub non-display area groups; each third sub non-display area group comprises a pair of third sub non-display areas; multiple lines of pixel driving circuits are arranged in the first sub display area; a plurality of first scanning circuits are arranged in the first sub non-display area; a plurality of second scanning circuits and third scanning circuits are arranged in the second sub non-display area; multiple lines of pixel driving circuitsare also arranged in the second sub display area; in the two third sub non-display areas of the same group of third sub non-display areas, one of the third sub non-display areas is provided with a plurality of first scanning driving circuits, and the other third sub non-display area is provided with a plurality of second scanning driving circuits. According to the array substrate and the displaydevice, the display device, which is relatively large in size and ultra-high in resolution ratio, can achieve normal display.

Owner:TRULY HUIZHOU SMART DISPLAY

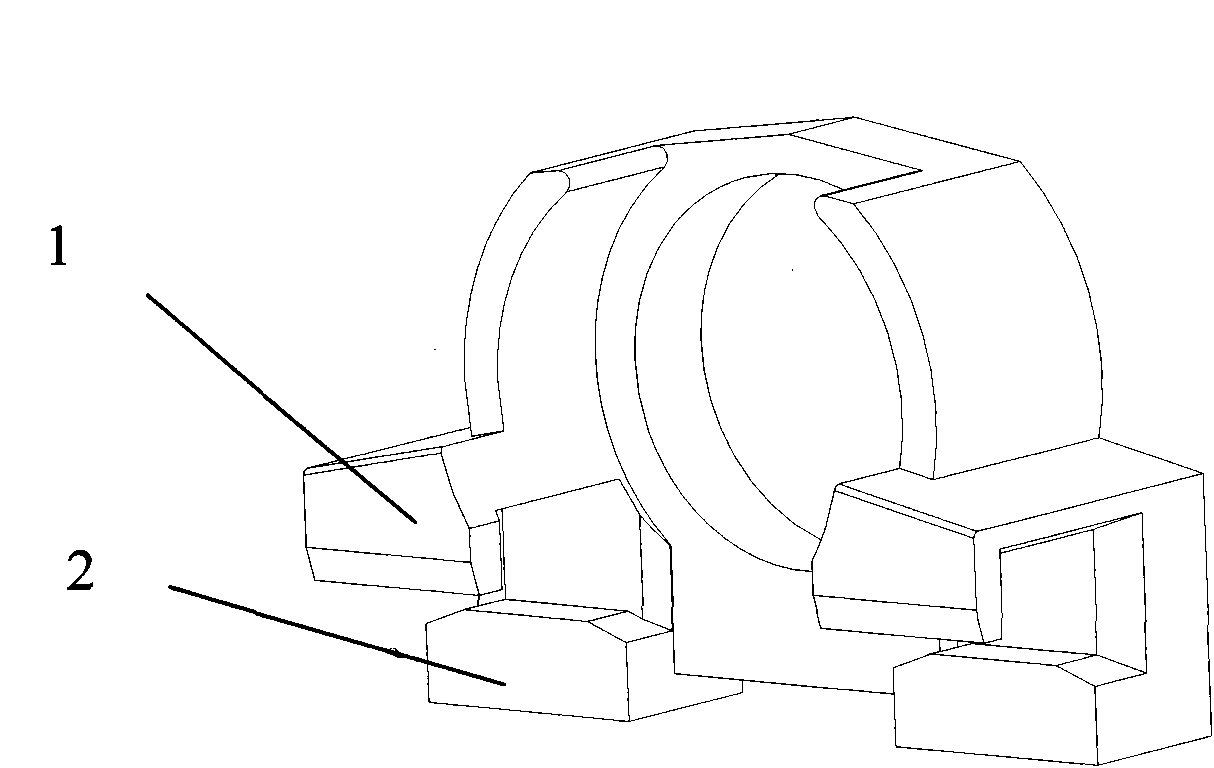

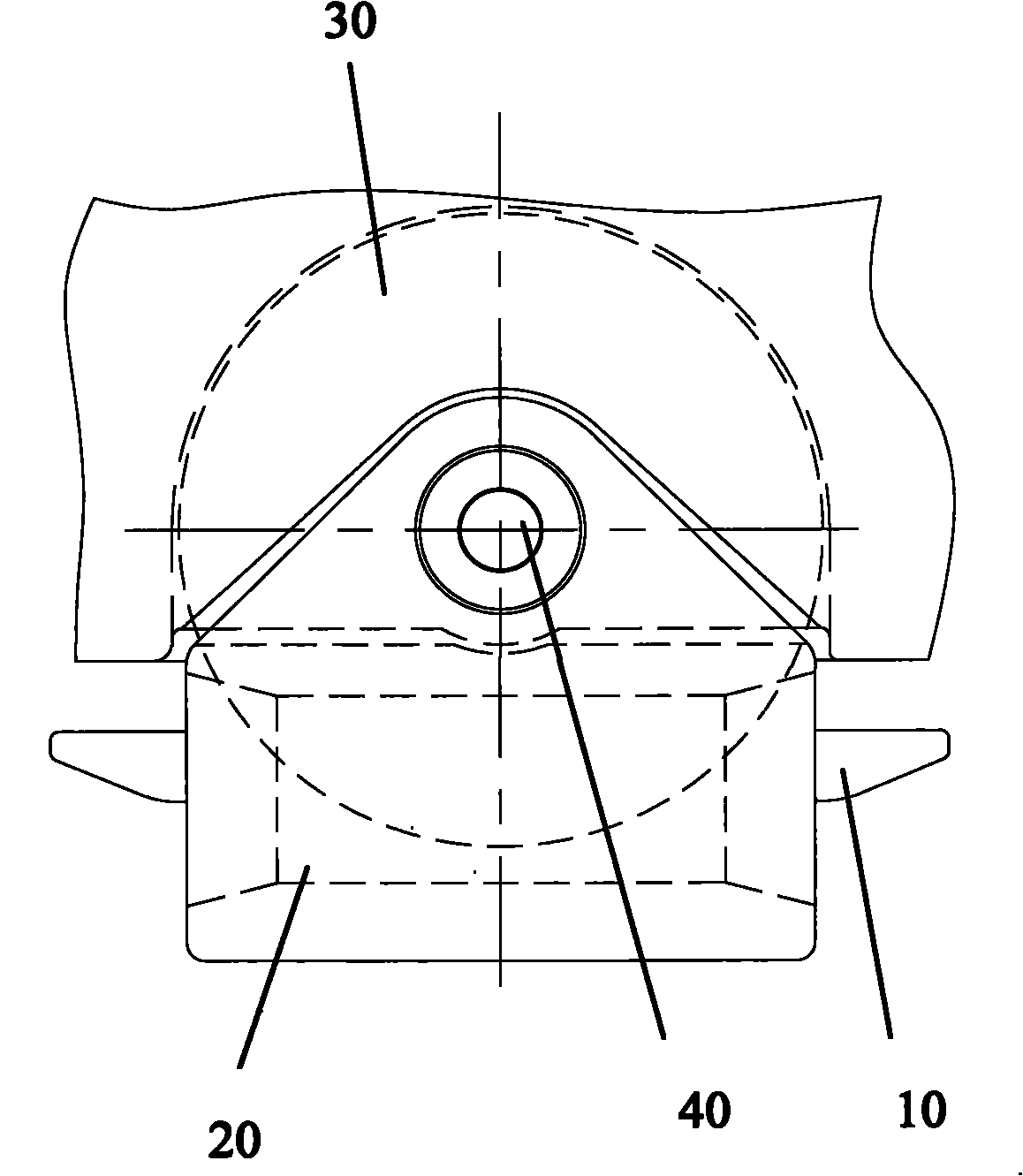

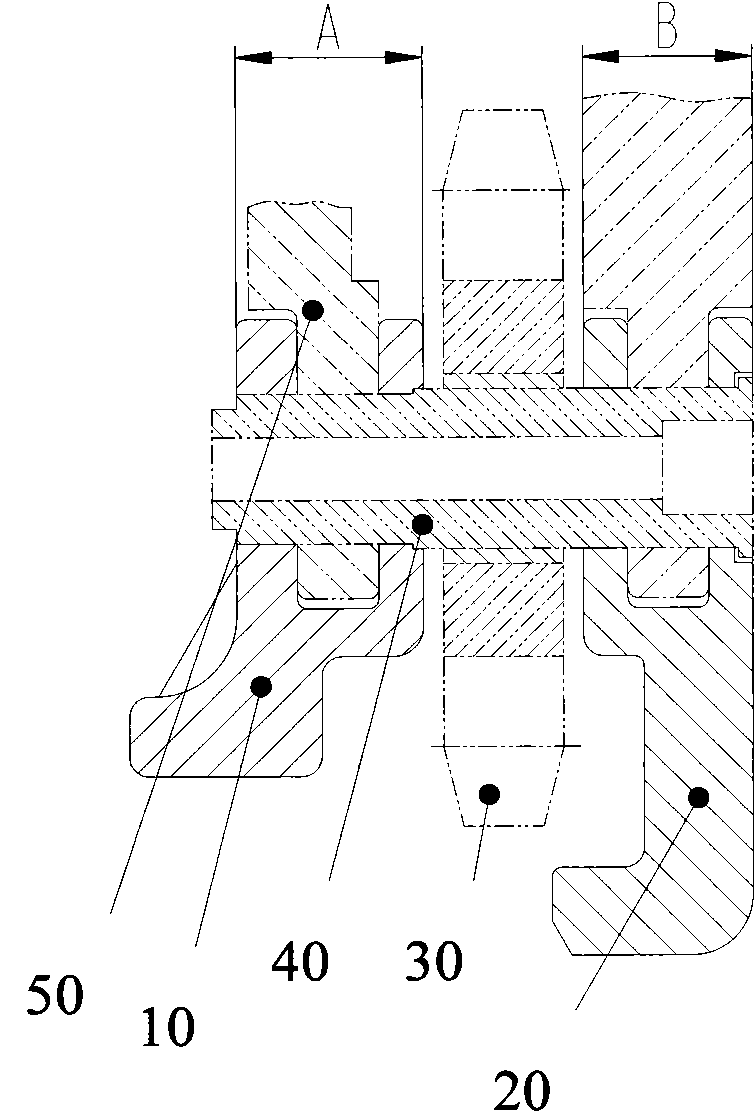

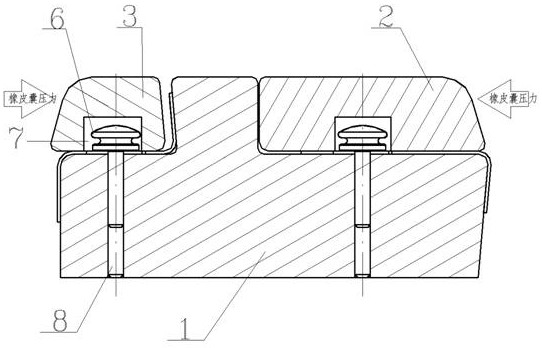

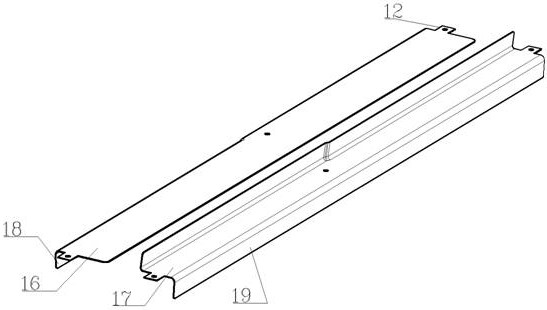

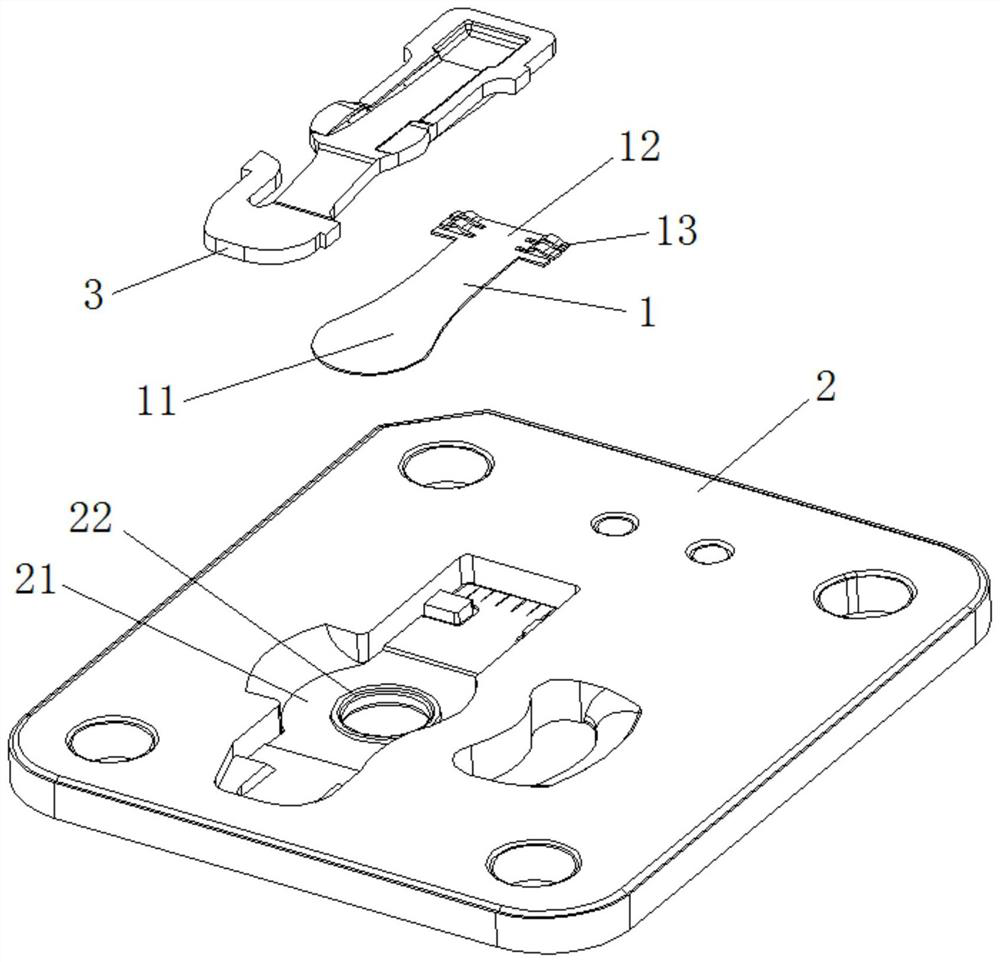

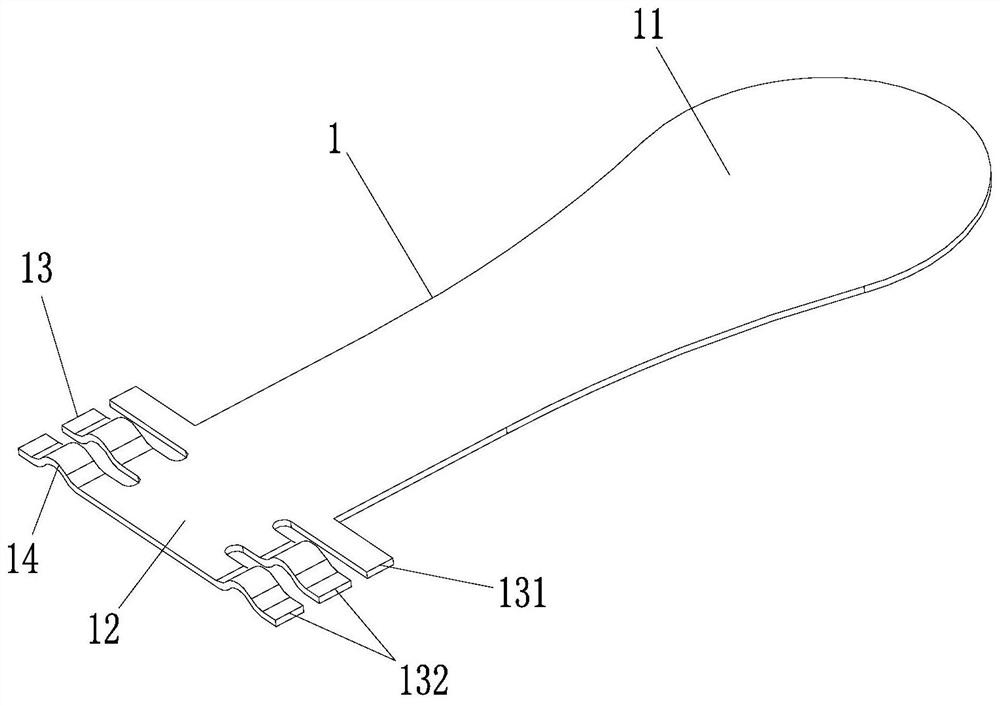

Guiding sliding shoe of coal cutter walking part

The invention relates to a guiding sliding shoe of a coal cutter walking part, which is engaged with a pin row of a conveyer to allow a walking wheel to roll on the pin. The guiding sliding shoe is characterized by comprising a guiding sliding shoe hook and a guiding sliding shoe plate which are respectively connected with the main body of the coal cutter, wherein the guiding sliding shoe hook and the guiding sliding shoe plate are clamped at two sides of the walking wheel of the coal cutter walking part. Because of being separately equipped in the guiding sliding shoe provided by the invention, the guiding sliding shoe hook and the guiding sliding shoe plate can be separately installed and replaced easily. And by increasing the widths of the guiding sliding shoe plate and the guiding sliding shoe hook, the invention enables the guiding sliding shoe to be endowed with increased strength and prolonged service life.

Owner:SHANGHAI CHUANGLI GRP

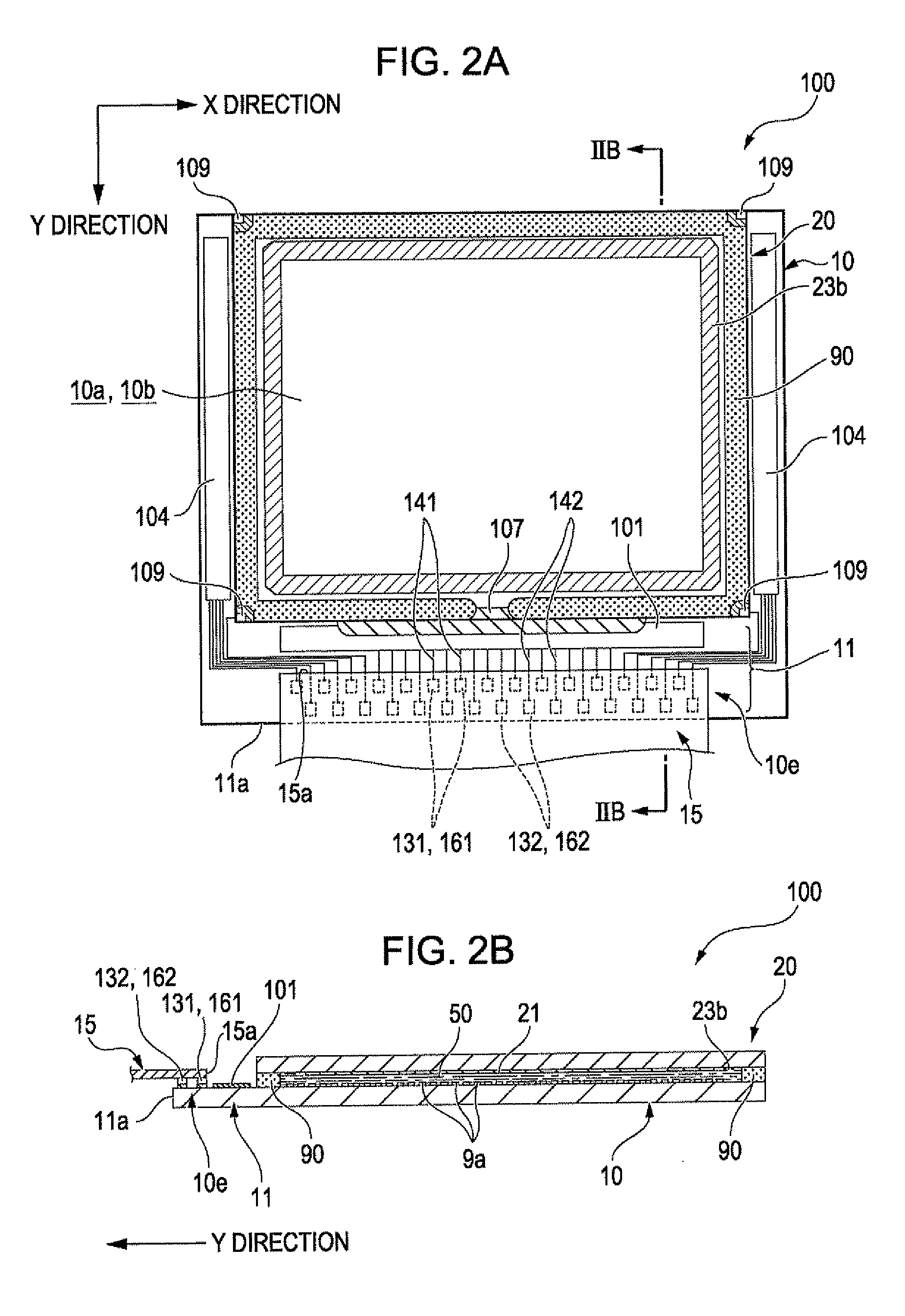

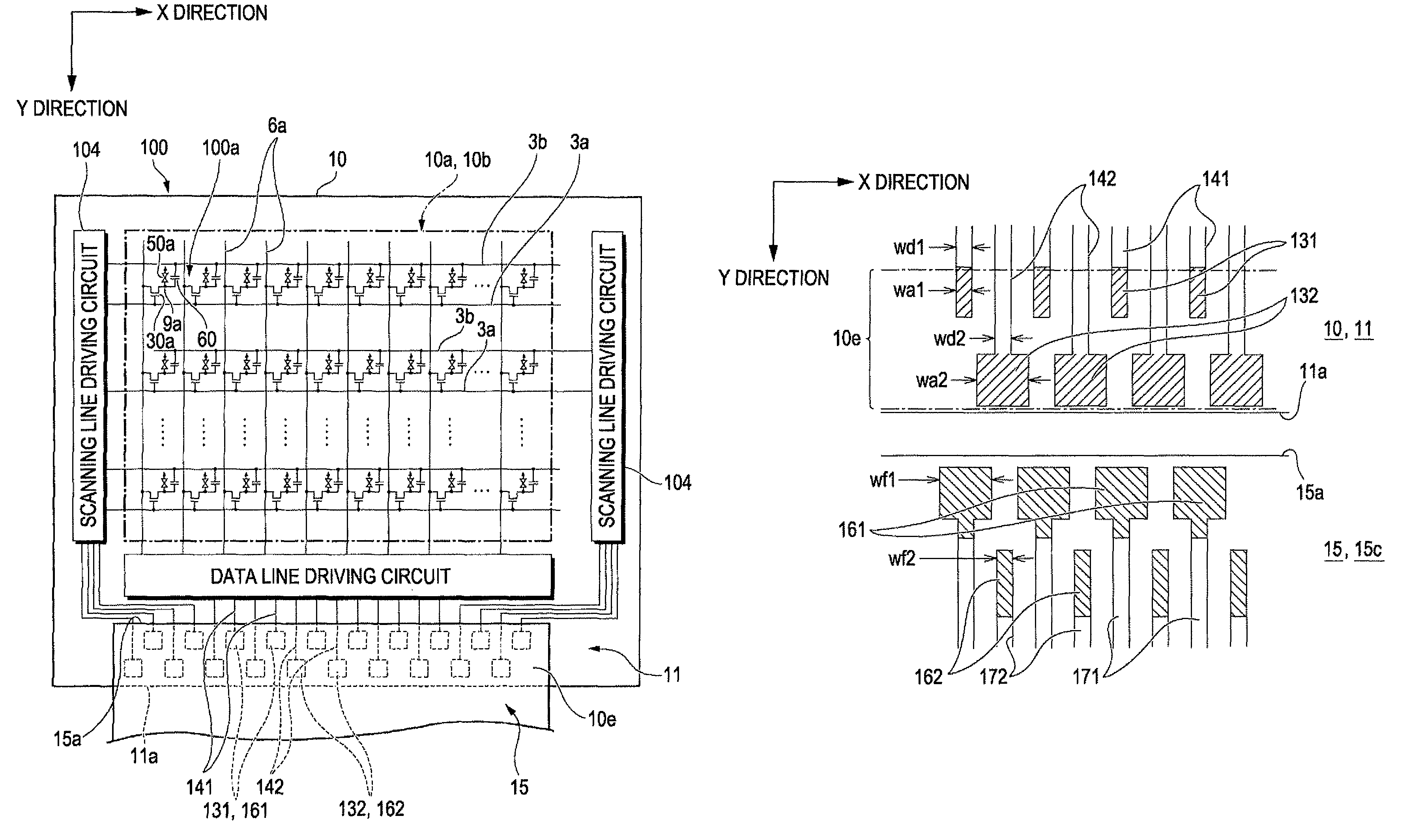

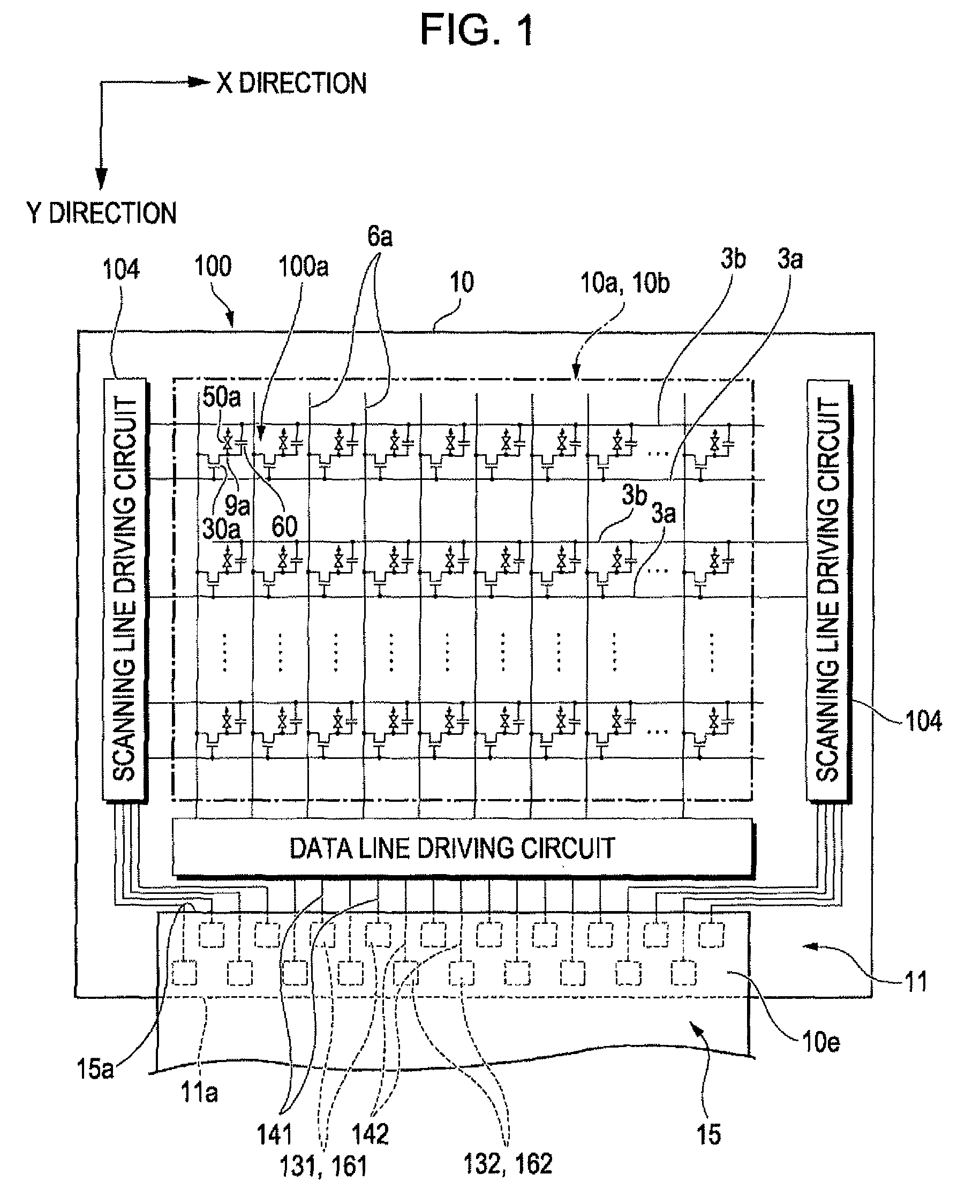

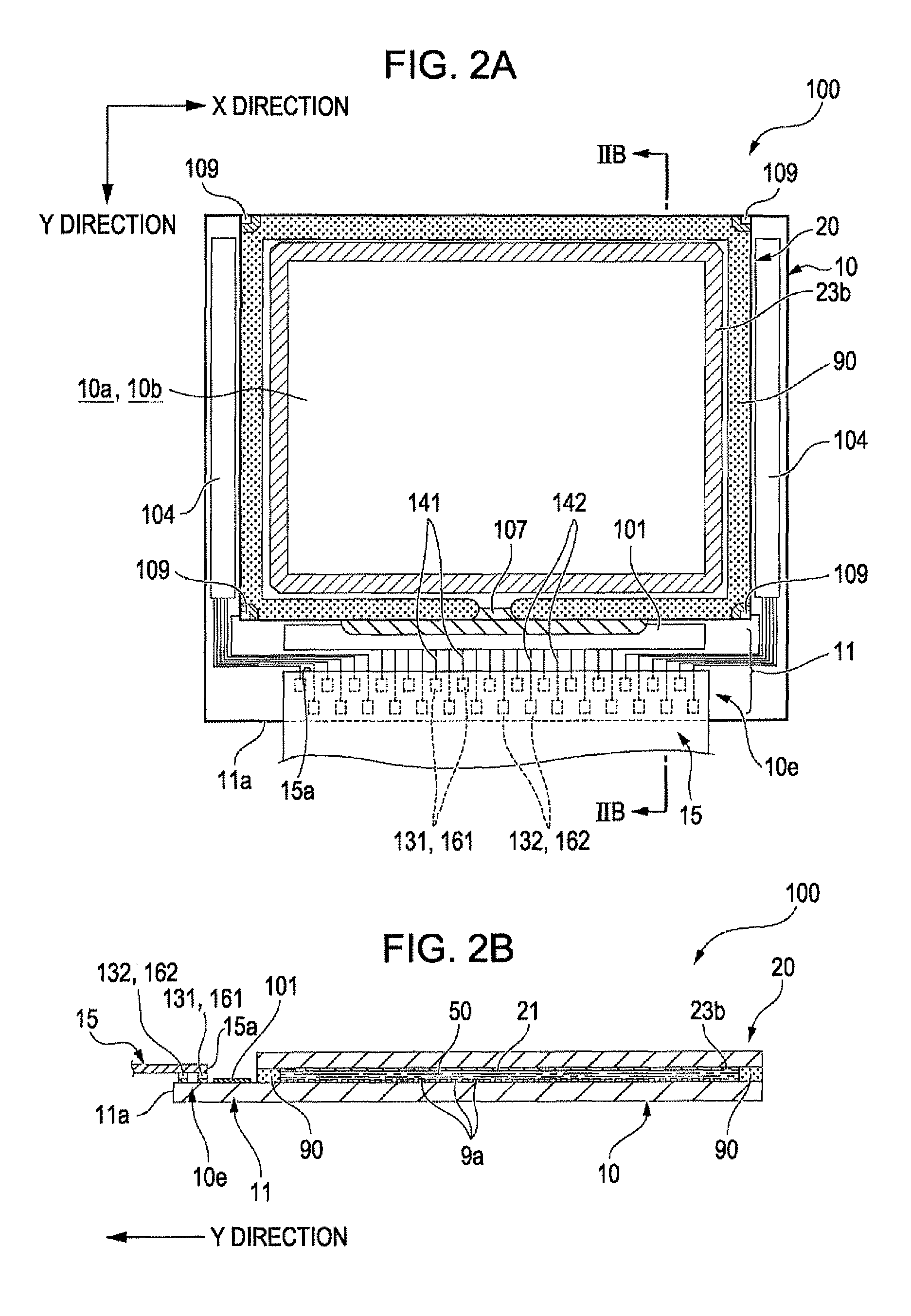

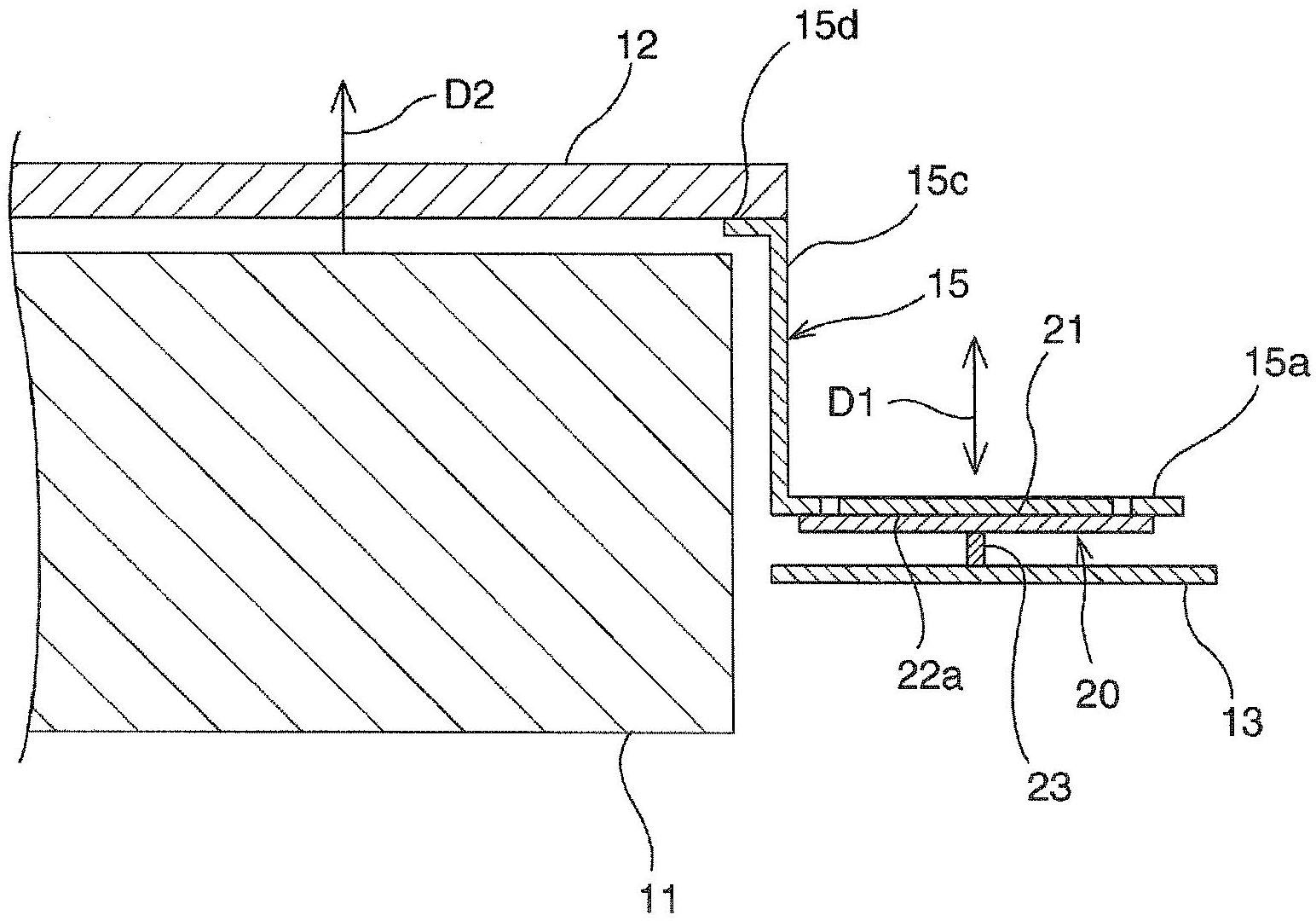

Mounting structure and electro optical device

ActiveUS20090225268A1Reliable electrical connectionIncrease the number ofDischarge tube luminescnet screensFinal product manufactureElectricity

Owner:SEIKO EPSON CORP

Mounting structure and electro optical device

ActiveUS7868989B2Reliable electrical connectionIncrease the number ofGas-filled discharge tubesDischarge tube luminescnet screensEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Pixel limiting structure, OLED structure, and display panel

ActiveCN109994529AIncrease width sizeReduce width sizeSolid-state devicesSemiconductor devicesLuminescenceBrightness perception

The embodiment of the invention relates to a pixel limiting structure, an OLED structure, and a display panel. The pixel limiting structure includes a first pixel limiting layer and a second pixel limiting layer; the first pixel limiting layer includes a first pixel limiting portion and a first stretching portion; the second pixel limiting layer includes a second pixel limiting portion and a second stretching portion; the first pixel limiting portion and the second pixel limiting portion together limit a pixel opening; the first stretching portion and the second stretching portion are separately located on two opposite sides of the same pixel opening; and the first pixel limiting portion and the second pixel limiting portion have an overlapping region on the other two opposite sides of thesame pixel opening. The invention can reduce the difference of the luminescence brightness of the OLED structure before and after stretching, and improve the stretching performance and display effectof the OLED structure.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

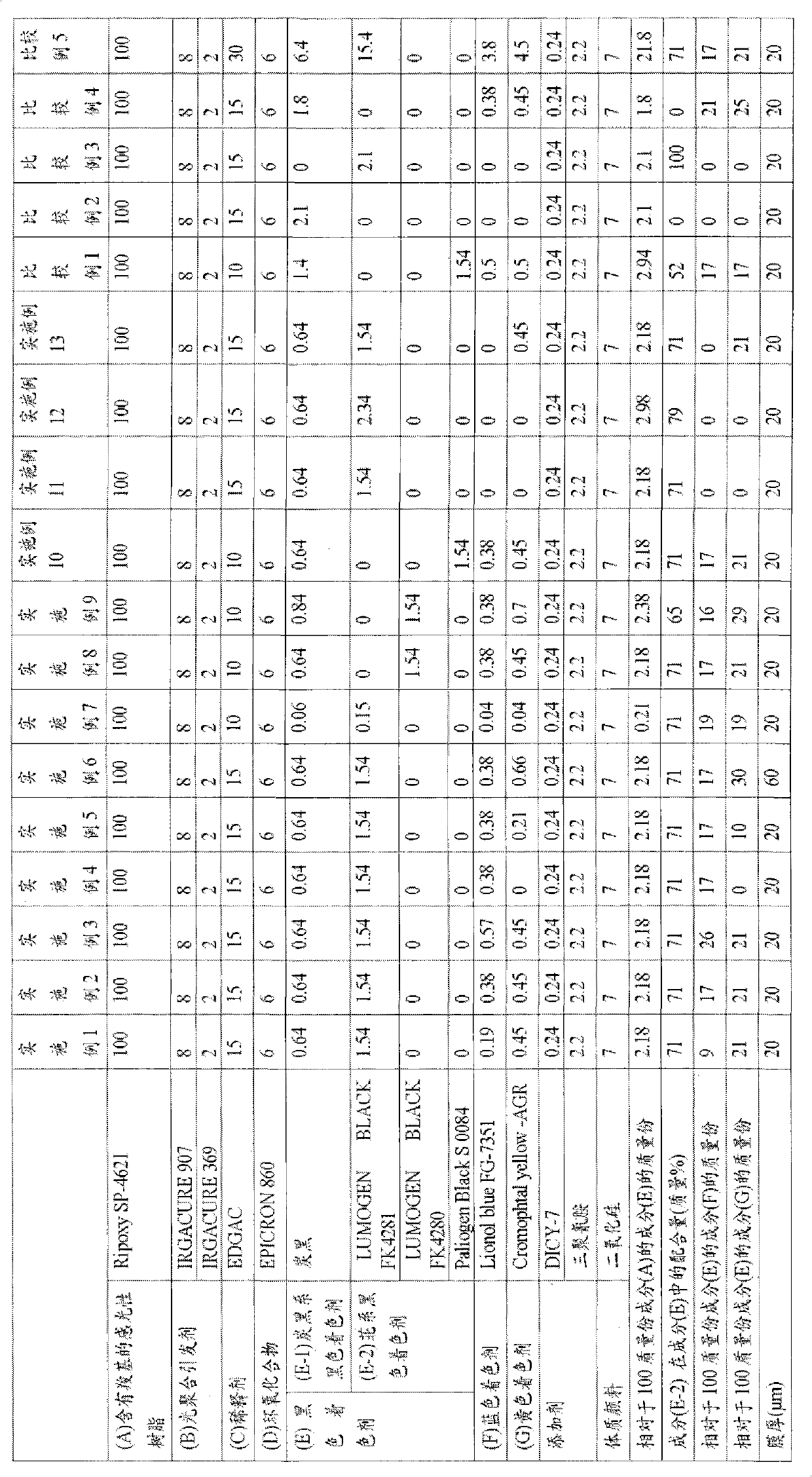

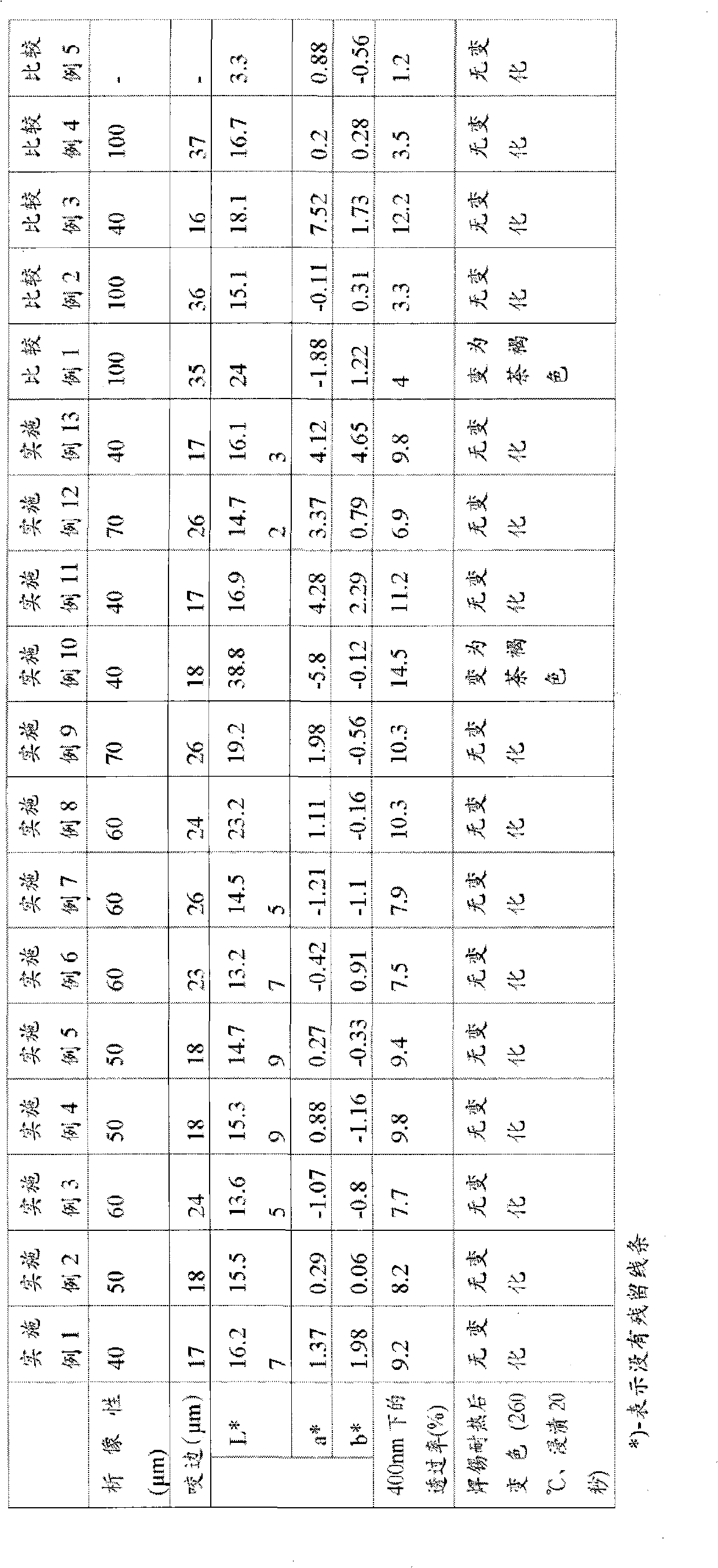

Black curable resin composition

ActiveCN102385244AInhibit sheddingAvoid defectsPrinted circuit detailsPhotosensitive materials for photomechanical apparatusPeryleneDiluent

The invention aims to provide a black curable resin composition that is excellent in resolution characteristics and easy for adjustment to a black color, and allows color tone variation after heat treatment to be prevented. The black curable resin composition includes: a photosensitive carboxylic resin (A); a photopolymerization initiator (B); a diluent (C); an epoxy compound (D); and a black colorant (E). The black curable resin composition is characterized in that the black colorant (E) includes a carbon black-based black colorant (E-1) and a perylene-based black colorant (E-2), and contains 53 mass% or more of the perylene-based black colorant (E-2).

Owner:TAMURA KK

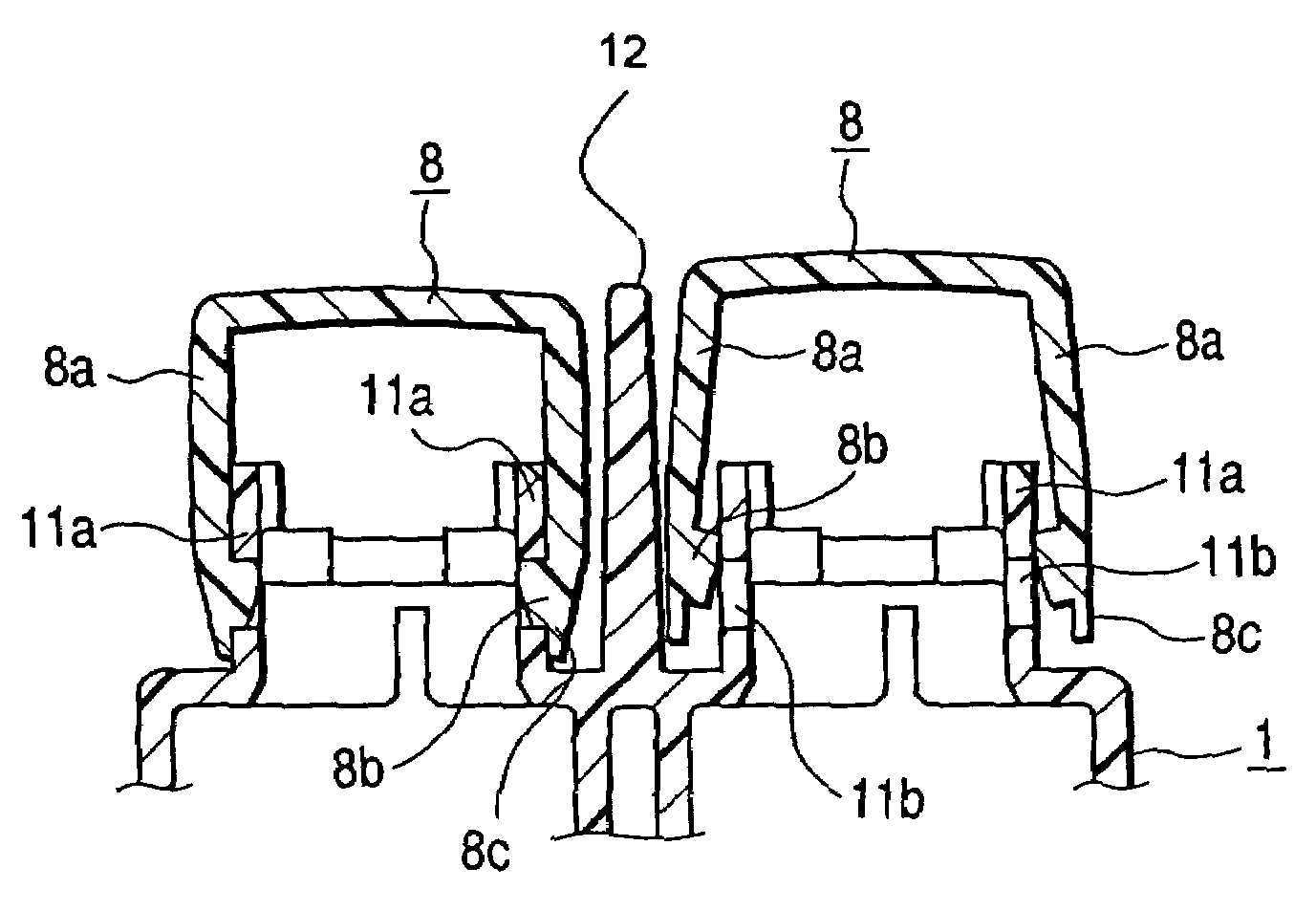

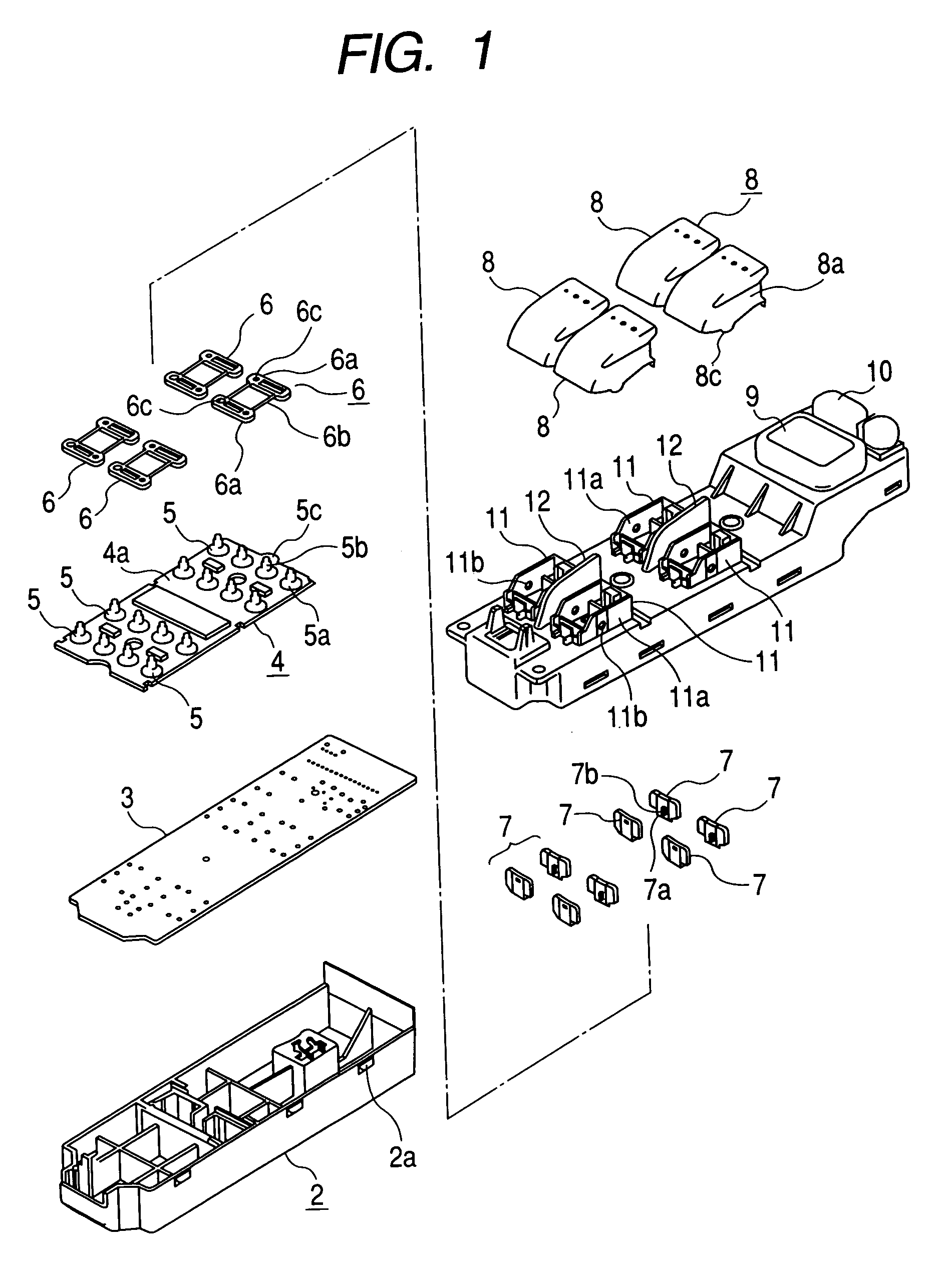

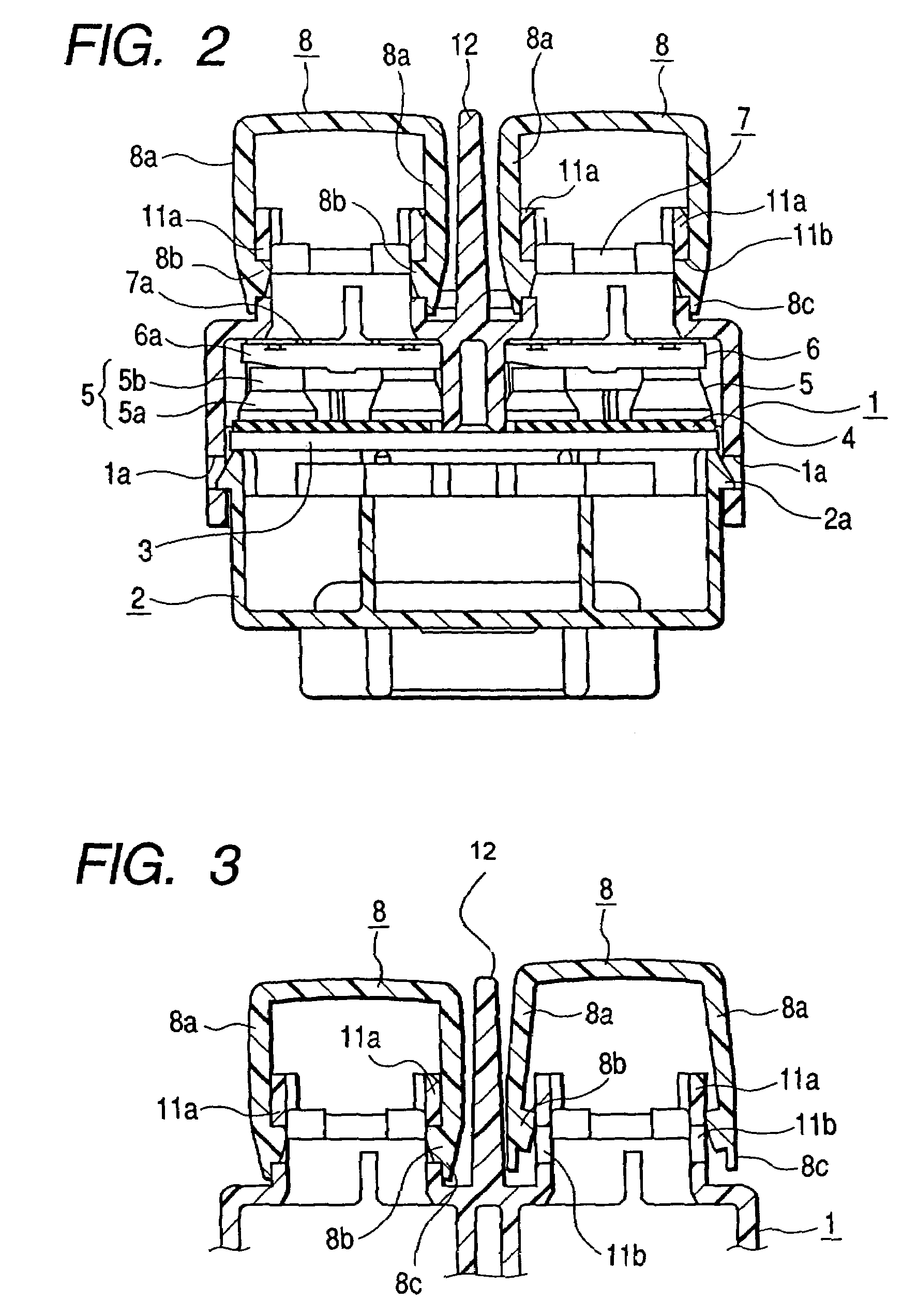

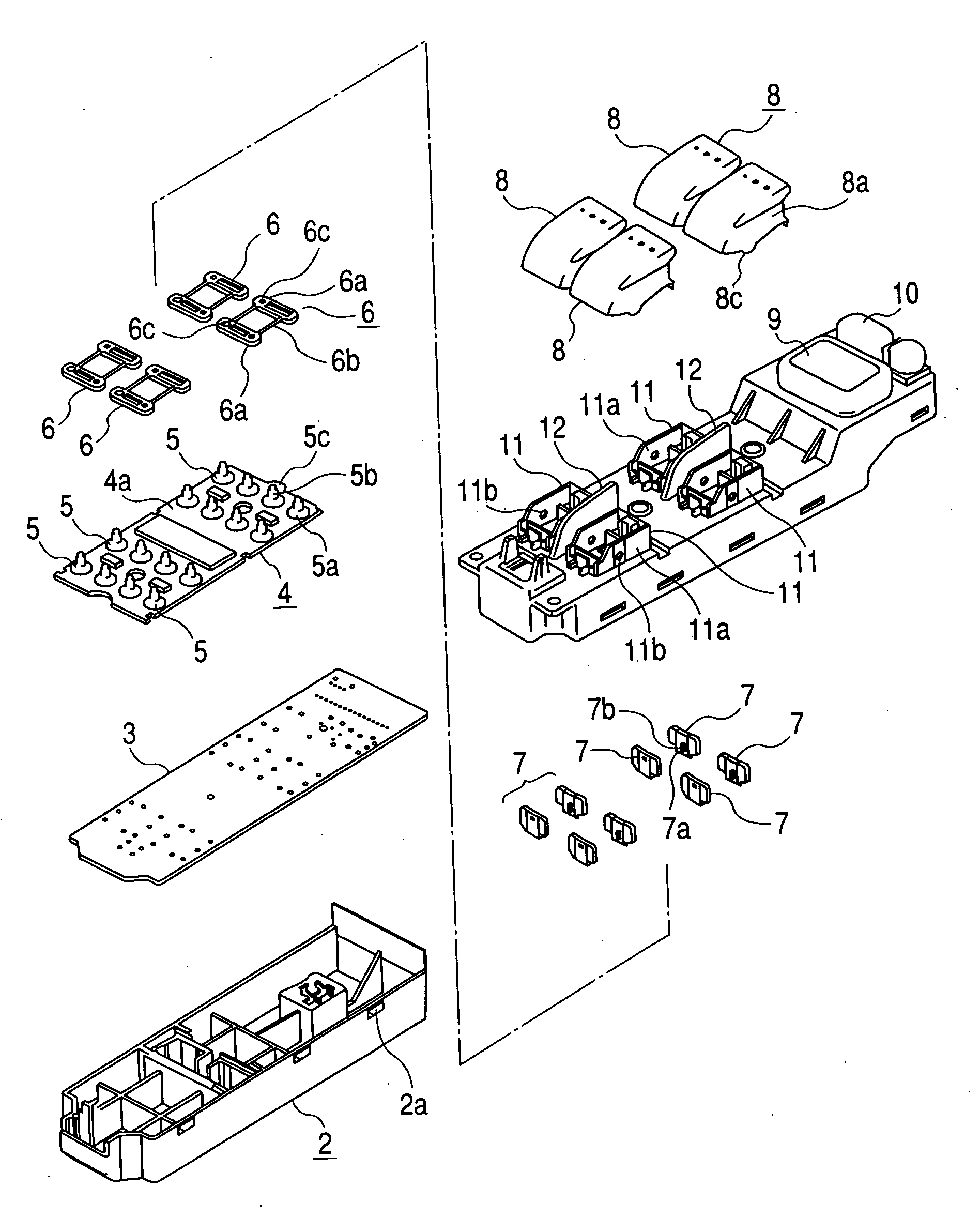

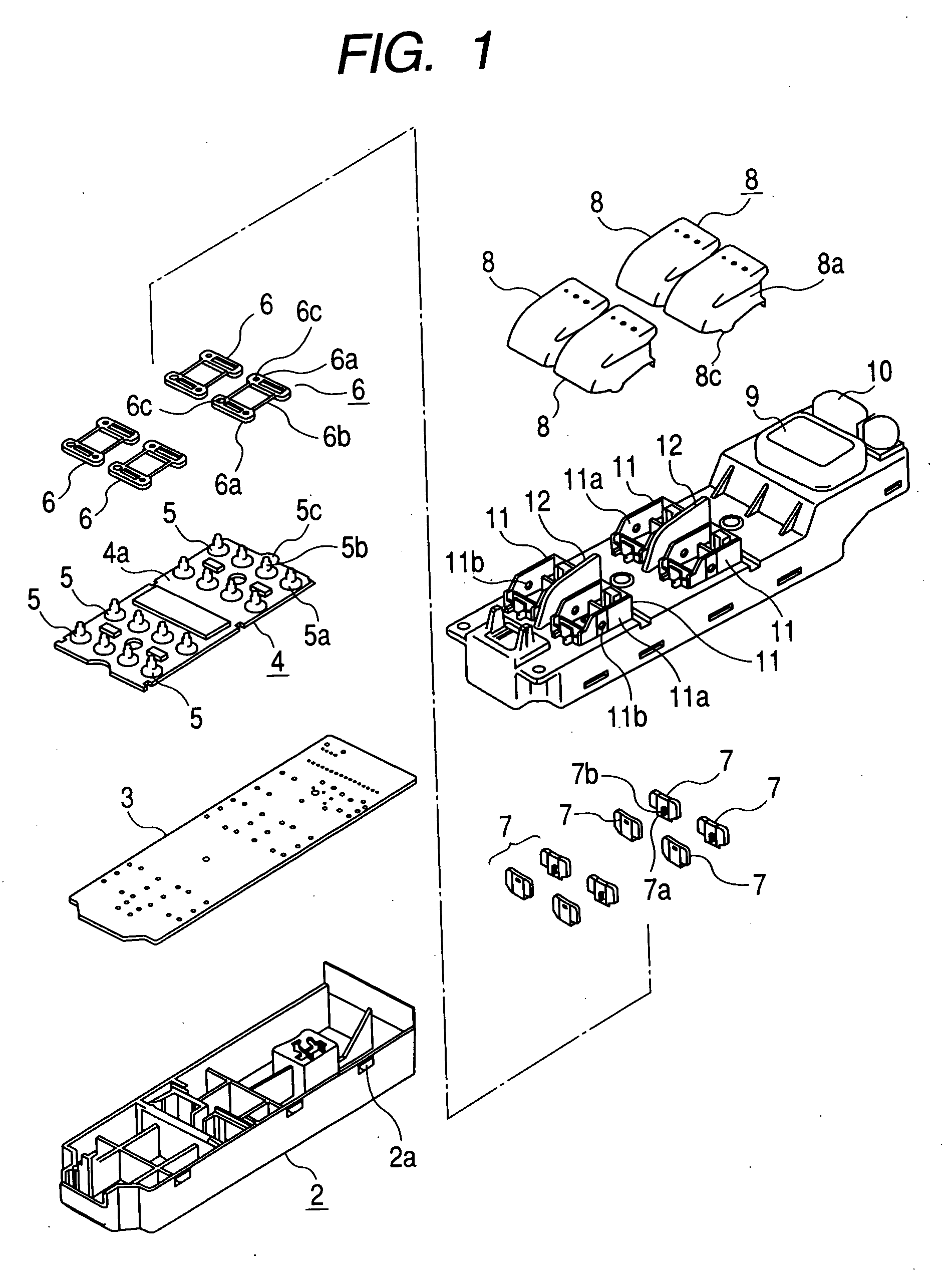

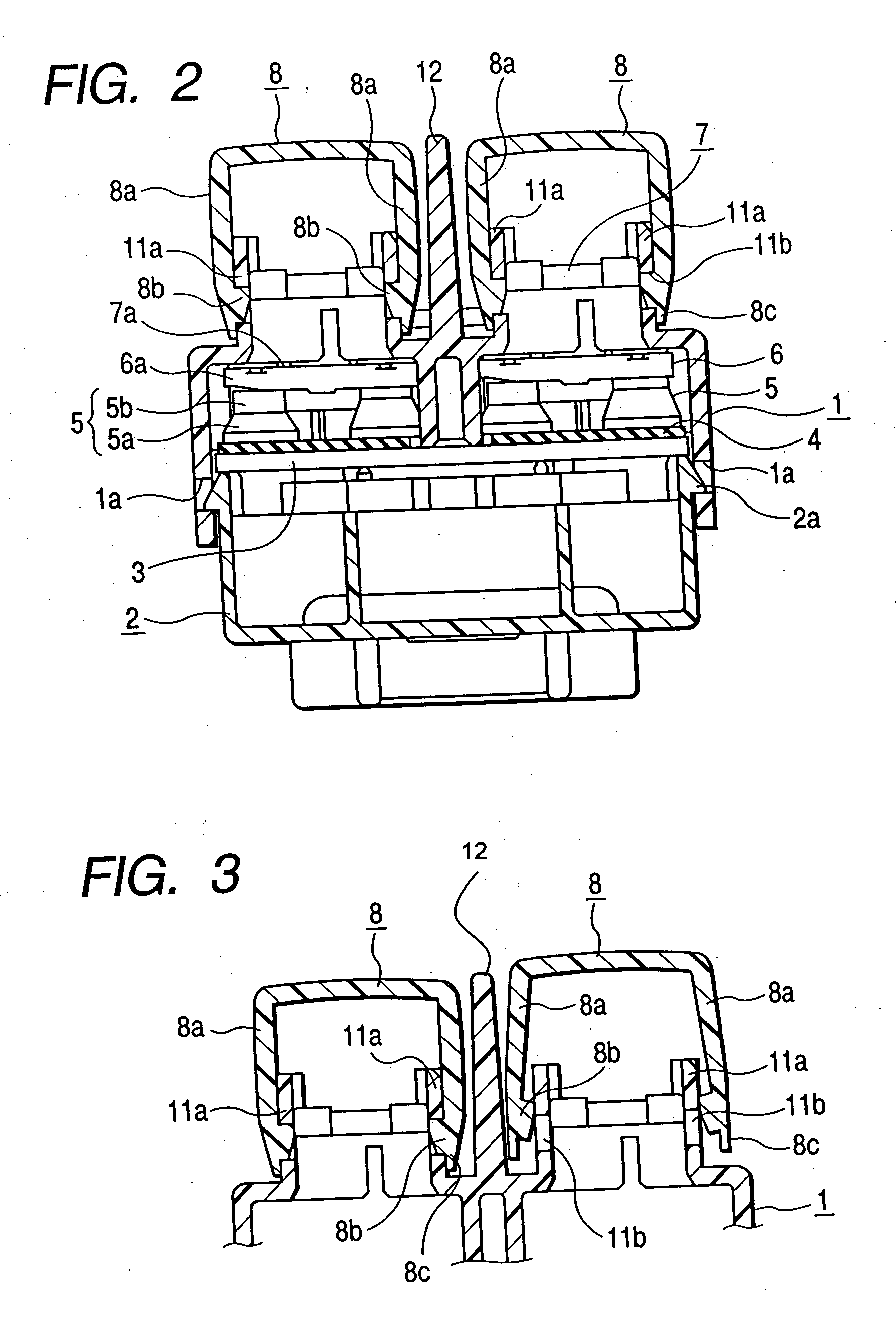

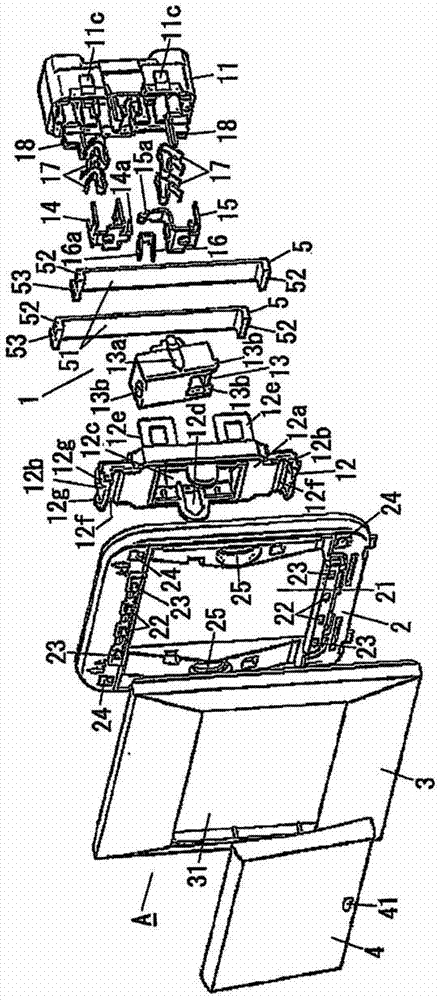

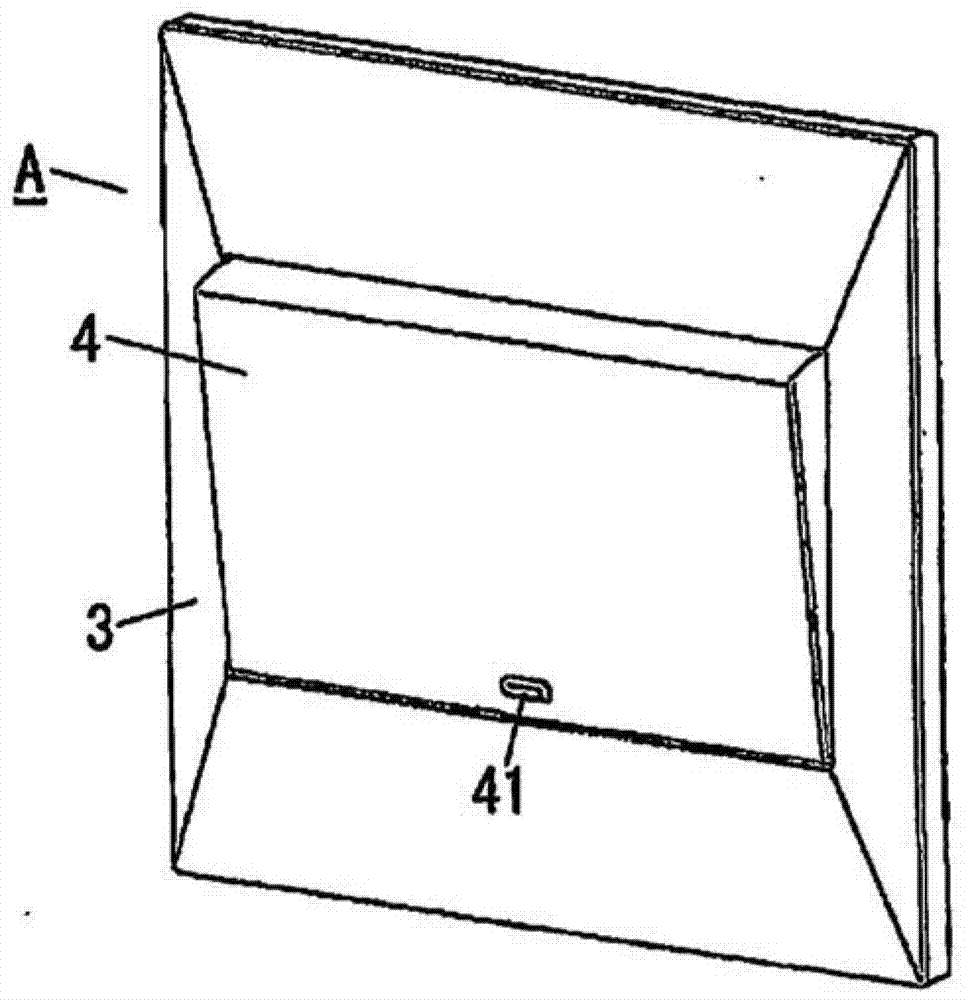

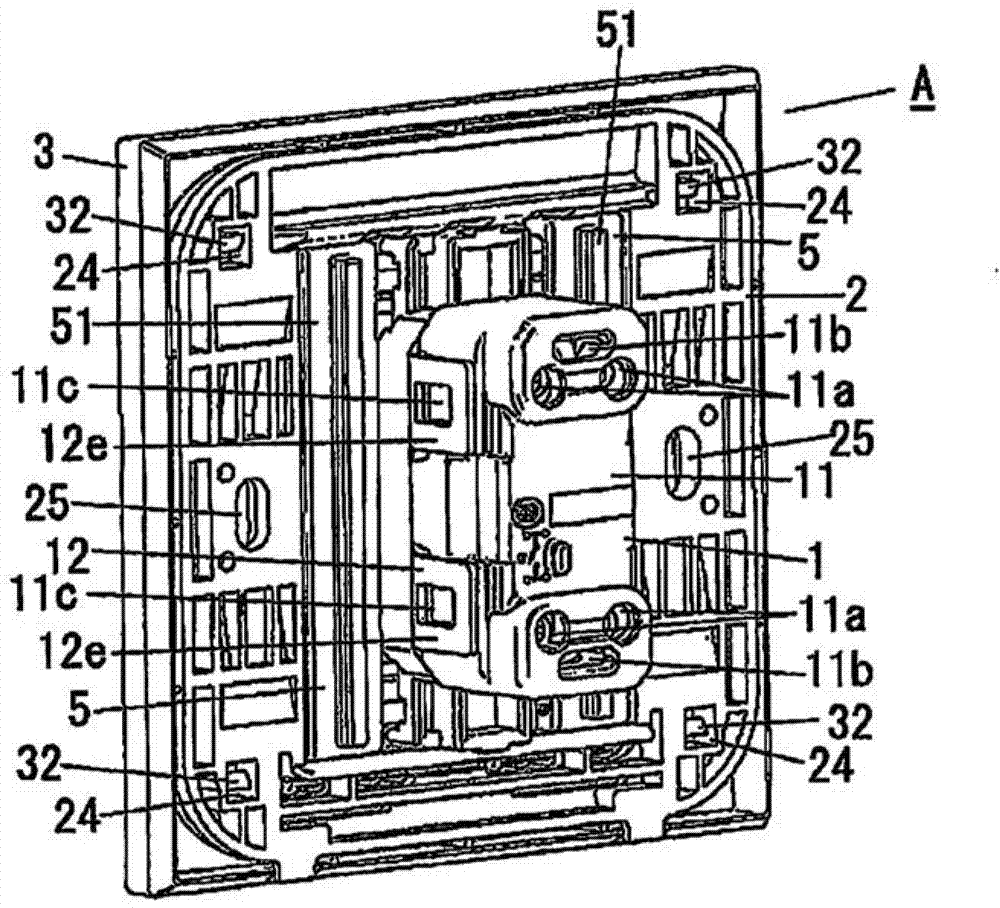

Rocking operation type electric component

ActiveUS7109428B2Mechanical strength is securedReduce the possibilityContact mechanismsKey modulesElectric signalElectrical element

A rocking operation type electric component is presented that includes: an operation knob that has a bottomed case-shaped configuration and is rockably held; a signal generating unit that includes a movable element pressed and driven by the operation knob and generates a different electric signal in response to a position change of the movable element; and a case on which a mounting frame for pivotally supporting the operation knob is protrusively provided formed and in which the signal generating unit is received. A pair of rotation shafts which face each other are protrusively formed on inner wall portions of the operation knob, respectively. Through-holes are respectively formed in a pair of wall portions of the mounting frame which face each other. The rotation shafts are fitted into the through-holes from the outside of the mounting frame to be rotatably supported by the mounting frame.

Owner:ALPS ALPINE CO LTD

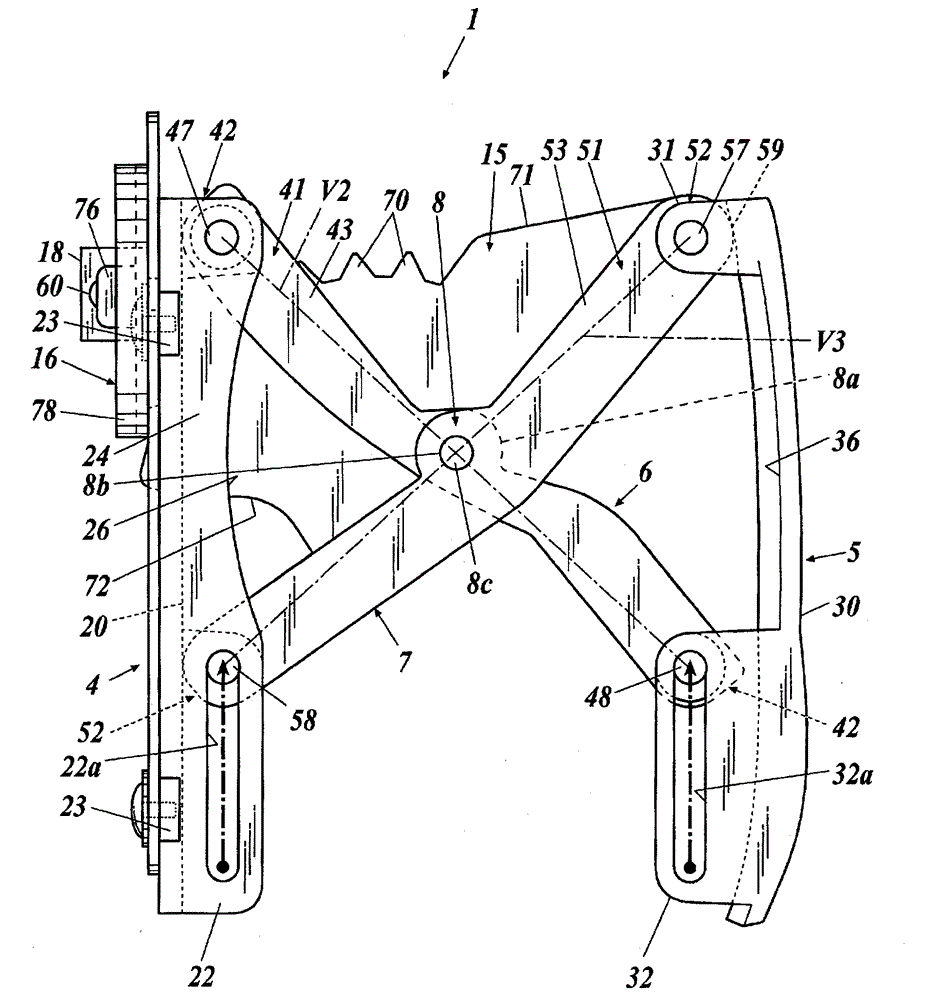

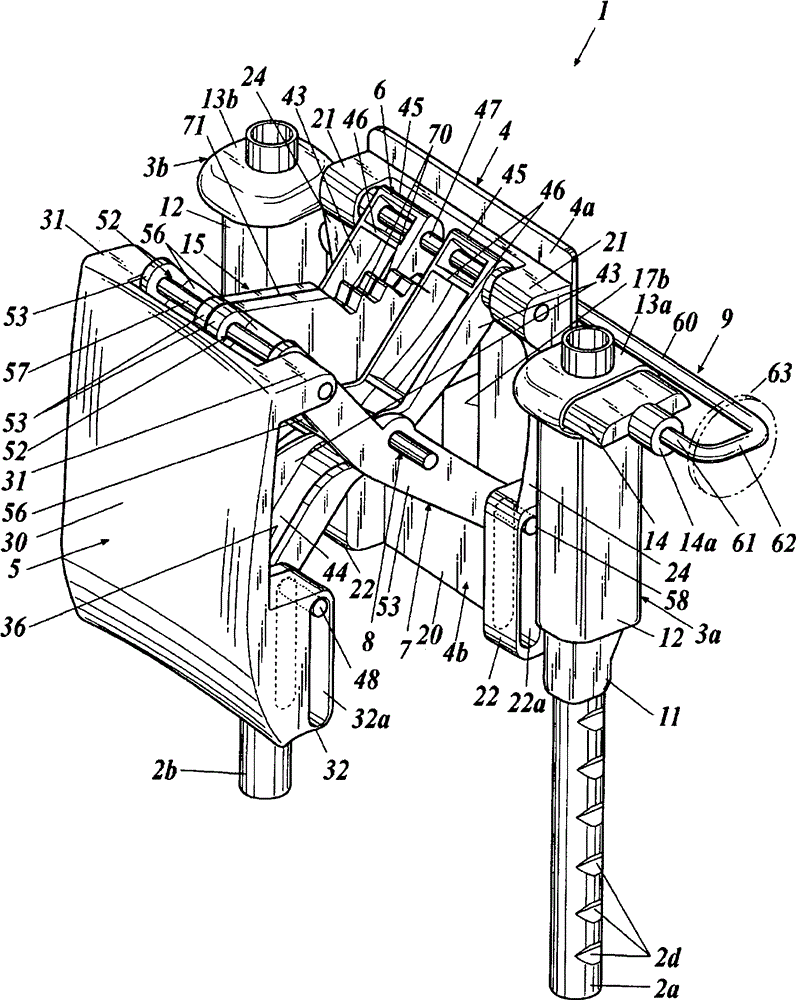

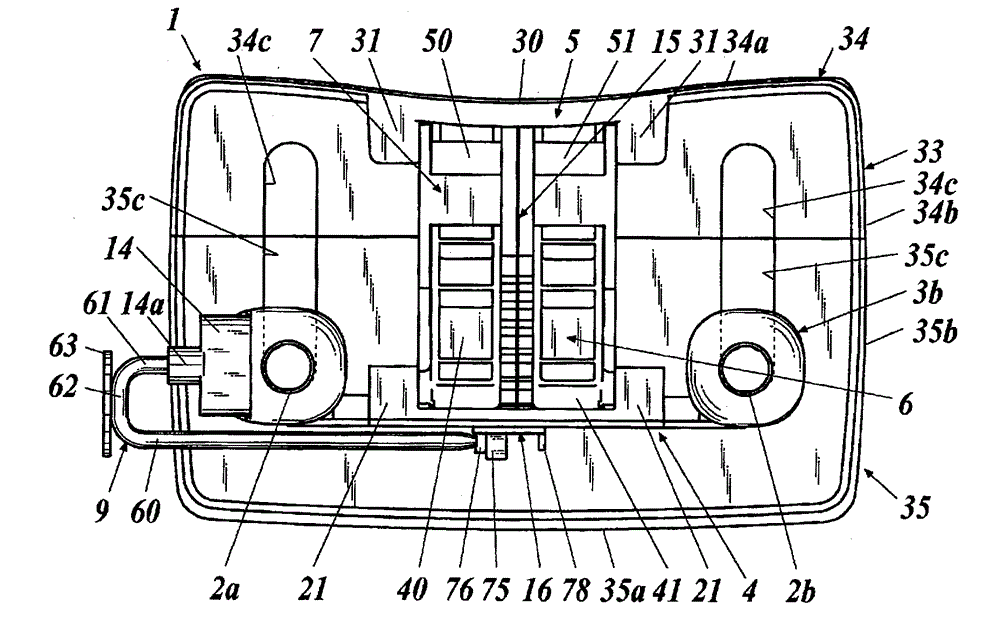

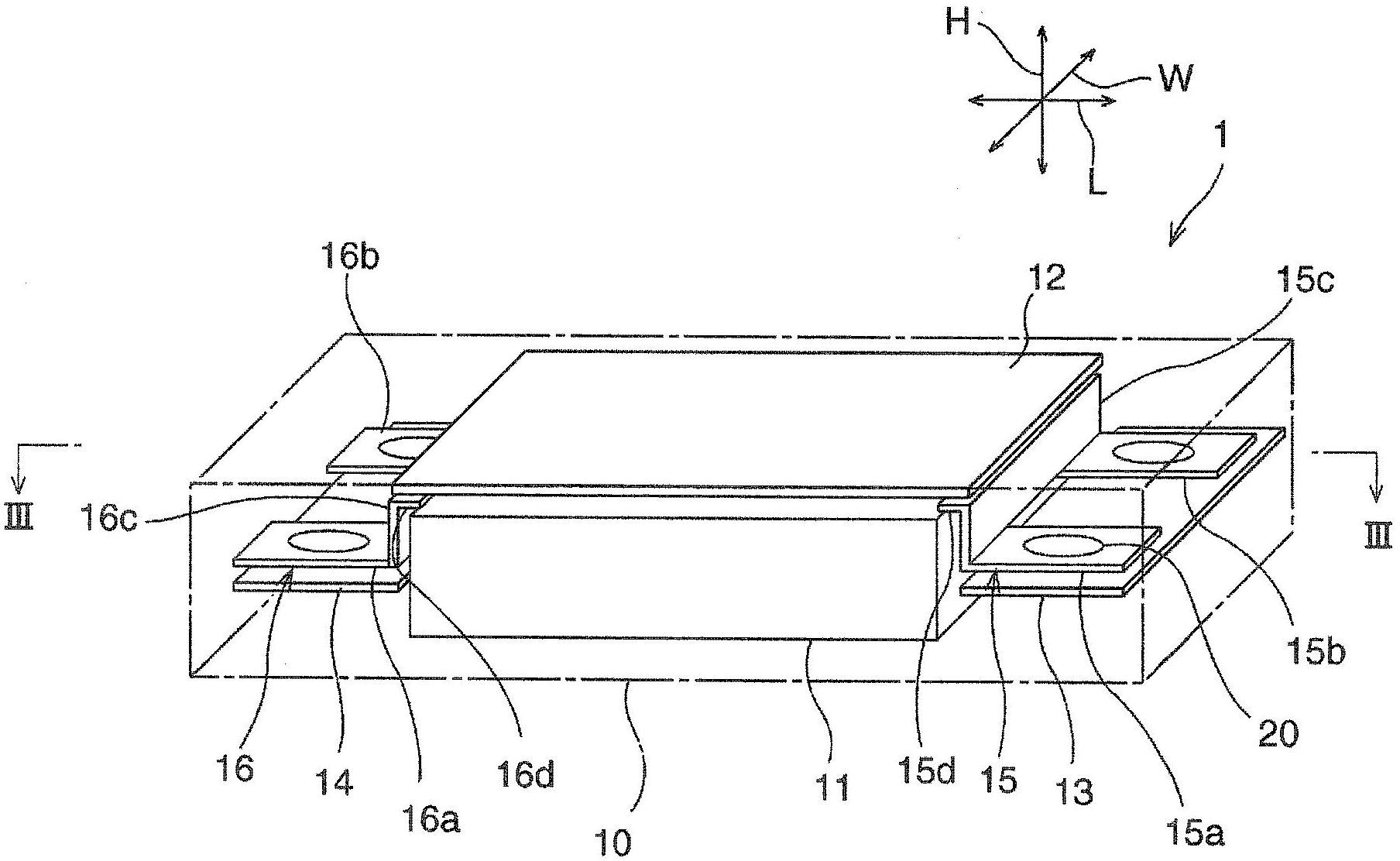

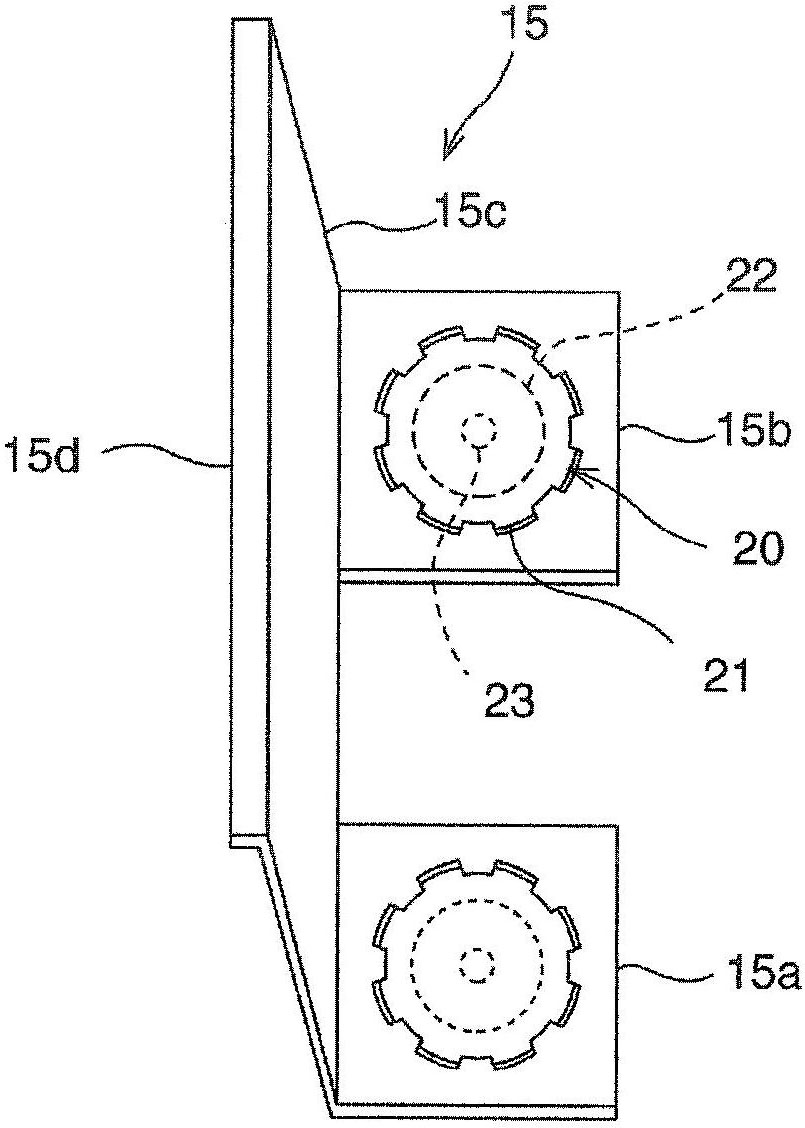

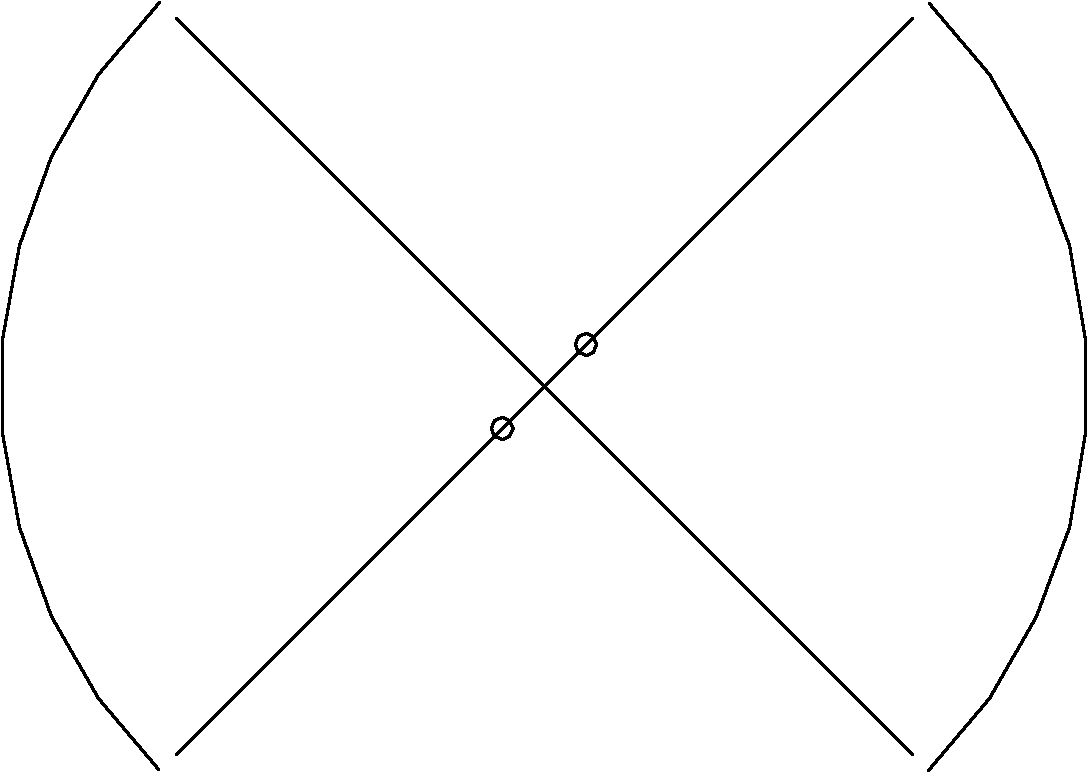

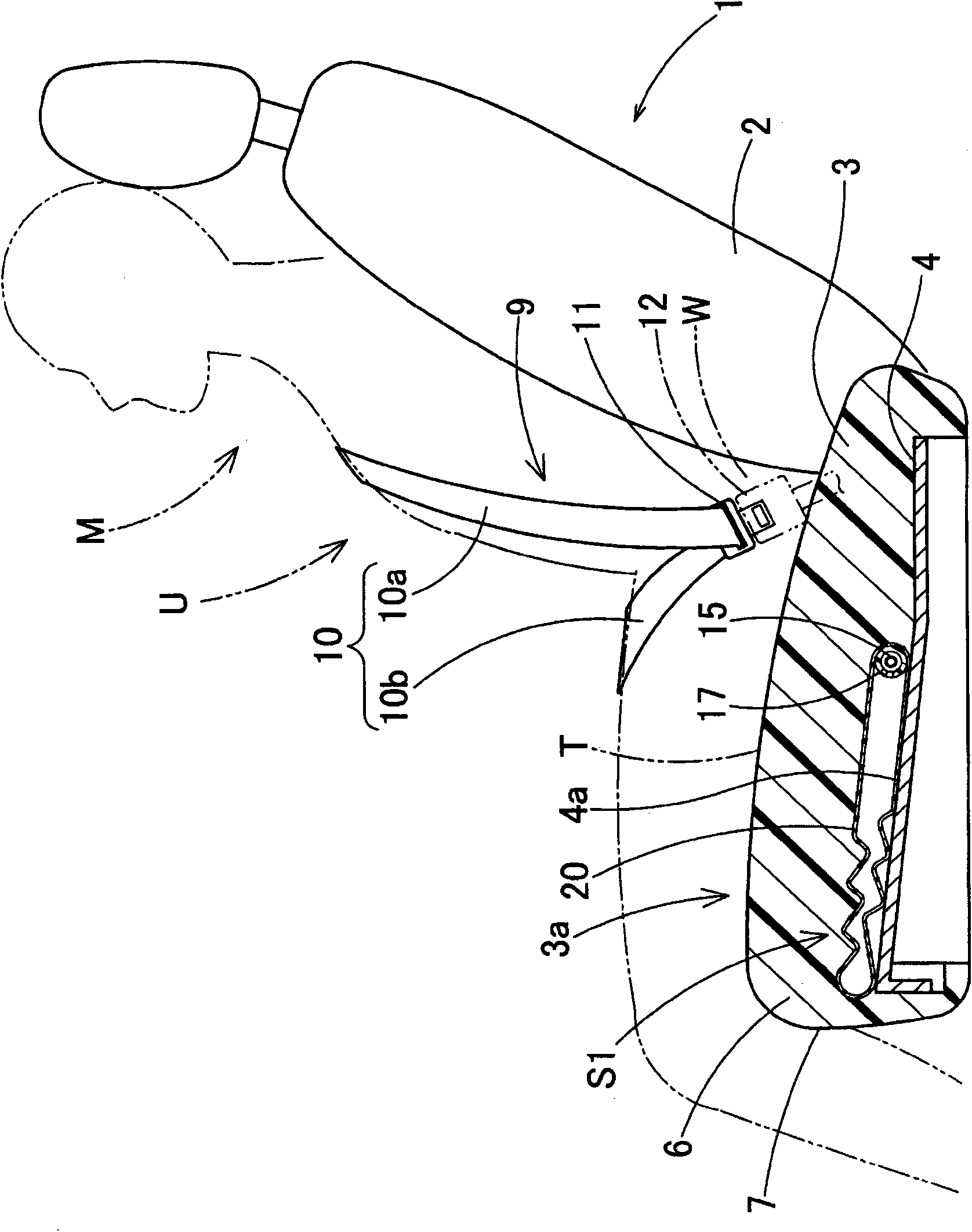

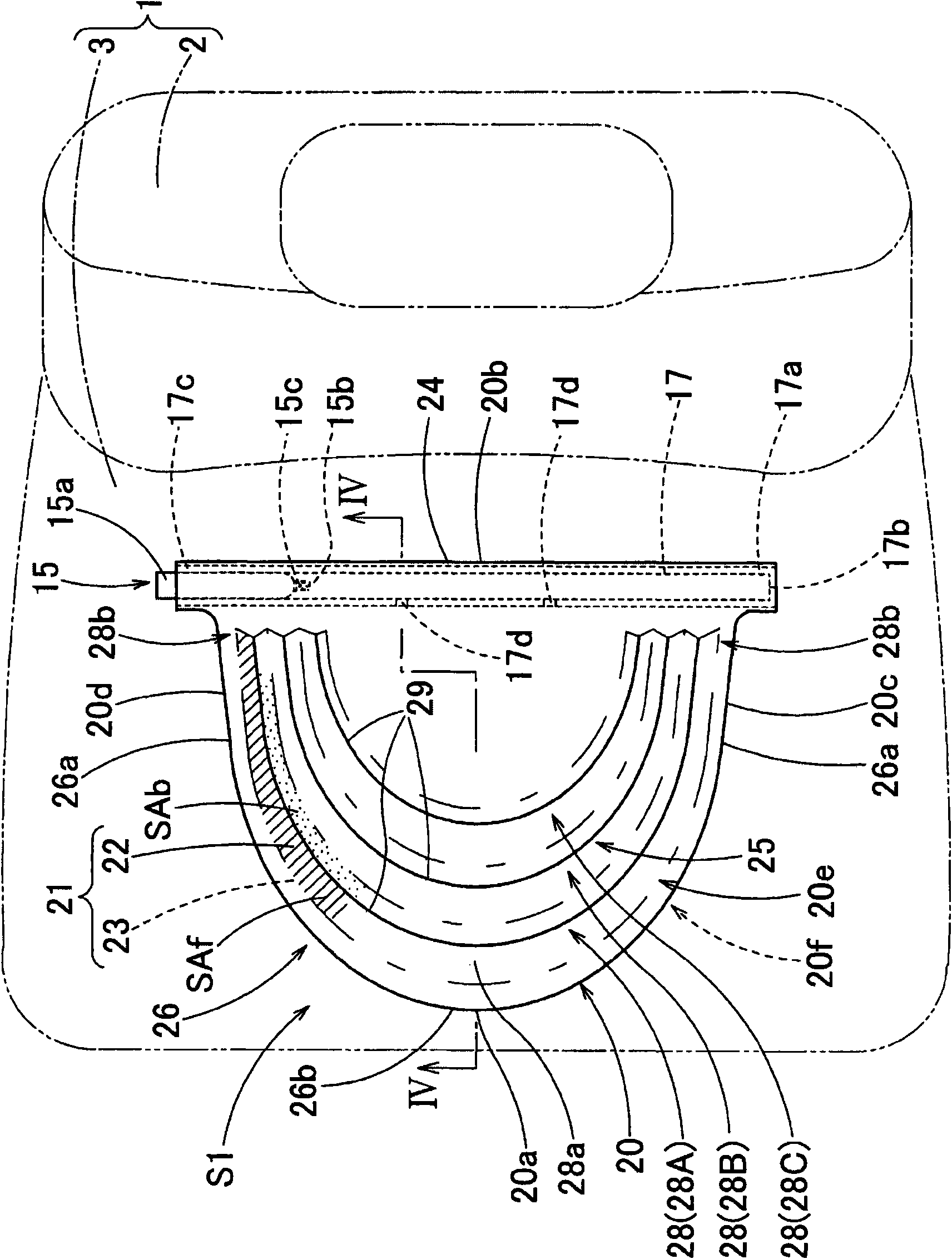

Head rest

The purpose of the present invention is to provide a head rest in which the position of a movable member can be adjusted in stages forwards and backwards during normal operation. This head rest (1) is provided with a first and second head rest pillar (2a, 2b), a fixed member (4) provided between the first and second head rest pillars (2a, 2b), a movable member (5) which can move in the direction forwards away from or backwards returning towards the fixed member (4), an X-link mechanism which links the fixed member (4) and the movable member (5) and which has an inside link (6) and an outside link (7) rotatably connected through a cross connection unit (8) in the center, and a forward-backward lock mechanism which comprises an engaged unit (15) and a locking member (16) for engaging said engaged unit (15) and which locks, and releases locking of, movement of the movable member (5) forwards and backwards relative to the fixed member (4).

Owner:TS TECH CO LTD

Rocking operation type electric component

ActiveUS20060054475A1Mechanical strength is securedReduce the possibilityContact mechanismsKey modulesEngineeringElectronic component

A rocking operation type electric component is presented that includes: an operation knob that has a bottomed case-shaped configuration and is rockably held; a signal generating unit that includes a movable element pressed and driven by the operation knob and generates a different electric signal in response to a position change of the movable element; and a case on which a mounting frame for pivotally supporting the operation knob is protrusively provided formed and in which the signal generating unit is received. A pair of rotation shafts which face each other are protrusively formed on inner wall portions of the operation knob, respectively. Through-holes are respectively formed in a pair of wall portions of the mounting frame which face each other. The rotation shafts are fitted into the through-holes from the outside of the mounting frame to be rotatably supported by the mounting frame.

Owner:ALPS ALPINE CO LTD

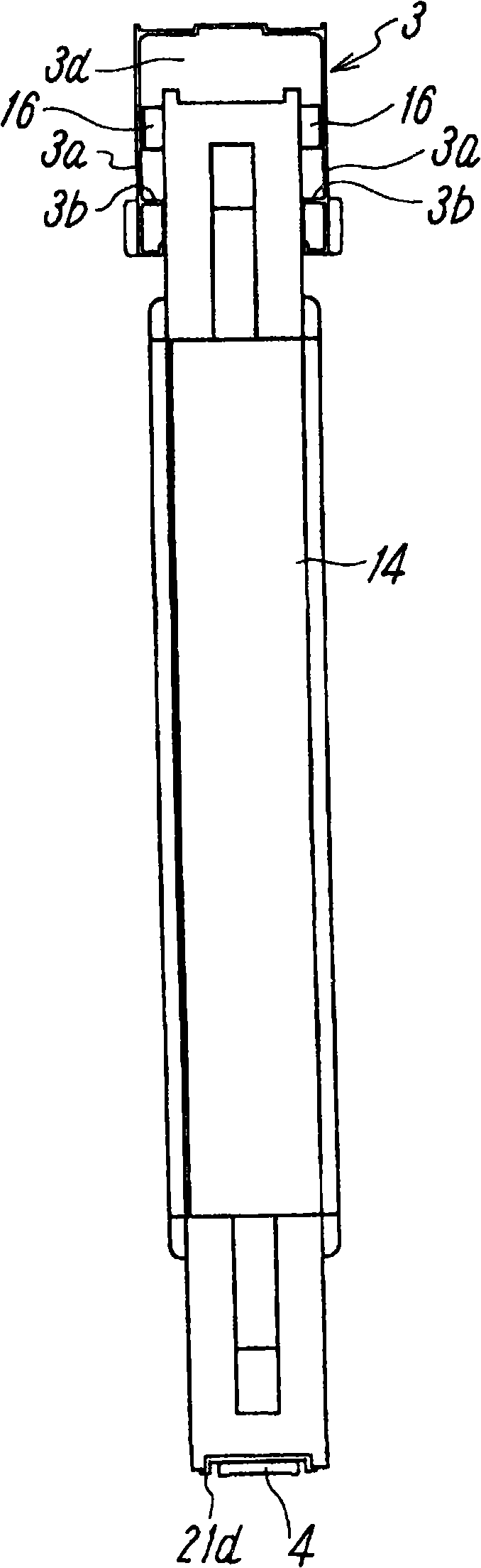

Electronic device with touch panel

InactiveCN102597932AIncrease width sizeInput/output processes for data processingVibration transmissionComputer science

Provided is an electronic device with a touch panel, wherein the device can reliably inform an operator of the completion of input, etc., and has a reduced thickness. The electronic device (1) with a touch panel is provided with a display panel (11), the touch panel (12), a vibratory element (20), and vibration transmission members (15, 16). The touch panel (12) is arranged above the display panel (11). The vibratory element (20) is arranged on the side of the display panel (11). The vibration transmission members (15, 16) transmit vibration of the vibratory element (20) to the touch panel (12). The vibratory element is arranged so that the vibration direction of a vibration plate (22) is parallel with the direction of the normal line of the display panel (11).

Owner:MURATA MFG CO LTD

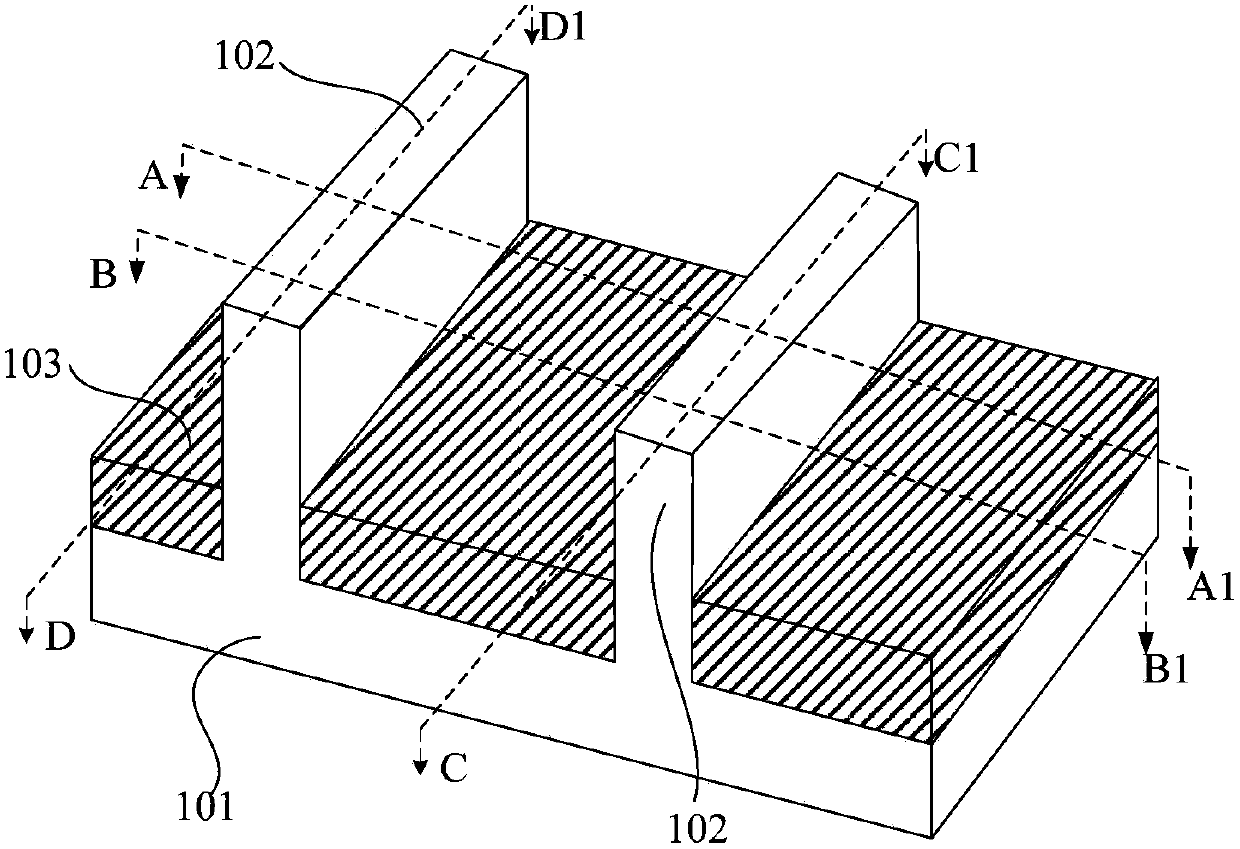

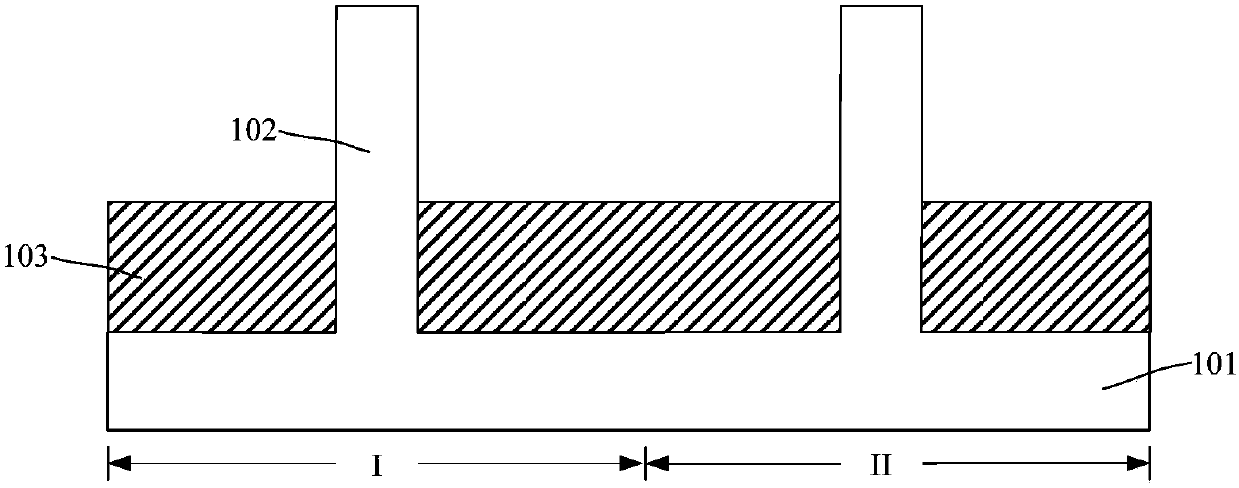

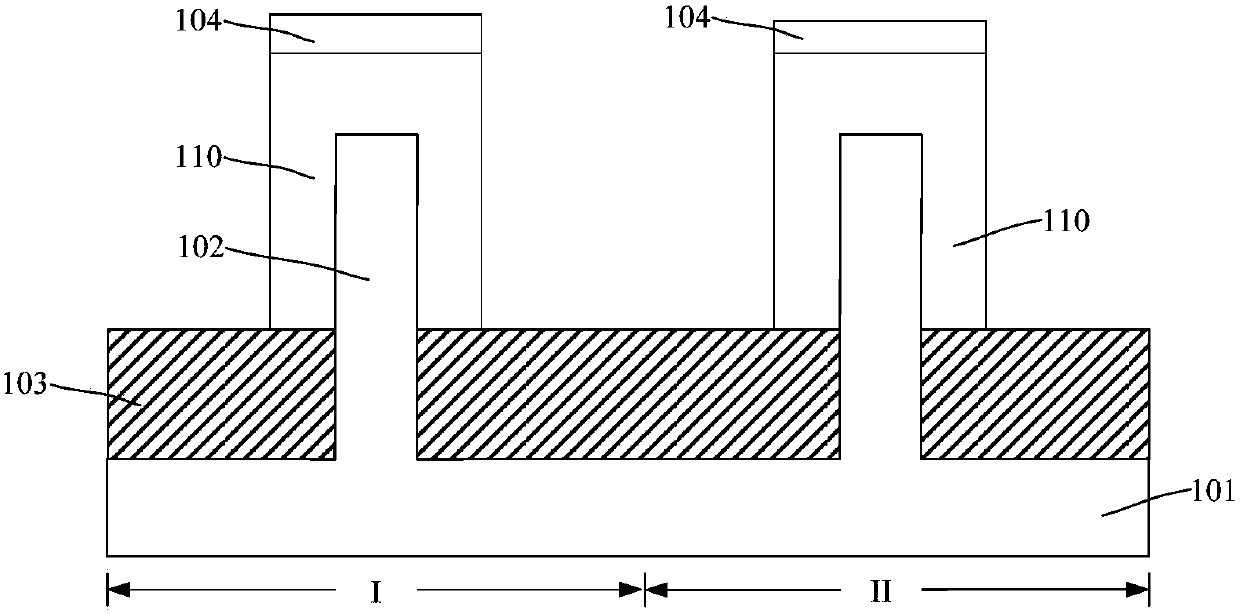

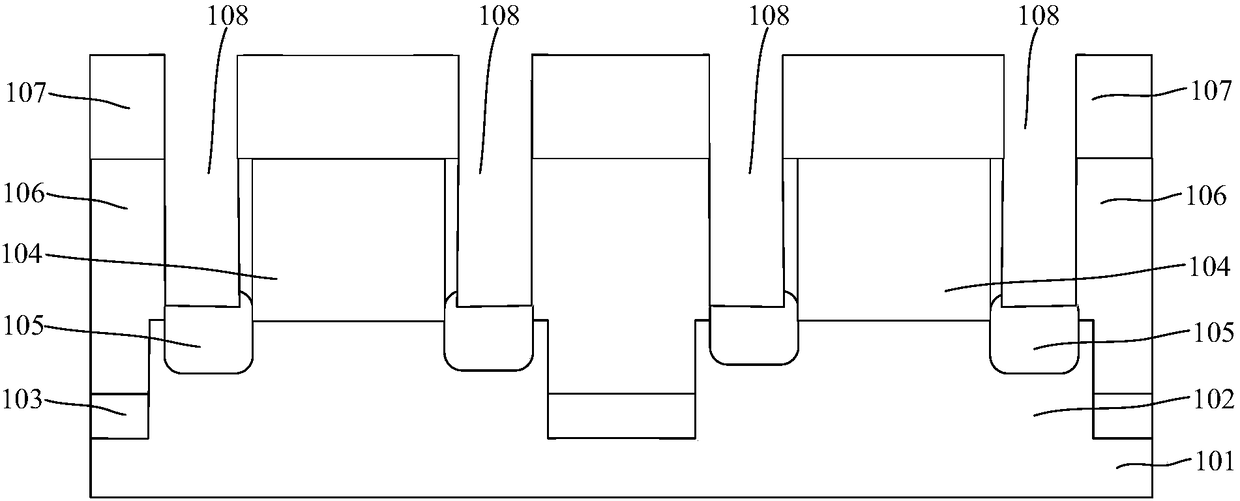

Fin field effect transistor and forming method thereof

ActiveCN107591436AImprove electrical performancePrevent proliferationSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical performanceField-effect transistor

The invention discloses a fin field effect transistor and a forming method thereof. The forming method comprises steps: a substrate comprising an NMOS area is provided, wherein convex fin parts are arranged on the substrate, isolation structures covering the side walls of the fin parts are arranged on the substrate, and the top part of the isolation structure is lower than the top part of the finpart; a gate structure is formed on the isolation structure and crosses the fin part; an N area mask lateral wall is formed on the fin part side wall in the NMOS area; the partial thickness of the finparts at two sides of the gate structure in the NMOS area is etched and removed, and the NMOS area fin part after etching and the N area mask lateral wall form an N area groove; an intrinsic blockinglayer is formed on the fin part exposed on the side wall of the N area groove; and an N-type doped epitaxial layer fully filling the N area groove is formed on the intrinsic blocking layer. Doped ions in the N-type doped epitaxial layer can be prevented from being diffused in a channel area below the gate structure, and the electrical performance of the formed fin field effect transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

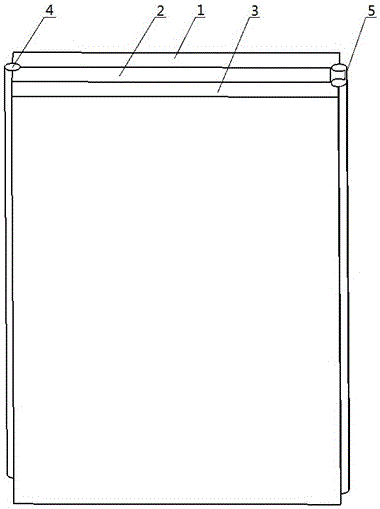

Foldable screen device

InactiveCN101316979AWidth size limitRemove restrictionsShutters/ movable grillesInsect protectionMechanical engineering

Owner:SEIKI HANBAI CO LTD

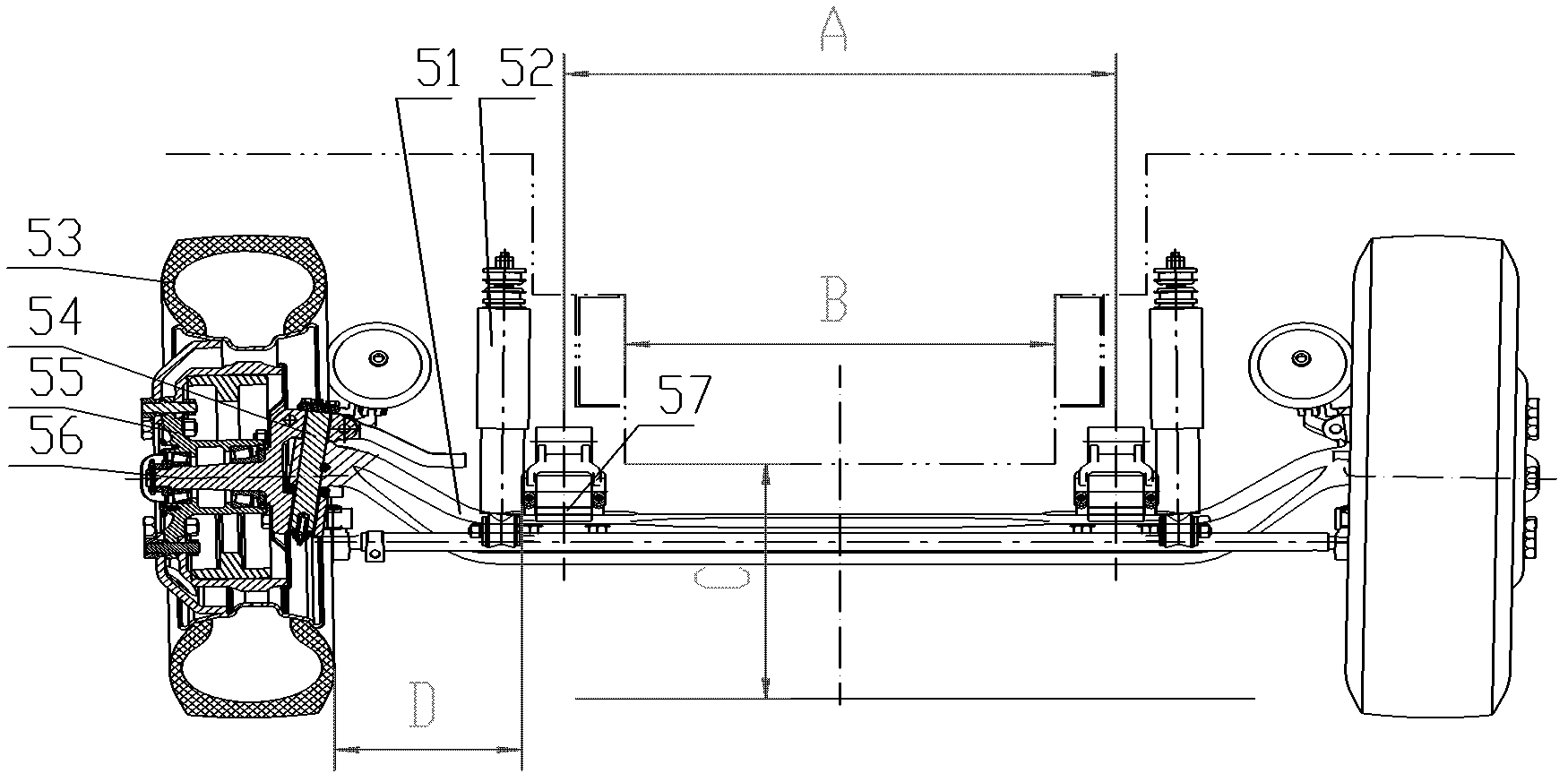

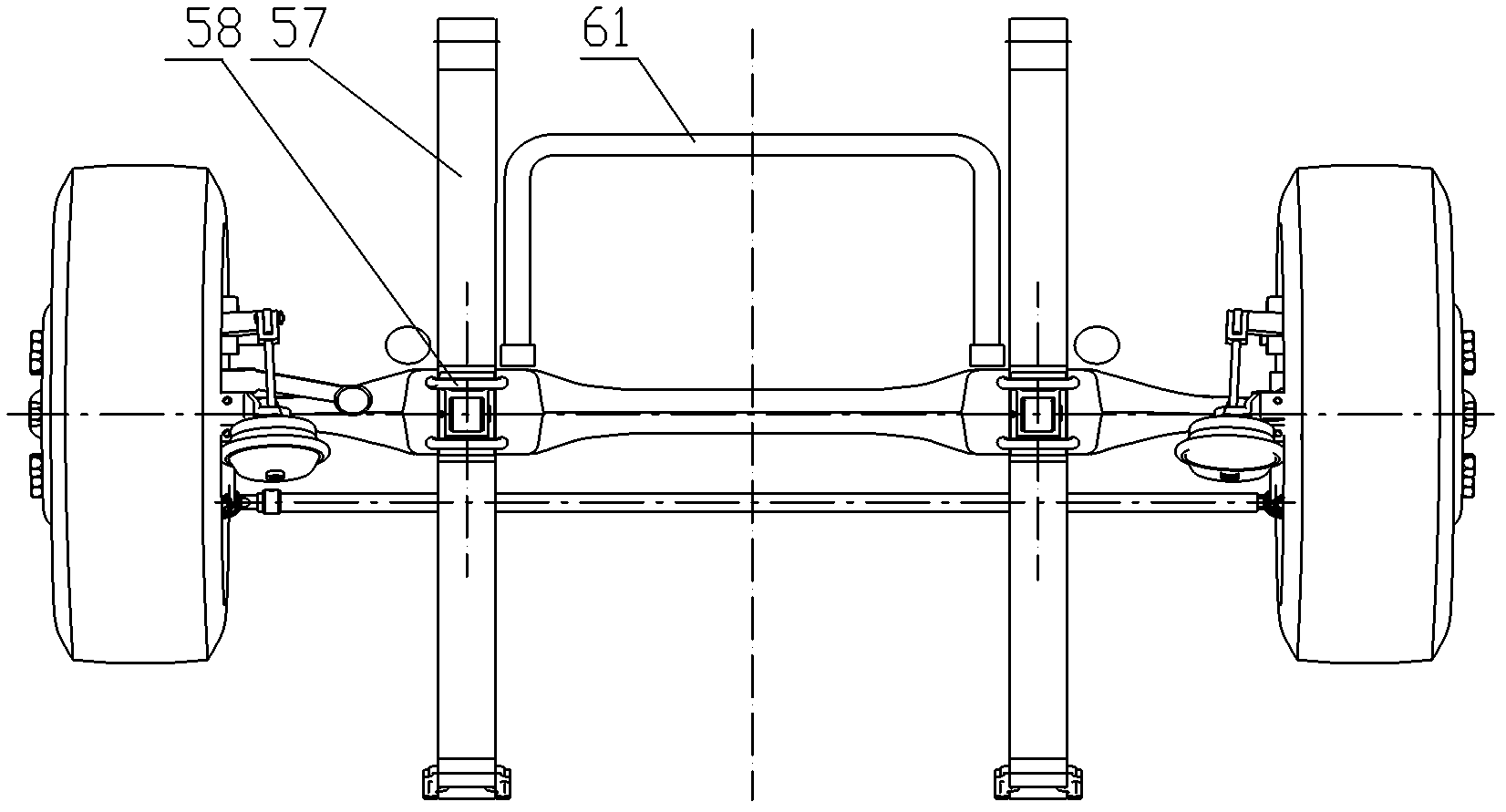

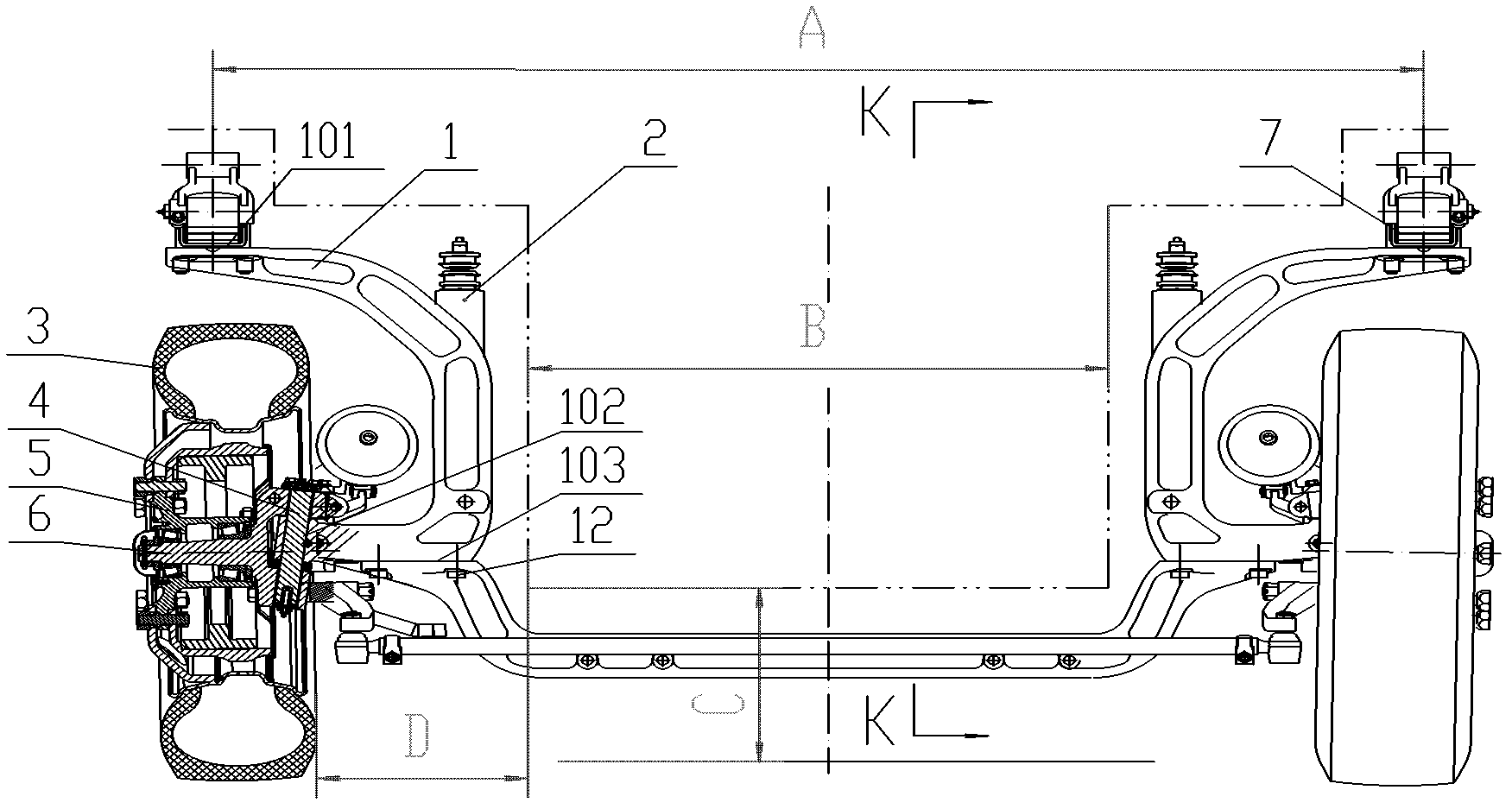

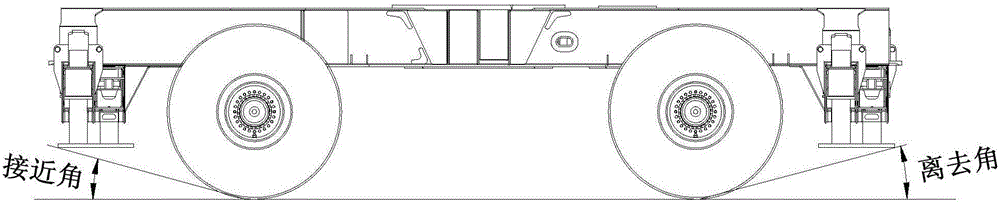

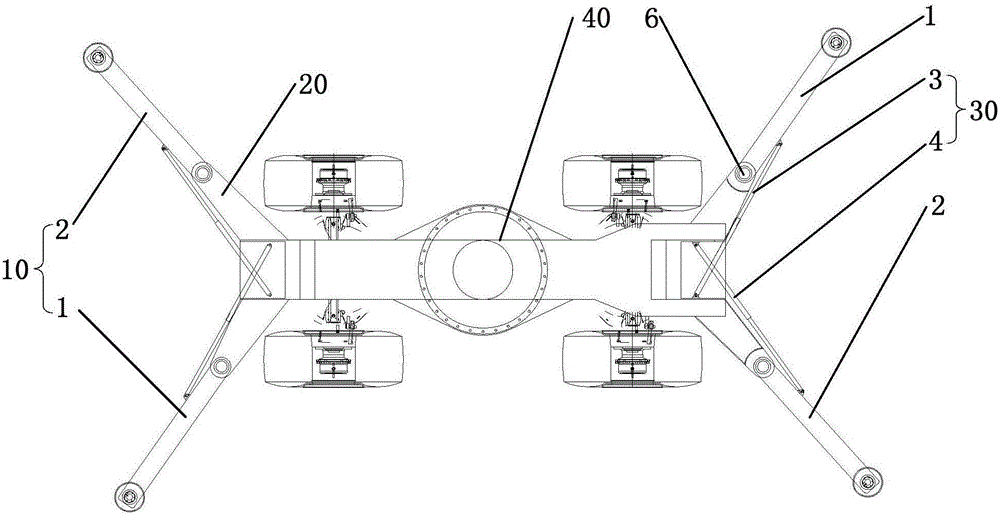

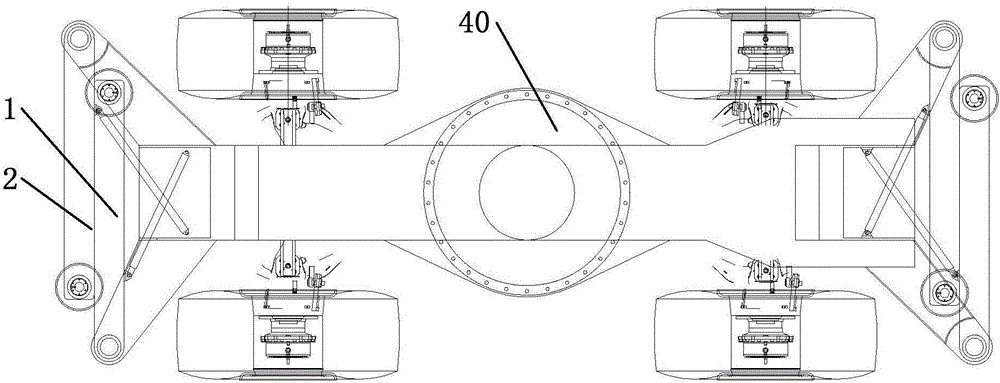

Vehicle suspension system and vehicle with same

InactiveCN103213468AIncrease widthLarge steering angleInterconnection systemsPivoted suspension armsTurn angleDrop structure

The invention provides a vehicle suspension system and a vehicle with the same. The vehicle suspension system comprises an axle and an elastic element which is arranged on the axle, wherein a bearing surface on the axle for mounting the elastic element is arranged at a position above the tops of wheels, so that the elastic element is arranged above the tops of the wheels. The vehicle suspension system is preferably a front suspension system, and the axle is preferably a front axle. C-shaped beam structures can be formed on the two sides of the axle respectively, the bearing surface of the elastic element is arranged at the upper ends of the C-shaped beam structures, and the lower ends of the C-shaped beam structures are provided with main pin mounting holes. A large-drop structure can be adopted at the middle section of the axle. According to the vehicle suspension system and the vehicle, the width of a passenger passage and the turning angle of the wheels can be greatly increased, large roll stiffness can be obtained under the condition that no lateral stabilizer bar is arranged, and meanwhile, one-step low floor can be realized.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

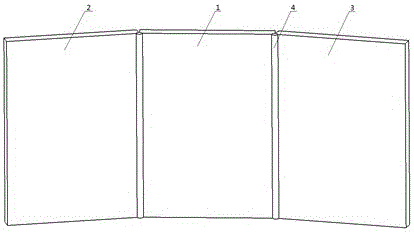

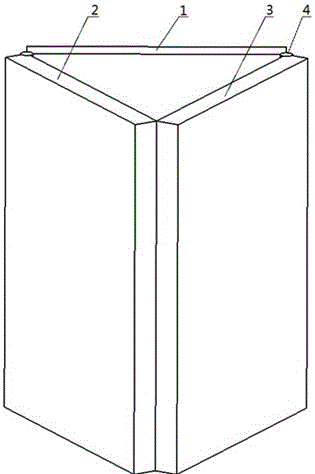

Sliding block type three-screen display equipment

The invention belongs to the field of electronic display and relates to sliding block type three-screen display equipment. The sliding block type three-screen display equipment comprises an upper cover, a main screen, a secondary screen I, a secondary screen II, a sliding block I and a sliding block II. Because of a sliding chute for the sliding block I and a sliding chute for the sliding block II, which are formed in the upper cover, three screens are closed and then are completely attached, so that an occupied space after the display equipment is closed is reduced. Meanwhile, no ordering relation exists when the display equipment is opened and closed, and the experience degree of a user is improved; a guiding surface I of the sliding block II and a guiding surface II of the sliding block II are arranged on the sliding block II, so that width sizes of the screens are equal, and the range of the display equipment is widened; the sizes of two ends of the sliding chute for the sliding block I are smaller than the size of the sliding block I by 0.2mm, and the sizes of two ends of the sliding chute for the sliding block II are smaller than the size of the sliding block II by 0.2mm, so that the display equipment does not move any longer and forms a whole body after being closed, and further the display equipment is convenient to carry.

Owner:BEIJING LINGYI TECH CO LTD

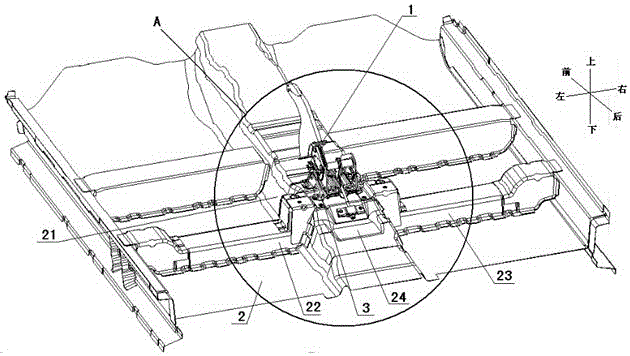

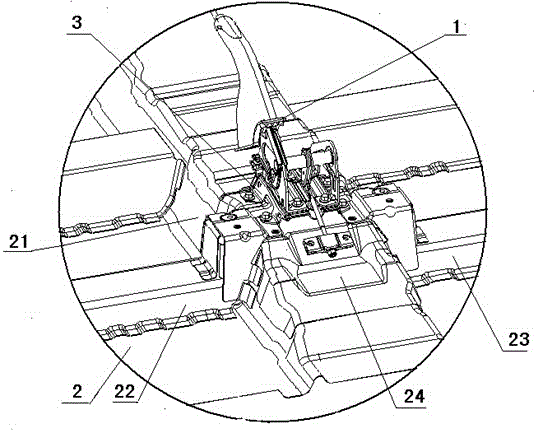

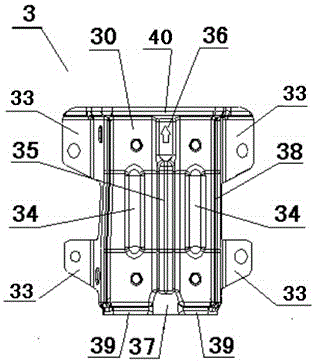

Automobile parking brake mounting bracket structure

InactiveCN105667471ASolve the difficulty of stamping and formingIncrease stiffnessHand actuated initiationsAutomotive engineeringParking brake

The invention relates to an automobile parking brake mounting bracket structure which comprises a parking brake, a front floor assembly and a parking brake bracket, wherein the front floor assembly comprises a front floor center channel, a reinforcement plate, a left rear cross beam assembly of the front seats and a right rear cross beam assembly of the front seats; a front bulge is arranged at the front part of the reinforcement plate; a rear mounting point is arranged on the front bulge; a rear bulge is arranged at the rear part of the front floor center channel; a front mounting point is arranged on the rear bulge; the whole parking brake bracket takes the shape of a frog, and four parking brake mounting faces are fixedly connected to the front floor assembly; the parking brake is fixedly connected with the parking brake bracket through bolts. The automobile parking brake mounting bracket structure can meet both the requirement on parking brake mounting and supporting and the requirement on the mounting stability of the parking brake; the design flexibility can be improved; furthermore, the rigidity of the rear mounting point of the front seats and the bending torsion mode of the whole automobile can be improved, and the effect of a connecting part on side collision force transmission is enhanced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

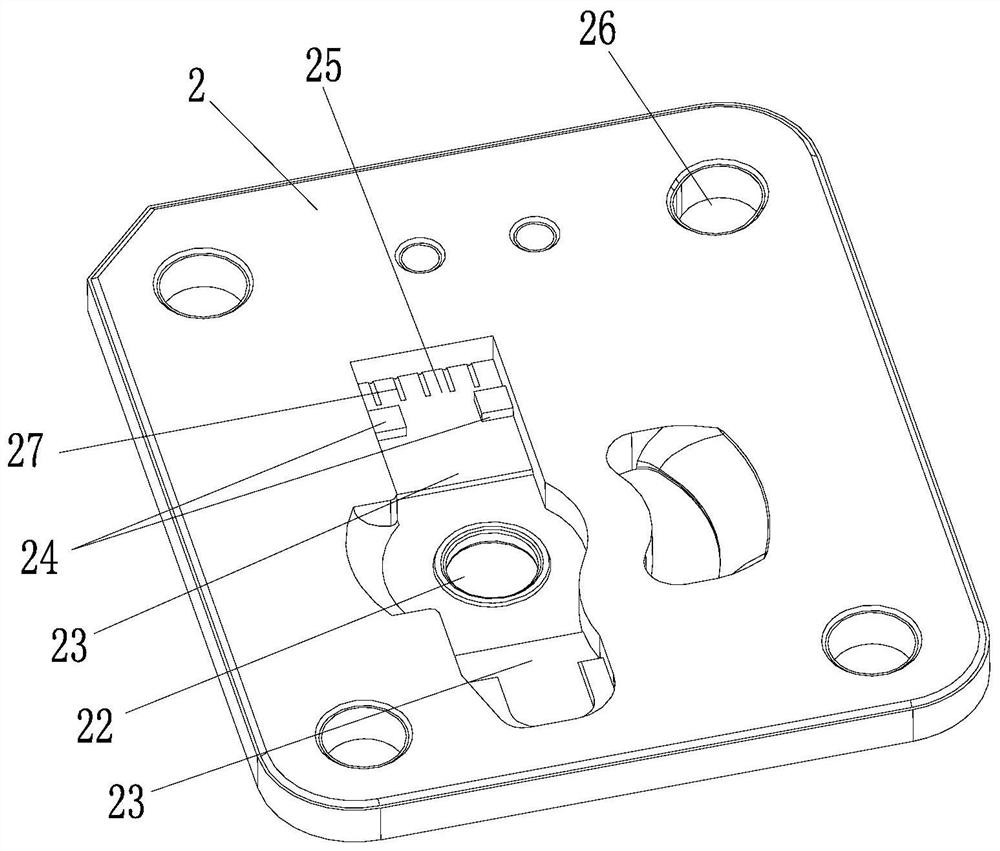

Switching block and switching device comprising switching block

The invention relates to a switching block and a switching device comprising the switching block, and specifically relates to a switching block (1) which can be detachably attached to a mounting frame used for wiring accessories. The switching block comprises a body (11) which is box shaped and has an opening on a front surface side; and a cover (12) which is attached to the body (11) to close the opening on the front surface side. A flipping component (13) for flipping internal contacts is arranged on a front surface of the cover (12). A handle (4) is detachably attached to the flipping component (13). Besides, the cover (12) has an attaching part (12b) for attaching the cover (12) to the mounting frame (2). The attaching part (12b) protrudes outwards over the body (11). According to the switching block (1), the handle (4) has a width larger than that of the body (11) and is attachable to the switching block (1).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

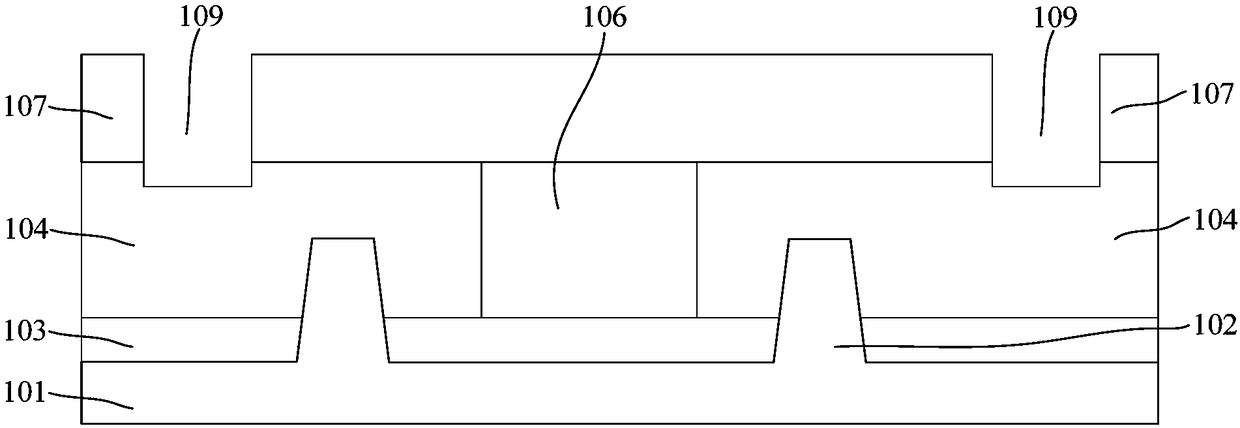

Forming method for fin-type field effect transistor

ActiveCN107591327AExcellent performanceImprove electrical performanceSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

The invention discloses a forming method for a fin-type field effect transistor, and the method comprises the steps: forming an N-region mask side wall on side walls of fin parts in an NMOS region; forming a supporting layer, which is closely attached to the side wall of the N-region mask side wall, on an isolated structure; removing a part of the fin parts at two sides of a grid structure of theNMOS region through etching, wherein the fin parts of the NMOS region and the N-region mask side wall form an N-region groove through enclosing; removing the supporting layer after the forming of theN-region groove; and forming an N-type doped epitaxial layer which is filled in the N-region groove. According to the invention, the supporting layer achieves the supporting of the N-region mask sidewall, prevents the N-region mask side wall from collapsing, and improves the performance of the formed fin-type field effect transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

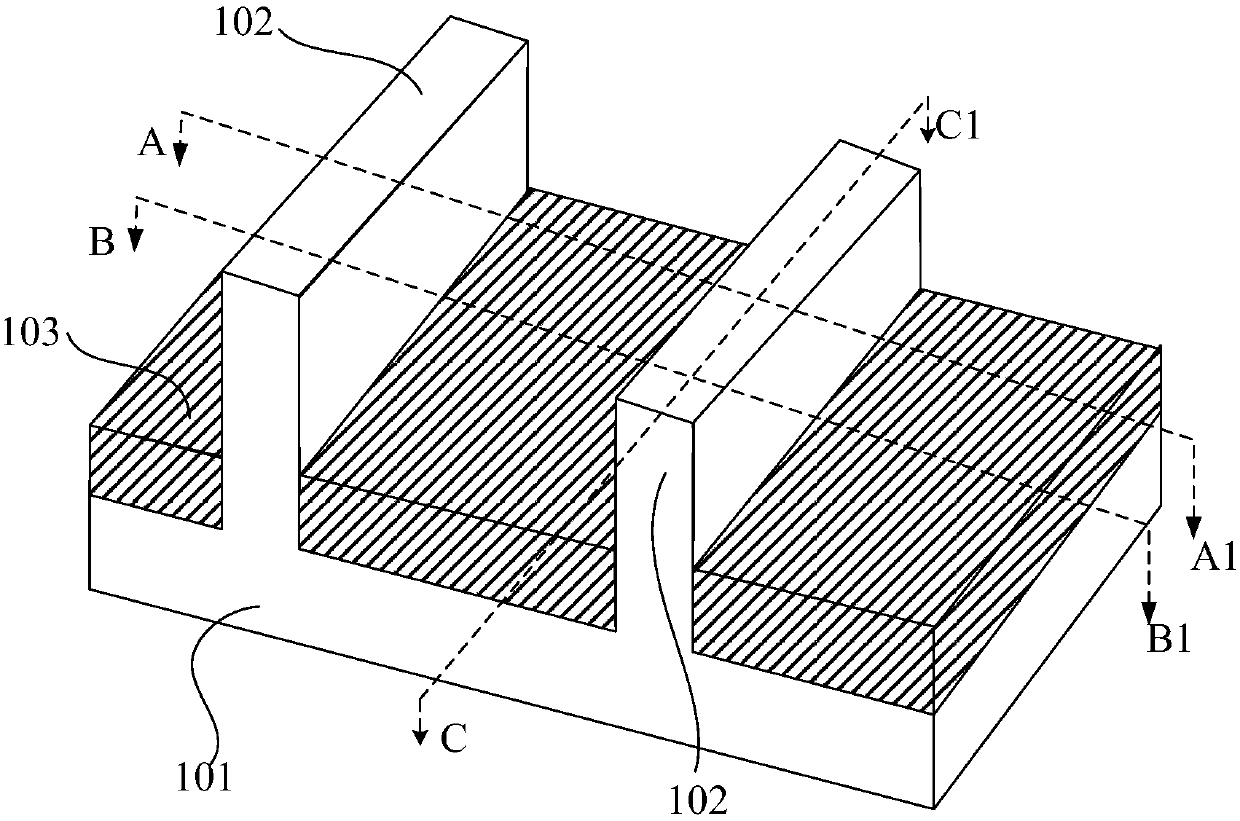

Slender Z-shaped part composite forming device and forming method

ActiveCN113441577AImprove forming efficiencyReduce in quantityVehicle componentsStructural engineeringInverted-T shape

The invention relates to the technical field of airplane sheet metal part manufacturing, in particular to a slender Z-shaped part composite forming device and forming method. The forming device comprises a die body I, a cover plate and a die body II; the die body I is in an inverted T shape and forms working faces used for the procedure A and the procedure B respectively; the width of the working face of the procedure B is matched with that of the web face of the Z-shaped part, and the shape of the inner side of the working face of the procedure B is matched with that of the outer side of the working face of the procedure A; steps are arranged on the working surfaces; the cover plate and the die body II are all molded surfaces, positioning pin avoiding grooves and die matching pin holes are formed in the cover plate and the die body II, and the die matching pin holes in the die body II are oblong holes; and the forming method comprises the steps that under the action of a rubber bag forming machine, the die body II is pressed towards the die body I, and the bent edge A is formed while the bent edge B is formed. By means of the forming device and the forming method, the problems that the forming efficiency is low, and particularly after the side face of the part is sunken and formed, the part is large in springback, the part is not prone to being attached to a die, and the correction workload is large can be effectively solved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

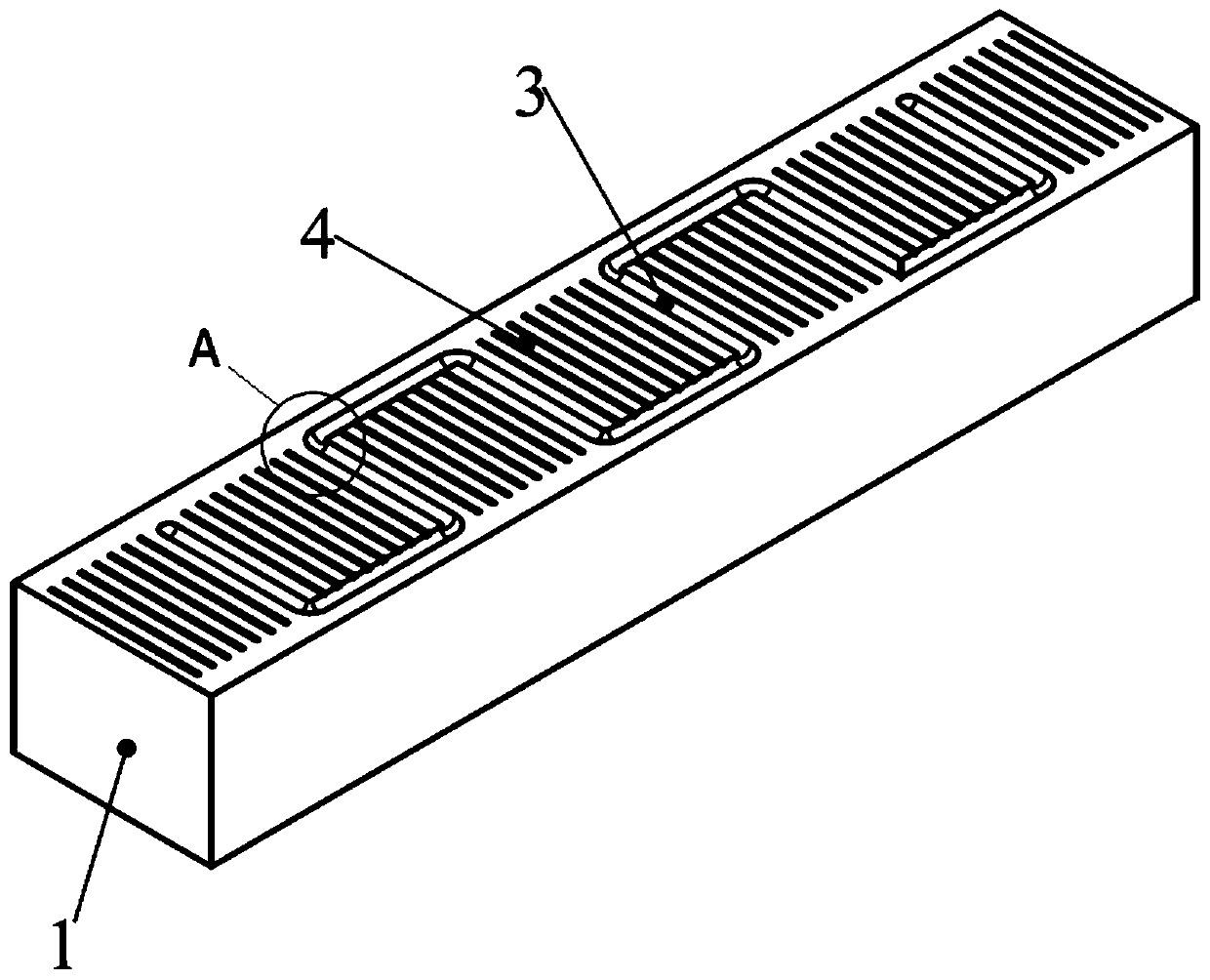

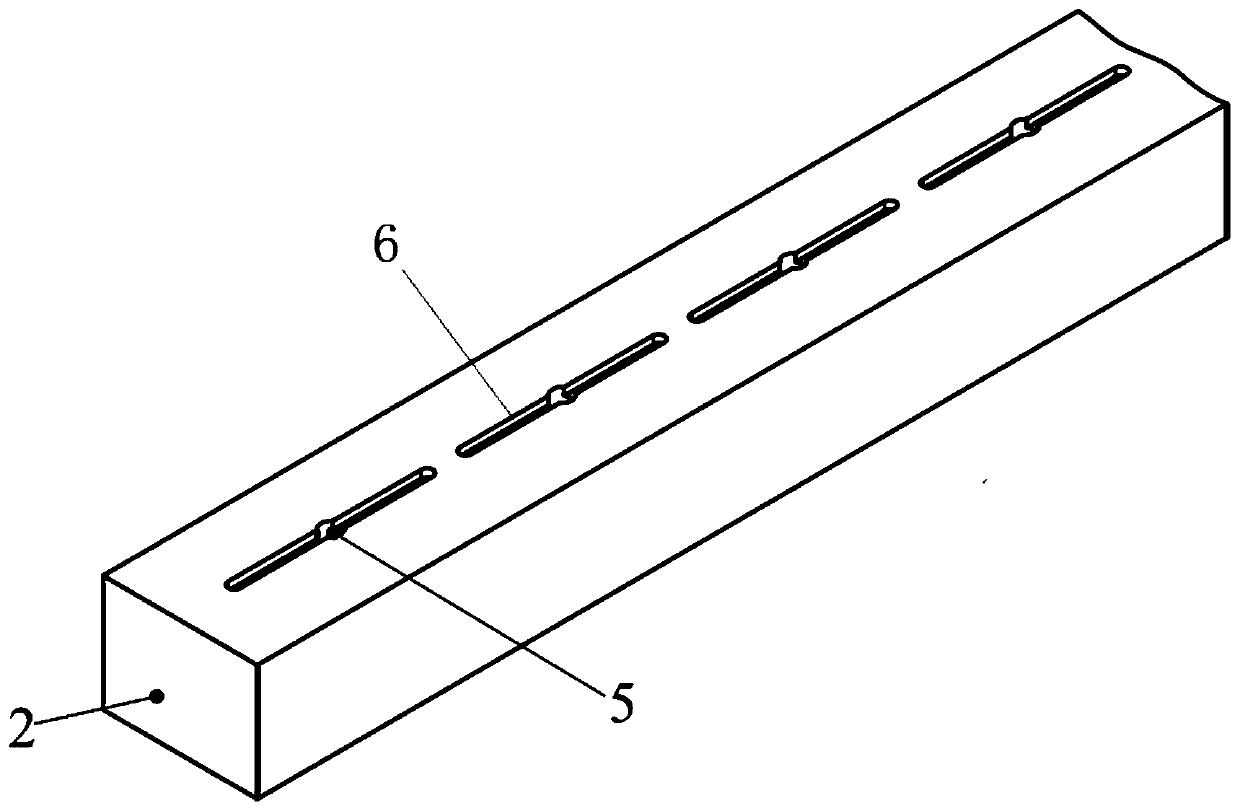

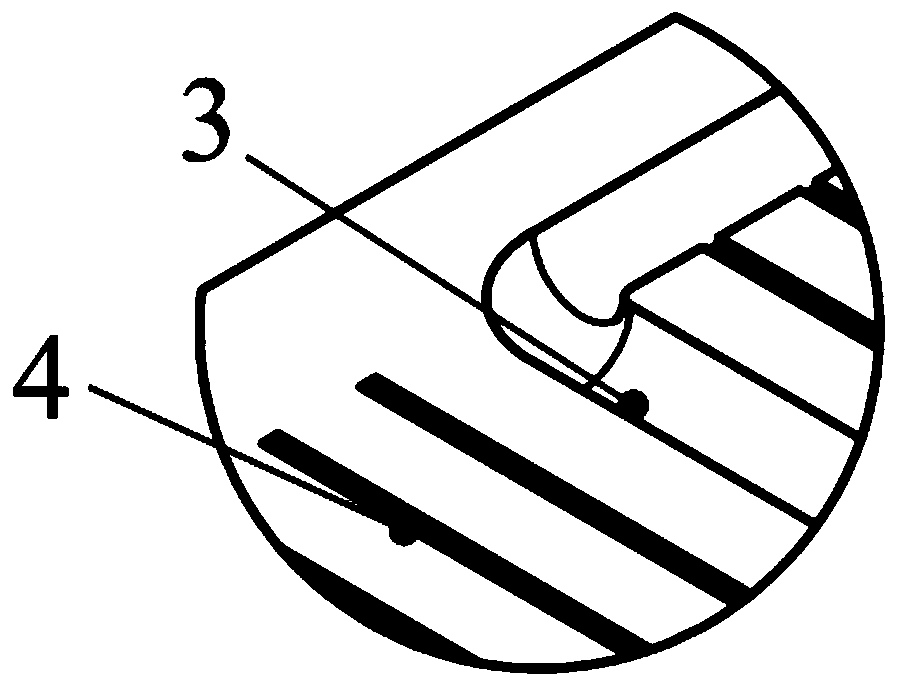

Microstructure channel and lubricating oil groove composite guide rail and method

InactiveCN111590339AGuaranteed bearing capacityGuaranteed normal formationLarge fixed membersMaintainance and safety accessoriesClassical mechanicsStructural engineering

The invention relates to a microstructure channel and lubricating oil groove composite guide rail and a method. The composite guide rail comprises a fixed guide rail and a sliding guide rail, whereinthe surface of the fixed guide rail and the surface of the sliding guide rail are in mutual contact, and the sliding guide rail can perform reciprocating rectilinear motion relative to the fixed guiderail; the surface, in contact with the sliding guide rail, of the fixed guide rail is provided with an oil feeding hole and an oil feeding groove, and the oil feeding hole is used for supplying oil to the oil feeding groove; the surface, in contact with the fixed guide rail, of the sliding guide rail is provided with lubricating oil grooves, multiple microstructure channels are uniformly distributed between the adjacent lubricating oil grooves, and the extension direction of the microstructure channels is perpendicular to the motion direction of the sliding guide rail; the lubricating oil grooves and the microstructure channels can simultaneously contain lubricating oil so as to form an oil film between the contact surfaces of the sliding guide rail and the fixed guide rail; and the quantity and size of the lubricating oil grooves and the microstructure channels are set according to the principle that the bearing capacity of the sliding guide rail is higher than a set demand under thesituation that the lubricating oil grooves and the microstructure channels are arranged.

Owner:SHANDONG UNIV

Frame structure and crane

The invention discloses a frame structure and a crane, relates to the field of engineering machinery, and is used for optimizing a structure of a traditional frame body. The frame structure comprises a frame body and support leg structures; the support leg structures are arranged at the end parts of the length direction of the frame body, and are rotationally or slidingly connected with the frame body; the support leg structures are located in an extending state; and the length directions of the support leg structures form acute angles with the length direction and the width direction of the frame body, so that the total length of the frame structure is larger than the length of the frame body, and the total width of the frame structure is larger than the width of the frame body. Under the precondition of not changing the size of the frame body, the length and the width sizes of the frame structure can be synchronously increased, so that the span of the crane is increased; and the weights of the support leg structures are far lower than the weight of the frame body in the prior art corresponding to the same span, so that the lifting weight can be increased when the span is increased.

Owner:XUZHOU HEAVY MASCH CO LTD

Air valve assembly and compressor using the air valve assembly

ActiveCN110985349BIncrease width sizeNo shakingPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveEngineering

The invention belongs to the technical field of compressors, and specifically discloses an air valve assembly, which includes an exhaust valve plate, a valve plate and a limiting plate. Installed in conjunction with the groove, the limit plate presses the exhaust valve plate into the groove, the tongue of the exhaust valve plate covers the exhaust port to form an opening and closing valve, and the root of the exhaust valve plate is provided with a grid pattern The grid-like pattern structure is composed of several grid bars arranged at intervals. One or more grid bars of the grid-like pattern structure are provided with a deformation structure. Flatten and stretch out across its width. The invention also discloses a compressor using the above air valve assembly. The invention has simple structure and low cost, and can well solve the problem of powder valve plate wear caused by the sloshing of the exhaust valve plate, which eventually leads to misalignment and poor sealing between the tongue of the exhaust valve plate and the exhaust hole of the valve plate, and severe internal combustion of the compressor. The problem of leakage and failure.

Owner:WANBAO GROUP COMPRESSOR CO LTD

Semiconductor structure and forming method thereof

ActiveCN108666267AEfficient removalRemove completelySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureMetal silicide

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the following steps of: forming a first through hole that penetrates through a dielectric layer and exposes a surface of a source-drain doping region; forming a second through hole that penetrates through the dielectric layer and exposes a top of a gate structure; depositing cap layers on abottom and sidewalls of the first through hole and a bottom and sidewalls of the second through hole; performing a first cleaning process on the bottom of the first through hole and the bottom of thesecond through hole to remove cap layers located on the bottom of the first through hole and the bottom of the second through hole; performing a second cleaning process on the source-drain doping region exposed at the bottom of the first through hole and the gate structure exposed at the bottom of the second through hole after the first cleaning process; forming metal layers on the bottom and thesidewalls of the first through hole, the bottom and the sidewalls of the second through hole and a top of the dielectric layer after the second cleaning process; and performing an annealing process on the metal layers to convert the metal layer located on the source-drain doping region into a metal silicide layer. According to the invention, the electrical properties of the formed semiconductor structure can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

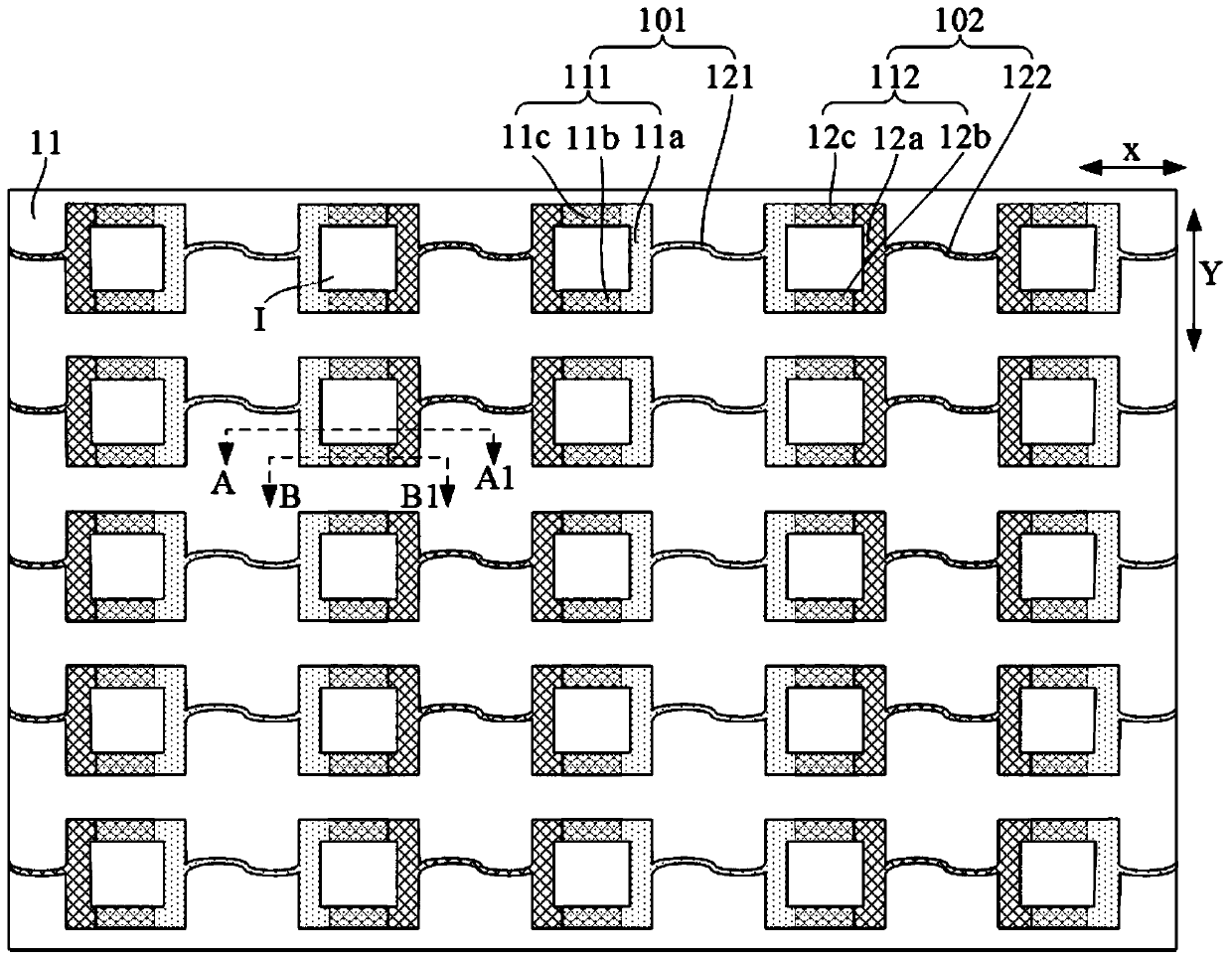

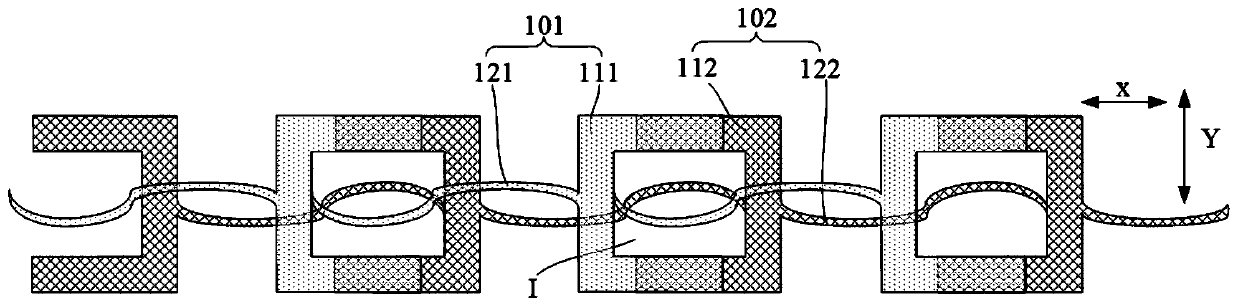

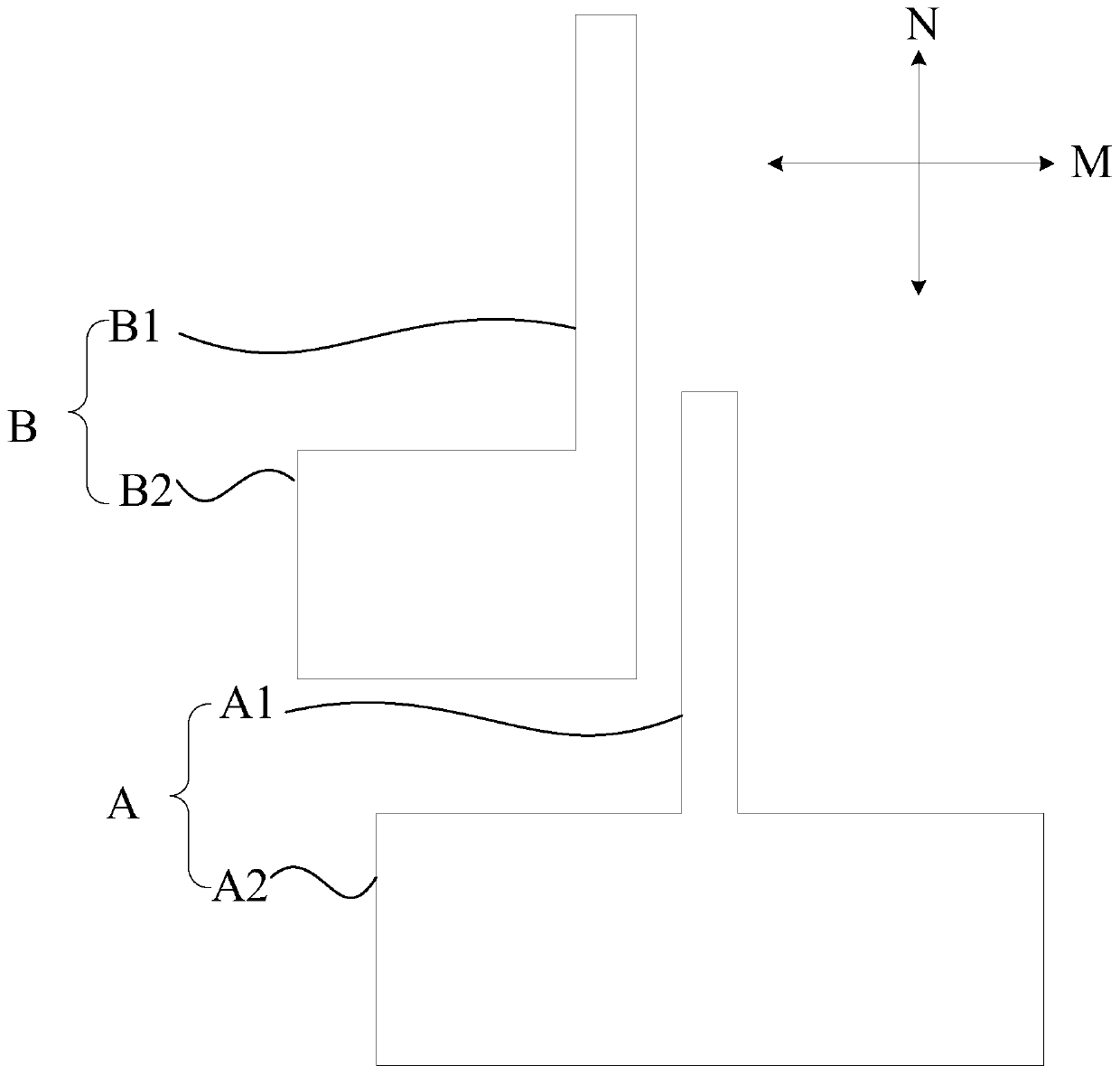

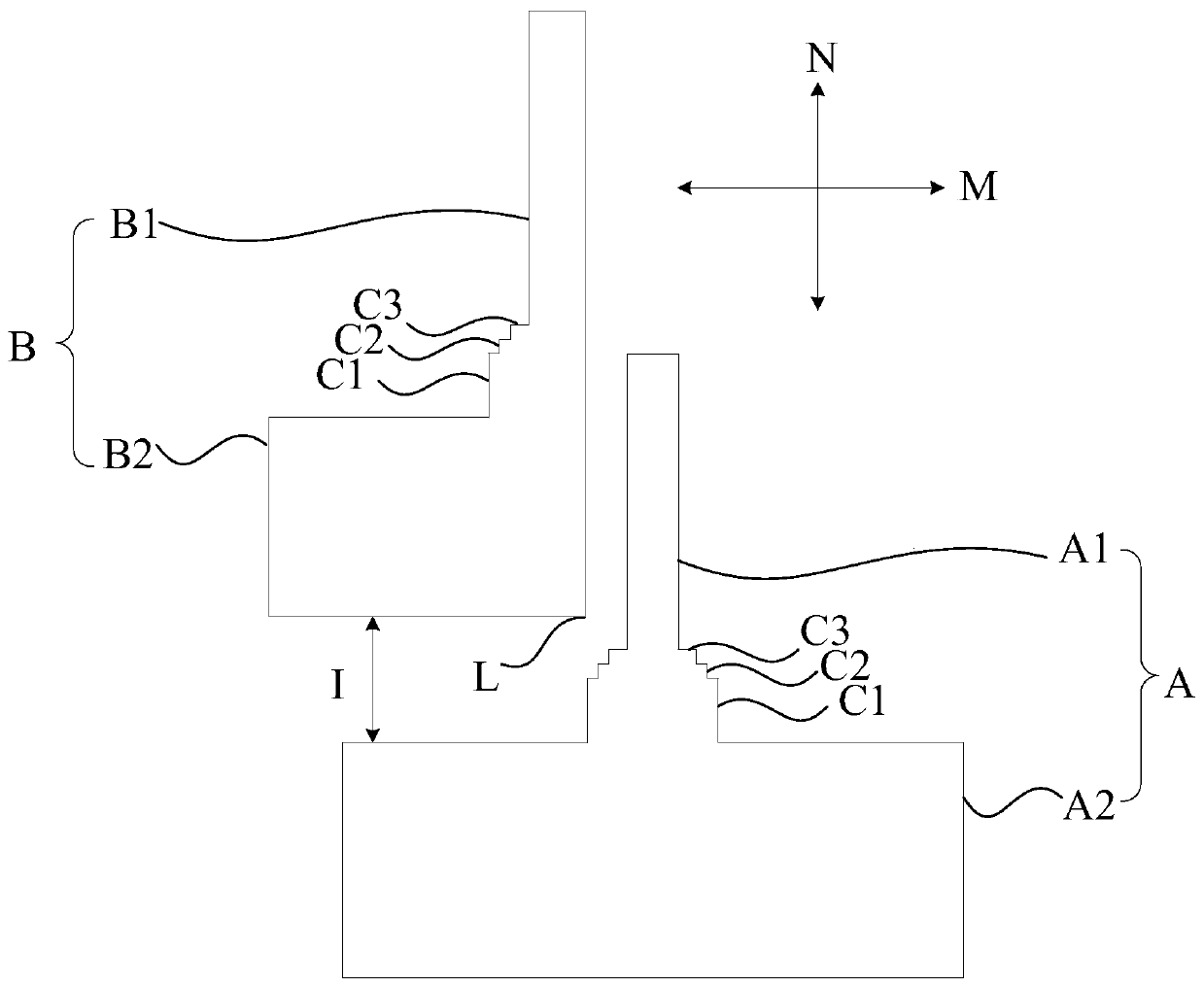

Layout correction method

PendingCN110515267AMake sure not to distortAvoid disconnectionOriginals for photomechanical treatmentManufacturing computing systemsCorrection methodProcess window

The invention provides a layout correction method, which comprises steps: an original layout is obtained, wherein the original layout comprises at least two target patterns, the target pattern comprises a first pattern and a second pattern, the first pattern is of a strip-shaped structure, the first pattern is connected with the second pattern, the second pattern of the other target pattern is arranged on one side or two sides of the first pattern of the target pattern, and the second pattern of the target pattern and the second pattern of the other target pattern are arranged at an interval;and at least one correction pattern is added to the side edge, close to the second pattern, of the first pattern of the target pattern, or, at least one pattern is dug out at the edge, close to the first pattern of the target pattern, of the other target pattern. After the layout correction method provided by the invention is adopted to complete correction, the manufactured mask plate can be additionally provided with process windows for exposure, and process defects such as line breakage or adhesion and the like are effectively avoided, so that an actual pattern finally formed on the substrate is ensured not to be distorted.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

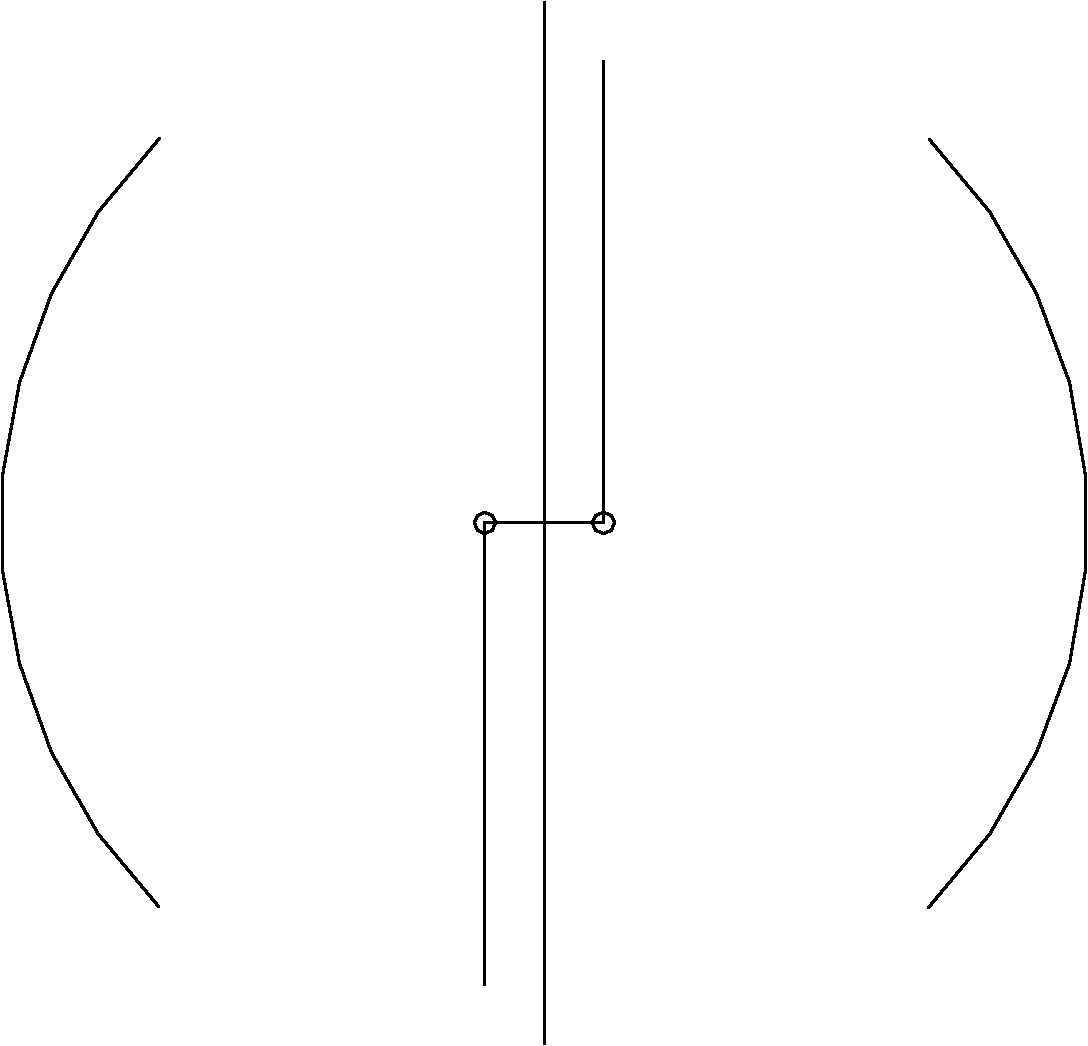

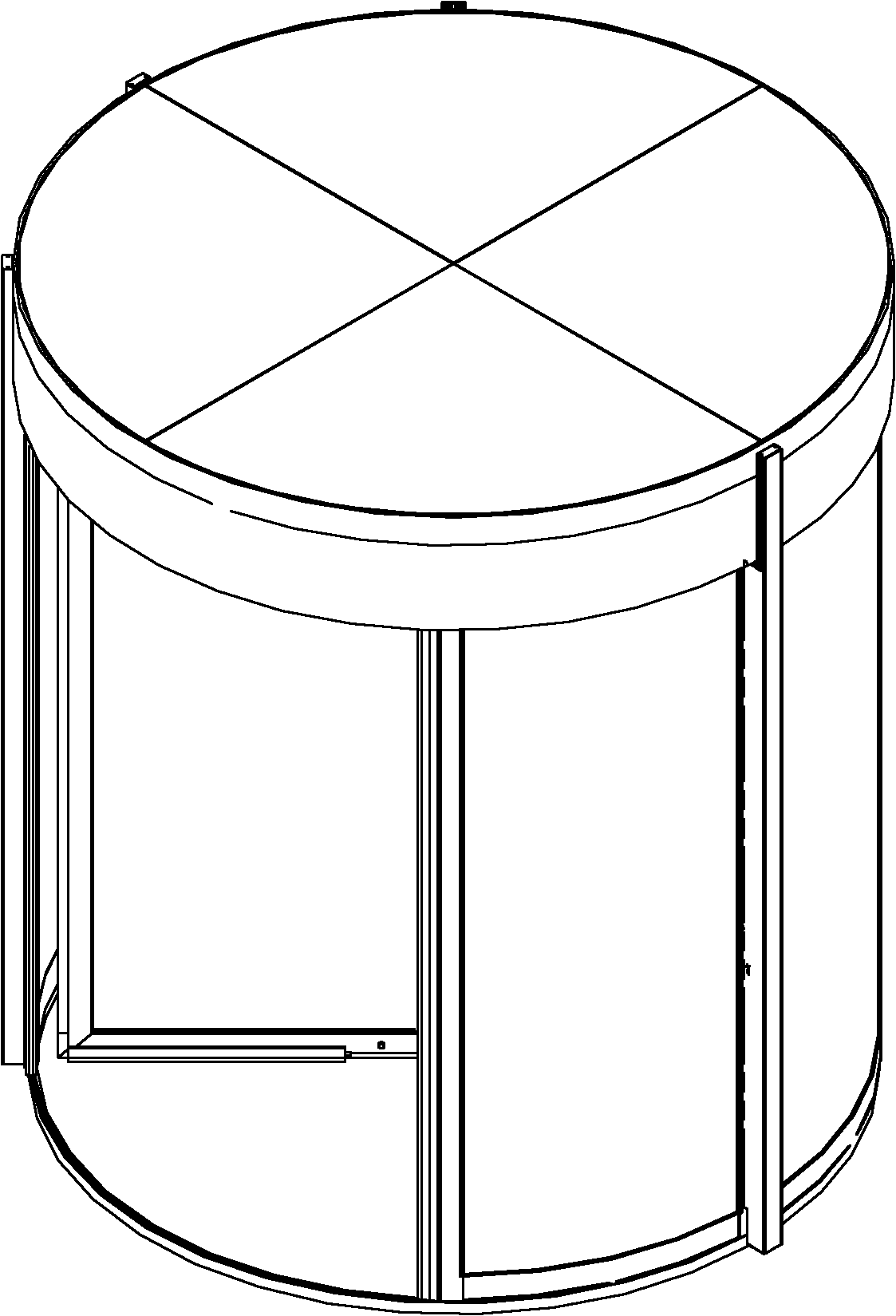

Single body rotating door with wide passageway

ActiveCN102206983AMeet traffic needsIncrease width sizeRevolving doorsPower-operated mechanismEngineeringMechanical engineering

Owner:北京宝盾门业技术有限公司

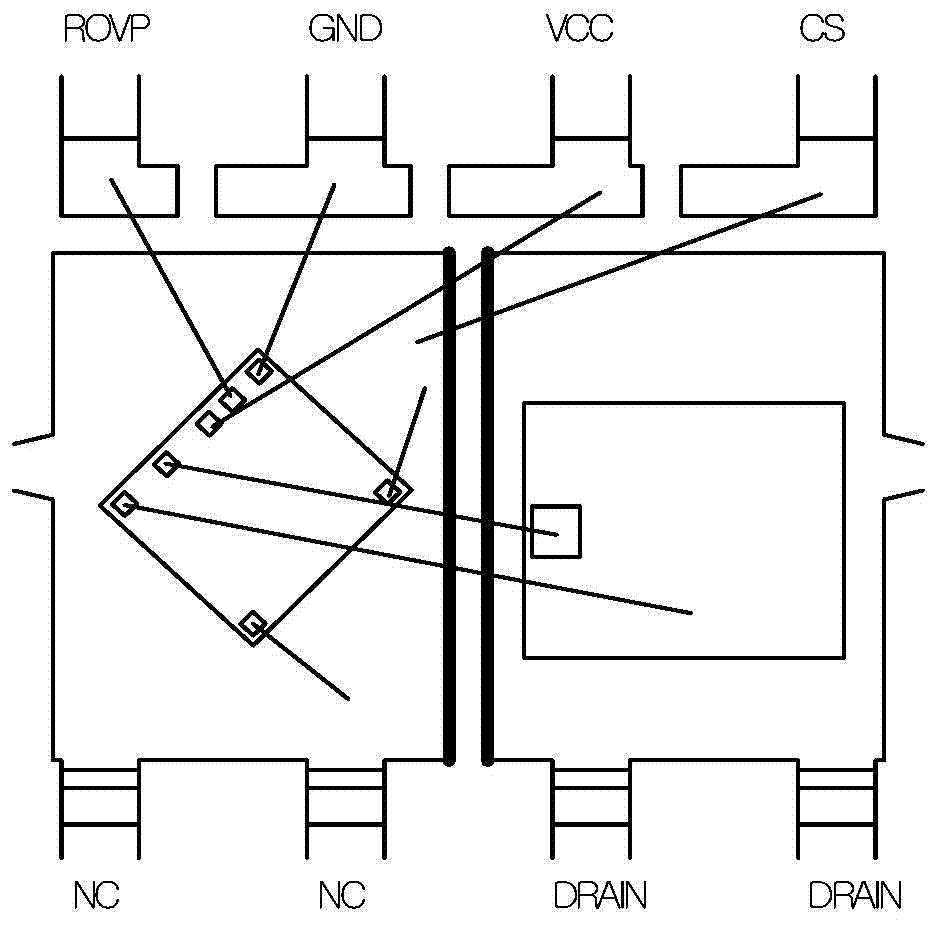

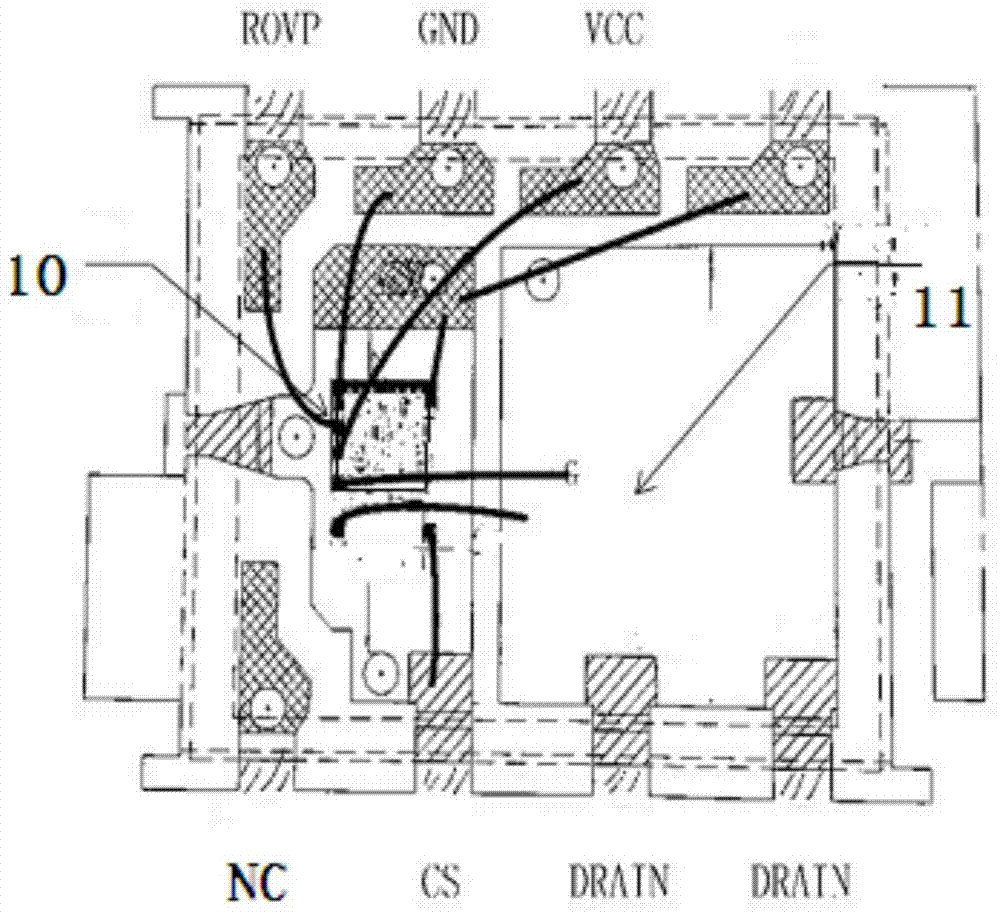

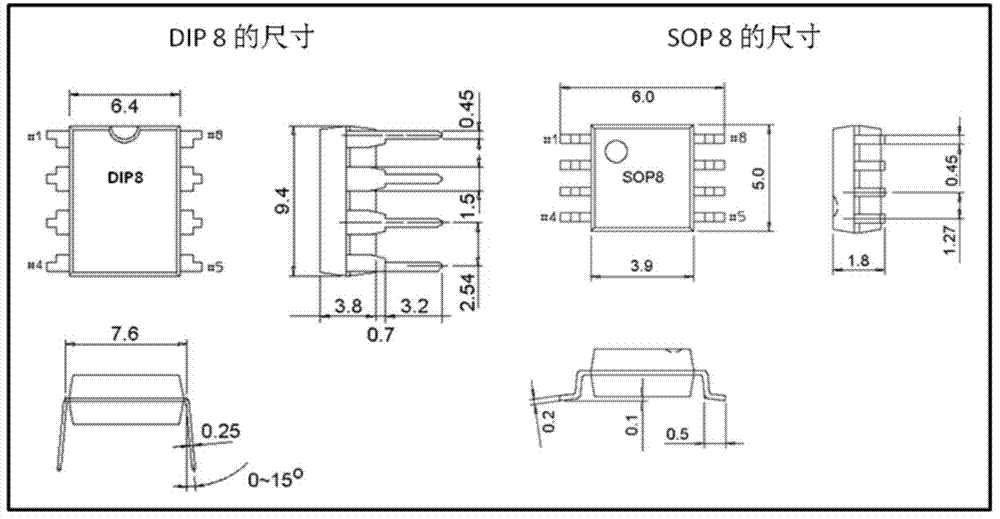

SOP8 package lead frame of high-power LED driving chip

InactiveCN104766920AImprove cooling effectReduce temperature riseSolid-state devicesSemiconductor devicesMOSFETEngineering

The invention discloses an SOP8 package lead frame of a high-power LED driving chip. The SOP8 package lead frame comprises a pin, side connection ribs, a first island and a second island, the pin and the two side connection ribs together support the first island and the second island, the width of the first island is larger than the standard width of an SOP8 package island, and the width of the second island is smaller than the standard width of the SOP8 package island. The size of the largest MOSFET chip borne by the first island is increased, and the SOP8 lead frame is suitable for packaging a 3 W-9 W built-in isolation type LED driving chip or a 12 W-24 W built-in isolation type LED driving chip and is wide in application range. The bearing area of the first island is correspondingly increased, and therefore the heat dissipation performance is good. No special requirements for the MOSFET chip exist, and therefore the cost is low; only one pin is needed, and therefore expandability is good. The SOP8 package lead frame can be widely applied to the field of semiconductor components.

Owner:广州华微电子有限公司

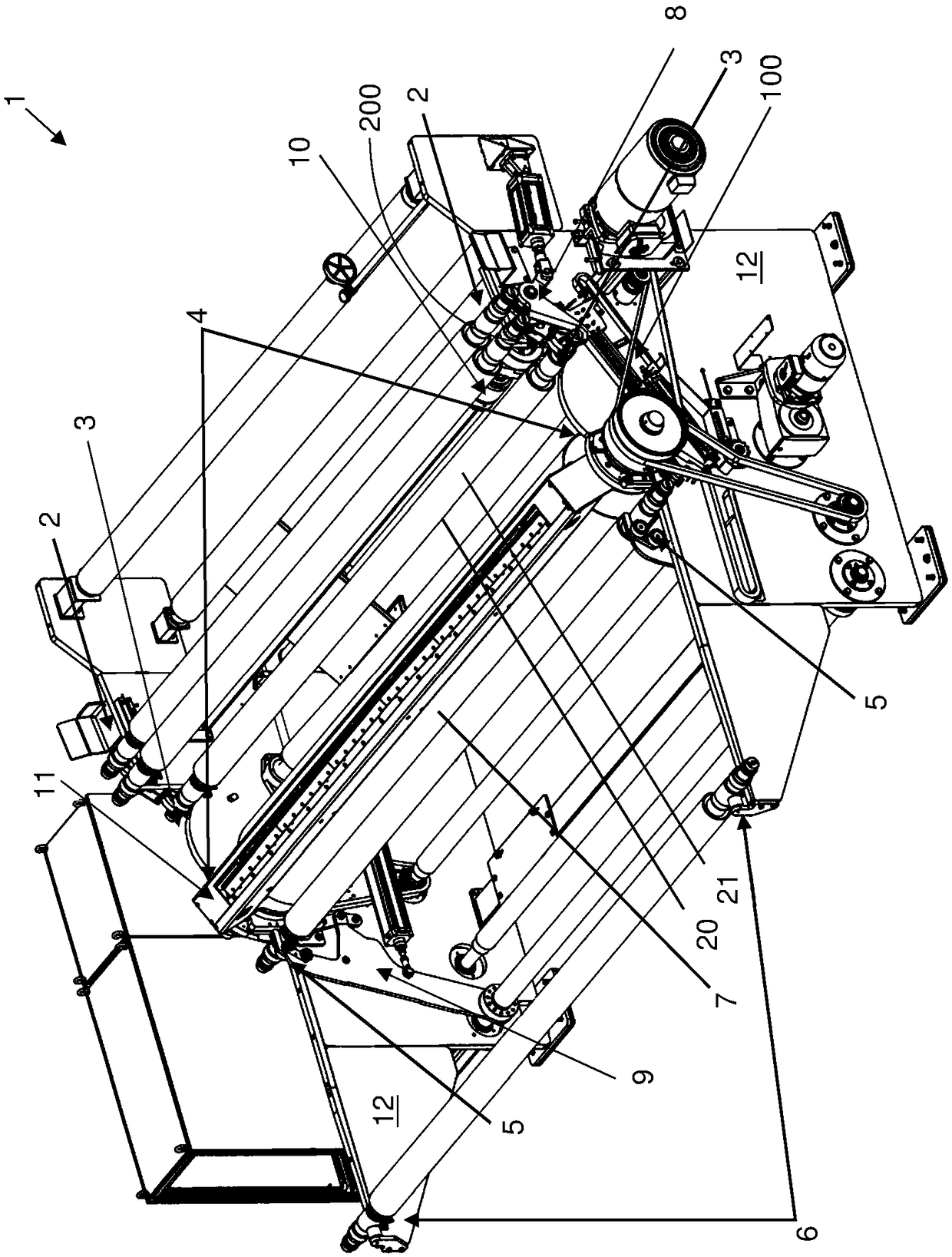

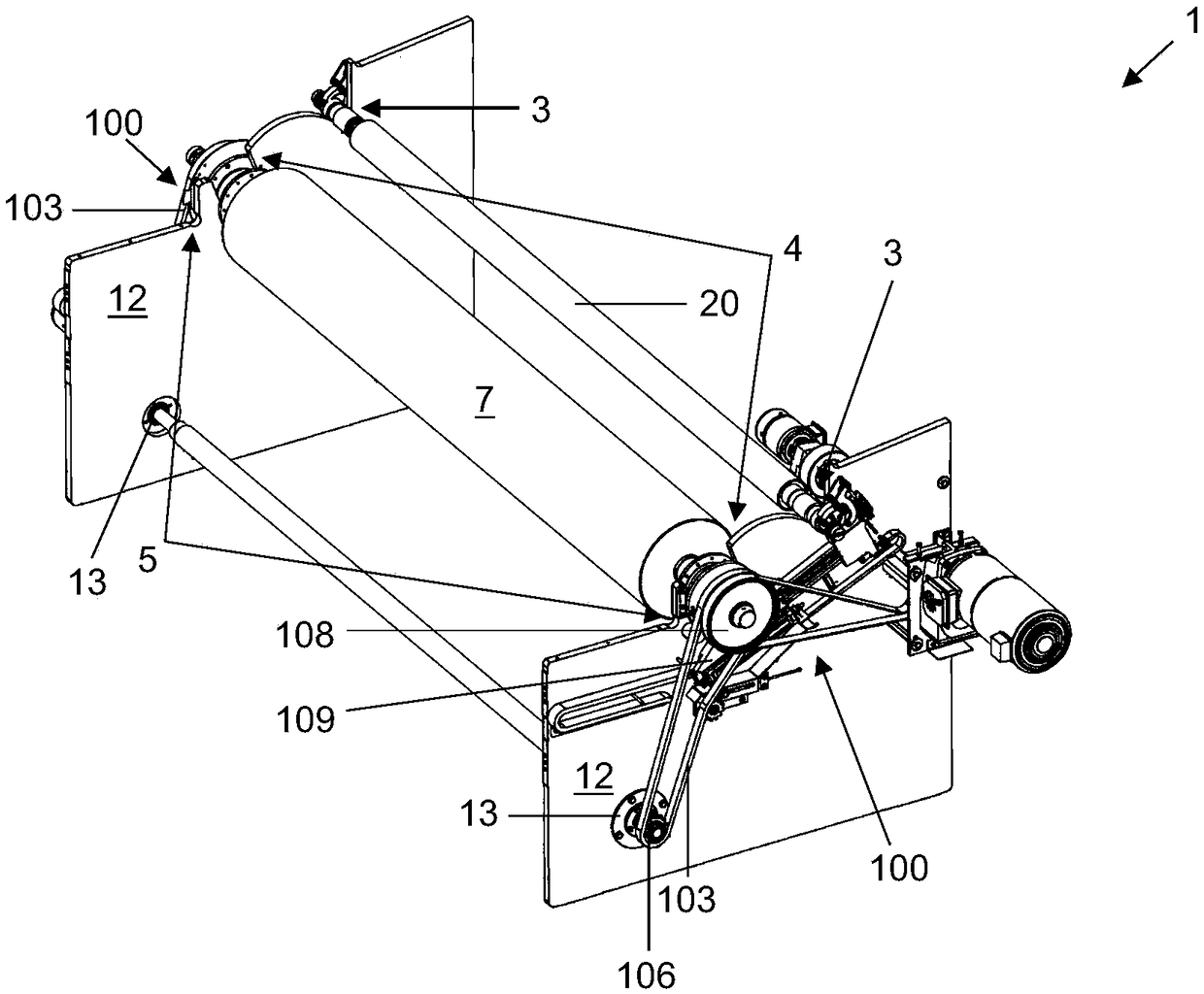

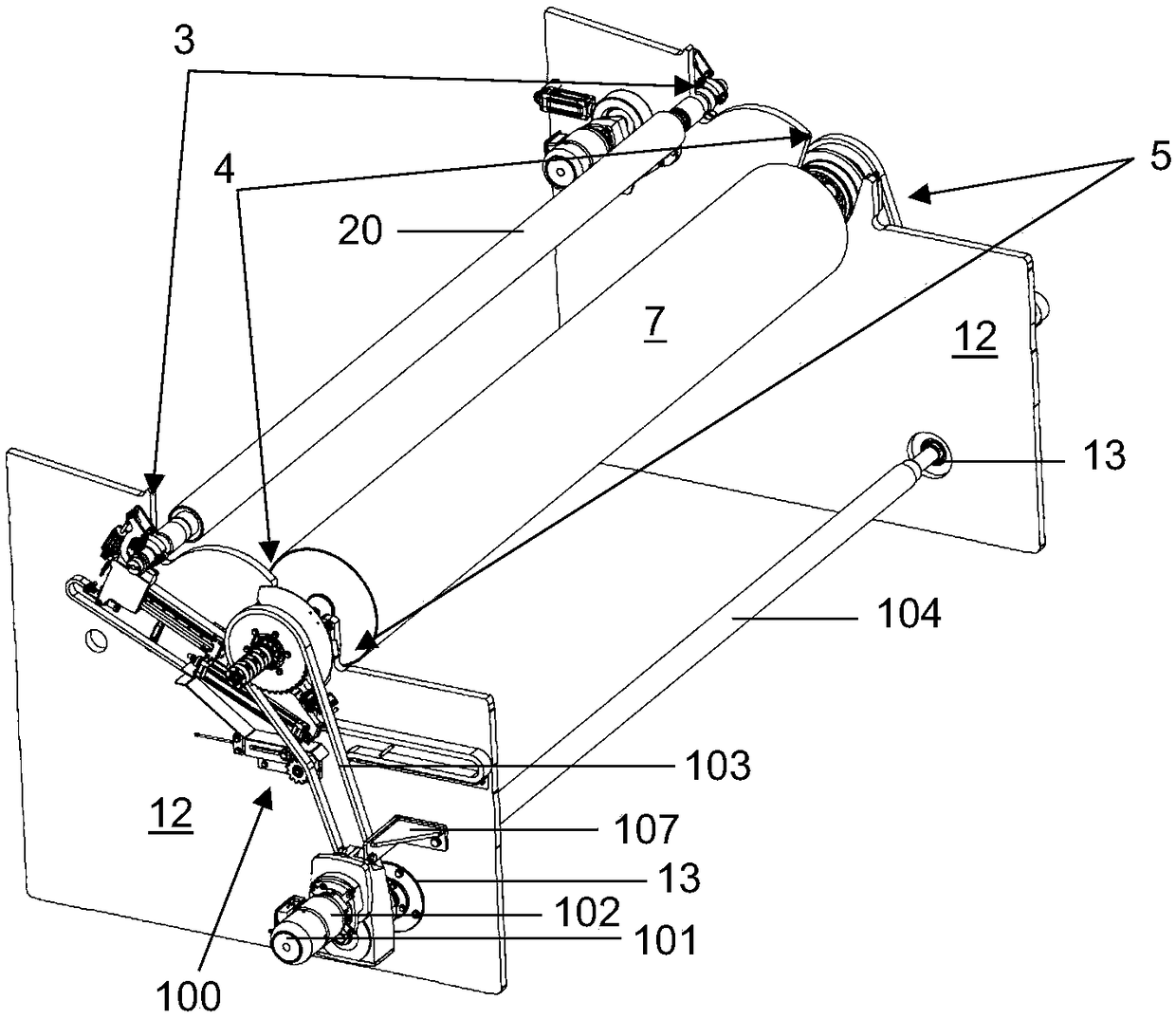

Locking mechanism of fabric coiler

ActiveCN108946252AImprove clamping actionAchieving additional degrees of freedomGripping headsLap-winding devicesEngineeringConductor Coil

A device (200) is set up to be combined into a fabric coiler, so that the winding shaft (20) is transferred from a waiting position (3) to a winding position (4) and / or a rolling position (5) by the device. The device has a lever arrangement structure that encloses the winding shaft from one side in a locked state, so that the lever arrangement structure observes in the longitudinal direction of the winding shaft and is opened towards one side of the winding shaft, and the lever is arranged in such a way, so that the gravity of the winding shaft is prevented from being guided into the lever arrangement structure in a manner of being used for canceling the locking force. The fabric coiler (1) is provided with a fiber net for winding the first winding shaft, and guiding a second winding shaft to a waiting position, and is provided with the device. The device is arranged on the conveying section in a waiting state, so that the lever arrangement structure clamps the second winding shaft ina clamping manner. The conveying section is configured in that the clamped second winding shaft moves from the waiting position towards the starting and winding position and / or the coiling position.

Owner:特吕茨施勒集团欧洲公司

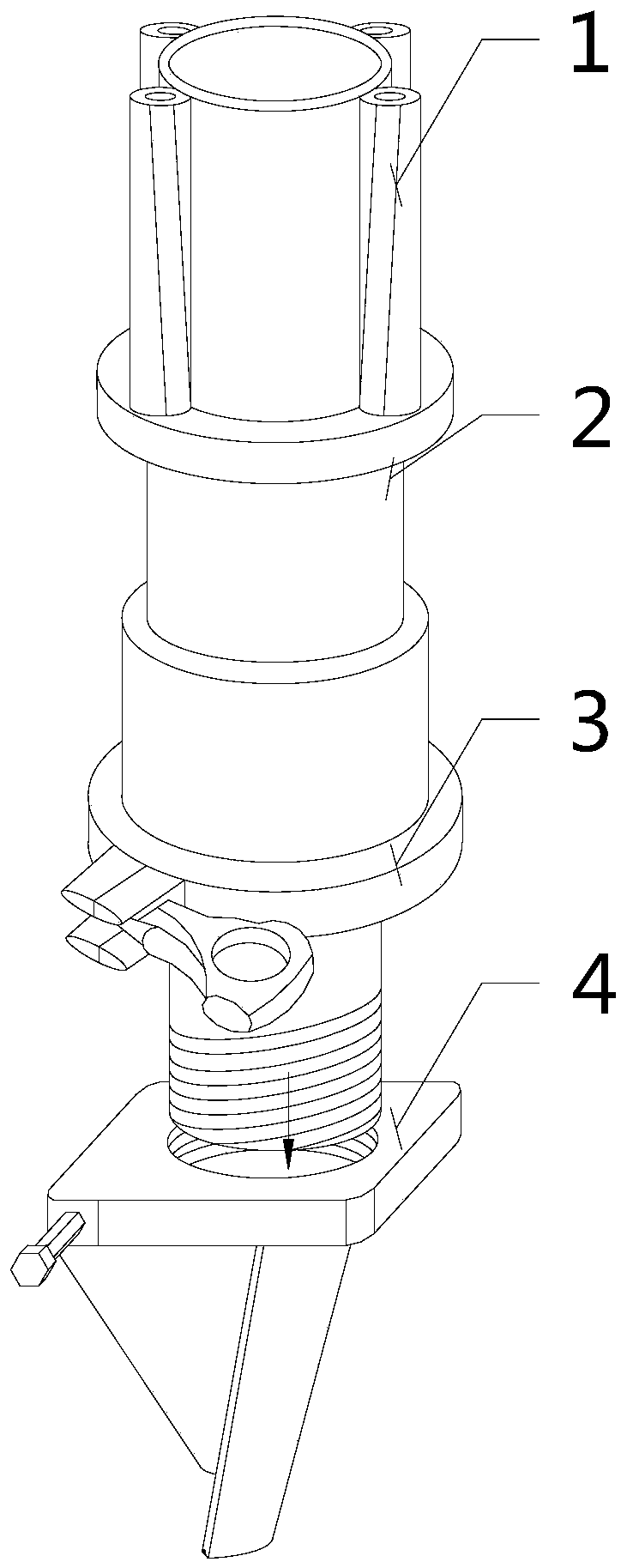

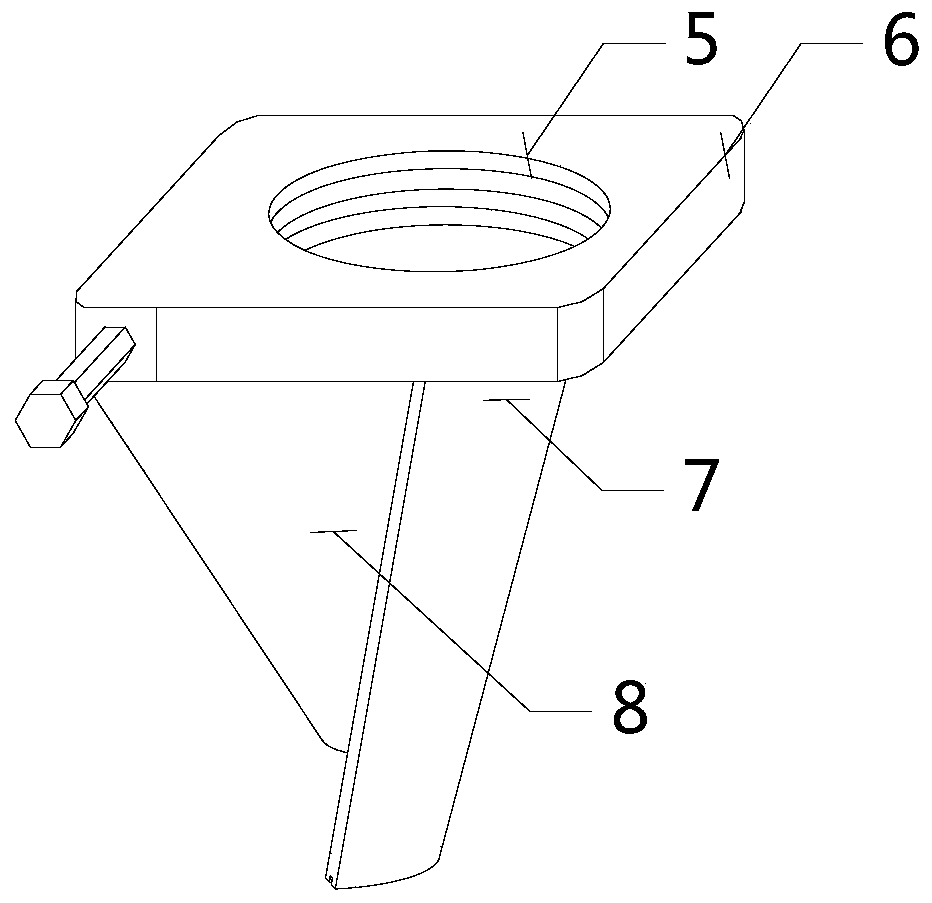

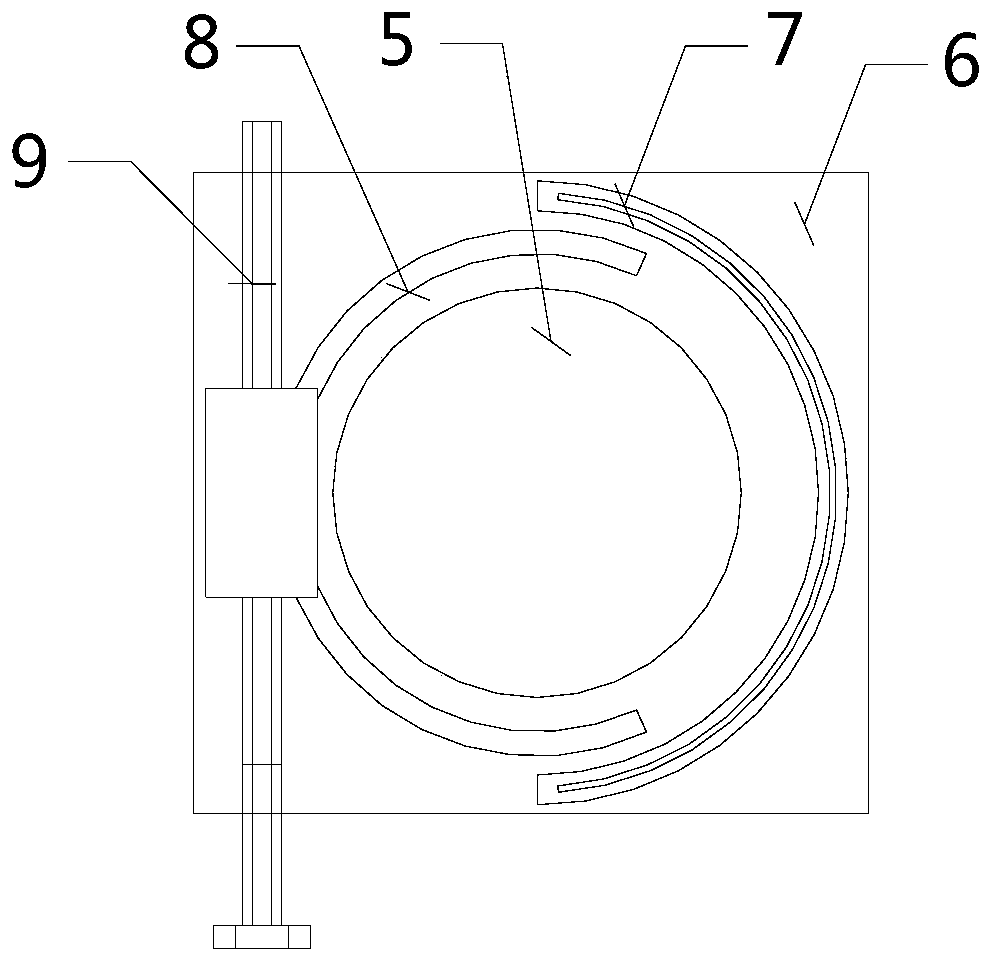

Culture medium filling device

The invention discloses a culture medium filling device. The device is composed of a material pipe, a filling head and the like, the filling head structurally comprises a connecting column, a connecting cylinder, a movable buckle and a guiding mechanism, the connecting column is installed at the top of the connecting cylinder, the other end of the connecting cylinder is in threaded connection withthe guiding mechanism, the movable buckle is installed in the middle of the connecting cylinder, the guiding mechanism is composed of a threaded opening, a leveling plate, a first arc plate and a second arc plate, and the threaded opening is formed in the middle of the leveling plate. According to the device, a mode that metal wires cooperate with screen cloth is adopted, when a culture medium isfilled, a net bag can be straightened due to the fact that the culture medium is contained, materials fall vertically, and along with gradual reduction of the filling content of the culture medium, the metal wires recover gradually to be in a semicircular bag shape to hold residual culture medium liquid drops to avoid continuous dripping.

Owner:常荣杰

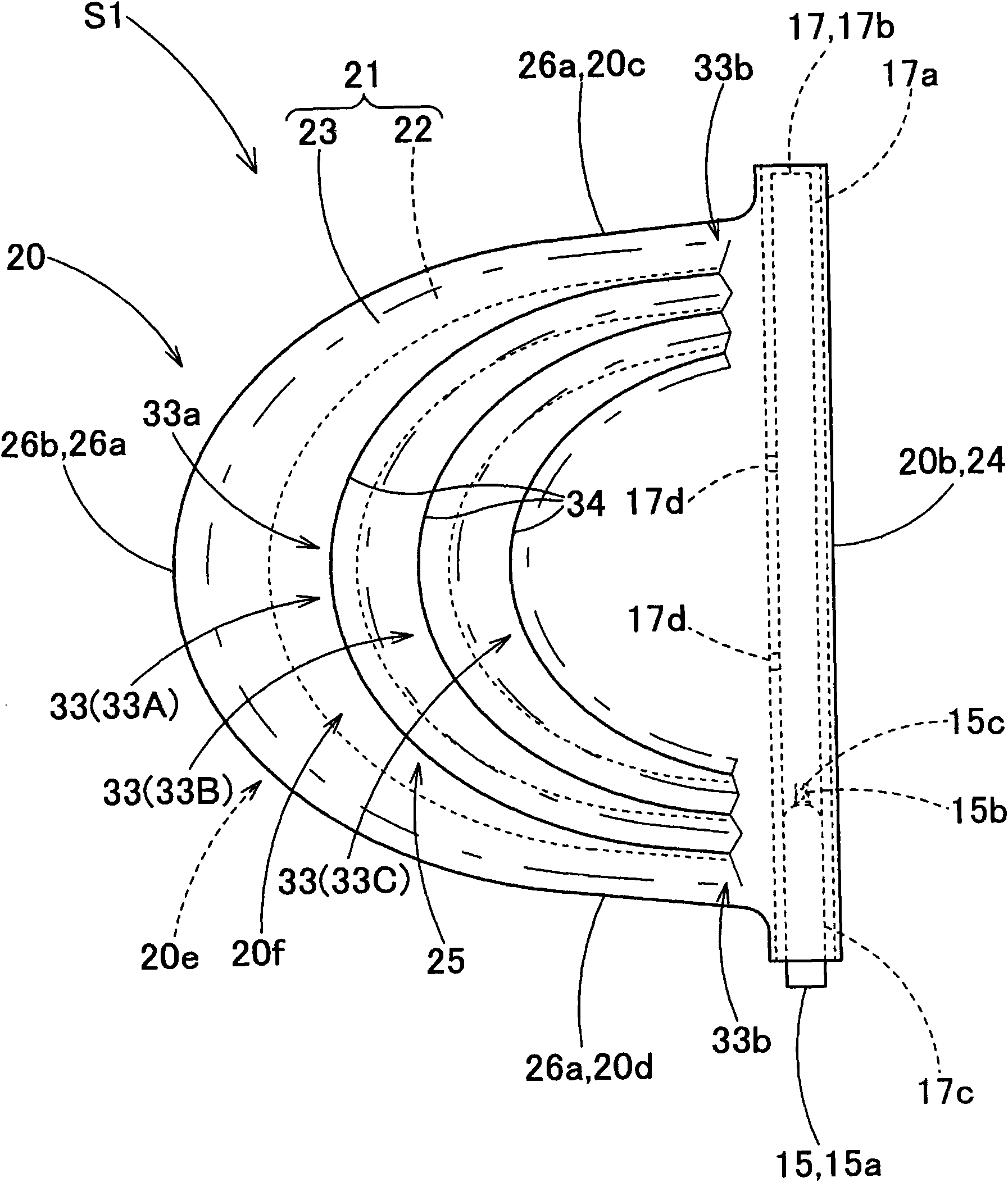

Resin airbag

InactiveCN102029969AIncrease width sizeIncrease thickness dimensionPedestrian/occupant safety arrangementCurve shapeEngineering

The invention provides a resin airbag and the circumferential wall of the airbag is made of sheet-shaped synthetic resin.When inflation gas flows into the airbag, the upper wall portion and the lower wall portion of the airbag expand in a separation mode.The three sides surrounded the expansion area are surrounded with outer peripheries.The upper and lower wall portions are connected with each other in a semi-circular arc shape by the section of the airbag along the thickness direction.A continuous curve shape expanding outwardly is formed when viewed downwardly.In the expansion area, foldingportions are concentrically configured toward the inner side thereof, which are in a curve shape surrounding the outer peripheries in three sides and expanding toward the outer peripheries.Each folding portion is in a V shape with two inclined parts along the section of the airbag in the thickness direction.The two inclined parts extend from the bottom of a recess.When inflation gas flows into the airbag, the width of the opening is enlarged due to the plastic deformation of the folding portions, so that the air bag expands.The wall thickness is set within a predetermined range, so that the turning of the wall toward the outer surface thereof is avoided.

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com