Locking mechanism of fabric coiler

A technology of fiber web and winding machine, which is applied in the direction of winding mechanism, fiber processing, and winding strips, etc., which can solve the problems of injury, uncontrollable movement, complex combination mode, etc., and achieve the effect of large clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

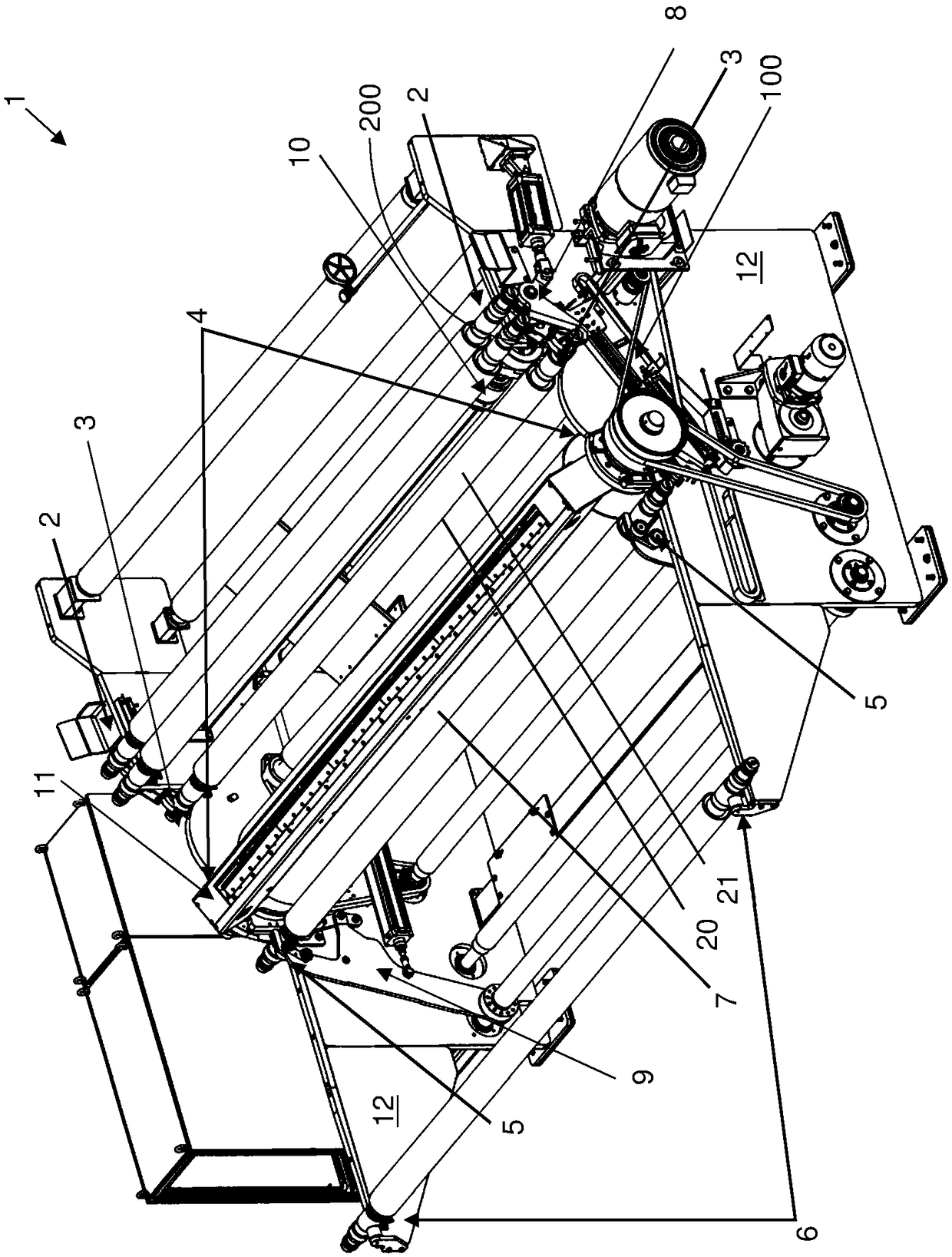

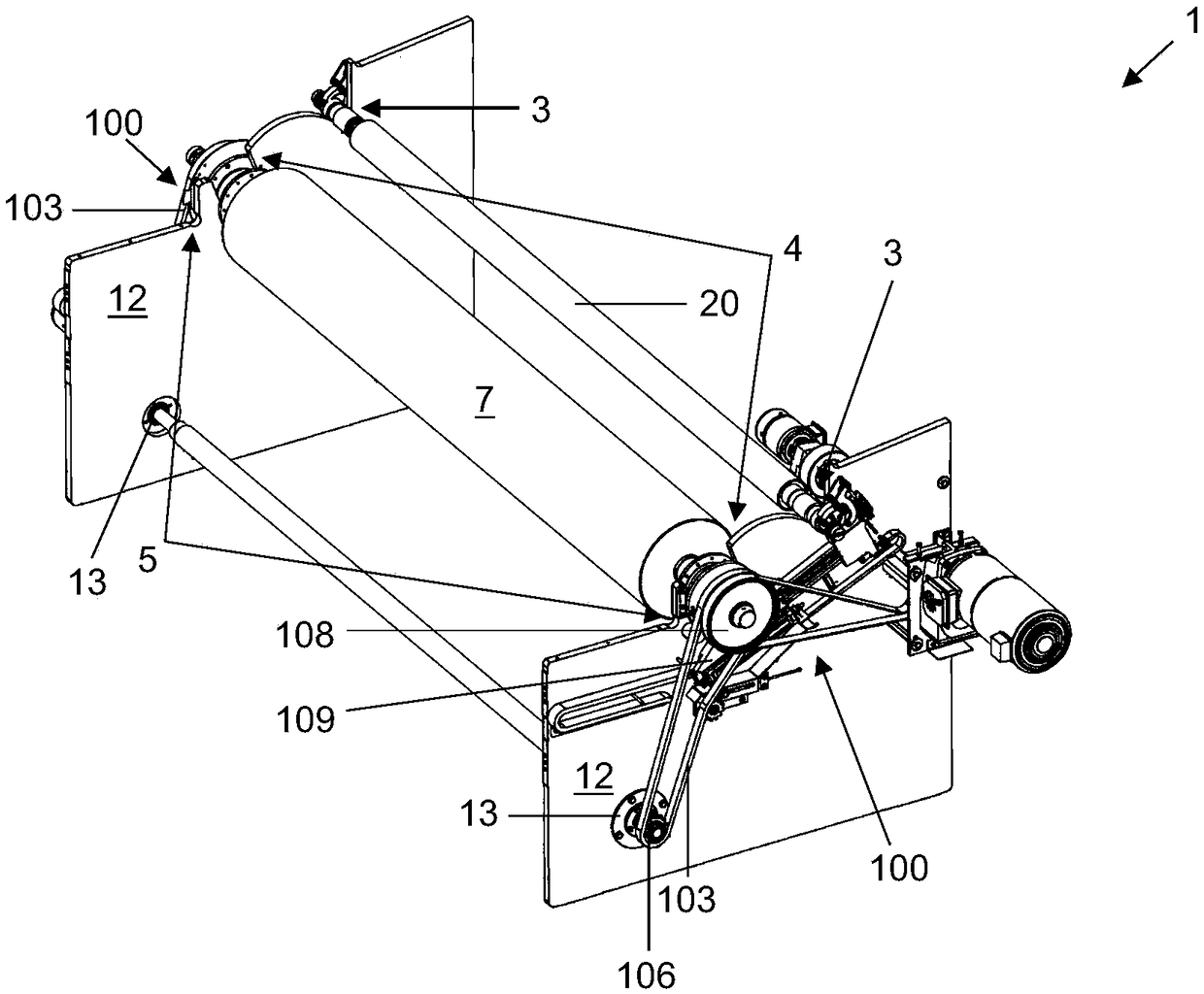

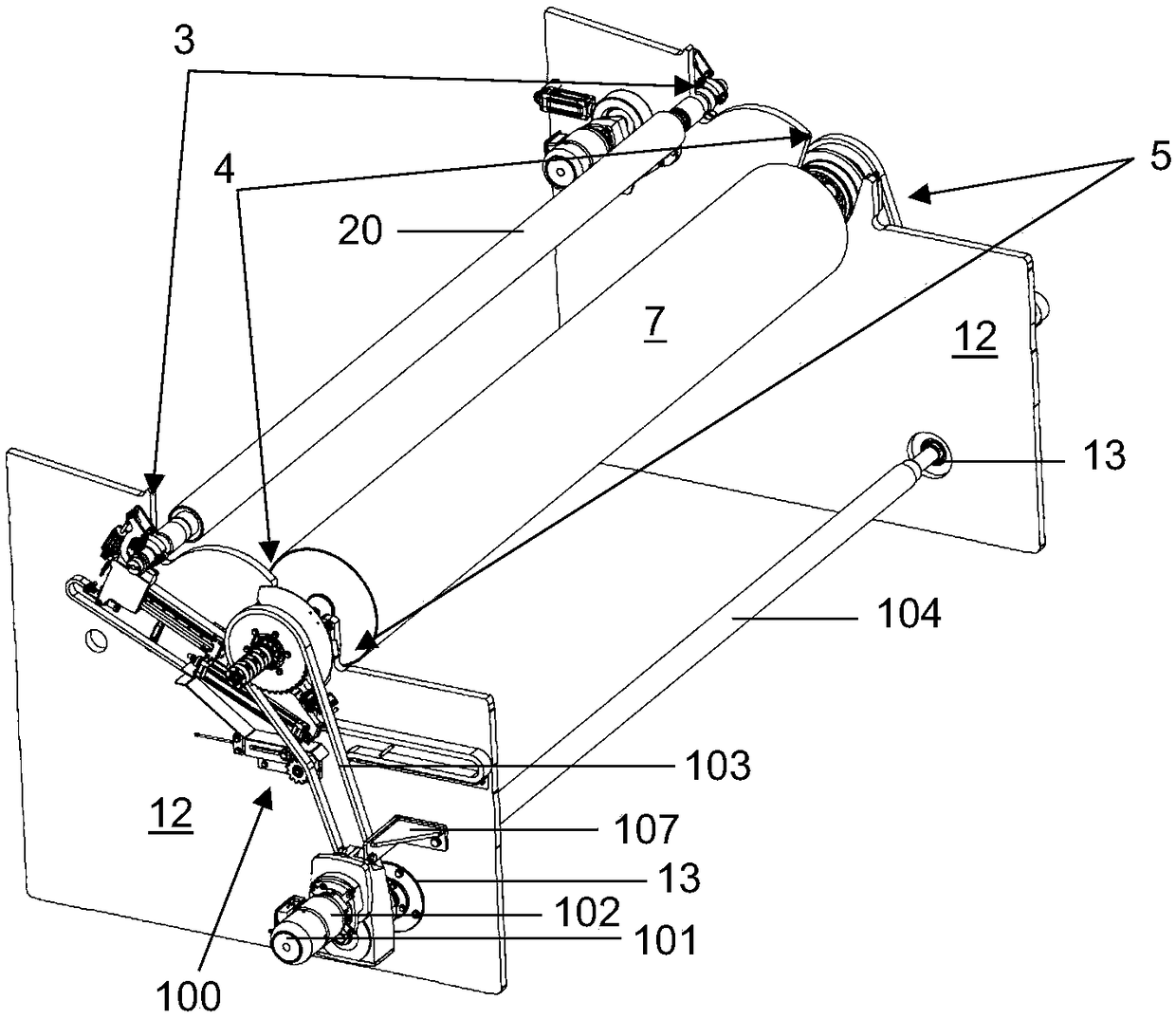

[0025] figure 1 A web winding machine 1 according to an embodiment of the invention is shown. Components that are not essential to the present invention will not be explained in detail.

[0026] The web winding machine 1 essentially comprises two frame walls 12 , which form a frame, which accommodates or holds all other functional components of the web winding machine 1 , via connecting bodies not shown.

[0027] In the area on the right, the machine frame wall 12 has a depository 2 in which unmarked winding shafts (here: two) are located.

[0028] The web winder 1 also comprises a recess on each frame wall 12 defining a waiting position 3 for the winding shaft 20 . Since the winding shaft is held on both sides by the frame walls 12 , the waiting position 3 is realized with two frame walls 12 . The machine frame wall 12 thus forms, with the waiting position 3 , a holding section for the winding shaft 20 to be wound.

[0029] In the waiting position 3 , the winding shaft 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com