Fin field effect transistor and forming method thereof

A fin-type field effect transistor and fin technology, which are applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of improving electrical performance and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

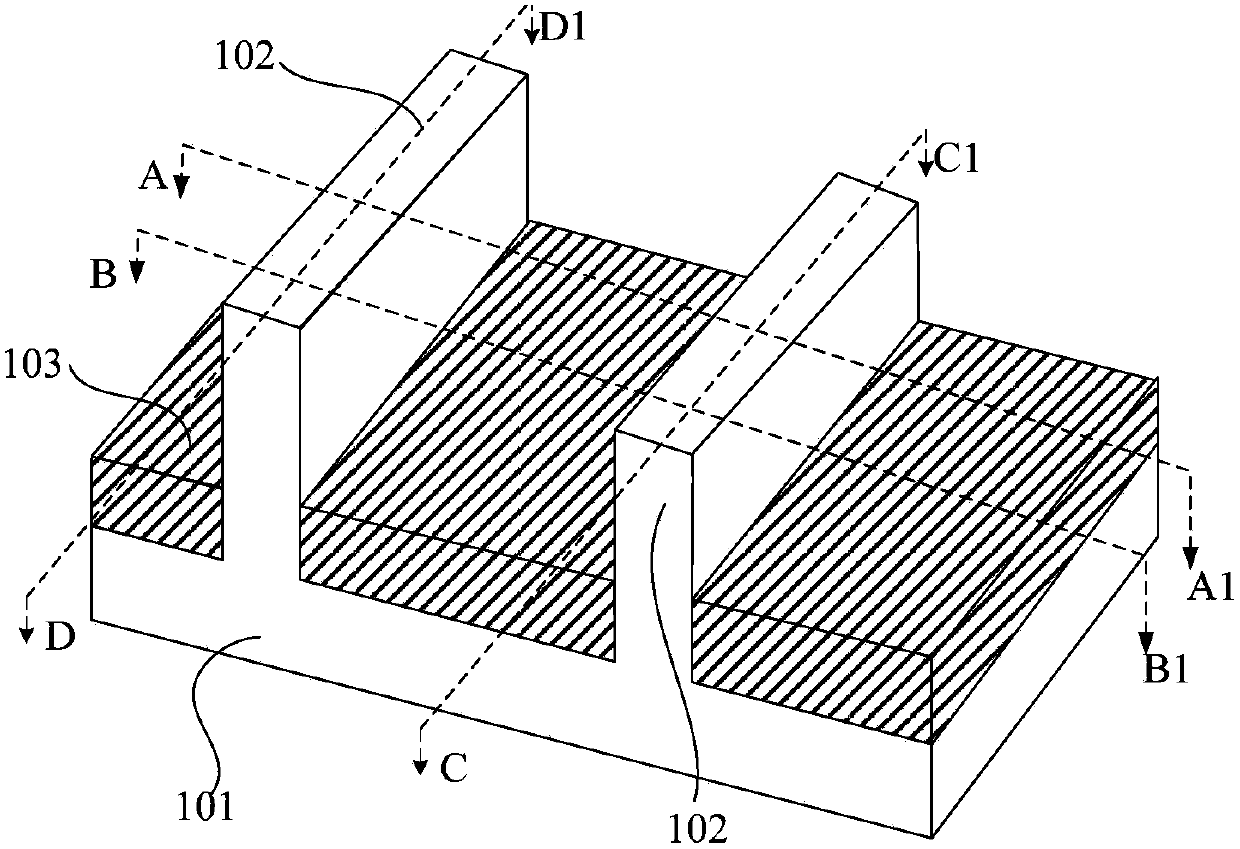

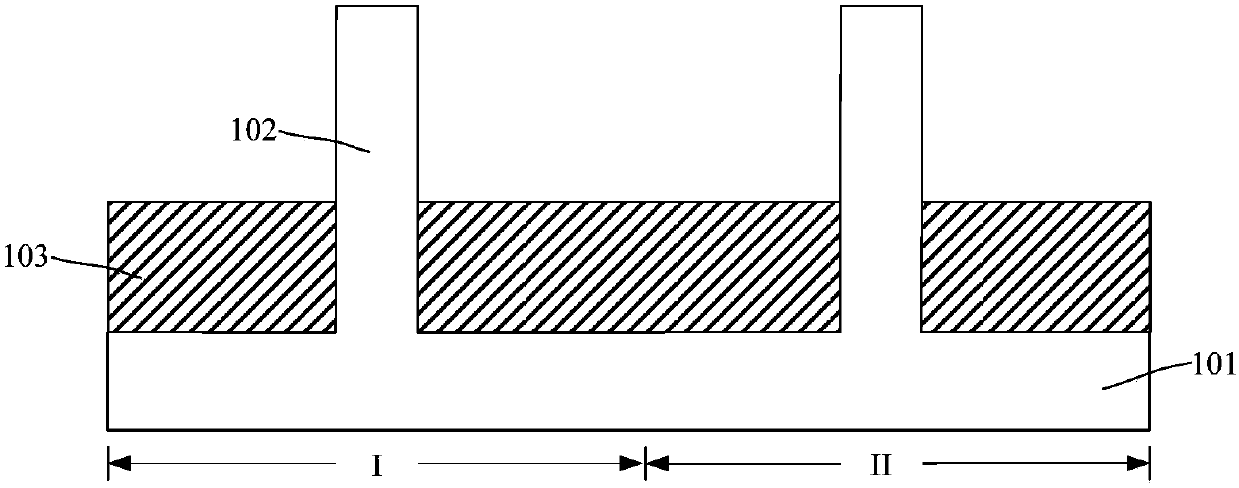

[0023] It can be known from the background technology that the electrical performance of the fin-type field effect transistor formed in the prior art needs to be improved, especially the electrical performance of the NMOS fin-type field effect transistor is poor.

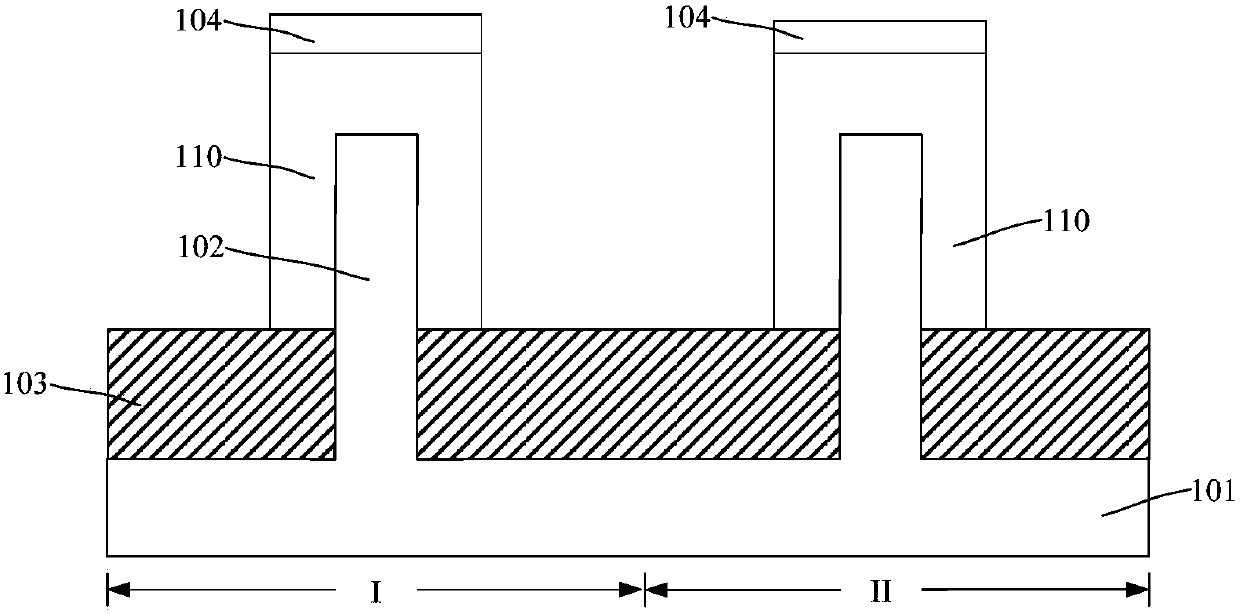

[0024] After analysis, the formation process of the NMOS fin-type field effect transistor includes the steps: forming a mask sidewall on the sidewall of the fin in the NMOS region; and etching and removing the fins of the thickness on both sides of the gate structure in the NMOS region. An N-zone groove is formed in the part; an N-type doped epitaxial layer filling the N-zone groove is formed. In order to limit the morphology and volume of the formed N region doped epitaxial layer, when the fins on both sides of the gate structure in the NMOS region are etched and removed, the mask sidewalls on the sidewalls of the fins are retained, so that the formation The two opposite sidewalls of the groove in the N region are mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com