Slender Z-shaped part composite forming device and forming method

A compound forming and parts technology, which is applied in the field of compound forming devices for slender Z-shaped parts, can solve the problems of large calibration workload, difficult part molding, and large springback of parts, so as to achieve small processing volume, not easily deformed, and improve The effect of forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

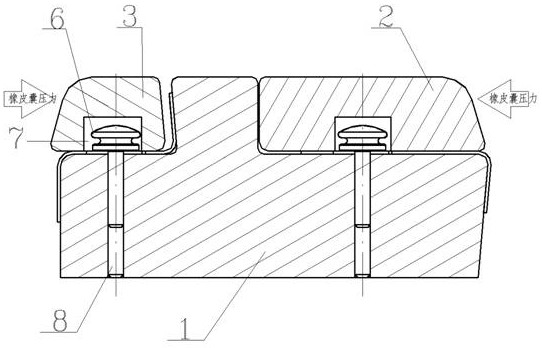

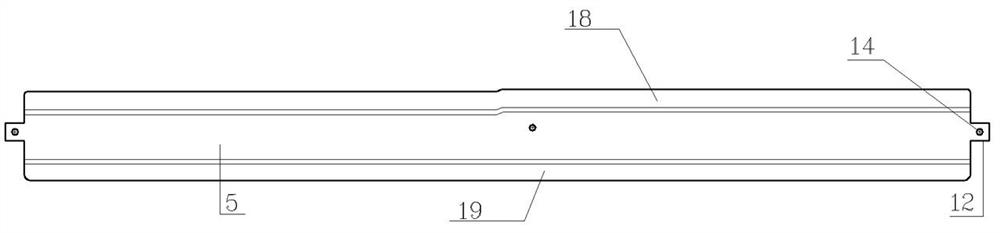

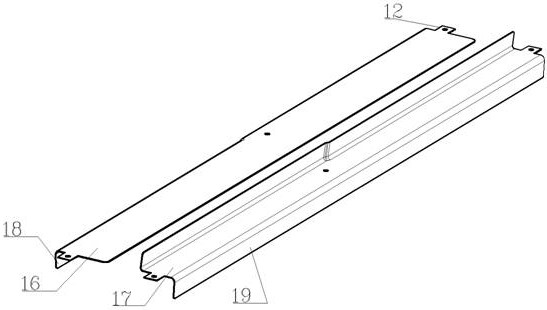

[0050] As a basic embodiment of the present invention, the present invention includes a compound forming device for elongated Z-shaped parts, including a mold body I 1 , a cover plate 2 and a mold body II 3 . The mold body I 1 is in the shape of a "convex" and forms working surfaces for the process A 16 and process B 17 respectively. The width of the working surface in the process A 16 is greater than the width of the working surface in the process B 17 , and the width of the working surface in the process B 17 matches the width of the web surface of the Z-shaped part 5 . The inner shape of the working surface in step B17 matches the outer shape of the working surface in step A16, and the outer shape of the working surface in step B17 and the outer shape of the working surface in step A16 can be the same or different. Steps 4 matching the sunken area on the side of the Z-shaped part 5 are provided on the working surfaces of the process A 16 and the process B 17 . The Z-shaped...

Embodiment 2

[0054] As the best embodiment of the present invention, the present invention includes a compound forming device for elongated Z-shaped parts, and the formed Z-shaped part 5 includes a flange A 18, a flange B 19 and a web. Refer to the attached Figure 10 , This forming device includes a mold body I1, a cover plate 2 and a mold body II 3, for the convenience of operation, the two ends of the mold body I 1 are provided with suspension rings 10, and the cover plate 2 is provided with a handle 11.

[0055] Refer to the attached Figure 5 , the mold body I 1 is in the shape of a "convex" and forms working surfaces for the process A 16 and the process B 17 respectively. Refer to the attached Figure 7 , the distance between the working surfaces of the process A 16 and the process B 17 needs to consider the unfolded shape of the part process B 17, and the value of L is generally 20-100 mm. The width of the working surface in the process B 17 matches the width of the web surface o...

Embodiment 3

[0062] As another preferred embodiment of the present invention, the present invention includes a composite forming method for elongated Z-shaped parts, comprising the following steps:

[0063] ⅰ. Design the first positioning hole 14 and the process lug 12 on the Z-shaped part 5 according to the three-dimensional digital model, and determine the expanded profile of the Z-shaped part 5, blanking and making the first positioning hole 14 according to the expanded profile;

[0064] ⅱ. Formed parts:

[0065] Process A 16: Position the Z-shaped part 5 on the mold body I 1 with the positioning pin 6, position the cover plate 2 with the counter-mold pin 8 and place it on the Z-shaped part 5, and use a rubber bladder hydraulic press to form the bent edge A of the sunken side 18;

[0066] Process B 17: Remove the Z-shaped part 5 formed in process 1, then rotate the Z-shaped part 5 by 180°, use the positioning pin 6 to position the Z-shaped part 5 on the mold body I 1, and use the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com