Cleaning machine with supporting and thrusting mechanism

A technology of a moving mechanism and a washing machine, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as high center of gravity of transportation and transfer, pollution, long transportation path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

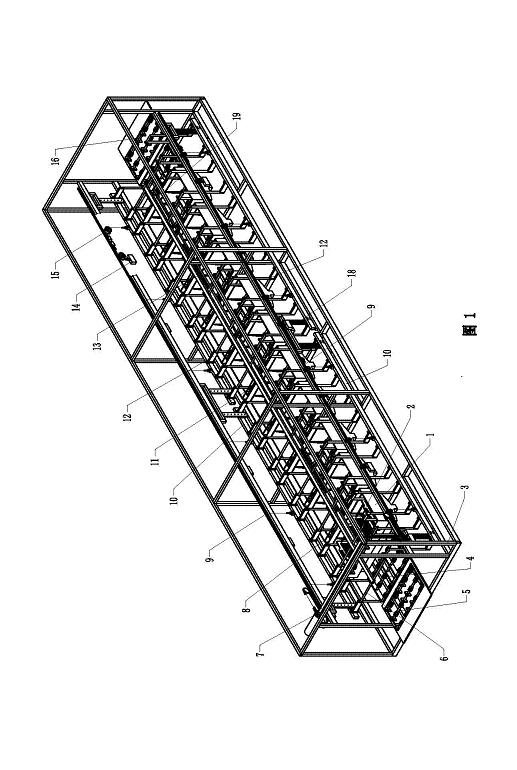

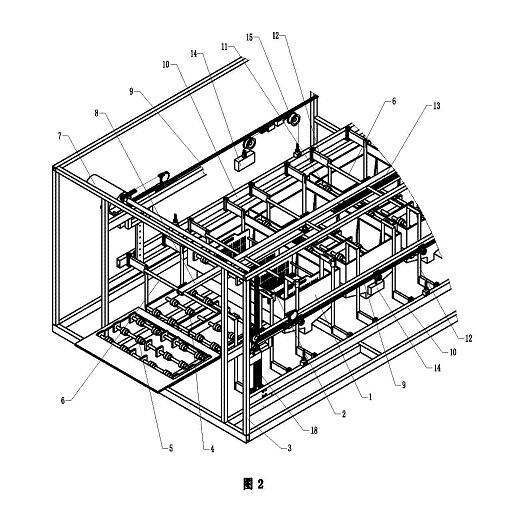

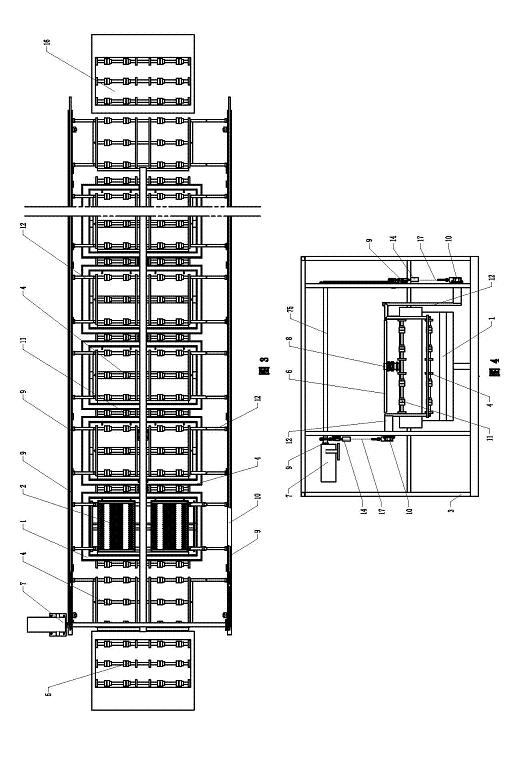

[0026] exist figure 1 , figure 2 In the cleaning machine with lifting and pushing mechanism shown, the main body of the frame 3 is a hexahedral rectangular frame structure, and the outside of the frame 3 is covered with panels or door and window assemblies, and there is also a cleaning tank between the internal cleaning tank area and other components. The partition makes the cleaning tank area of the washing machine form a relatively closed working space. Ten cleaning tanks 1 are arranged in sequence along the length direction in the frame-type frame 3, and the distance between adjacent cleaning tanks 1 is equal to each other. on the frame of the lower part. The pipeline system used to provide the cleaning liquid leads to the cleaning tank 1. An ultrasonic system can also be installed in the cleaning tank 1 according to the process requirements. According to the different cleaning requirements of silicon materials and wafers, each cleaning tank 1 is filled with different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com