Black curable resin composition

A technology of curable resin and composition, which can be used in secondary processing of printed circuits, printed circuit parts, and photosensitive materials for opto-mechanical equipment, etc. Achieve improved resolution and dimensional accuracy, prevent insufficient photocuring, and improve resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 comparative example 1~5

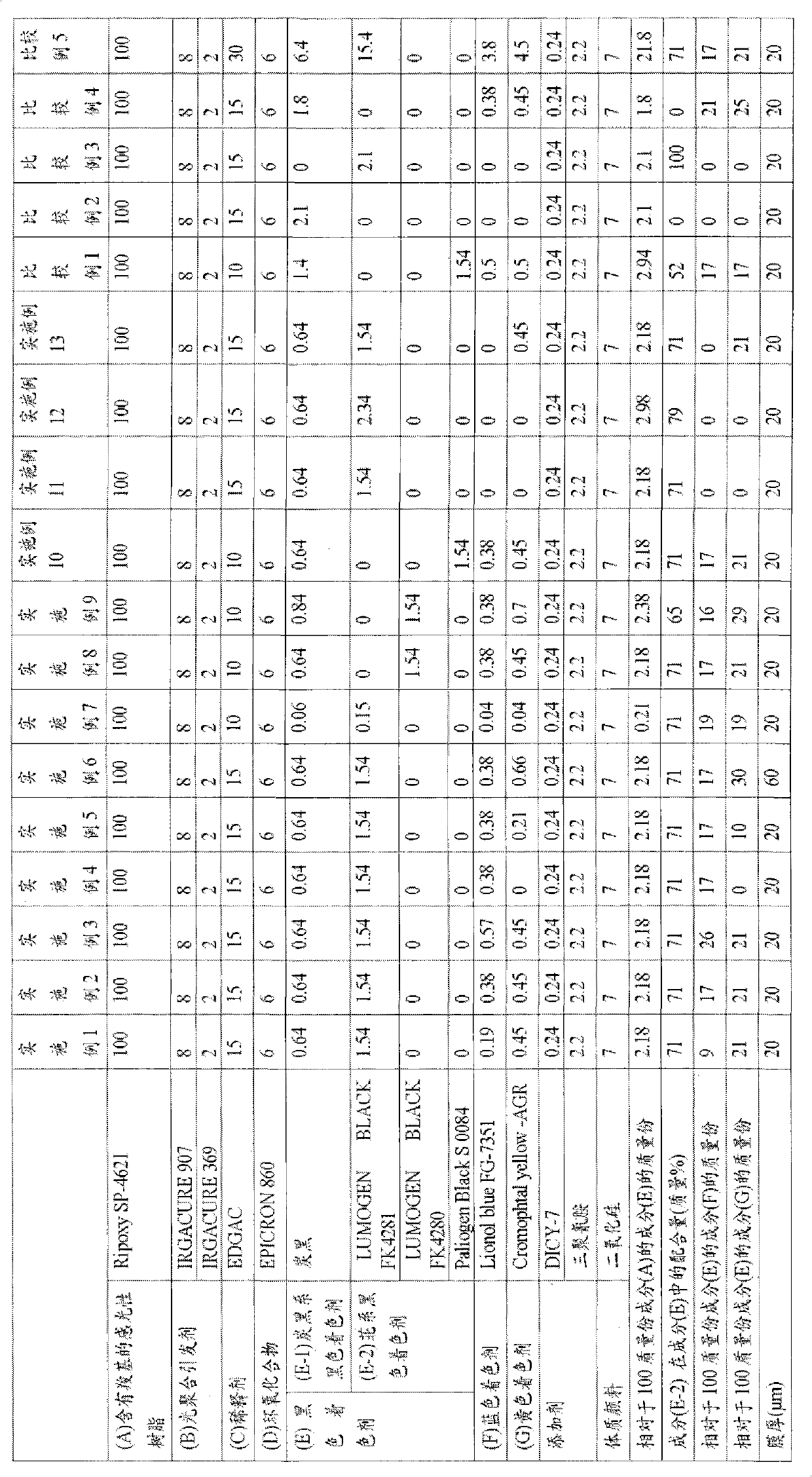

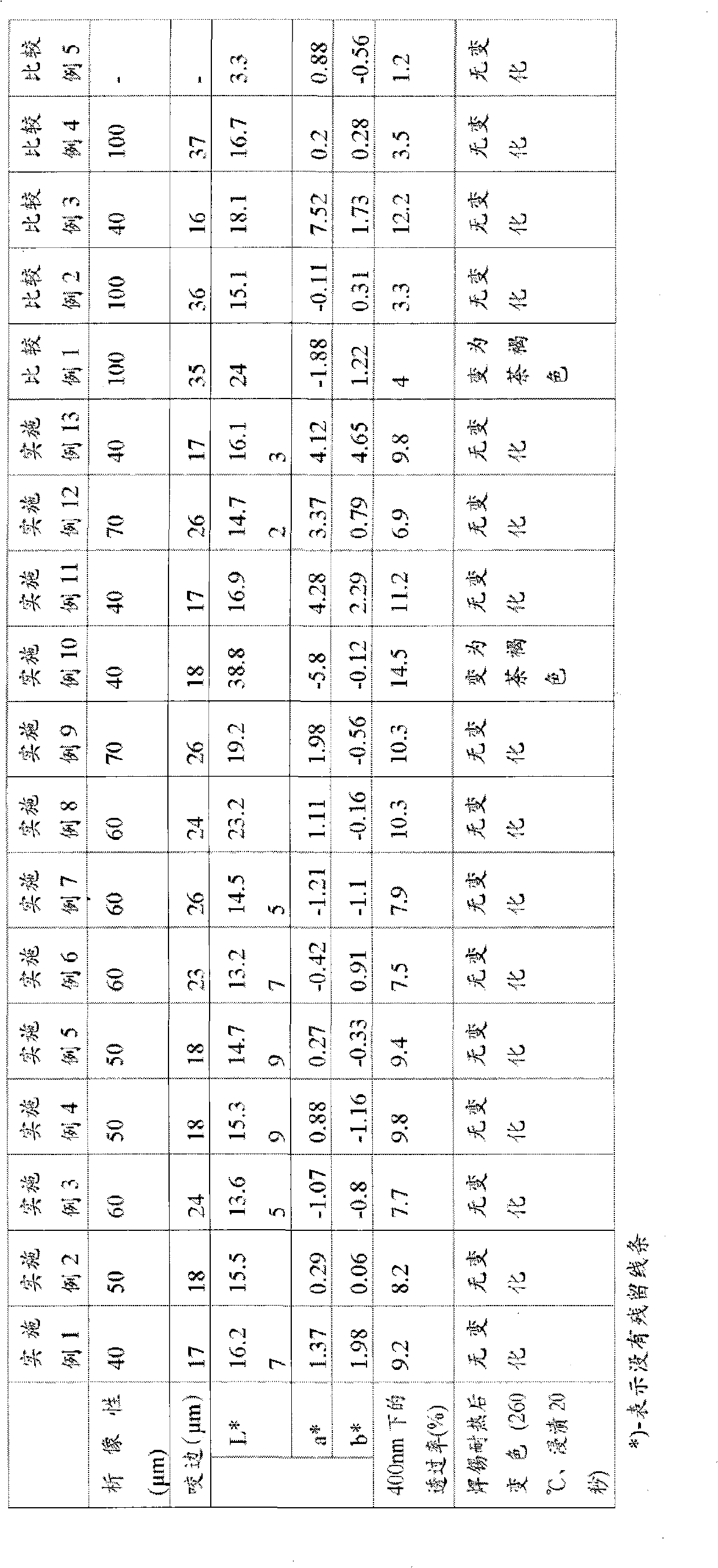

[0069] The ingredients shown in Table 1 below were blended in the mixing ratio shown in Table 1 below, and after premixing with a mixer, they were mixed and dispersed using a three-roll mill at room temperature to prepare Examples 1-13 and Comparative Example 1. ~5 Black curable resin composition used. Then, the prepared black curable resin composition was coated on the substrate by the following test piece preparation process to prepare a test piece. The compounding amount of each component shown in the following Table 1 shows a mass part unless otherwise indicated.

[0070] 【Table 1】

[0071]

[0072] In addition, the details of each component in Table 1 are as follows.

[0073] (A) carboxyl-containing photosensitive resin

[0074] ·Ripoxy SP-4621: Showa Polymer Co., Ltd., polyacid-modified cresol novolac type acrylic epoxy resin

[0075] (B) Photopolymerization initiator

[0076] ·IRGACURE 907: 2-Methyl-1-[4-(methylthio)phenyl]-2-morpholinopropane-1-one manufactured by Ciba Fine Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com