Guiding sliding shoe of coal cutter walking part

A technology for guiding sliding shoes and shearers, which is applied in earthwork drilling, slitting machinery, propulsion, etc., can solve the problems of waste of materials, increased maintenance costs of shearers, etc., and achieve the effect of increasing strength and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

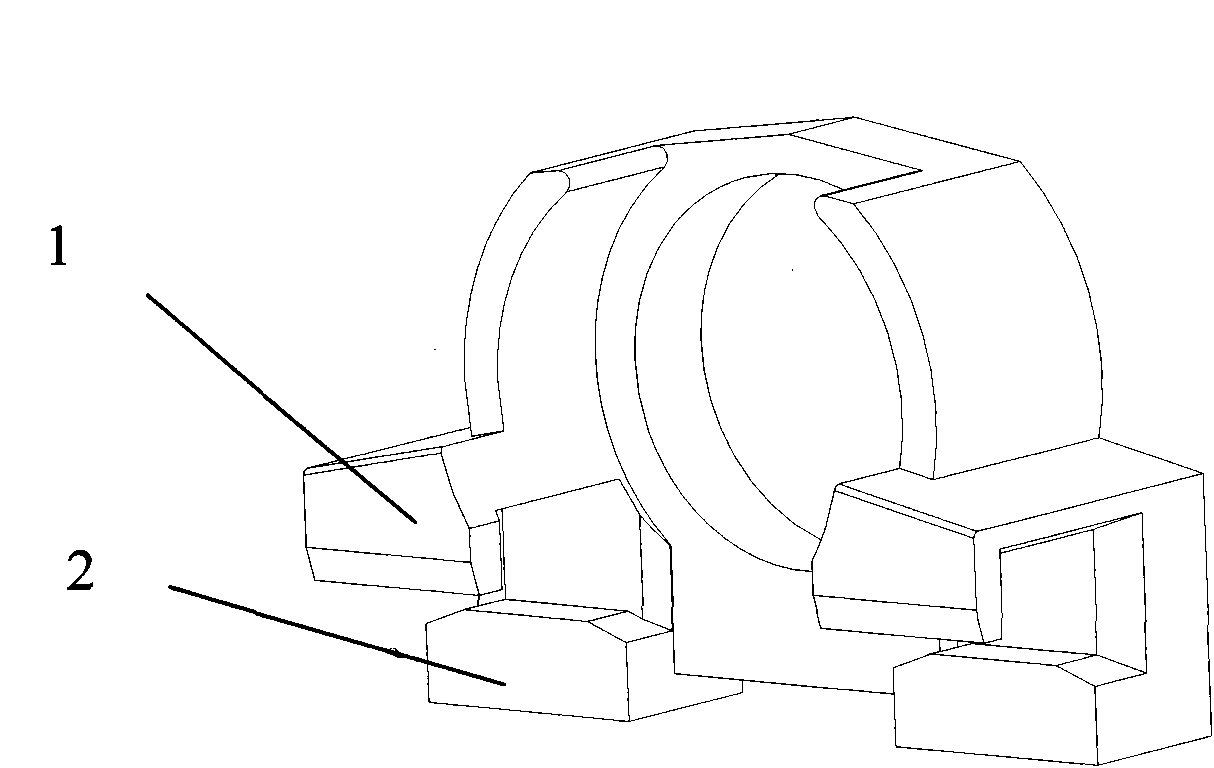

[0026] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0027] The walking part of the shearer meshes with the pin row of the conveyor through the guide shoe provided, so that the traveling wheels roll on the pin row to drive the shearer to walk.

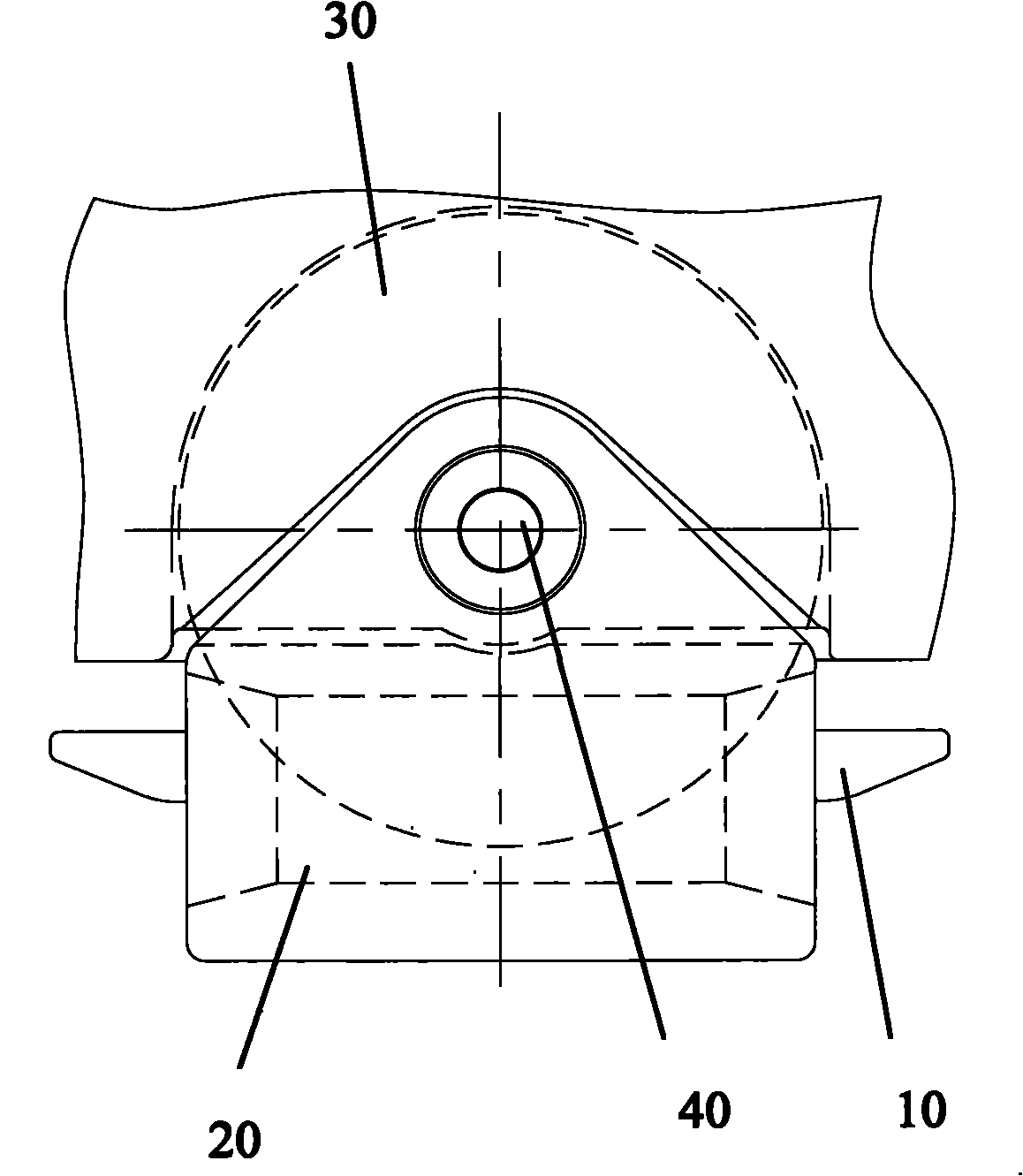

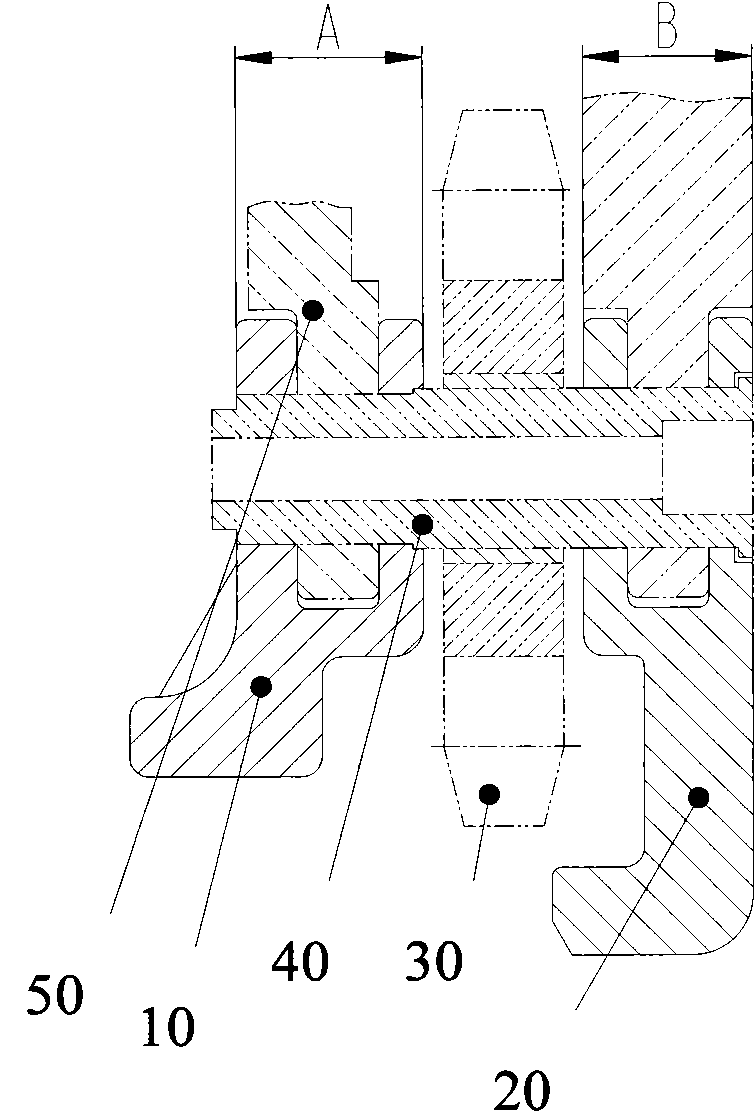

[0028] Please refer to figure 2 and image 3 As shown, the present invention improves the guide shoe of the walking part of the coal mining machine to include a guide shoe hook 20 and a guide shoe plate 10 respectively connected to the main body 50 of the coal mining machine. Guide shoe hook 20, guide shoe plate 10 are clamped at walking wheel 30 both sides, are connected with each other through the through hole that guide shoe hook 20, walking wheel 30, guide shoe plate 10 are provided with with bearing pin 40 successively.

[0029] See Figure 4 As shown, the top of the guide shoe plate 10 is provided with a first groove 11 , and a pair of shoe plate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com