Automobile parking brake mounting bracket structure

A technology for installing brackets and car hands, applied in the direction of manual starting devices, etc., can solve the problems of not being able to increase the transmission of side impact force, the workload of parts modification, and the inability to improve the front seats, etc., so as to solve the difficulty of stamping and improve the Overall rigidity, the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

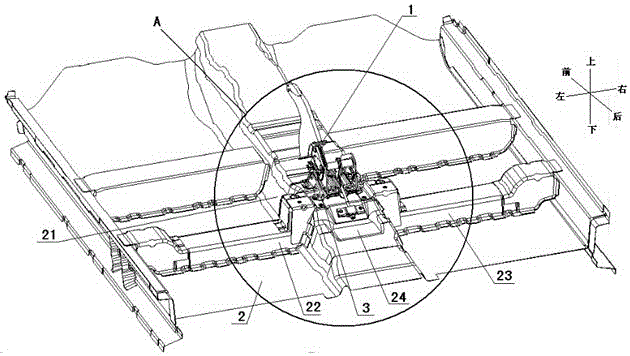

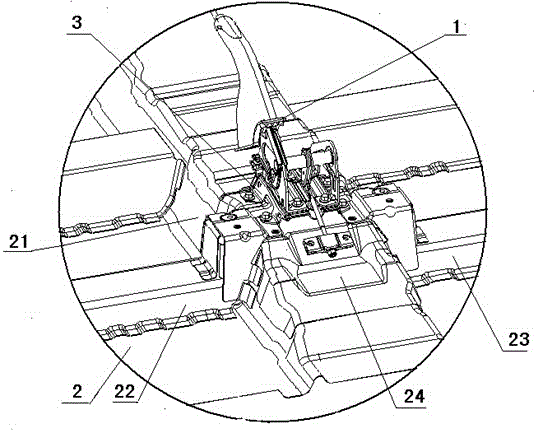

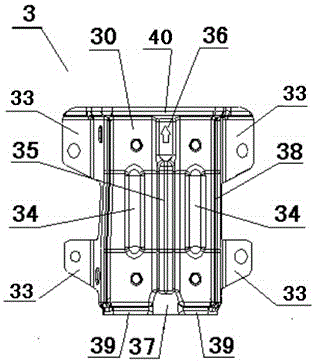

[0029] see figure 1- Figure 6 The shown car handbrake mounting bracket structure includes a handbrake 1, a front floor assembly 2 and a handbrake bracket 3; the front floor assembly 2 includes a front floor central passage 21, a reinforcement plate connected to the rear of the front floor central passage 24. The left rear crossbeam assembly 22 of the front row seat and the right rear crossbeam assembly 23 of the front row seat have a prominent substantive feature: there is a front protrusion on the front part of the reinforcing plate 24, the front The left side and the right side above the protrusion are respectively provided with a rear mounting point 25; a rear protrusion is provided at the rear of the front floor central channel 21, and a front mounting point is respectively provided on the left side and the right side of the rear protrusion 26. The left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com