Tape

a technology of tape and surface, applied in the field of tape, can solve the problems of increasing environmental pollution, increasing the disposal and disposal of gypsum board sheathing and other panels, and even lethal to humans, and achieves the effects of increasing the length dimension, and increasing the resistance to pulling for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

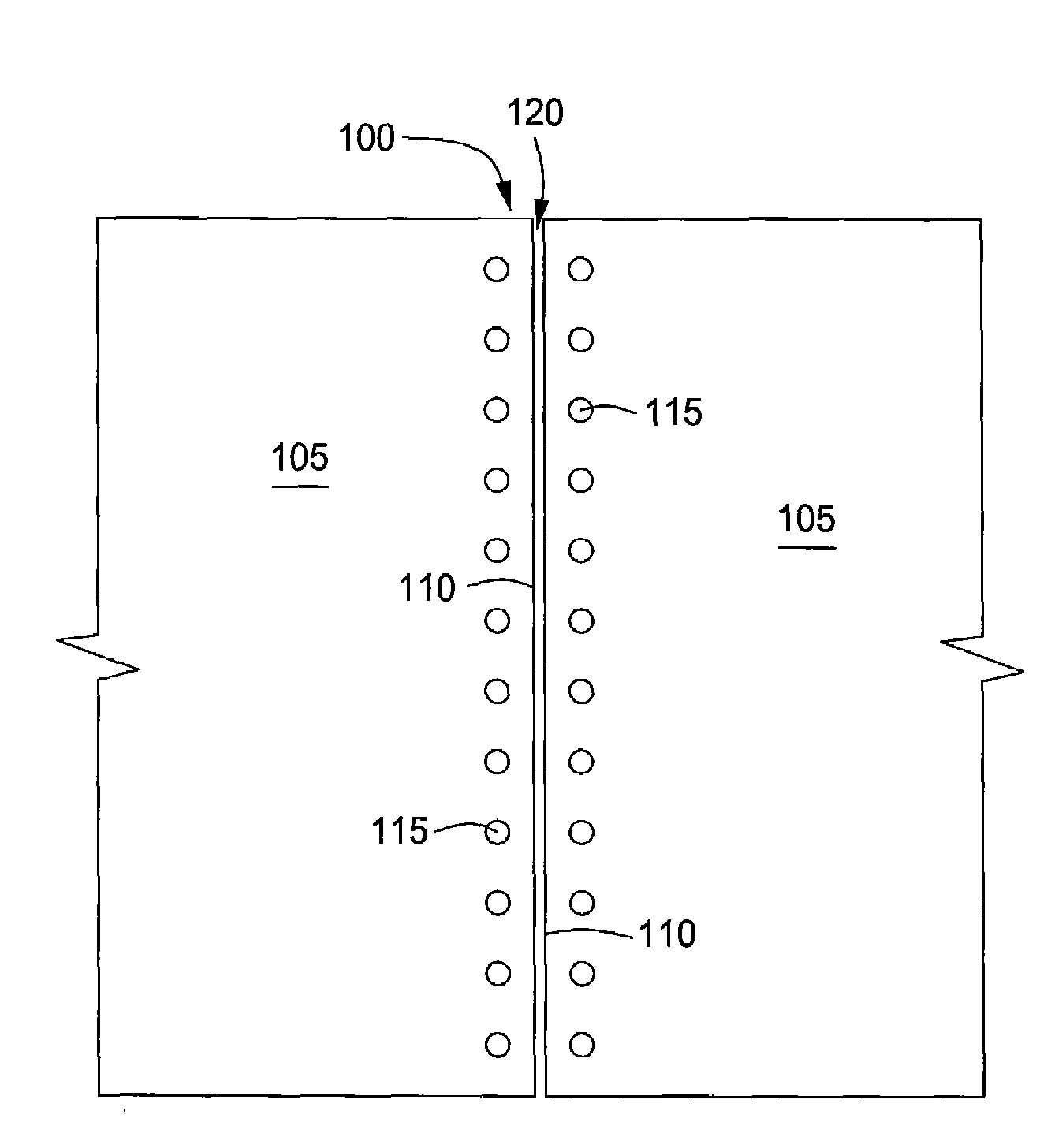

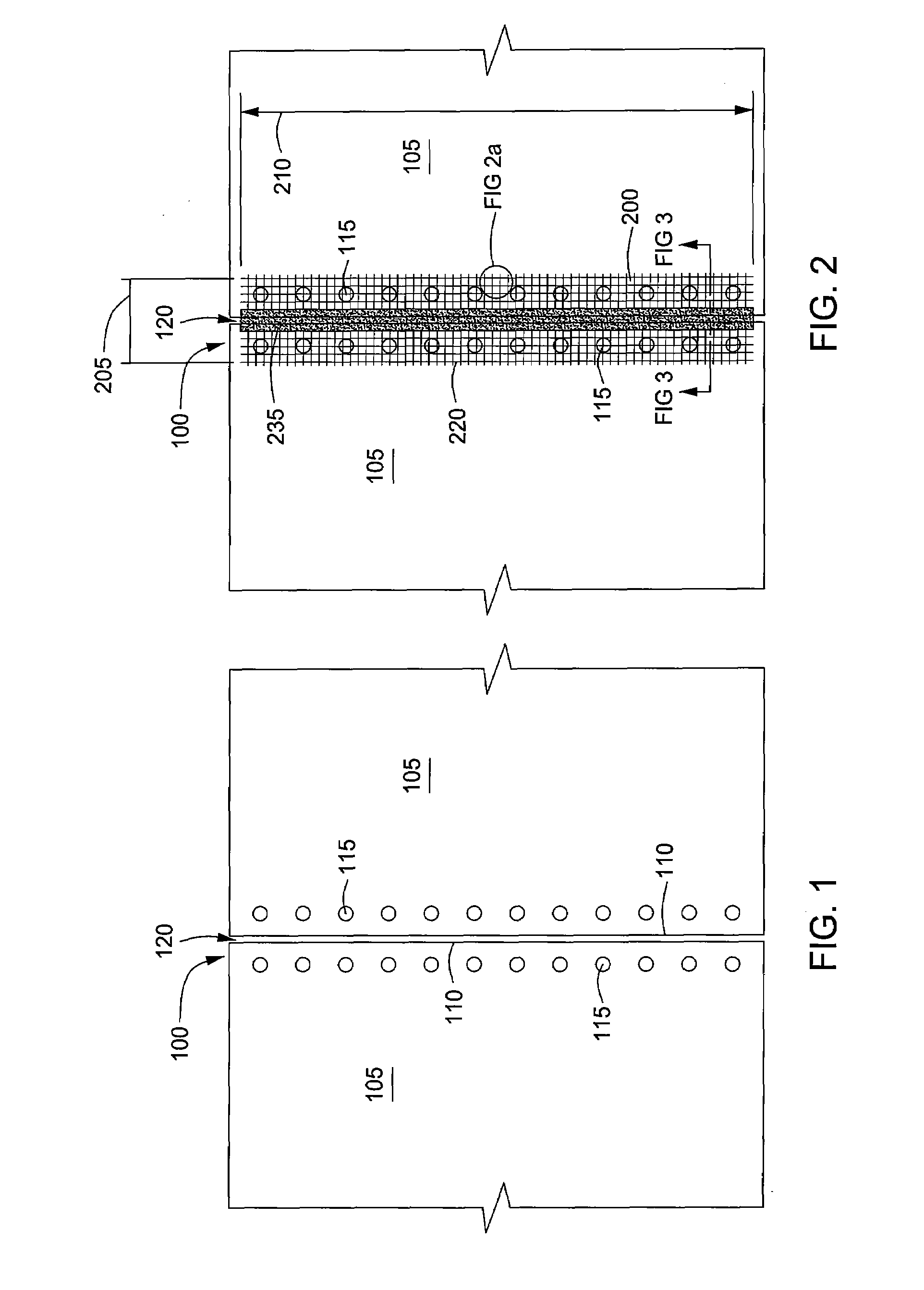

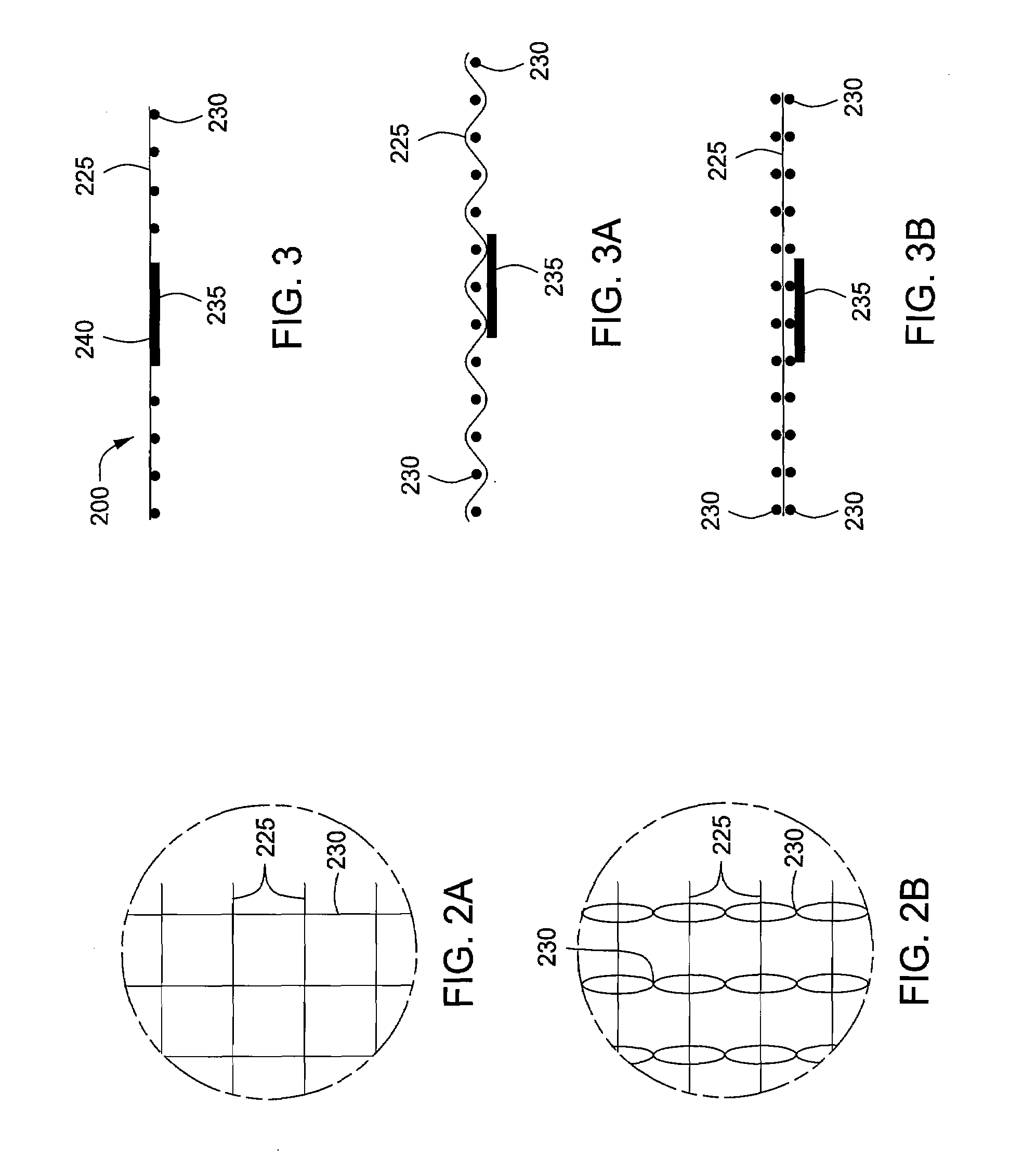

[0030]FIG. 1 is a front view of a portion of a panel joint 100. The panel joint 100, as shown, has two panels 105 which are adjacent at edges 110. The panels 105 connect to a support element, not shown, with fasteners 115. The support element may be any element for supporting the panels 105 including, but not limited to, wood studs, metal studs, concrete blocks, or furring channels. The fasteners 115 may be any fastener including, but not limited to, screws, or nails, or an adhesive. In one embodiment, the panels 105 are gypsum board sheathing panels. Although it should be appreciated that any paneling may be used. With the panels 105 attached to the support element, a small gap 120 or discontinuity exists between the panels 105. In order to finish the panel surface, a tape and a compound are applied to the panel joint 100. The compound cures into a hardened material which covers the tape and the joint. The compound is then smoothed into a continuous surface as will be described in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com