Laser etching circuit structure of touch panel

A circuit structure, touch panel technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve problems such as disconnection, inconsistent line width of trace 33, deviation of laser moving path 32, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted in this creation are hereby drawn to illustrate in detail the characteristics and functions of the preferred embodiment of this creation as follows, so that Li can fully understand it, but it should be noted that these contents are not constituting the limitations of the invention.

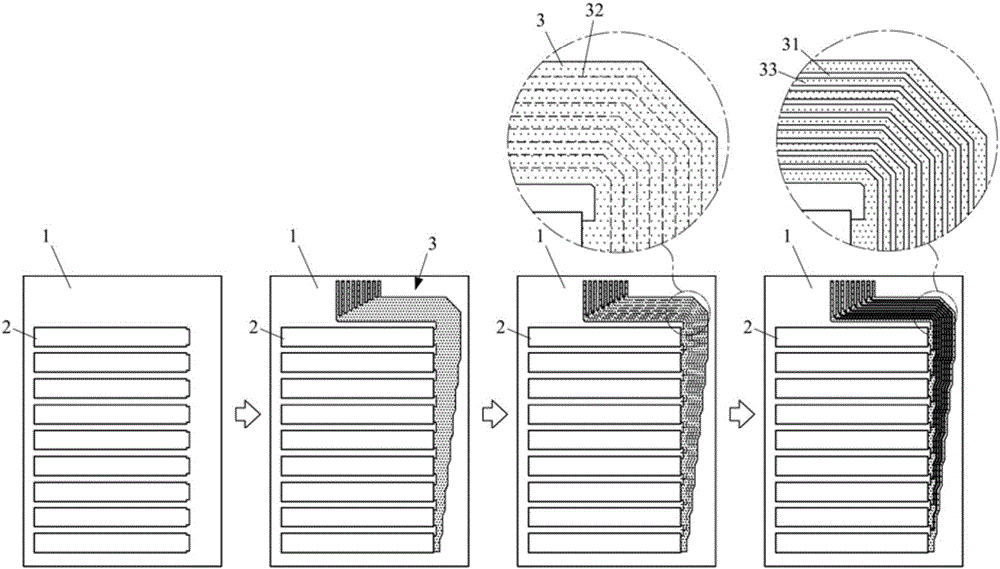

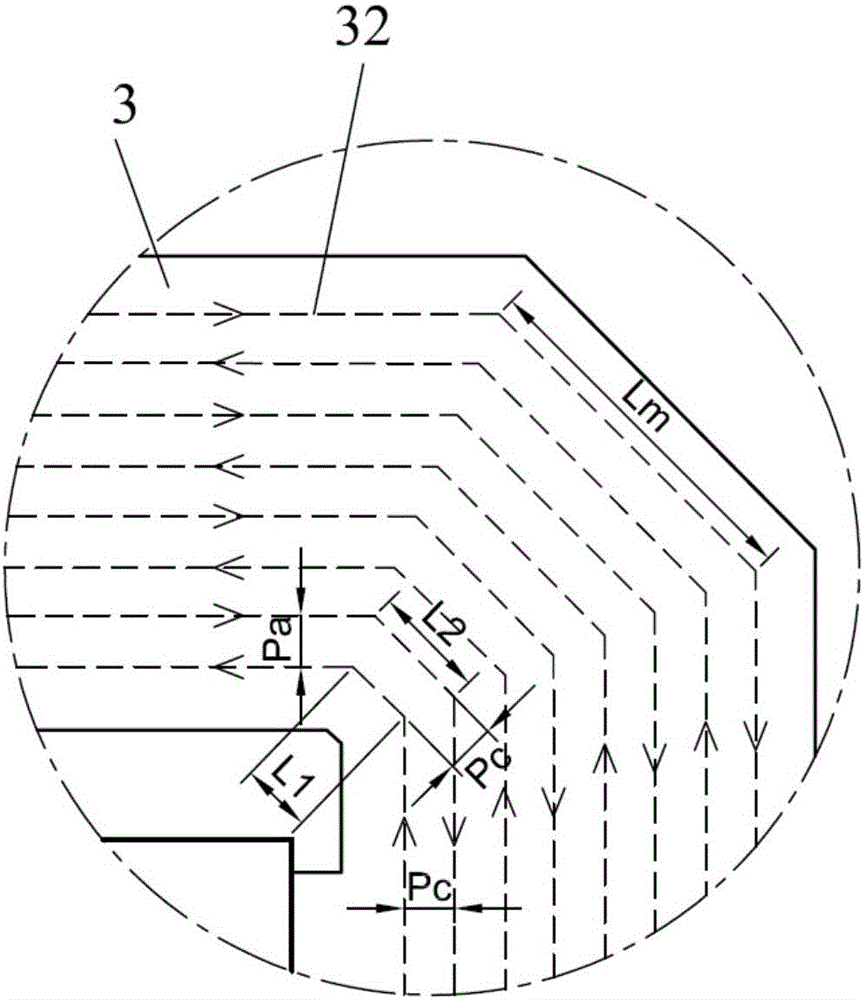

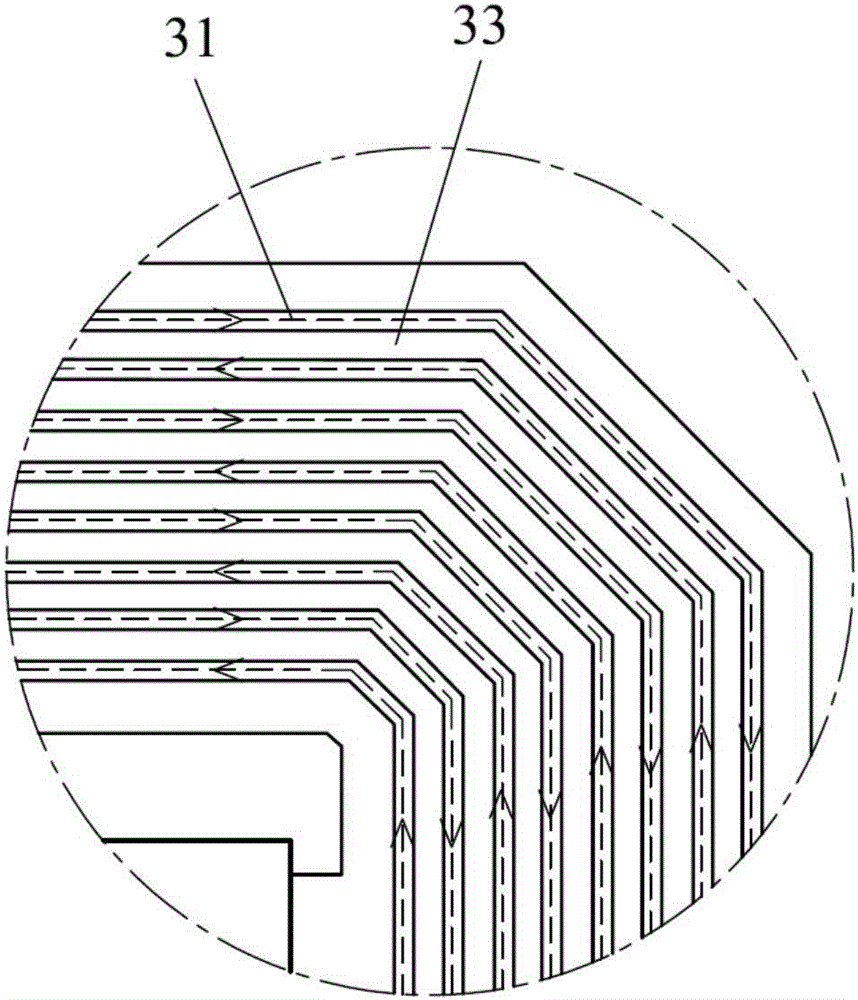

[0016] Please also see Figure 5 , Image 6 and Figure 7 As shown, it is a structural schematic diagram, a partial circuit schematic diagram, and a partial circuit enlarged schematic diagram of a preferred embodiment of the laser-etched circuit structure of the touch panel of the invention. The invention provides a laser etching circuit structure of a touch panel, which is located on a touch substrate 1 and is connected to a plurality of transparent electrodes 2 in telecommunications. The laser etching circuit structure of the touch panel includes a main circuit area 5 and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com