Scissor type rubbish pushing and pressing structure and rubbish collecting box adopting same

A scissor-type, garbage technology, applied in garbage collection, trash can, application, etc., can solve the problems of uneven force on scissors frame, inclined garbage push plate, etc., and achieve the effect of easy maintenance, reduced friction, and high guiding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with accompanying drawing.

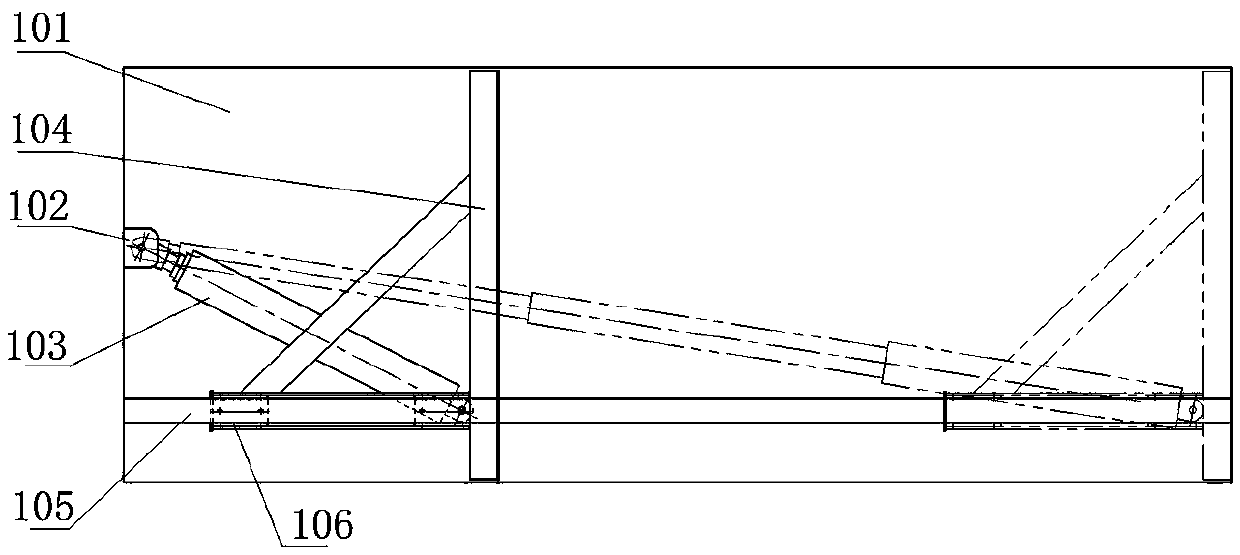

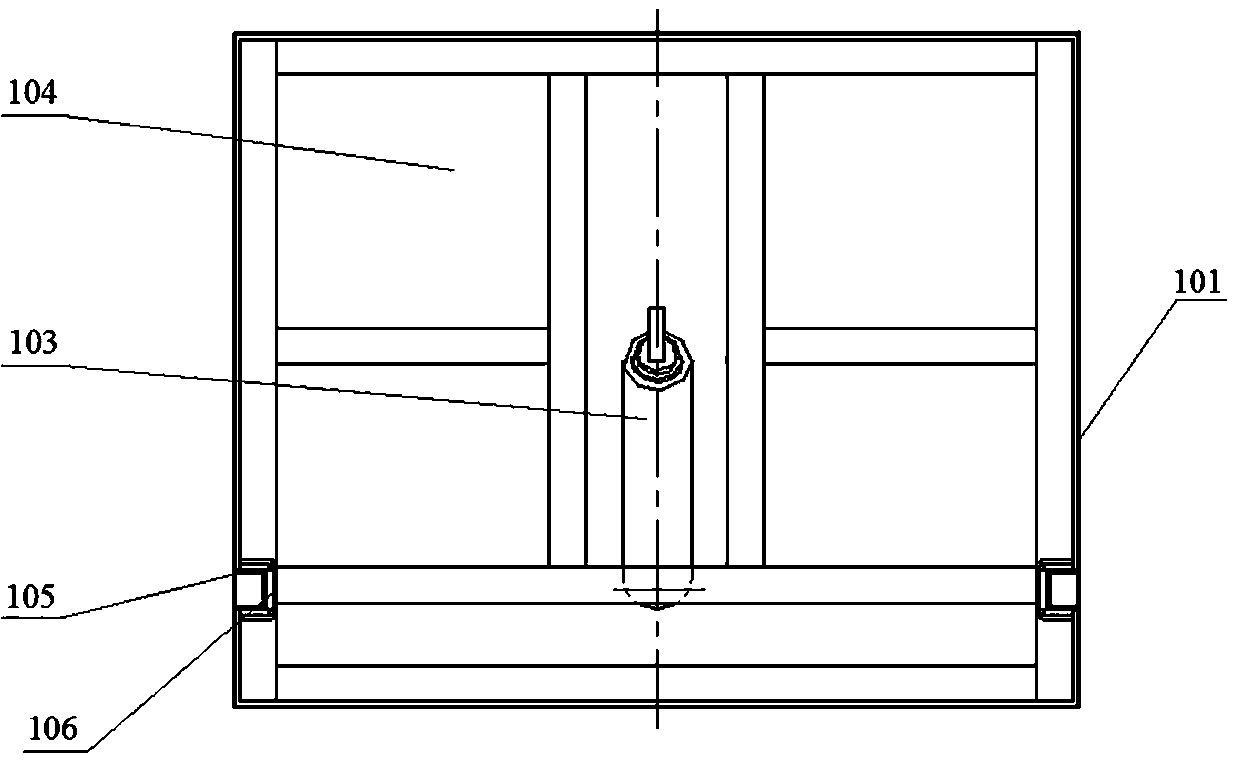

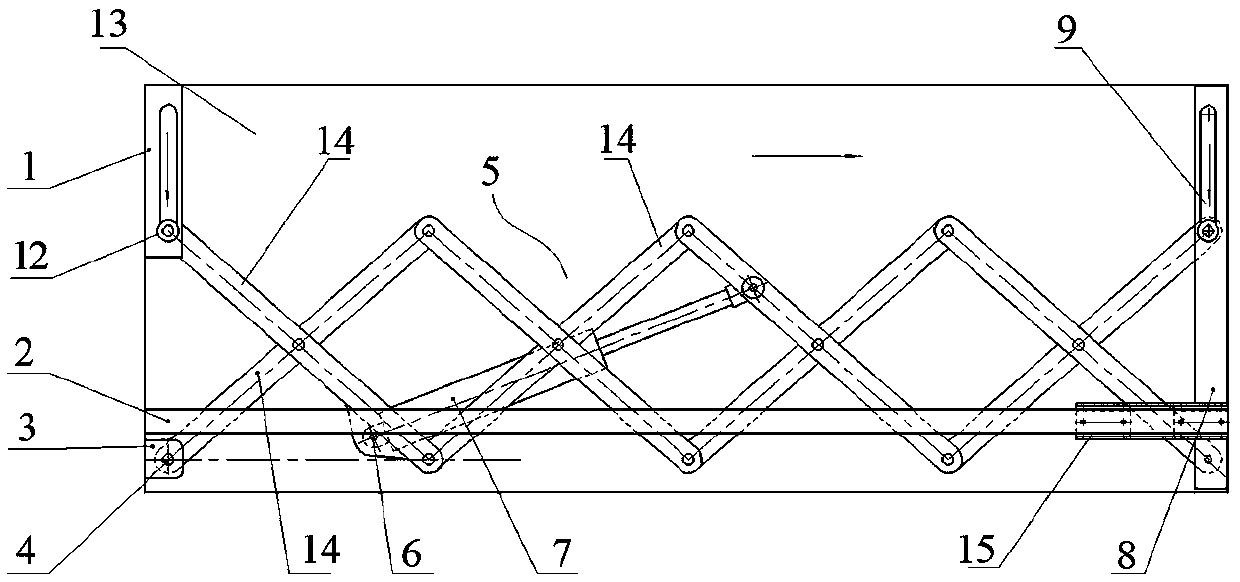

[0062] An embodiment of the garbage collection box in the present invention is for example Figure 3~Figure 6 Shown, comprise rubbish bin body 13, be provided with scissors frame 5, rubbish push pedal 8, push pedal guide rail 2 and telescopic cylinder 7 in the rubbish bin body 13. Wherein the rubbish push plate 8 adopts the form that the front side is a vertical plane.

[0063] The scissors frame 5 is horizontally telescopic and includes four scissor bars 14 that form an X-shaped hinge. The lower front end of the scissor frame 5 is hinged on the bottom of the garbage push plate 8, the top of the garbage push plate 8 is provided with a push plate chute 9 extending up and down, and the upper front end of the scissor frame 5 is hinged with guide rollers 12. The guide roller 12 guides and cooperates with the push pedal chute 9 up and down, and is arranged in the push pedal ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com