Robotic device for visual inspection of internal components of pebble bed reactor core cavity

A visual detection and reactor technology, applied in the field of robotics, can solve the problems of difficult positioning of the detection device and inability to detect the core cavity, and achieve the effects of easy position determination, convenient positioning, and increased range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

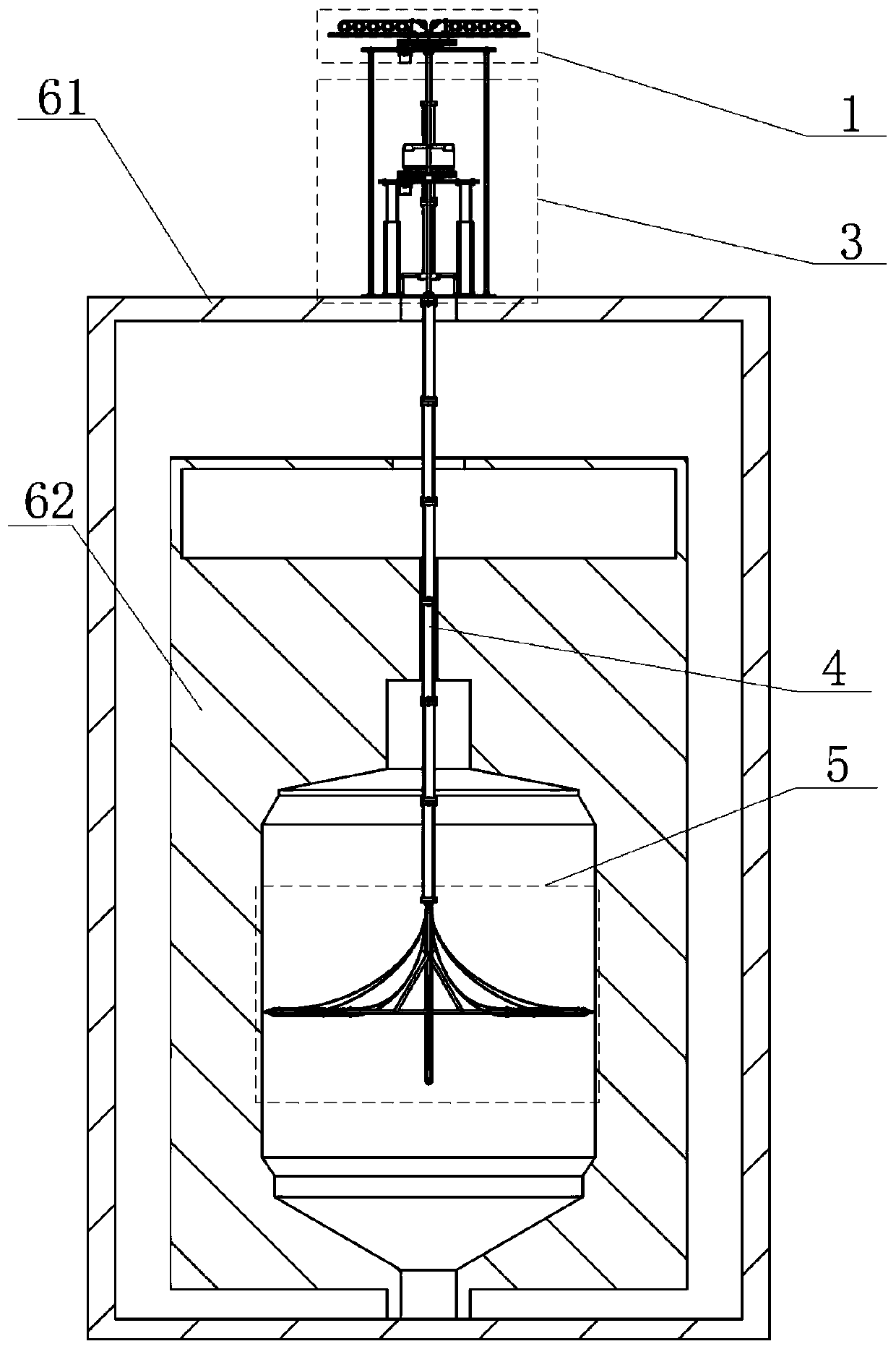

[0028] figure 1 It is a front view of an embodiment of a robot device designed by the present invention for visual inspection of components in the core cavity of a pebble bed reactor (cross-sectional view of the reactor hall and pebble bed reactor), including a drive unit 1, a lifting and rotating mechanism 3, and a connecting pipe Component 4 and vision inspection robot 5 .

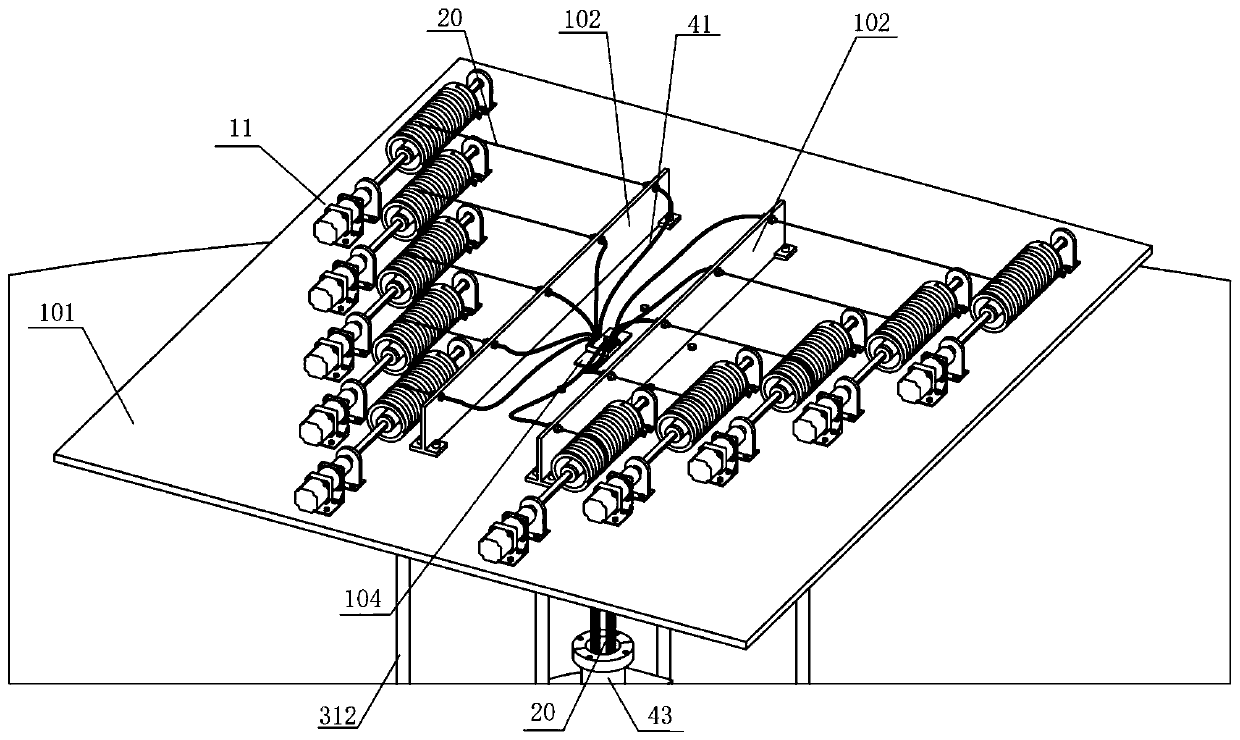

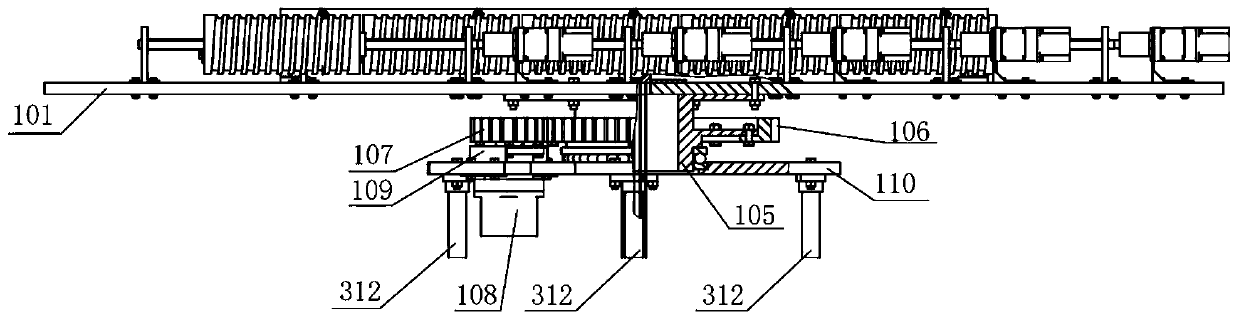

[0029] figure 2 yes figure 1 The perspective view of the drive unit in the shown embodiment, image 3 yes figure 1 The left side view of the drive unit in the shown embodiment (partial parts in section), the drive unit 1 is fixed above the lifting and rotating mechanism 3, including the drive platform 101, the drive platform motor 108, the winch unit 11, the rope group 20 and the first transmission Mechanism; hoisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com