Guide and rotation mechanism for crane hanger

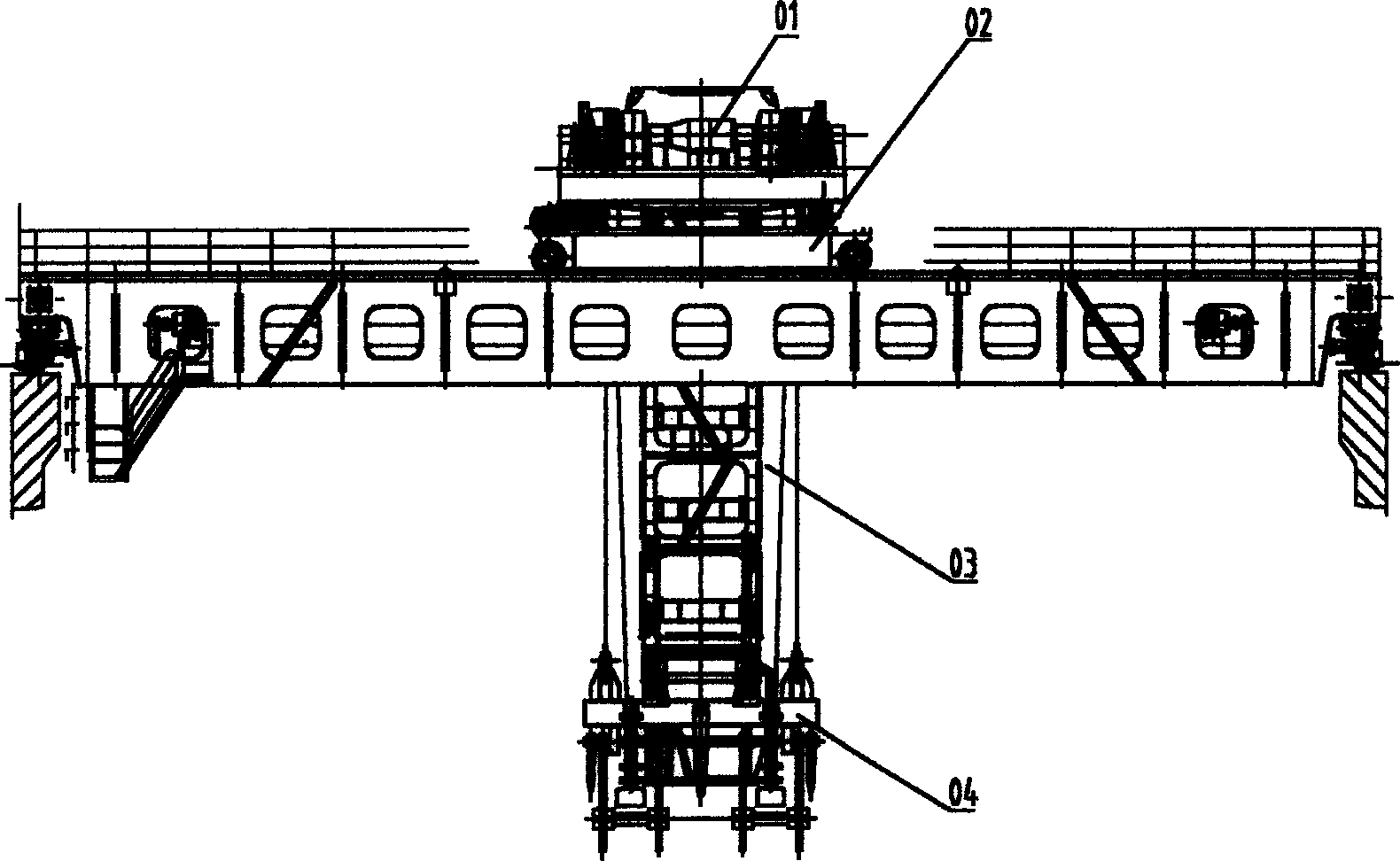

A technology of a rotating mechanism and a guiding mechanism, which is applied in the directions of load hanging elements, transportation and packaging, can solve the problems of poor vertical lifting guidance, easy swinging of spreaders and heavy objects, and poor operation stability, and achieves the guiding structure. The effect of simplifying, lowering the upper limit, and increasing the operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

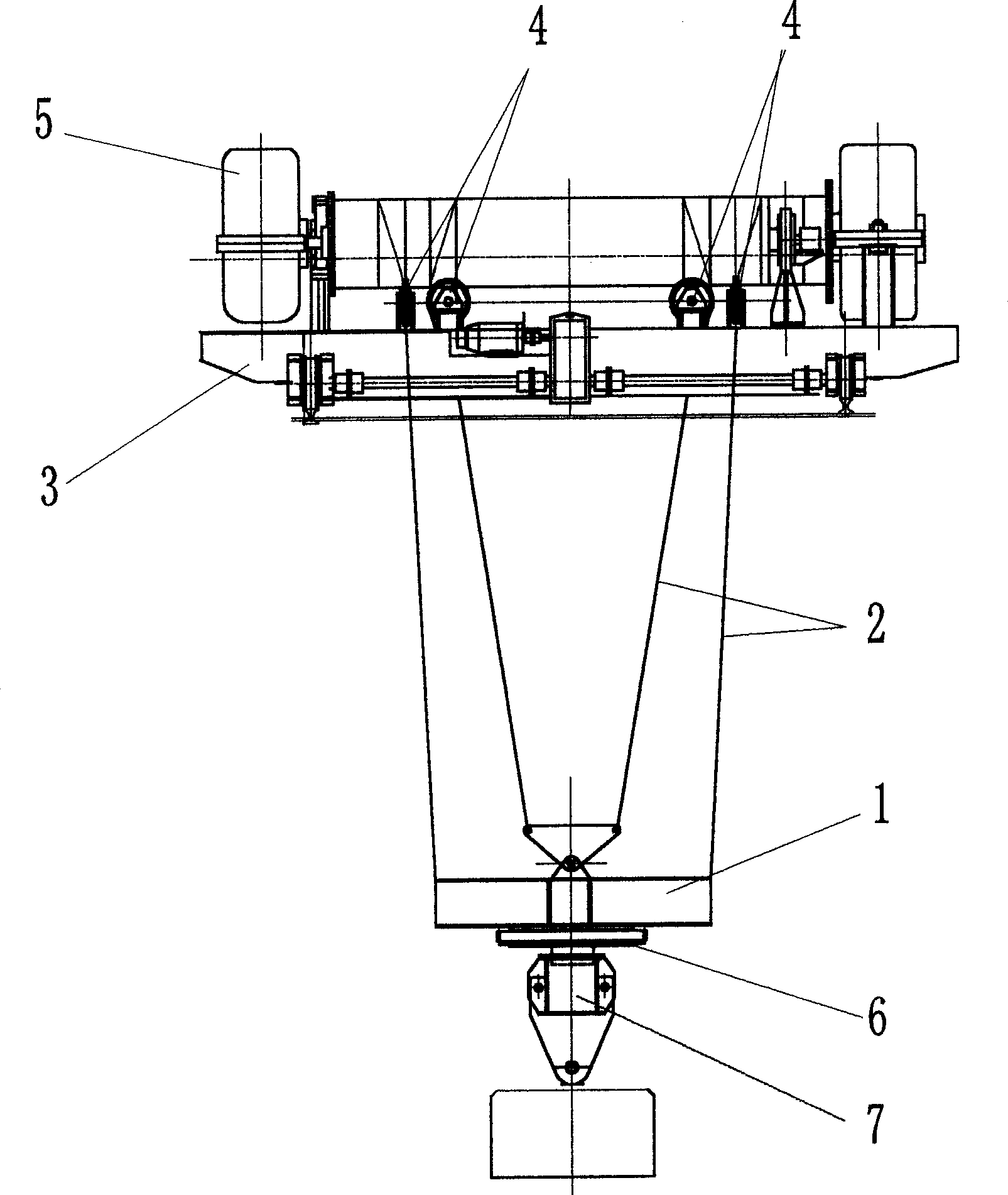

[0017] The guide and rotation mechanism of the crane spreader of the present invention will be described in detail below in conjunction with the accompanying drawings.

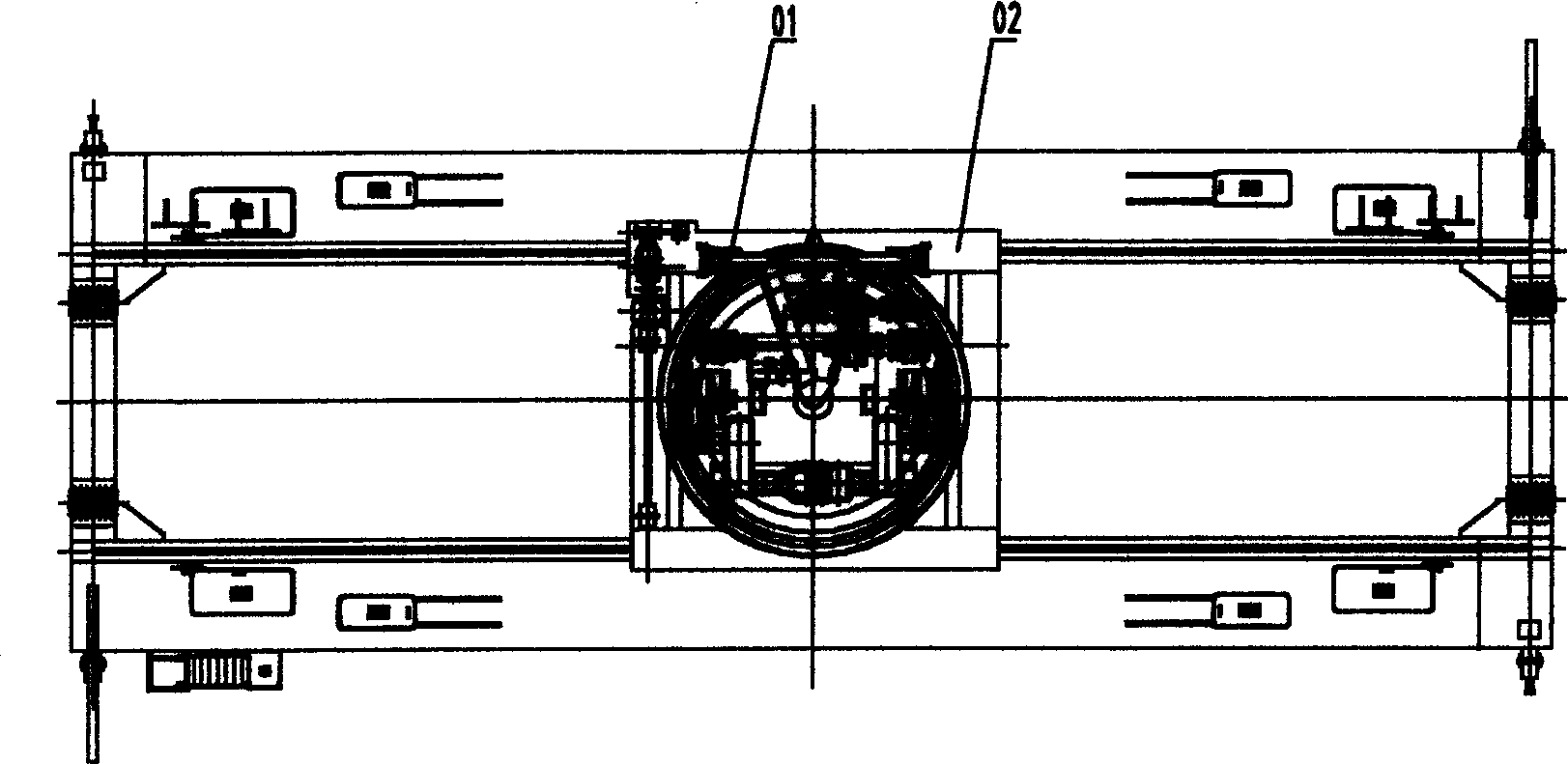

[0018] image 3 and Figure 4 Shown, the guide mechanism of the crane spreader. The guiding mechanism is composed of a cross beam 1 (or called an upper beam), a steel wire rope 2 and a pulley device 4 arranged on a trolley frame 3 . Four pairs of mutually perpendicular pulley devices are arranged on the trolley frame, that is to say, the pulley devices are distributed in a rectangle on the trolley frame, and each corner of the rectangle is provided with two mutually perpendicular pulley devices. The wire ropes that wind down from the pulley device in the hoisting mechanism 5 are connected with four beam ends of the cross beam respectively, forming a cross shape. One end of the steel wire rope is fixed on the reel, and the other end is fixed on the cross beam, so four directions adopt the same fixing method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com