Continuous absorption method for byproduct hydrogen chloride gas in chlorination reaction

A hydrogen chloride gas, chlorination reaction technology, applied in the directions of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of increased investment and operating costs, more impurities in hydrochloric acid, and increased equipment investment and operating costs, etc. To achieve the effect of saving equipment costs and operating costs, continuous absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

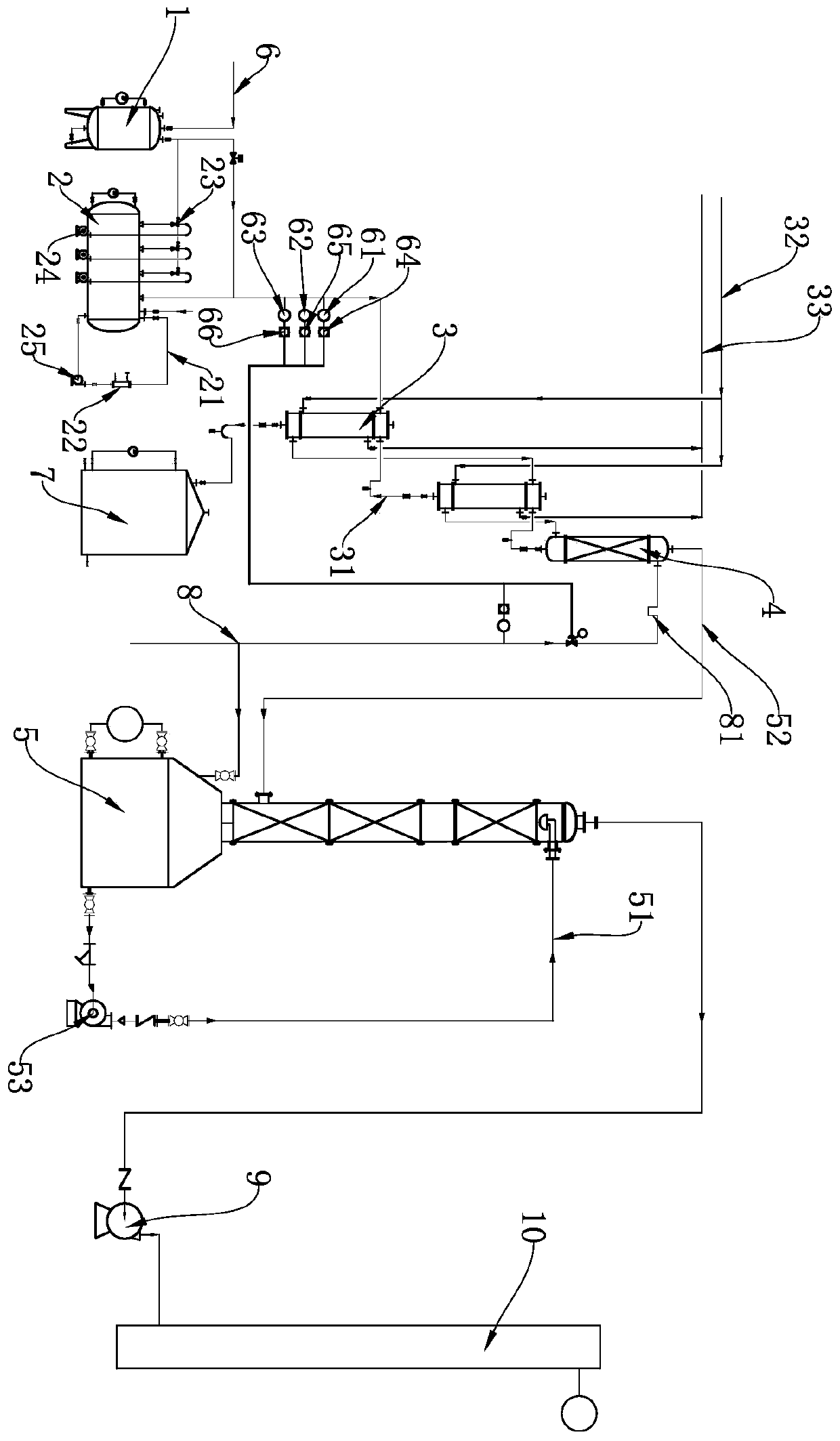

[0032] The production process of bisphenol A bis(diphenyl phosphate) is that the first step is phosphorus oxychloride and bisphenol A to generate bisphenol A bis(dichlorophosphate), and the second step is bisphenol A bis(dichlorophosphate) ) react with phenol to produce the target product. The hydrogen chloride gas produced in the two-step synthesis is continuously buffered by the buffer tank and then enters the hydrochloric acid washing tank filled with concentrated hydrochloric acid. At the entrance of the concentrated hydrochloric acid washing tank, it is fully mixed with concentrated hydrochloric acid through a Venturi mixing tube to remove the entrained hydrogen chloride gas. Phosphorus oxychloride and phenol. The concentrated hydrochloric acid in the concentrated hydrochloric acid washing tank is circulated and cooled by an external cooling device.

[0033] The hydrogen chloride gas that has been pressurized, decomposed and washed to remove impurities in the concentrate...

Embodiment 2

[0036] The production process of brominated polystyrene is that bromine chloride reacts with polystyrene to form the target product. The by-product hydrogen chloride gas is continuously buffered by the buffer tank and then enters the hydrochloric acid washing tank filled with concentrated hydrochloric acid. At the entrance of the concentrated hydrochloric acid washing tank, it is fully mixed with concentrated hydrochloric acid through a Venturi mixing tube to remove the bromine entrained in the hydrogen chloride gas. The concentrated hydrochloric acid in the hydrochloric acid washing tank is circulated and cooled by an external cooling device.

[0037] The hydrogen chloride gas that has been pressurized, decomposed and washed to remove impurities in the concentrated hydrochloric acid washing tank continuously enters the falling film absorption tower and the packed absorption tower that are arranged in series with two gradients, and is sprayed and absorbed step by step; the fres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com