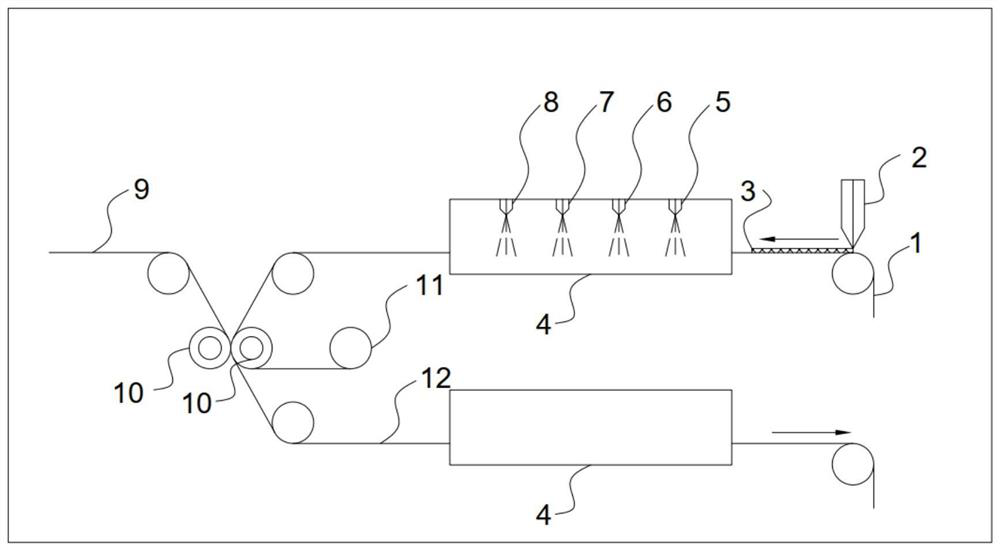

A high-yield fuel cell catalytic electrode coating production method and equipment thereof

A production method and technology for catalytic electrodes, which are applied in battery electrodes, devices for coating liquid on surfaces, coatings, etc., can solve the problems of falling catalytic layer, high transfer rate of catalytic layer, swelling of proton exchange membrane, etc. The layer is uniform, the transfer efficiency is improved, and the transfer effect is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Mix 15g 10% Pt / C solid catalyst with 60g 5wt% perfluorosulfonic acid resin solution, add 30g deionized water and 450g isopropanol, ultrasonically disperse for 15min; then add 1.5g propylene glycol ethyl ether, ultrasonically Disperse for 30 minutes, then disperse with high-speed stirring for 60 minutes, then place it in a vacuum box and evacuate for 10 minutes to eliminate air bubbles, and obtain catalyst slurry;

[0050] (2) Weigh 0.5g nano silicon dioxide, 0.5g nano manganese dioxide, 0.5g phosphotungstic acid and 10g 5wt% perfluorosulfonic acid resin solution respectively, add 249.75g deionized water and 249.75g ethanol, 249.75g Deionized water and 249.75g of ethanol, 249.75g of deionized water and 249.75g of ethanol, 245g of deionized water and 245g of ethanol are stirred evenly to obtain compound solutions with a content of 0.1wt%, respectively, and are fed to the support body to moisturize Treatment, anti-oxidation treatment, enhanced proton conduction treatme...

Embodiment 2

[0055] (1) Take by weighing 10g 90% Pt / C solid catalyst and 20g 20wt% perfluorosulfonic acid resin solution and mix, add 13g deionized water and 167g ethanol, ultrasonic dispersion 15min; Add 2g 2-ethoxyethanol again, Ultrasonic dispersion for 30 minutes, followed by high-speed stirring for 100 minutes, and then placing it in a vacuum box for 20 minutes to eliminate air bubbles to obtain a catalyst slurry;

[0056] (2) Weigh 1g nano-zinc oxide, 1g nano-zirconia, 1g phosphomolybdic acid and 5g 20wt% perfluorosulfonic acid resin liquid respectively, add 249.5g deionized water and 249.5g isopropanol, 249.5g Deionized water and 249.5g of isopropanol, 249.5g of deionized water and 249.5g of isopropanol, 247.5g of deionized water and 247.5g of isopropanol were stirred evenly to obtain compound solutions with a content of 0.2wt% respectively. Load it into the spray booth where the support body is sprayed with moisturizing treatment, anti-oxidation treatment, enhanced proton conductio...

Embodiment 3

[0061] (1) Weigh 12g of 60% Pt / C solid catalyst and 30g of 10wt% perfluorosulfonic acid resin solution and mix, add 18g of deionized water and 240g of methanol, ultrasonically disperse for 15min; then add 1.8g of 2-ethoxyethanol , ultrasonically dispersed for 30 minutes, then dispersed with high-speed stirring for 80 minutes, and then placed in a vacuum box for 15 minutes to eliminate air bubbles to obtain a catalyst slurry;

[0062] (2) Weigh 1g of nano-zinc oxide, 1g of nano-zirconia, 1g of silicotungstic acid and 10g of 10wt% perfluorosulfonic acid resin solution respectively, and add 249.5g of deionized water, 249.5g of ethanol, and 249.5g of deionized Water and 249.5g of ethanol, 249.5g of deionized water and 249.5g of isopropanol, 245g of deionized water and 245g of isopropanol were stirred evenly to obtain compound solutions with a content of 0.2wt% respectively, which were respectively loaded into the opposite support The spray booth for spraying moisturizing treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com