Fully-automatic LED phosphor coating apparatus and control method thereof

A fluorescent powder, fully automatic technology, applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problem that it is difficult to buy fully automatic coating equipment for the process, and cannot produce high-quality LED modules, etc. problems, to achieve the effect of reducing production and maintenance costs, accurate control, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

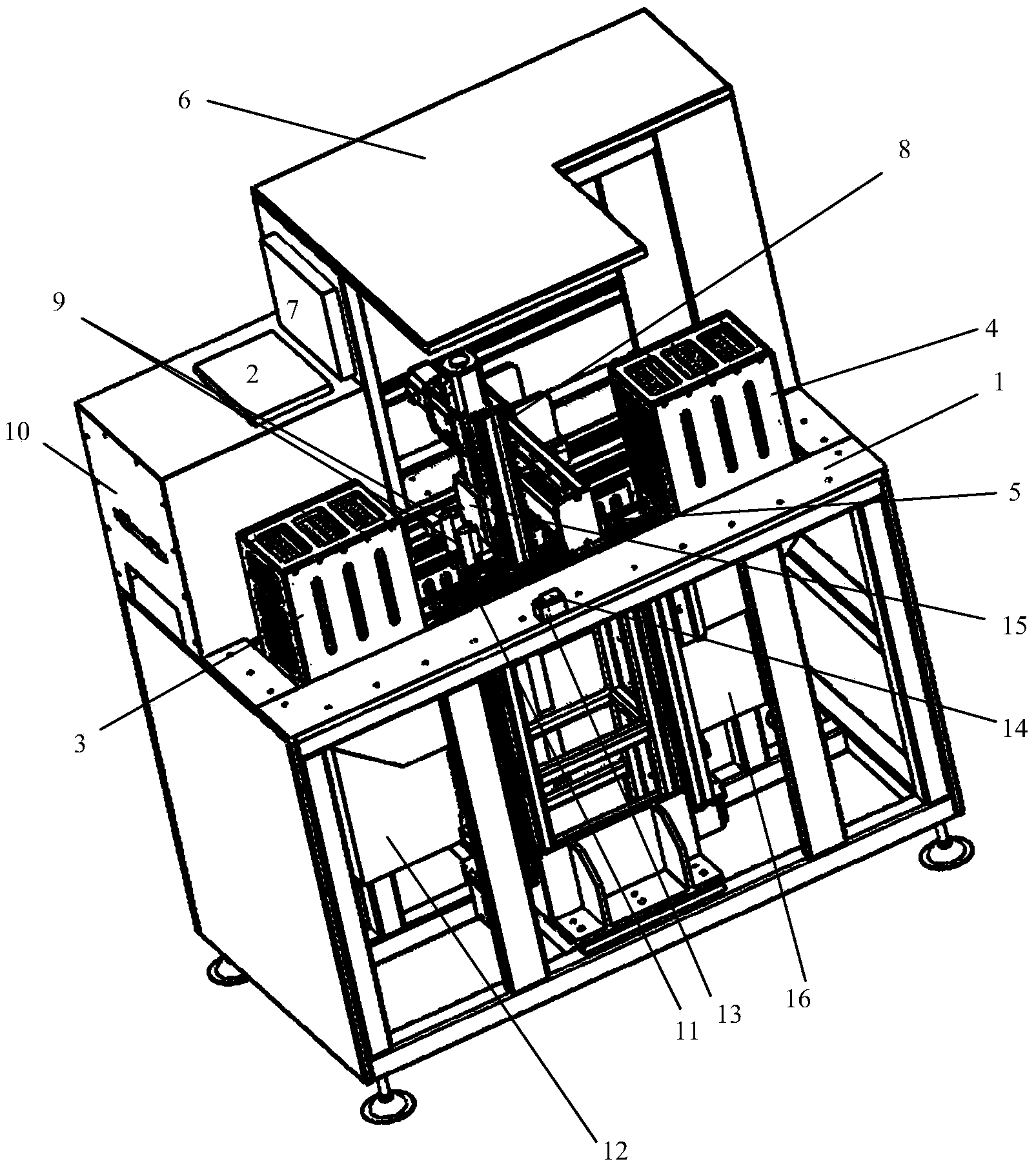

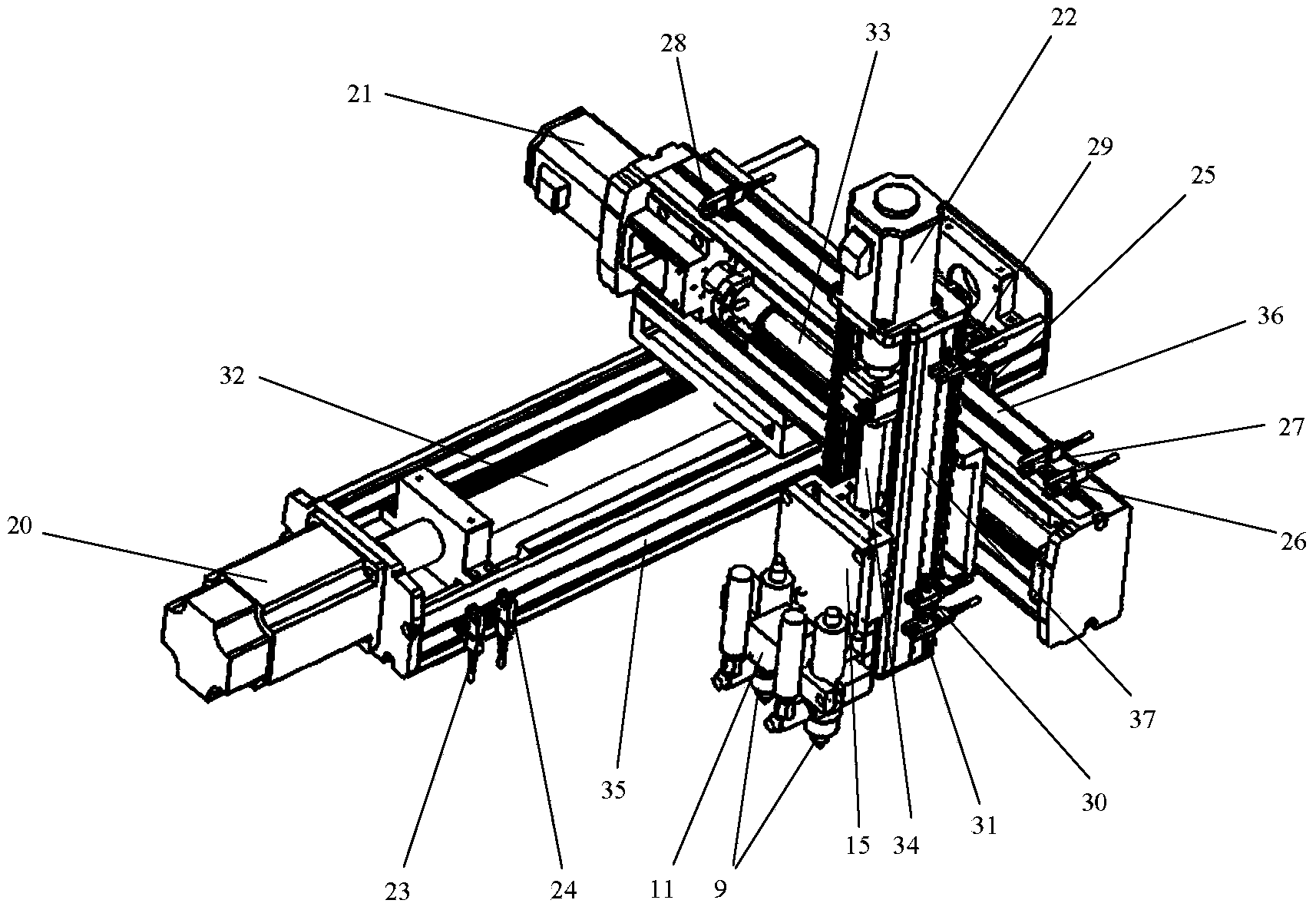

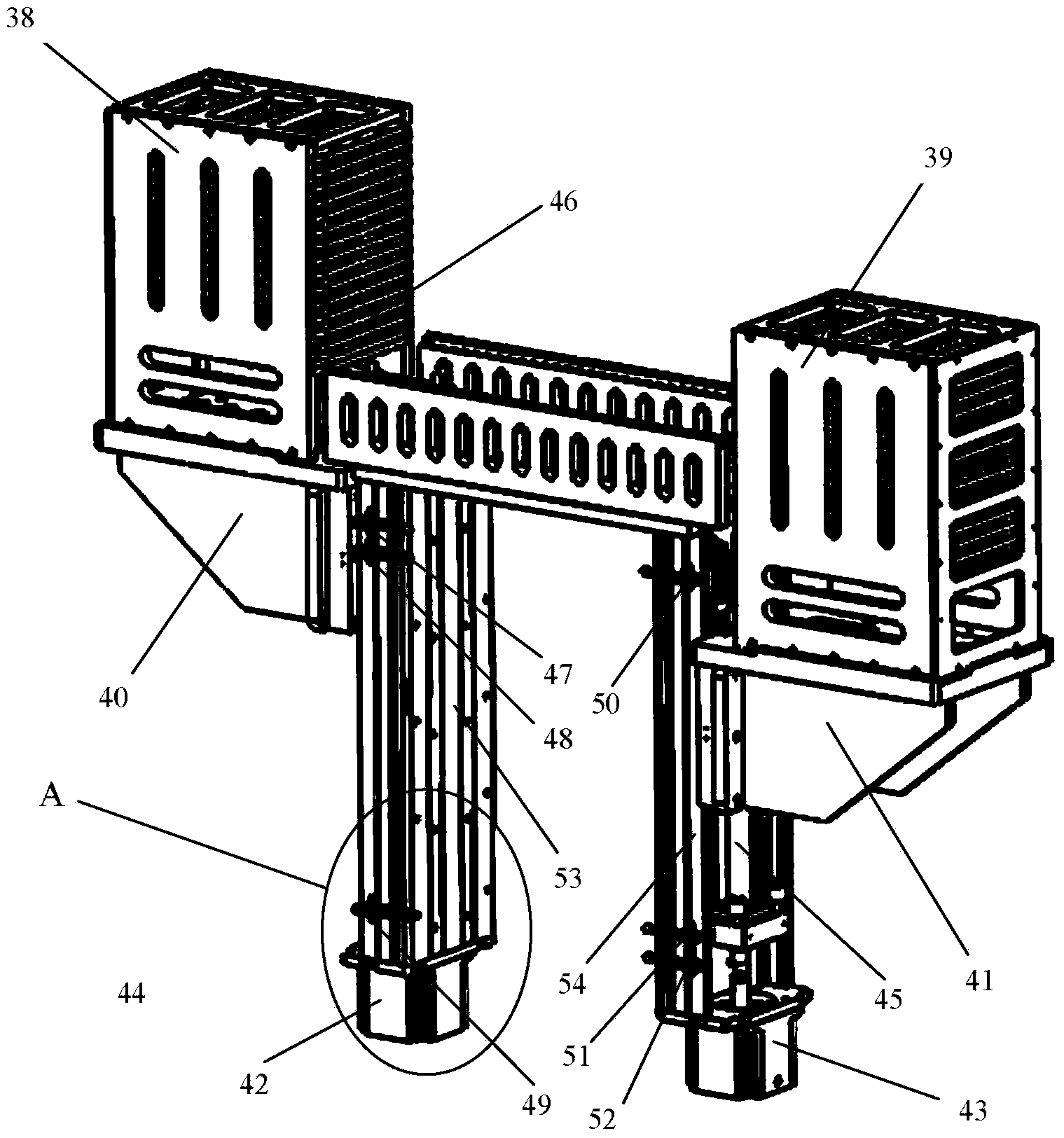

[0041] Such as figure 1 As shown, the fully automatic LED phosphor coating equipment described in this embodiment includes a frame 1, a main control box 12 and an industrial computer host 16 are fixed below the frame 1, and an XYZ axis motion platform 8, a material Tray dragging mechanism 5, nozzle control box 10, waste material box 13 and cleaning sponge 14, material pan dragging mechanism 5 is located below the Z-axis working area of XYZ axis motion platform 8, waste material box 13 and cleaning sponge 14 are located in the material pan dragging On the side of the mechanism 5 and within the Z-axis working area of the XYZ-axis motion platform 8, a loading device 3 is installed on the left side of the tray dragging mechanism 5, and an unloading device 4 is installed on the right side, and the XYZ-axis motion platform 8, a protective plate rib 6 is installed above, a control circuit is installed in the main control box 12, a spraying device 9 and an image acquisition device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com