Intelligent spraying system in fresh leaf conveyor belt

A technology of spraying system and conveyor belt, applied in the improvement field of intelligent spraying system, can solve the problems of slow temperature reduction, inability to reduce temperature, unfavorable tea quality, etc., and achieve the effect of improving quality and avoiding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

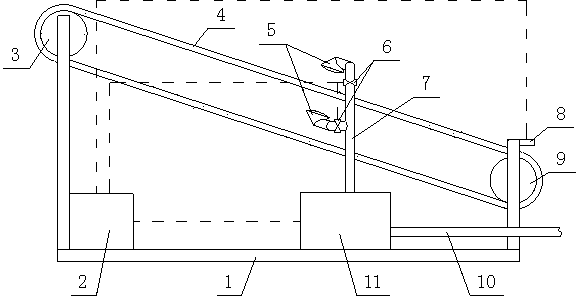

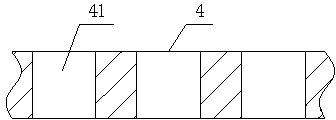

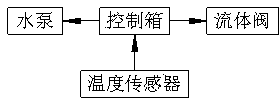

[0017] Such as Figure 1 to Figure 3 As shown, an intelligent spraying system in a fresh leaf conveyor belt 4 includes a conveyor belt 4 , a spraying device, a temperature sensor 8 , a fluid valve 6 and a control box 2 .

[0018] The spraying device includes a spray head 5 and a water pump 11 , the spray head 5 is connected to the water outlet of the water pump 11 through a pipeline 7 , and sprays water mist to the fresh leaves on the conveyor belt 4 . The water pump 11 is fixed on the frame 1 on one side of the conveyor belt 4 . The water inlet of the water pump 11 communicates with the water pipe 10 . A water purification device is arranged between the water inlet of the water pump 11 and the water pipe 10. The water purification device adopts a commonly used water purification device in the prior art, mainly for the purpose of filtering out silt impurities in the water and ensuring that the fresh leaves are sprayed. The purity of the water ensures the quality of the subse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com