Self-frost-inhibition heat exchanger using condense substances

A heat exchanger, condensing technology, used in evaporators/condensers, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as extra energy consumption reducing system efficiency, unable to fundamentally suppress frost formation, etc. To achieve the effect of compact structure, low cost and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

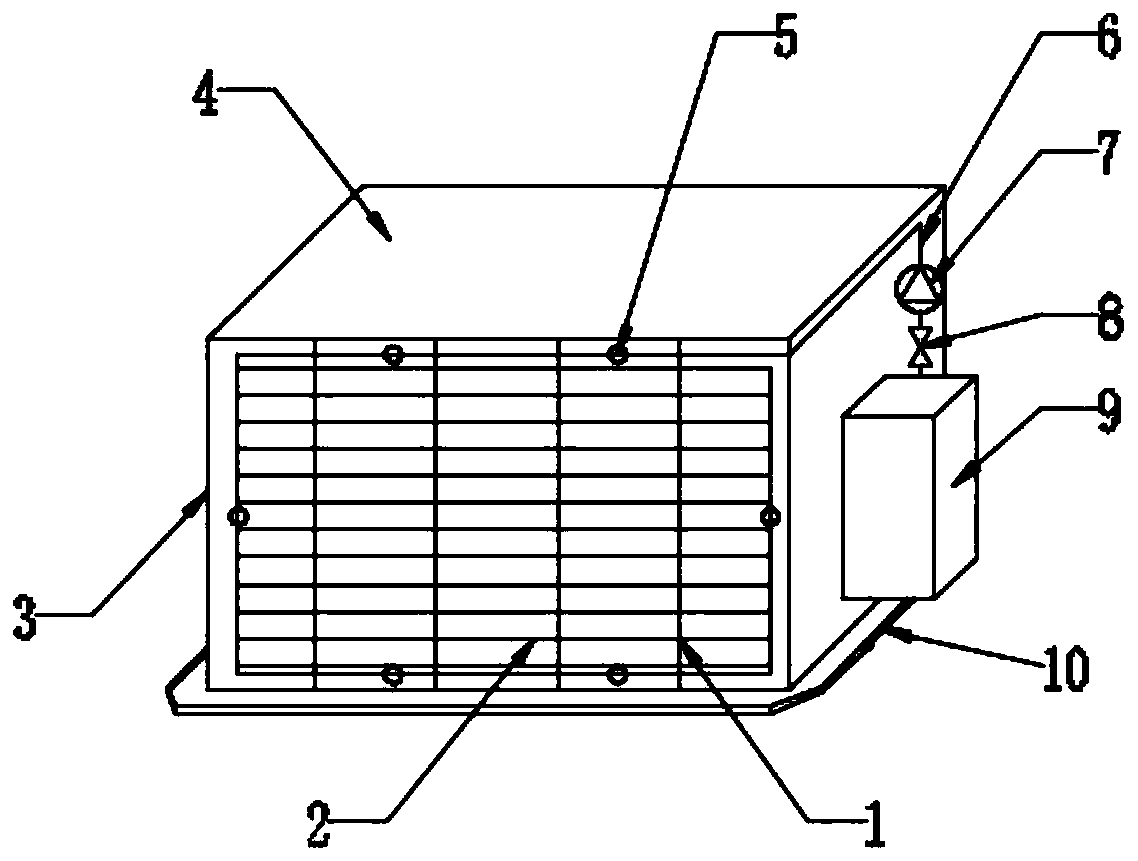

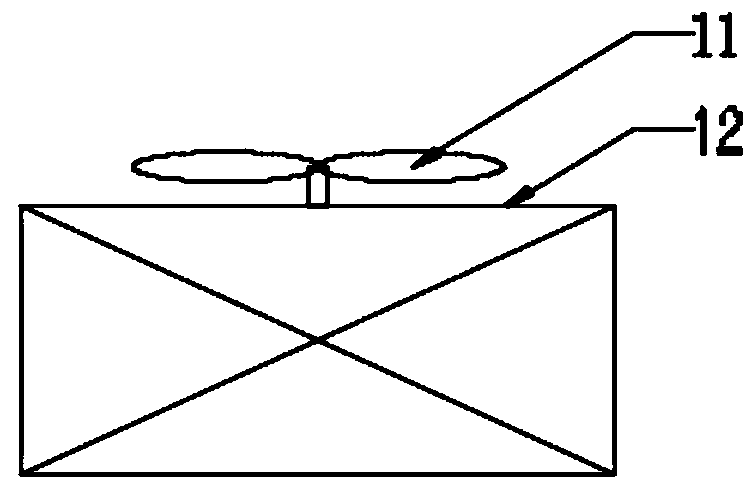

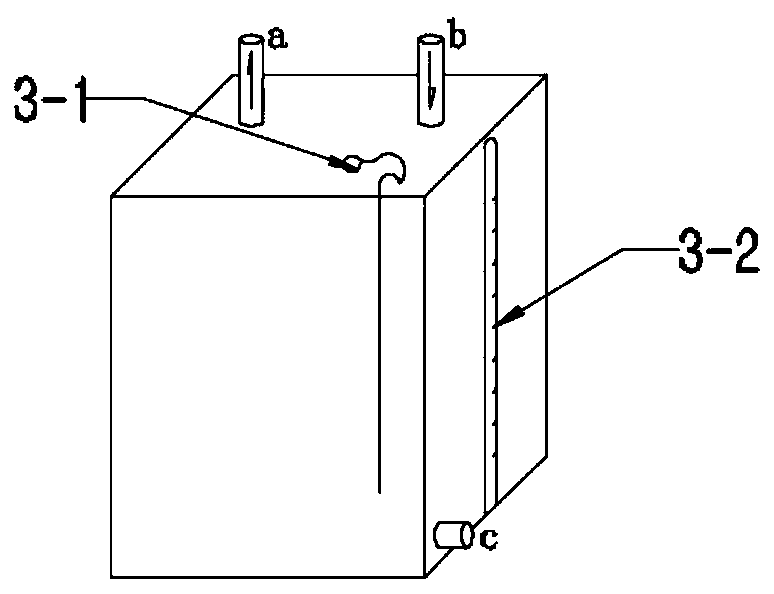

[0022] Such as figure 1 , figure 2 and image 3 As shown, the specific implementation method is as follows:

[0023] A self-frost suppression heat exchanger using condensable substances, including fins 1, heat exchange tubes 2, side plates 3, top plates 4, atomizing nozzles 5, spray hoses 6, plunger pumps 7, and solenoid valves 8. Liquid storage tank 9, water receiving tray 10, fan 11 and front cover 12. The fins 1, heat exchange tubes 2, side plates 3, top plate 4, water tray 10, fan 11 and front cover plate 12 form a heat exchanger unit; the atomizing nozzle 5 and spray hose 6 , a plunger pump 7, a solenoid valve 8 and a liquid storage tank 9 form a spray frost suppression unit; the liquid storage tank 9 is a fully sealed structure, placed on the side of the heat exchanger, and connected to the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com