Method and device for coupling treatment of desulfurization wastewater zero discharge and flue gas white elimination for coal-fired power plant

A technology for desulfurization wastewater and coal-fired power plants, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. problems, achieve good economy, eliminate colored plumes, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

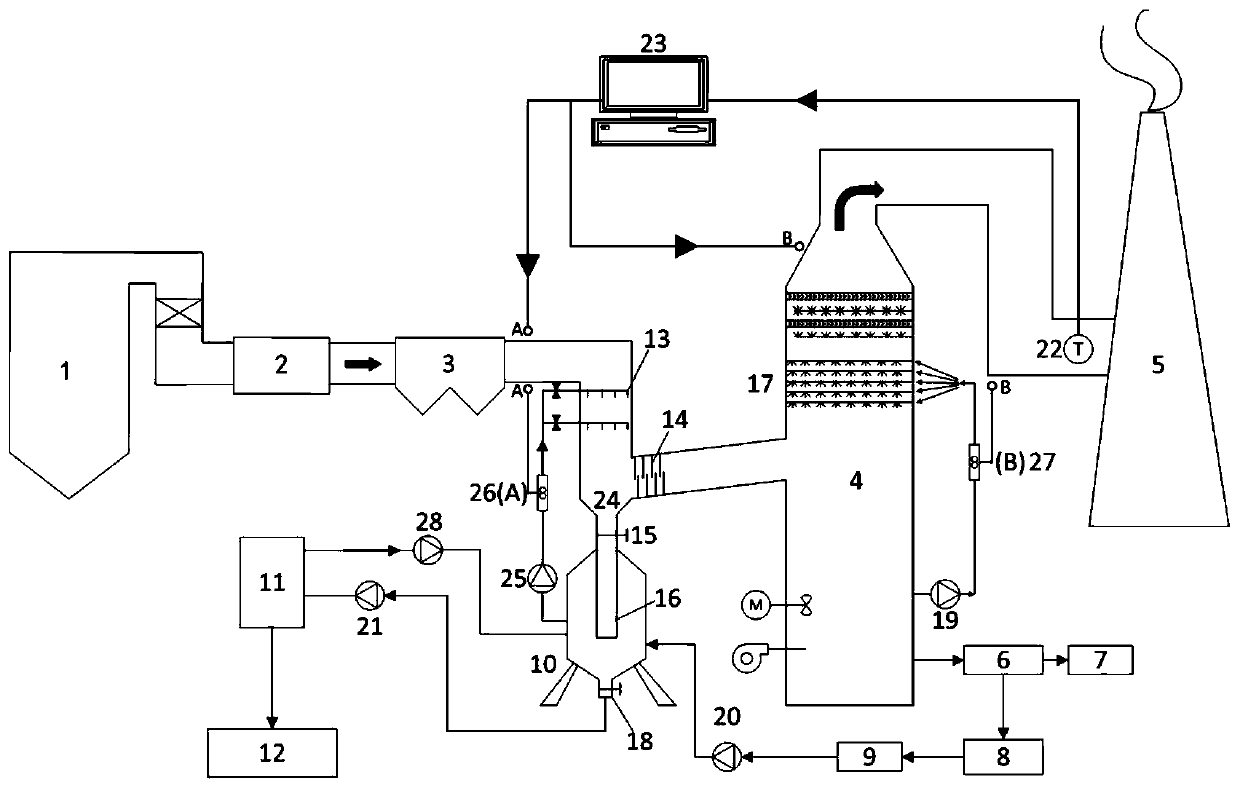

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036]The main process flow of the present invention is that the desulfurization wastewater discharged from the dehydration system first enters the outlet tank to adjust the total amount of water inflow, and is pumped by the inlet pump to the cylindrical concentration pool located under the vertical flue behind the electrostatic precipitator. The water volume is always kept at a certain water level, and the water collection pipe is deep into the concentration pool at least 1.2m deep to prevent the flue gas from being poured into the concentration pool; Among the two rows of spraying devices in the channel, one is for use and the other is for standby. If a large amount of spraying water is required, the two rows of spraying devices can be turned on at the same time. The front end of each row of spraying devices is equipped with an electric gate valve for water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com