High-definition high-bulk wear-resistant paper and preparation method thereof

A technology of bulky and wear-resistant paper, which is applied in the field of surface wear-resistant paper, can solve the problems that laminate flooring cannot meet customer requirements, affects the brightness and clarity of laminate flooring, and the number of wear-resistant rotations of wooden floors is unstable. , to achieve good surface flatness, shorten the production process, and improve the effect of bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

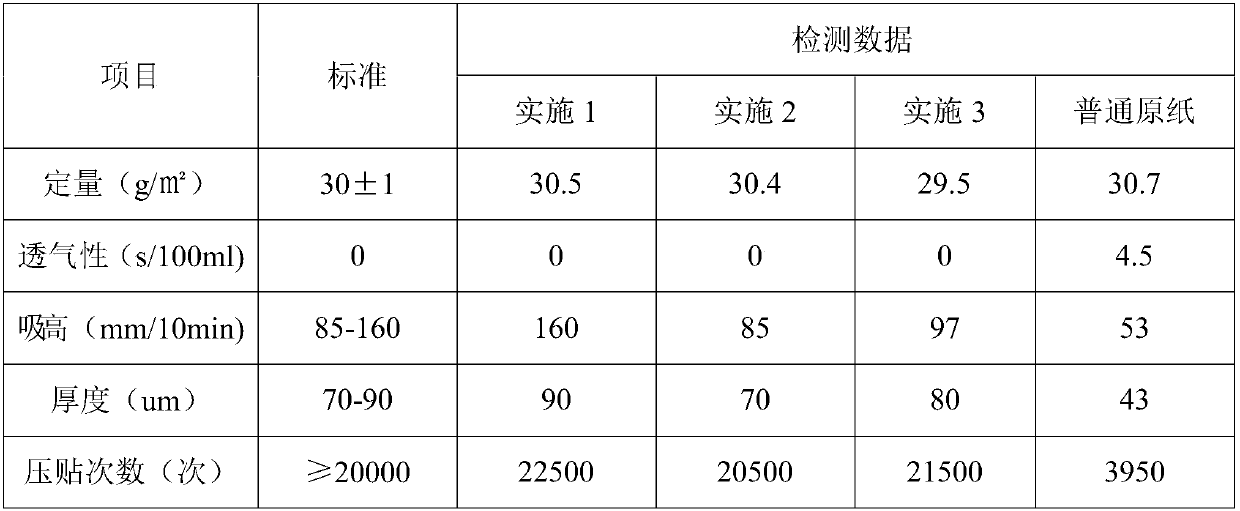

Embodiment 1

[0063] The high-definition and high-bulk wear-resistant paper described in Example 1, in terms of mass fraction, has a raw material composition as follows:

[0064] Wood pulp, 40% on a dry basis

[0065] Filler 50%

[0066] Auxiliary 10%;

[0067] Among them, the filler is aluminum oxide, and the aluminum oxide filler is a mixed filler of models 180# and 220#.

[0068] Al2O3 is made up of the raw materials of following percentage by weight:

[0069] 180# 75%

[0070] 220# 25%.

[0071] Wood pulp consists of the following raw materials in weight percentages:

[0072] Bleached Kraft Long Fiber Wood Pulp 60%

[0073] Bleached kraft short fiber wood pulp 40%.

[0074] Auxiliary is made up of the raw material of following percentage by weight:

[0075] Aluminum sulfate 1.7%

[0076] Polyacrylamide 0.8%

[0077] Wet strength agent 97.5%.

[0078] The preparation method of the high-definition and high-bulk wear-resistant paper described in Example 1 specifically comprises ...

Embodiment 2

[0084] The high-definition and high-bulk wear-resistant paper described in Example 2 has the following raw material composition in terms of mass fraction:

[0085] Wood pulp, 85% on a dry basis

[0086] Filler 10%

[0087] Auxiliary 5%;

[0088] Among them, the filler is aluminum oxide, and the aluminum oxide filler is a mixed filler of models 180# and 220#.

[0089] Al2O3 is made up of the raw materials of following percentage by weight:

[0090] 180# 80%

[0091] 220# 20%.

[0092] Wood pulp consists of the following raw materials in weight percentages:

[0093] Bleached Kraft Long Fiber Wood Pulp 80%

[0094] Bleached kraft short fiber wood pulp 20%.

[0095] Auxiliary is made up of the raw material of following percentage by weight:

[0096] Aluminum sulfate 3.5%

[0097] Polyacrylamide 1.5%

[0098] Wet strength agent 95%.

[0099] The preparation method of the high-definition and high-bulk wear-resistant paper described in Example 2 specifically comprises the ...

Embodiment 3

[0105] The high-definition and high-bulk wear-resistant paper described in Example 3, in terms of mass fraction, has a raw material composition as follows:

[0106] Wood pulp, 60% on an absolute dry basis

[0107] Filler 33%

[0108] Auxiliary 7%;

[0109] Among them, the filler is aluminum oxide, and the aluminum oxide filler is a mixed filler of models 180# and 220#.

[0110] Al2O3 is made up of the raw materials of following percentage by weight:

[0111] 180# 70%

[0112] 220# 30%.

[0113] Wood pulp consists of the following raw materials in weight percentages:

[0114] Bleached Kraft Long Fiber Wood Pulp 90%

[0115] Bleached kraft short fiber wood pulp 10%.

[0116] Auxiliary is made up of the raw material of following percentage by weight:

[0117] Aluminum sulfate 1.5%

[0118] Polyacrylamide 1.2%

[0119] Wet strength agent 97.3%.

[0120] The preparation method of the high-definition and high-bulk wear-resistant paper described in Example 3 specifically c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com