Tanning technology for treatment and reuse of waste chrome liquor of bate without discharge and its treatment device

A technology of waste chromium solution and zero discharge, which is applied in the field of gray lye waste chromium solution treatment device, and can solve problems such as environmental hazards, waste of water resources, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

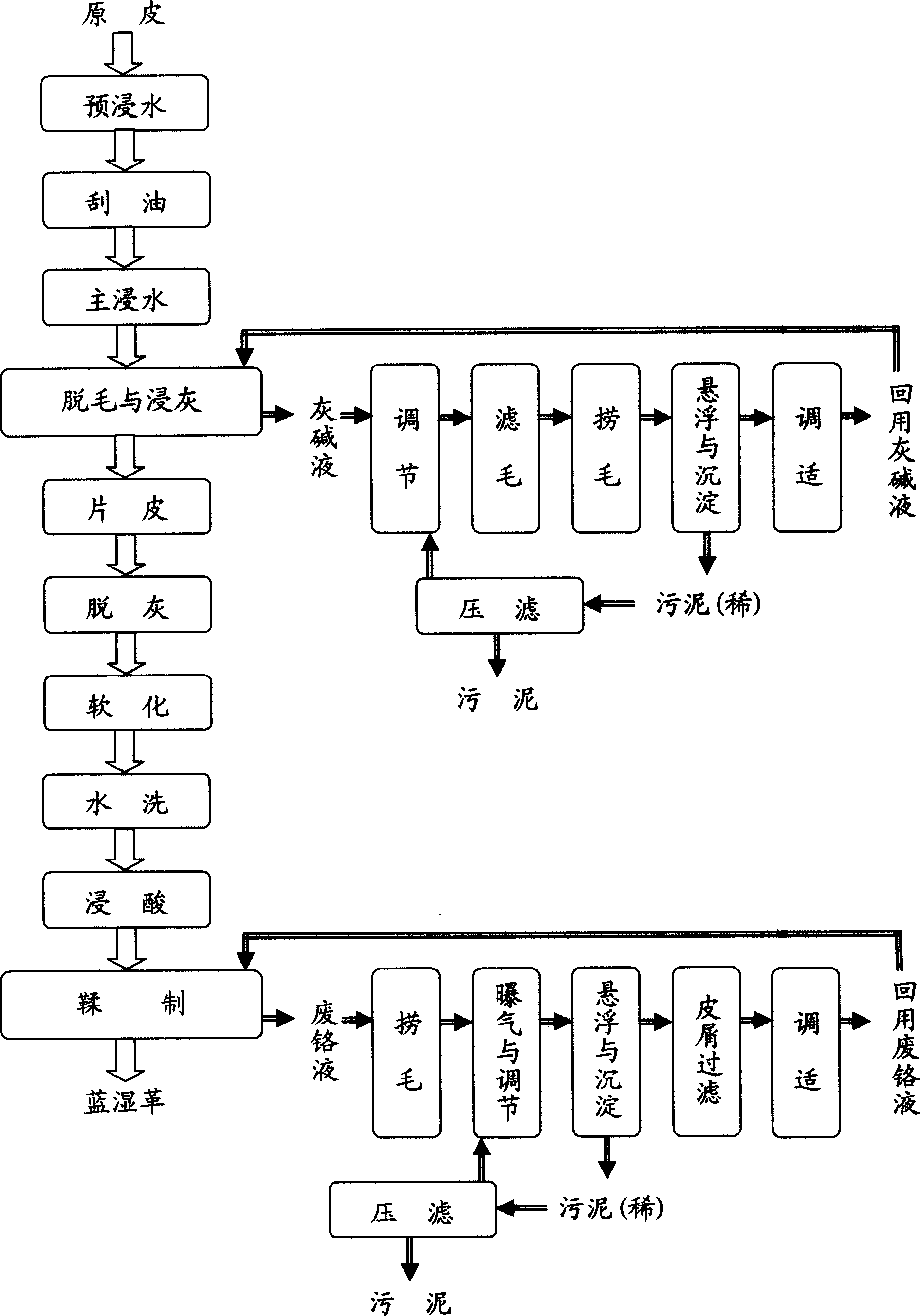

[0029] Such as figure 1 As shown, after the raw hide is pre-soaked, oil-scraped, and main soaked in water, it is dehaired by the hair-preserving method and then limed, and the ash lye produced in the dehairing and liming steps is treated and reused in the dehairing and liming steps; Afterwards, skinning, deliming, softening, water washing, pickling and tanning are carried out to obtain wet blue leather; the waste chromium liquid generated in the tanning step is treated and reused in the tanning step.

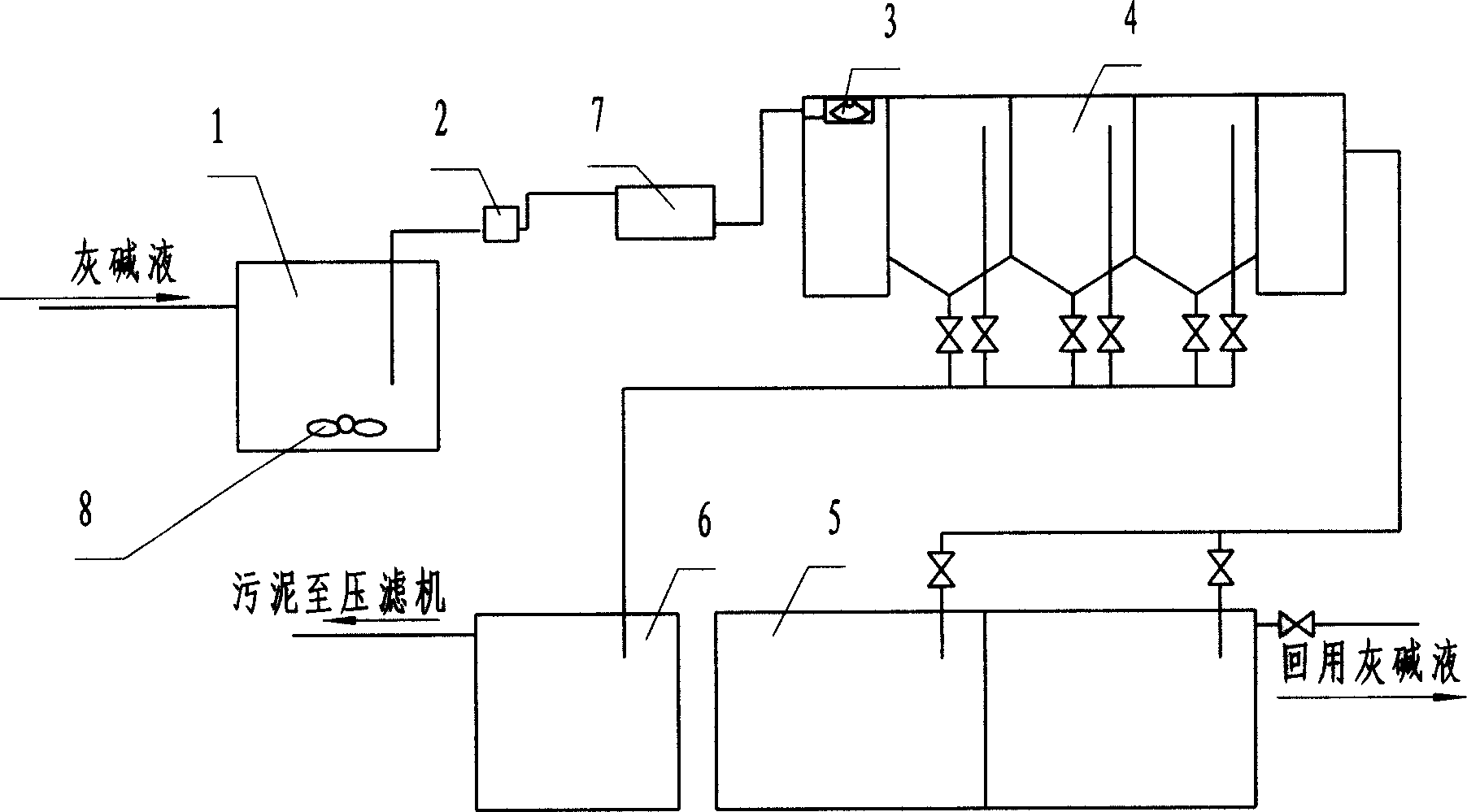

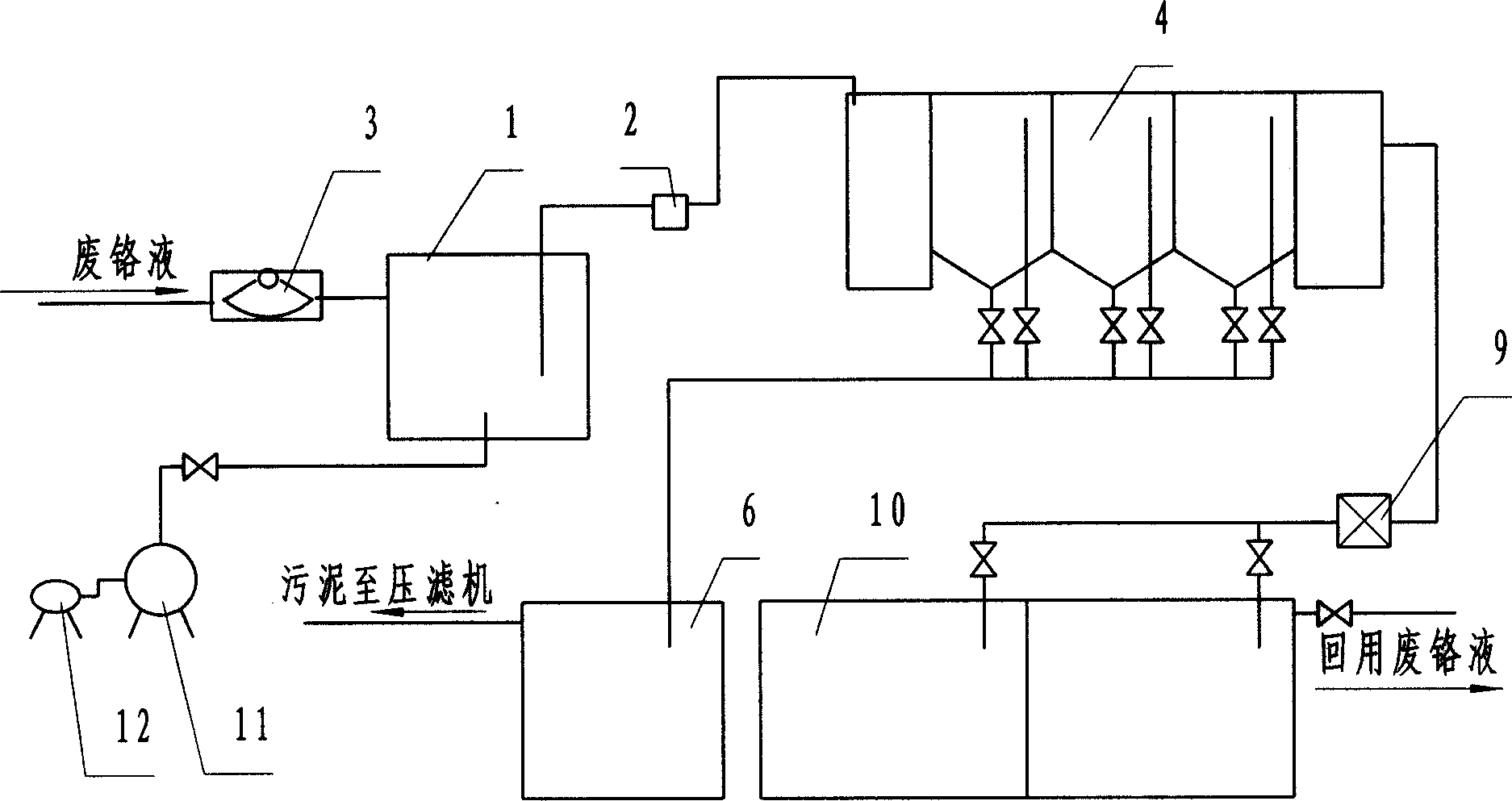

[0030] Ash lye treatment is done through ash lye treatment device. Such as figure 2 and Figure 4As shown, the ash lye treatment device includes a regulating tank 1, a pump 2, a hair filter 7, a hair removal machine 3, a suspension and sedimentation tank 4, an ash lye recovery tank 5, a sludge tank 6, and a stirring system 8; 2 is set between the adjustment tank 1 and the filter machine 7; the hair removal machine 3 is set on the top of the liquid inlet tank 13 of the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com