Farmyard homemade gas stove

A technology of gas stoves and farmhouses, applied in the field of heating, can solve problems such as smoke, insufficient coal combustion, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is described in detail below in conjunction with accompanying drawing and specific example:

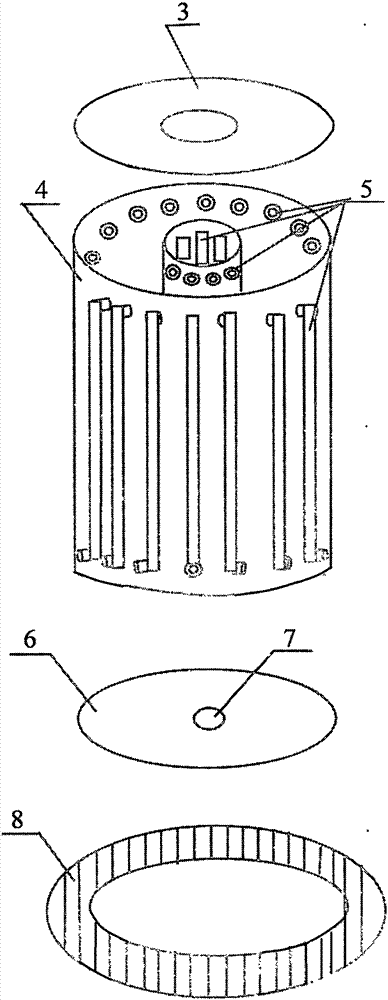

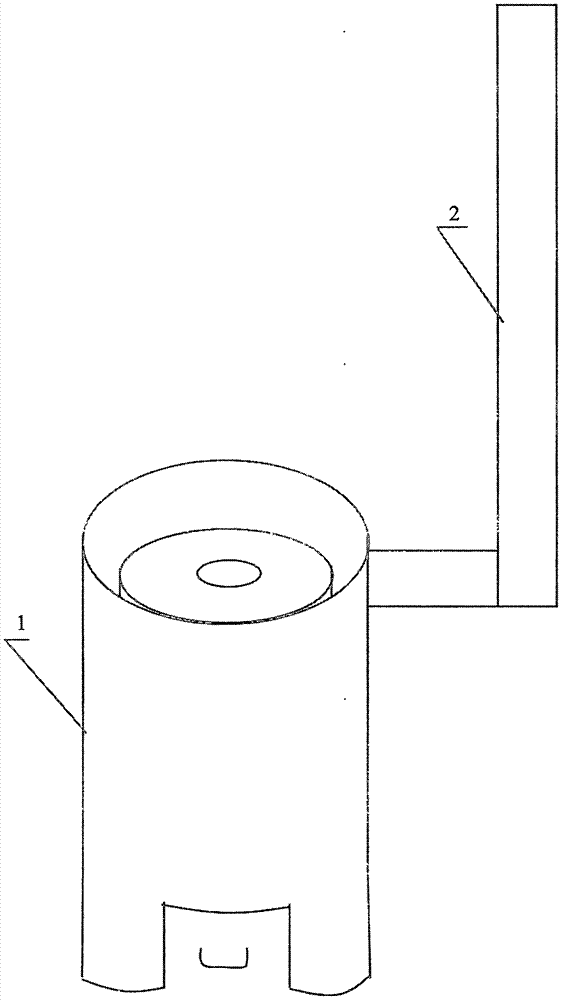

[0009] like figure 1 , figure 2 Shown is a specific example figure of the present invention, and the earthen gas stove of farmhouse comprises body of heater 1, and said body of heater comprises chimney 2, fire grate 8; Described coal storage tank 4 comprises smoke guide pipe 5, upper end The cover 3 and the lower end cover 6; the lower end cover 6 includes a vent hole 7.

[0010] In the cold season, install the present invention indoors or outdoors, first assemble the coal storage tank (fired with refractory mud) 4 and the lower end cover 6, then pour part of the coal into the coal storage tank 4 and compact it, the coal is slightly lower At the outlet of the smoke guide pipe 5, then ignite coal in the furnace body 1 in the way of a normal stove, and after the coal is burned, the coal in the coal storage tank 4 will release gas after being heated to a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com