Fen-flavor liquor second-batch distiller grain refermentation technology

A fragrant liquor and re-fermentation technology, which is applied in the preparation of alcoholic beverages, microorganisms, and microorganism-based methods, etc., can solve the problems of high cost and poor wine quality, achieve low cost, high wine yield, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

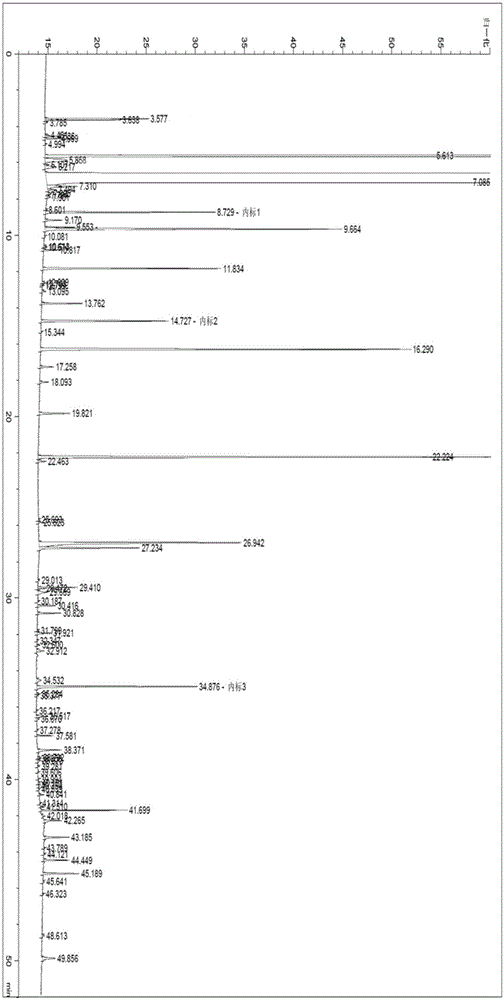

Image

Examples

Embodiment 1

[0065] (1) Making bran koji:

[0066] a. Production of Baiqu:

[0067] The fungus is Aspergillus hanoi;

[0068] The raw materials include fermented material and water, and the weight ratio of fermented material (dry weight) to water is 100:65;

[0069] The fermented material is 85% bran+15% fresh distiller's grains, wherein the weight of fresh distiller's grains is calculated by dry weight;

[0070] Make:

[0071] ①Cultivation of first-level strains: 12°Bx wort culture medium is used for cultivation, the cultivation temperature is 28-30°C, and the time is 4 days.

[0072] ②Secondary strain culture: Add 1 times the water to the bran, mix well and put it into a 250mL Erlenmeyer flask with a thickness of about 1cm, steam sterilize at 0.1MPa for 30min, cool and inoculate at 28-30℃ for 20h, The mycelium grows and connects into a cake shape, which can be shaken for treatment, and the bottle is buckled at 35 hours, and the co-culture is dried for 3.5 days for later use;

[0073...

Embodiment 2

[0095] Alcohol is not added and used during the fermentation of grains thrown away, and other conditions are the same as in Example 1. Alcohol yield: 5%.

Embodiment 3

[0097] The mixed distiller's koji in the second-crop fermenting process of the fragrance type was replaced with 10% black koji and 5% Saccharomyces cerevisiae, and other conditions were the same as in Example 1. Alcohol yield: 4.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com