Modification technology of iron reduction and component reconstruction for molten slag

A steel slag and modification technology, applied in the manufacture of converters, furnace types, furnaces, etc., can solve the problems of ineffective utilization of steel slag thermal energy, restrict the utilization of steel slag, waste water resources, etc., to improve production profits, solve utilization problems, and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Coke chips after drying, yellow sand (particle diameter all≤3mm) are dropped into molten steel slag in proportion, and the specific ratio of described molten steel slag, coke chips and yellow sand is:

[0024] Molten steel slag: coke chips: yellow sand=1:0.12:0.12;

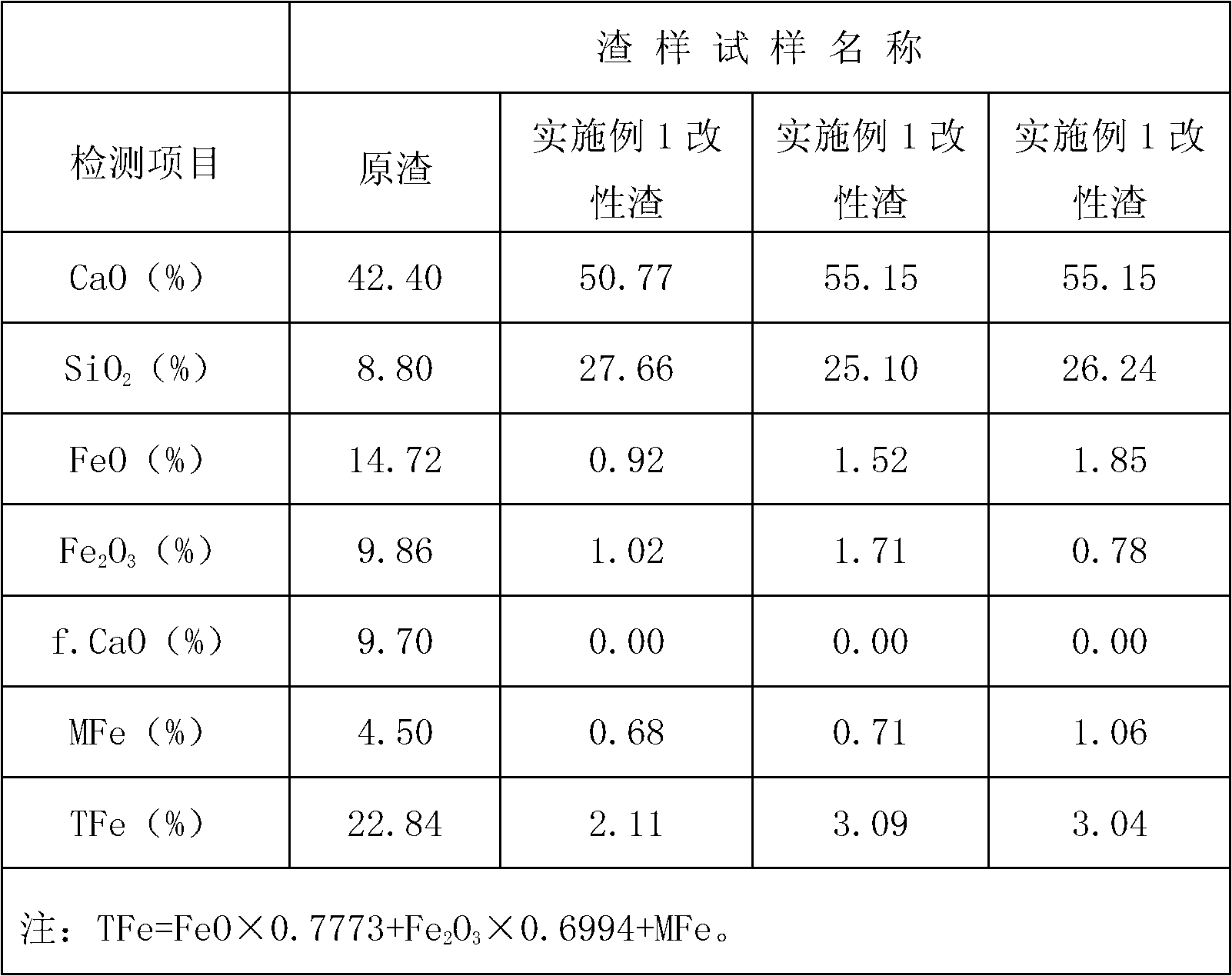

[0025] Then raise the temperature of the steel slag to 1500°C, after it fully reacts (the boiling on the top surface of the slag tends to be calm, without up and down tumbling), and after natural cooling, analyze its chemical composition. The analysis results are shown in Table 1: the analysis method used is "YB / T 140-2009 Analysis Method for Steel Slag for Cement".

Embodiment 2

[0027] Coke chips after drying, yellow sand (particle diameter all≤3mm) are dropped into molten steel slag in proportion, and the specific ratio of described molten steel slag, coke chips and yellow sand is:

[0028] Molten steel slag: coke chips: yellow sand = 1: 0.10: 0.11;

[0029] Then raise the temperature of the steel slag to 1500°C, after it fully reacts (the boiling on the top surface of the slag tends to be calm, without up and down turbulence), and after natural cooling, analyze its chemical composition. The analysis results are shown in Table 1: the analysis method used is "YB / T 140-2009 Analysis Method for Steel Slag for Cement".

Embodiment 3

[0031] Coke chips after drying, yellow sand (particle diameter all≤3mm) are dropped into molten steel slag in proportion, and the specific ratio of described molten steel slag, coke chips and yellow sand is:

[0032] Molten steel slag: coke chips: yellow sand = 1: 0.08: 0.10;

[0033] Then raise the temperature of the steel slag to 1500°C, after it fully reacts (the boiling on the top surface of the slag tends to be calm, without up and down turbulence), and after natural cooling, analyze its chemical composition. The analysis results are shown in Table 1: the analysis method used is "YB / T 140-2009 Analysis Method for Steel Slag for Cement".

[0034] Table 1

[0035]

[0036] It can be seen from Table 1 that the steel slag raw material contains 22.84% iron, and after adding different proportions of coke and yellow sand, the iron content is significantly reduced to about 2%-3%. f. CaO content has been reduced from 9.70% to 0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com