Method for treating manganese-containing wastewater generated during electrolytic manganese processing

A waste water treatment, electrolytic manganese technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve environmental pollution, high treatment cost, low economy and other issues to achieve the effect of reducing cost, low processing cost and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

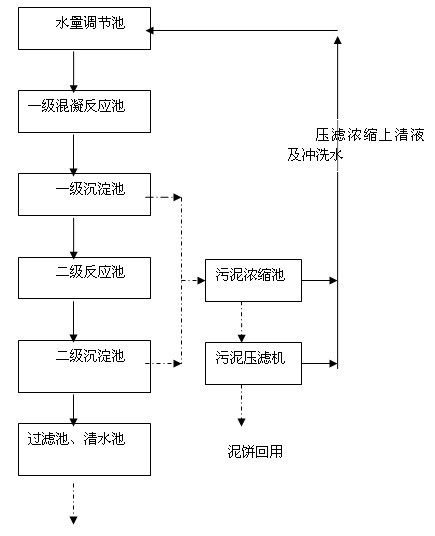

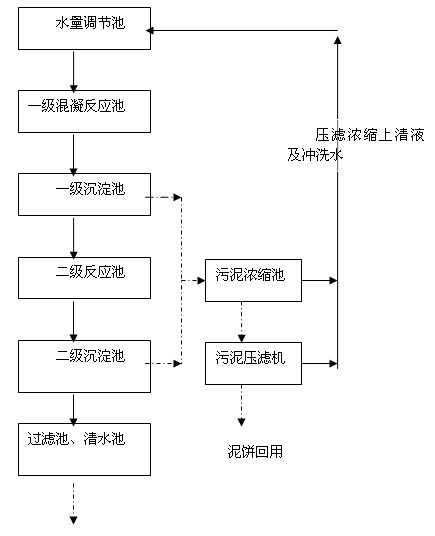

[0020] Such as figure 1 Among them, the manganese-containing wastewater treatment method of electrolytic manganese processing of the present invention comprises the following steps:

[0021] 1. Collect manganese-containing wastewater and merge it into the waste water pool, and pretreat the manganese-containing waste water in the waste water pool to intercept and remove suspended matter and floating matter in the waste water, and reduce the operating cost of the sewage treatment system; it can also be routinely treated The water quality and quantity of wastewater are adjusted to reduce the impact load of water quality and quantity on subsequent treatment facilities.

[0022] 2. Put the manganese-containing wastewater in the wastewater pool into the primary coagulation reaction tank, and use sodium hydroxide to adjust the pH value to 9.3 + 0.10, delivery energy and Mn 2+ Carbonate for replacement reaction, the amount of carbonate added is 1.5-2.8 times the manganese content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com