Waste gas control method by removing sulfur dioxide for resource utilization

A technology for sulfur dioxide and waste gas treatment, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of high cost of desulfurization raw materials, secondary pollution, limited sources, etc., and achieve low operating costs and fast desulfurization speed. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The garbage leachate of the urban garbage landfill is used as the absorption liquid, and the waste gas of the coal-fired boiler is treated by the method of the present invention, and the sulfur resource is recovered from the waste gas, and at the same time, the harmless treatment of the garbage leachate of the urban garbage landfill is realized, and the use of waste is realized. The purpose of treating waste and recycling sulfur resources. Taking the treatment of a coal-fired boiler with a scale of 35T / h as an example, the amount of waste gas to be treated is 60000Nm 3 / h, the content of sulfur dioxide in the exhaust gas is 1500ppm, the pH value of the leachate of the urban waste landfill as the exhaust gas desulfurization absorbent is 8.5, the concentration of ammonia nitrogen is 2000mg / L, the CODcr is 8600mg / L, and the ferrous ion (Fe 2+ ) concentration is 18mg / L, manganese ion (Mn 2+ ) concentration is 12mg / L, and the effective alkalinity is 1200mg / L (based on Na 2...

Embodiment 2

[0031] Sodium carbonate is used as the absorbing liquid, the method of the invention is used to control the sintering waste gas of the crude lead smelter, and recover sulfur resource from the waste gas. The amount of sintering waste gas to be treated is 60000Nm 3 / h, the exhaust gas temperature is 180°C, the sulfur dioxide content in the exhaust gas is 1500ppm, and the concentration is 5% sodium carbonate (Na 2 CO 3 ) lye is the absorbing liquid.

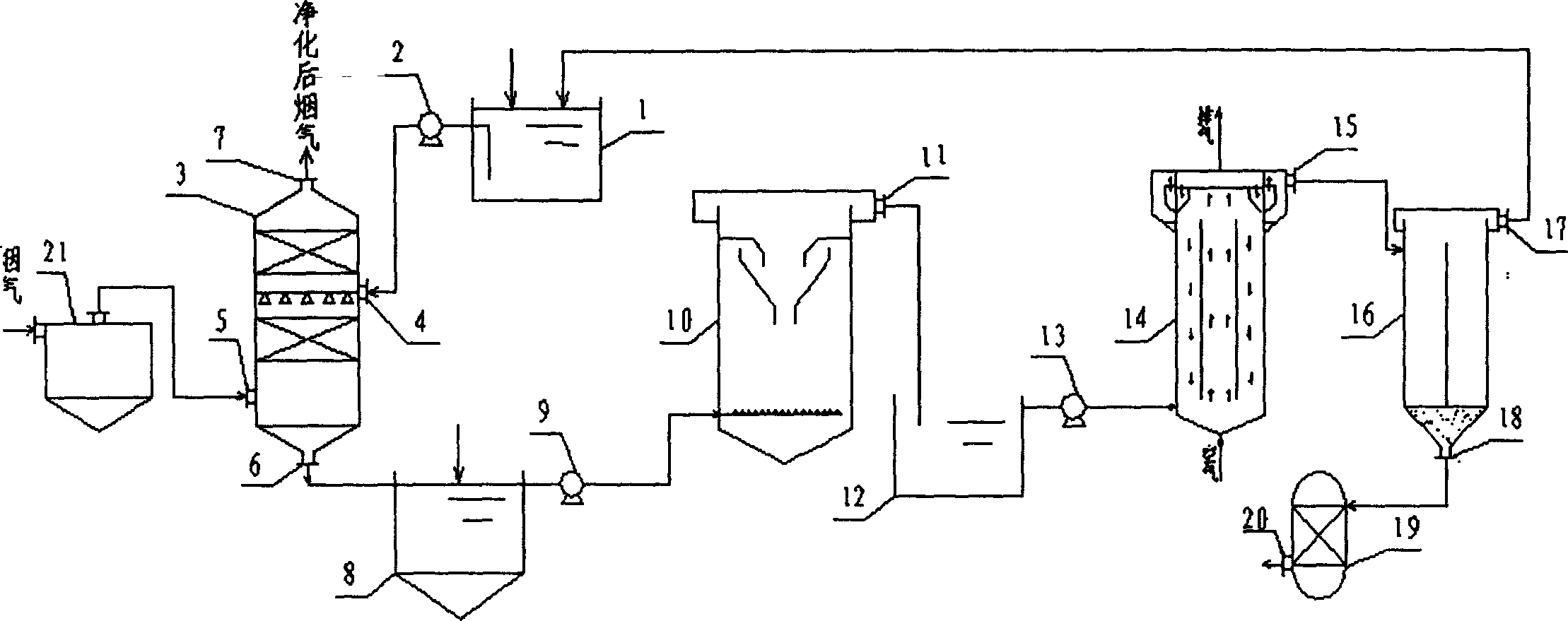

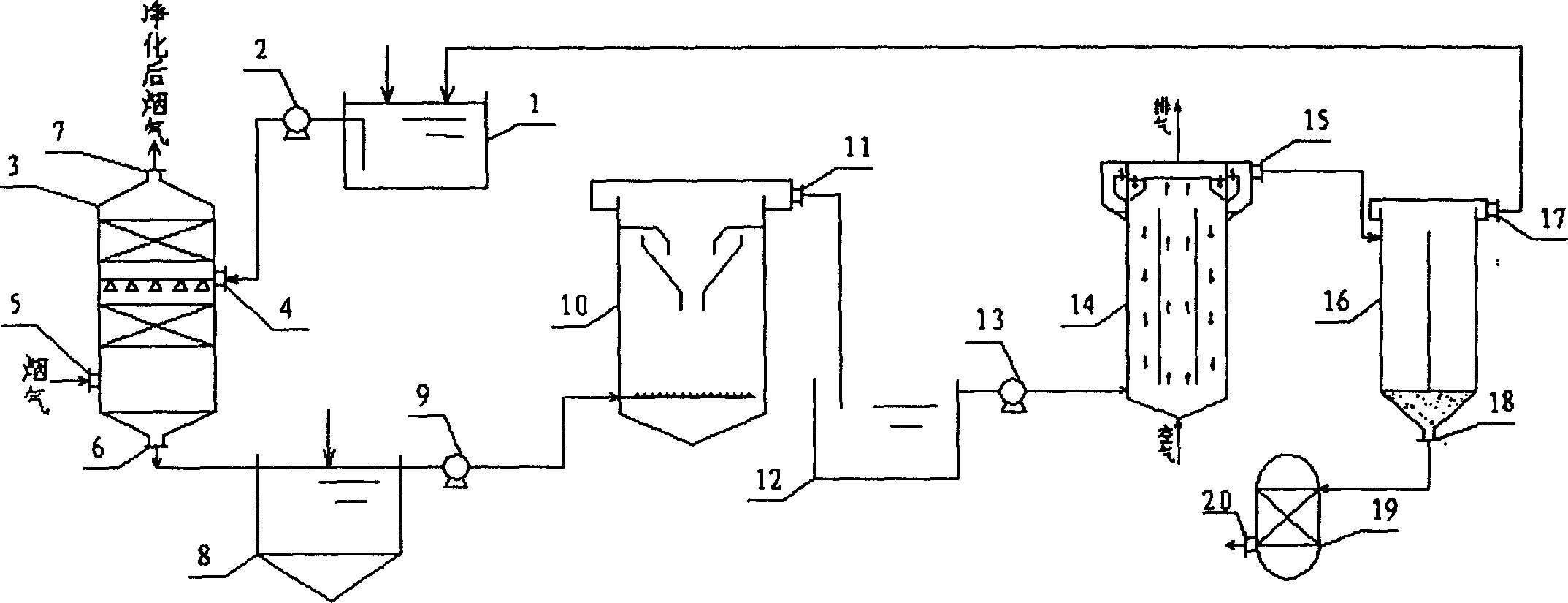

[0032] The technological process of this embodiment is as attached figure 2 shown. 5% sodium carbonate (Na 2 CO 3 ) alkaline water pump 2 into the waste gas absorption device through the water inlet 4 on the top of the waste gas absorption device 3, and simultaneously the sintering waste gas enters the waste gas absorption device 3 from the waste gas inlet 6 at the bottom of the waste gas absorption device, and the sulfur dioxide (SO 2 ) absorbed into sodium carbonate (Na 2 CO 3 ) lye and the alkaline substance sodium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com