Patents

Literature

350 results about "Low-carbon economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A low-carbon economy (LCE), low-fossil-fuel economy (LFFE), or decarbonised economy is an economy based on low carbon power sources that therefore has a minimal output of greenhouse gas (GHG) emissions into the biosphere, but specifically refers to the greenhouse gas carbon dioxide. GHG emissions due to anthropogenic (human) activity are the dominant cause of observed global warming (climate change) since the mid-20th century. Continued emission of greenhouse gases may cause long-lasting changes around the world, increasing the likelihood of severe, pervasive and irreversible impacts for people and ecosystems.

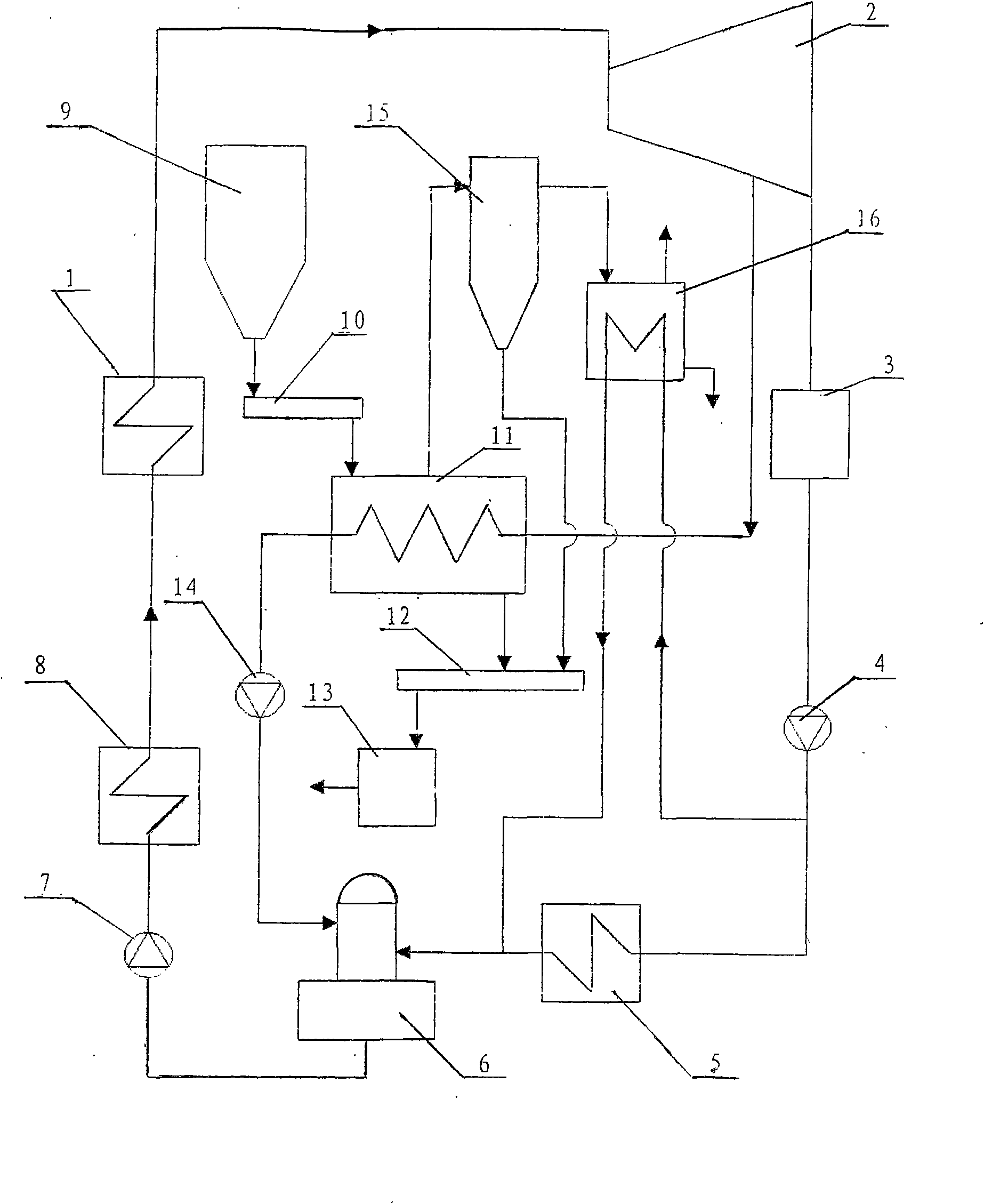

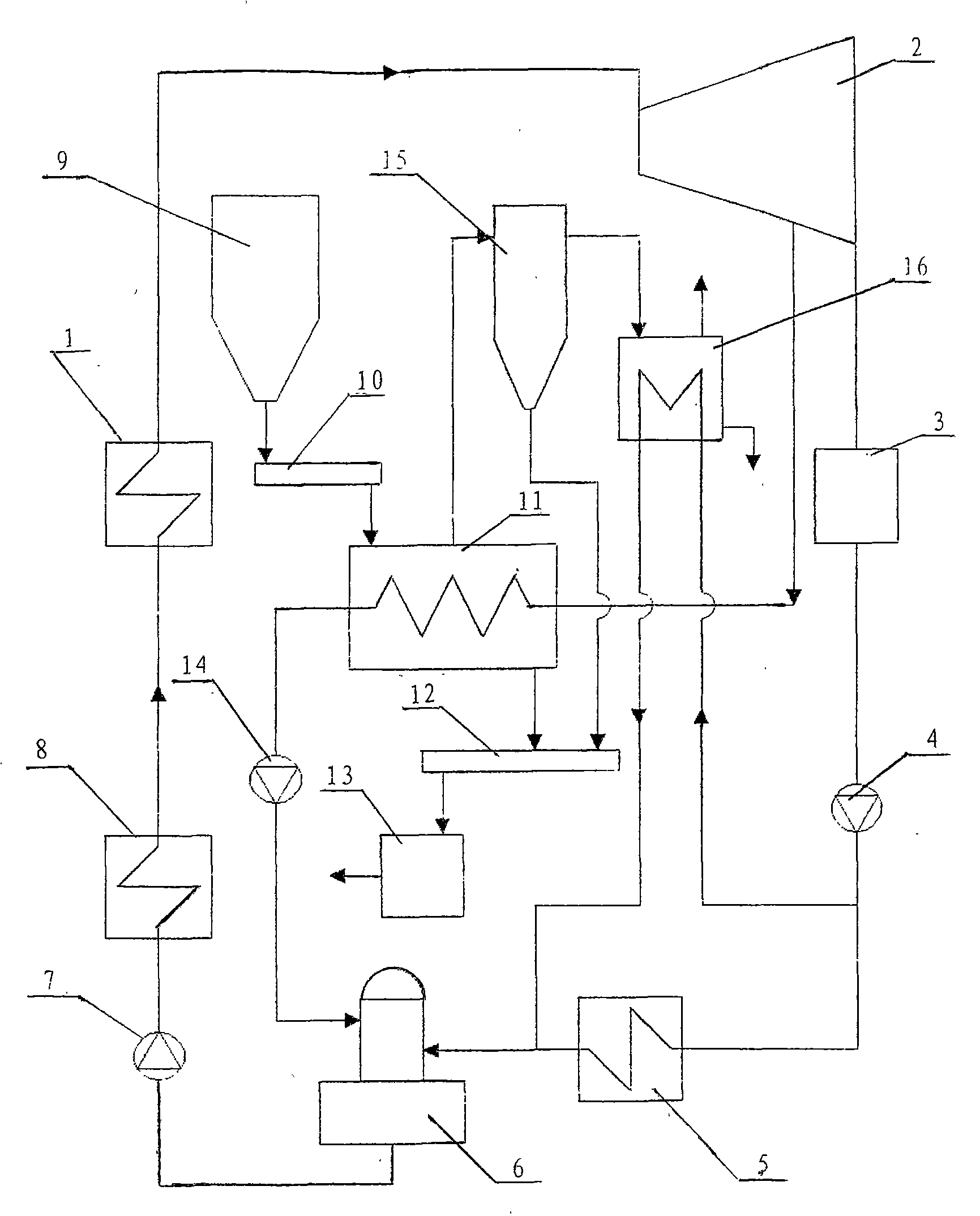

Thermal power generation system based on high-moisture lignite pre-drying upgrading and recovering technology

ActiveCN101881191AIncrease energy densityReduce smoke lossDrying solid materials with heatSteam regenerationDeaeratorHigh pressure

The invention relates to a thermal power generation system based on a high-moisture lignite pre-drying upgrading and recovering technology. The thermal power generation system comprises a boiler, a turbine, a condenser, a condensation pump, a low pressure heater, a deaerator, a water feed pump, a high pressure heater, a wet coal bin, a wet coal feeder and a coal mill and is characterized in that a lignite pre-drying device, a drain pump, a dry coal feeder, a dust remover and a heat energy and waste water recovering device are additionally arranged in the power generation system. The invention improves the energy density of fire coal and accordingly increases the efficiency of the boiler, and is capable of reducing the investment of the boiler and a milling system by a larger extent, simultaneously reducing the plant power utilization ratio, further improving the energy source comprehensive utilization efficiency of a thermal power generation plant, recovering a great deal water by using coal to produce water and saving precious water resources. The invention achieves the effects of high efficiency, energy saving, water saving and emission reduction and accords with the industrial policy of developing the low-carbon economy in China.

Owner:CHINA POWER ENG CONSULTING GRP +1

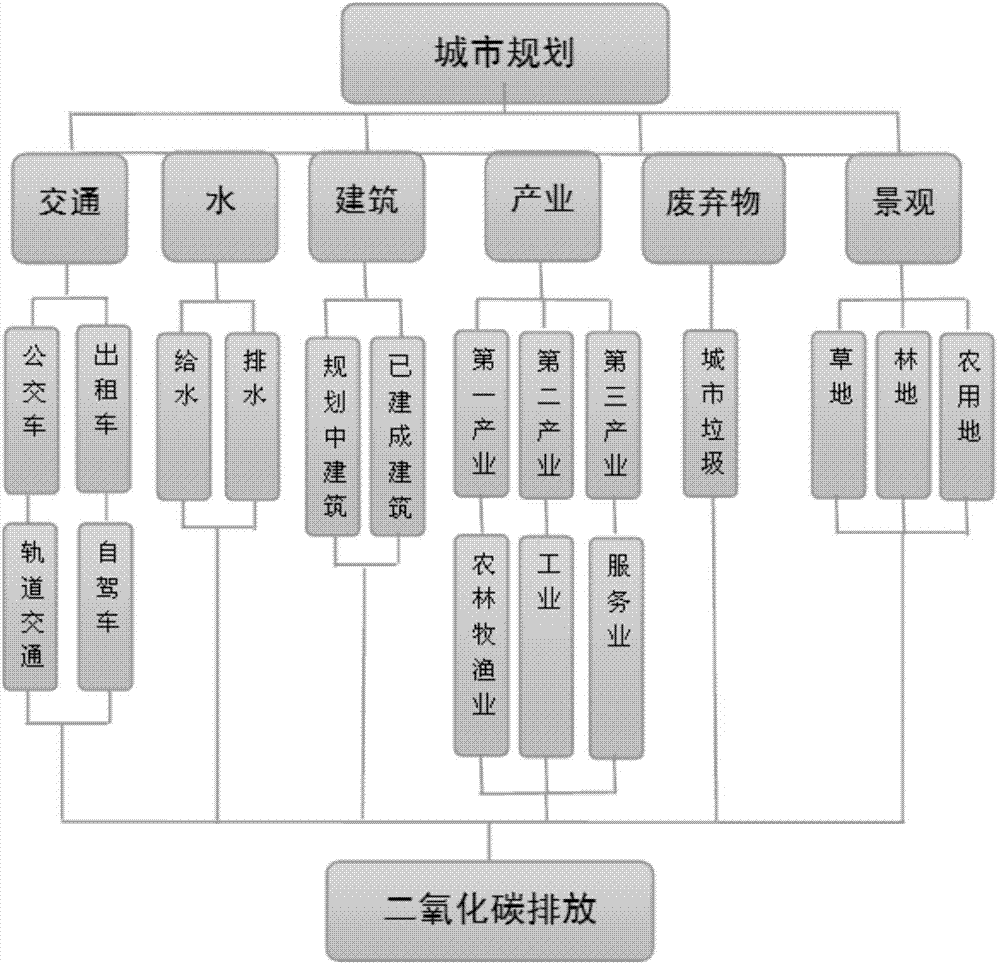

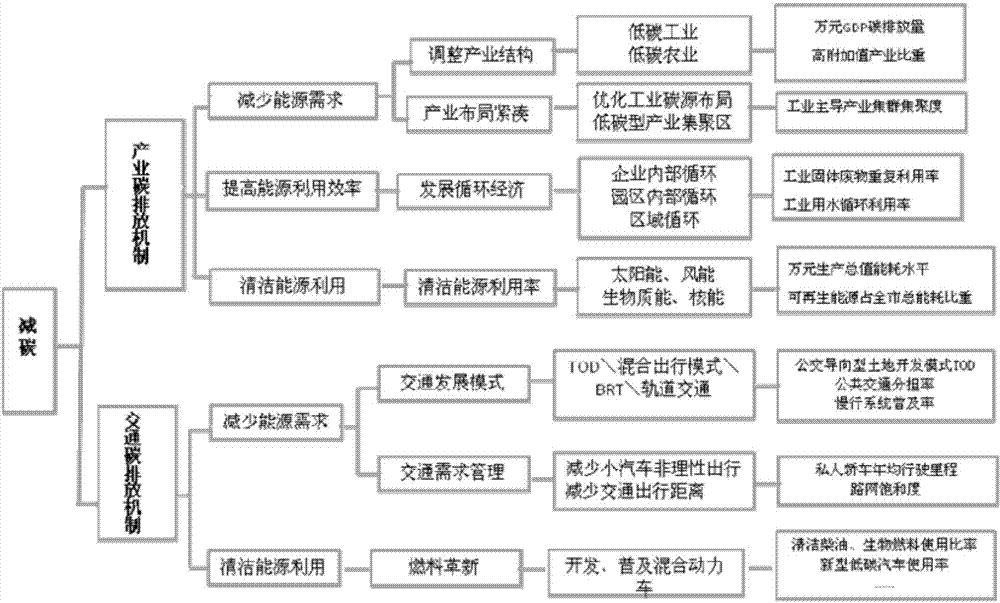

Carbon emission metering method based on city planning

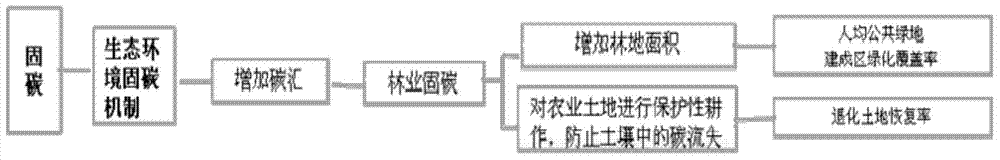

InactiveCN103870678AAchieve quantificationSpecial data processing applicationsCarbon sinkEmission standard

The invention discloses a method and a technique for analyzing and judging the whole carbon emission metering of the city based on city planning. According to the method and the technique, city planning low-carbon emission fields are divided into six aspects, namely traffic, water, buildings, industries, wastes and carbon sink, and the total carbon emission of the whole city is obtained by carbon emission accounting of the specific aspects. According to the method, the energy resource carbon emissions of land are metered and planned by analyzing land usage and gross land characteristics in the city planning, or the traffic carbon emission can be predicted according to traffic road network density and flow and further the total carbon emission of the city at different planning stages is predicted; finally, organic joint of the carbon emission and international and national carbon emission standards is realized while the carbon emission conforms to a city planning system so as to promote low-carbon economic development and low-carbon cause.

Owner:SHANGHAI ZED CONSTR SCI & TECH +1

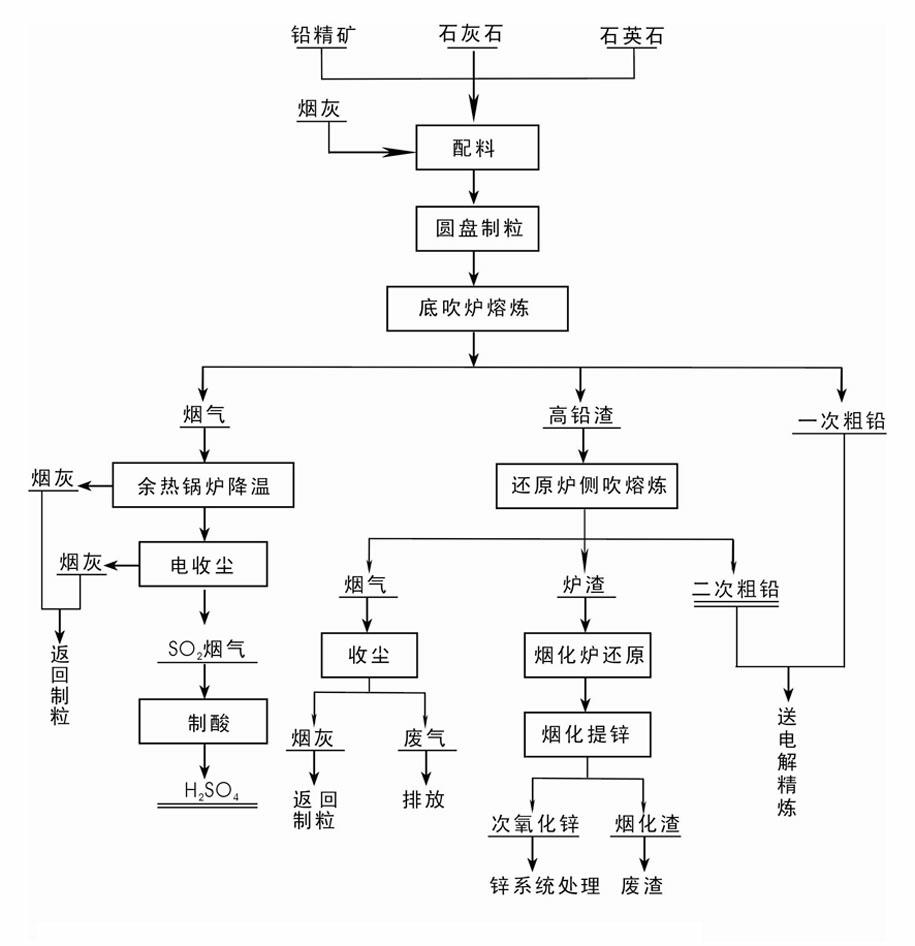

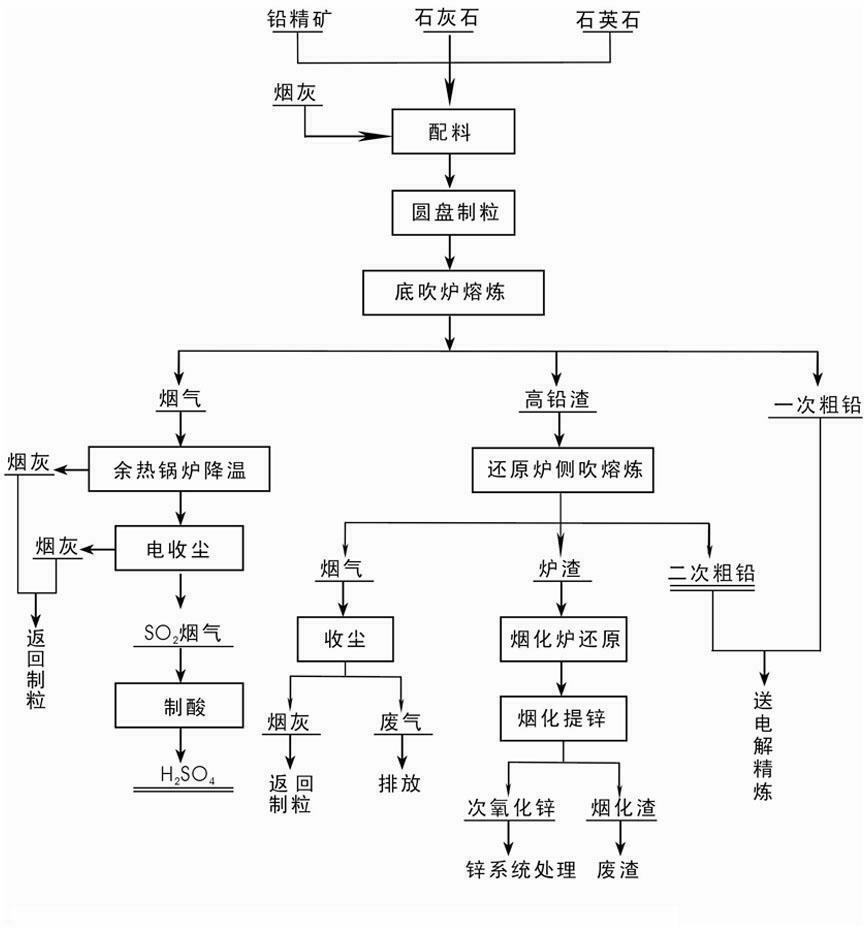

Oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process

InactiveCN102634674AEasy to separateShort and easy smelting processProcess efficiency improvementSlagOxygen

The invention relates to an oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process, belonging to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom oxygen blowing smelting furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting crushed coal as fuel; and after high-sulfur smoke produced by the bottom oxygen blowing smelting furnace is subjected to waste heat recovery by a first waste heat boiler and dust collection by an electric dust collector, and delivering the high-sulfur smoke to a sulfuric acid workshop for acid making. According to the process disclosed by the invention, a blast furnace, a slag casting machine and corresponding auxiliary facilities are omitted, the advantages of little investment and high automation level are achieved, and the industrial production of low pollution and low-carbon and economy is realized.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

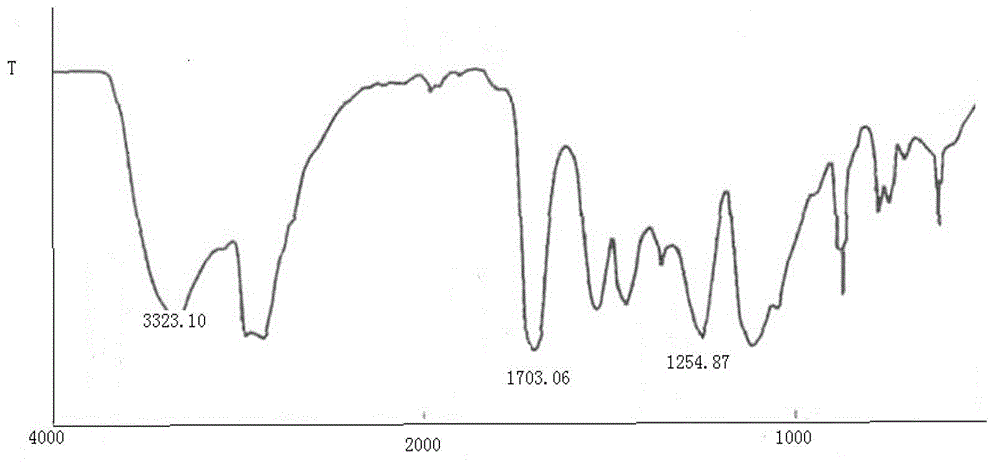

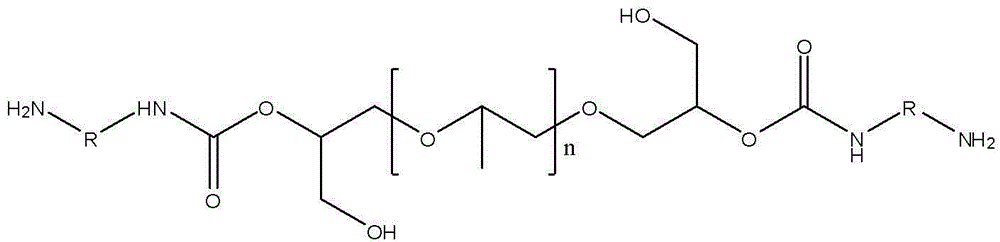

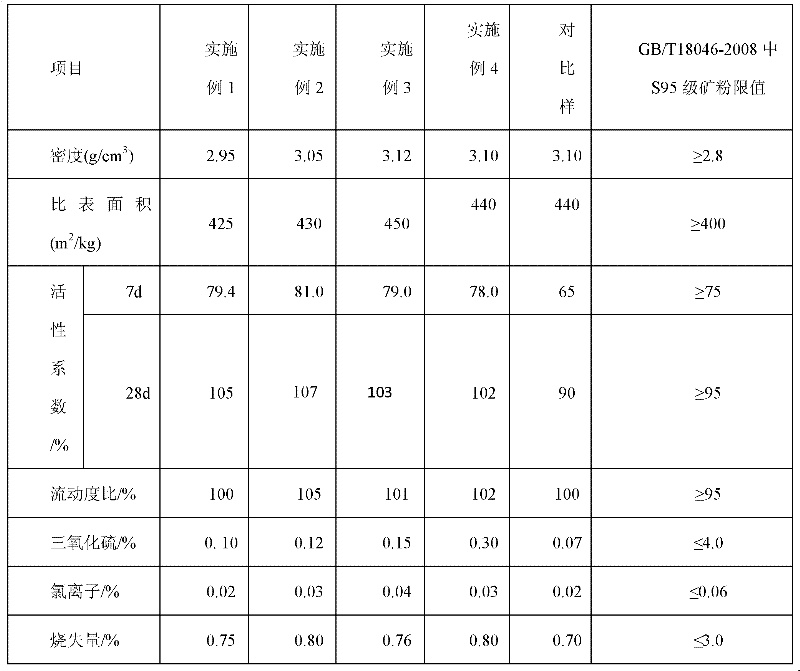

Preparation method of non-isocyanate polyurethane and application of non-isocyanate polyurethane in spraying polyurea

InactiveCN102718964ANo post-processing requiredReduce energy consumptionPolyurea/polyurethane coatingsPotassium iodineHydrolysis

The invention discloses a preparation method of non-isocyanate polyurethane and application of the non-isocyanate polyurethane in spraying polyurea. The preparation method of the non-isocyanate polyurethane comprises the following steps: (1) preparing a polyether diol diglycidyl ether intermediate; (2) preparing a heterogeneous loaded potassium carbonate and potassium iodide catalyst; (3) preparing polyether bicyclo carbonate; and (4) preparing the non-isocyanate polyurethane product. The invention has the advantages as follows: 1, the preparation method is low in energy consumption, free of pollution and low in cost and has a concept of environment friendliness, low-carbon economy and atomic economy; and 2. the prepared non-isocyanate polyurethane, as a amine resin for the spraying polyurea, has better chemical resistance, hydrolysis resistance and the penetration resistance and is superior to amino-terminated polyether in adhesion to substrate and leveling property.

Owner:GUANGXI UNIV FOR NATITIES

Aerated concrete regenerative building block produced by using garbage clinkers and manufacturing method thereof

The invention relates to an aerated concrete regenerative building block produced by using garbage clinkers and a manufacturing method thereof. The manufacturing method comprises the following steps of: adopting the garbage clinkers, flying ash, river sand, silicate cement, lime, calcium sulfate, poly-carboxylate water reducing agent, aluminum powder, glcditsia sinensis powder, borax, sodium chloride and water as raw materials; stirring the raw materials into a paste by using a double-shaft hybrid stirring machine, and pouring the paste into a die; performing delaying curing for gas development and solidification; forming the paste through machinery cutting; putting the formed garbage clinker aerated concrete regenerative building block into a still kettle to perform steam curing; and raising the temperature to heat up the building block for 2 to 3 hours first, heating the building block for 5 to 8 hours at a constant temperature of between 95 and 100 DEG C, and then naturally cooling the building block for 1 to 2 hours to obtain a garbage clinker aerated concrete regenerative building block product. The product has the advantages and effects of light weight, high strength, no pollution, low cost and good benefit, and accords with a national prescription for saving energy, reducing emissions, developing low-carbon economy and protecting the environment.

Owner:清远绿由环保科技有限公司

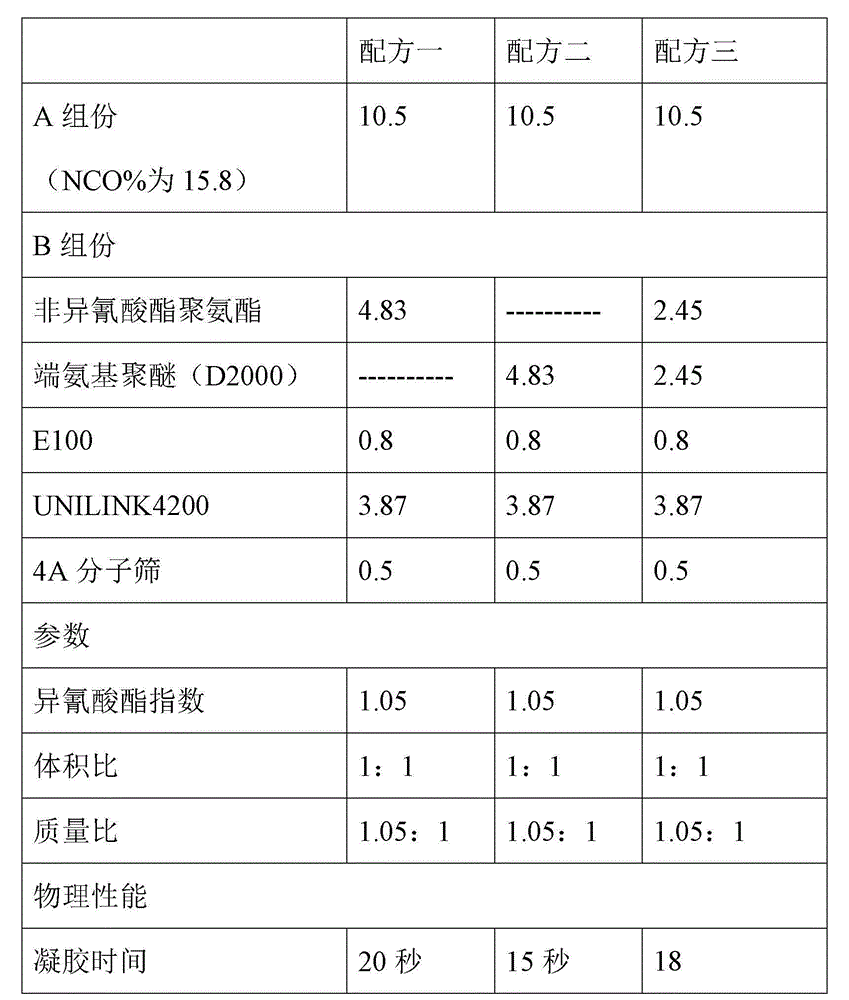

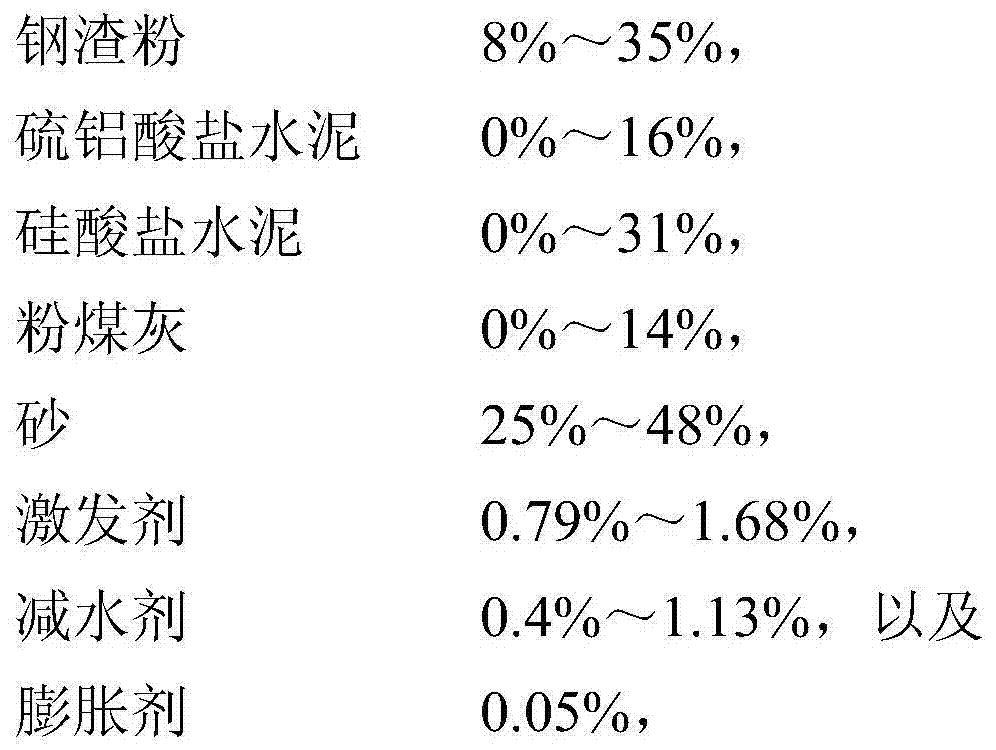

Modified steel slag composite admixture and preparation method thereof

InactiveCN102491664AOvercoming stability issuesImprove early activitySolid waste managementWork performanceSlag

The invention discloses a modified steel slag composite admixture and a preparation method thereof. The modified steel slag composite admixture comprises 55-75wt% of micro mineral slag powder, 20-40wt% of micro steel slag powder, and 1-5wt% of sintering desulphurization slag. Concrete prepared by mixing the modified steel slag composite admixture of the invention with cement has the following characteristics: the seven day active index is greater than 75%, the twenty-eight day active index is greater than 100%, the specific surface area is equal to or greater than 400m<2> / kg, the sulfur trioxide content is equal to or less than 4.0%, the chloride ion content is equal to or less than 0.06%, the ignition loss amount is equal to or less than 3.0%, and the autoclaving stability is qualified. The modified steel slag composite admixture which allows a low early strength disadvantage of steel slag composite admixtures to be overcome, working performances of concrete to be effectively improved, the strength and the endurance of concrete to be improved, and energy consumption required by slag grinding to be effectively reduced and is in favor of the low carbon economy realization, is a resource use type concrete admixture.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

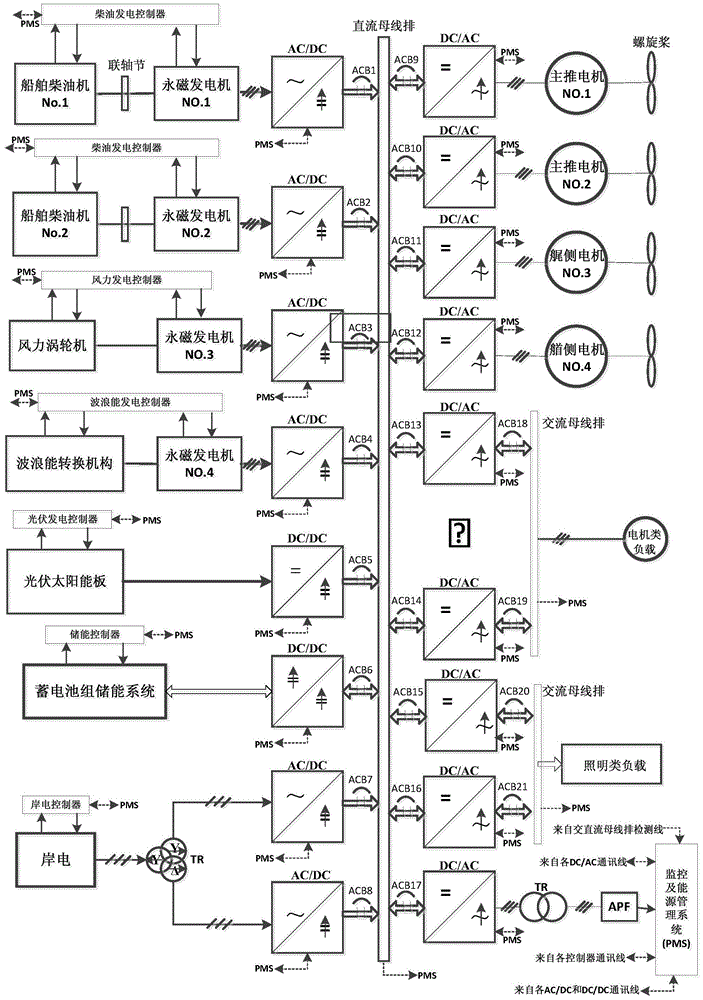

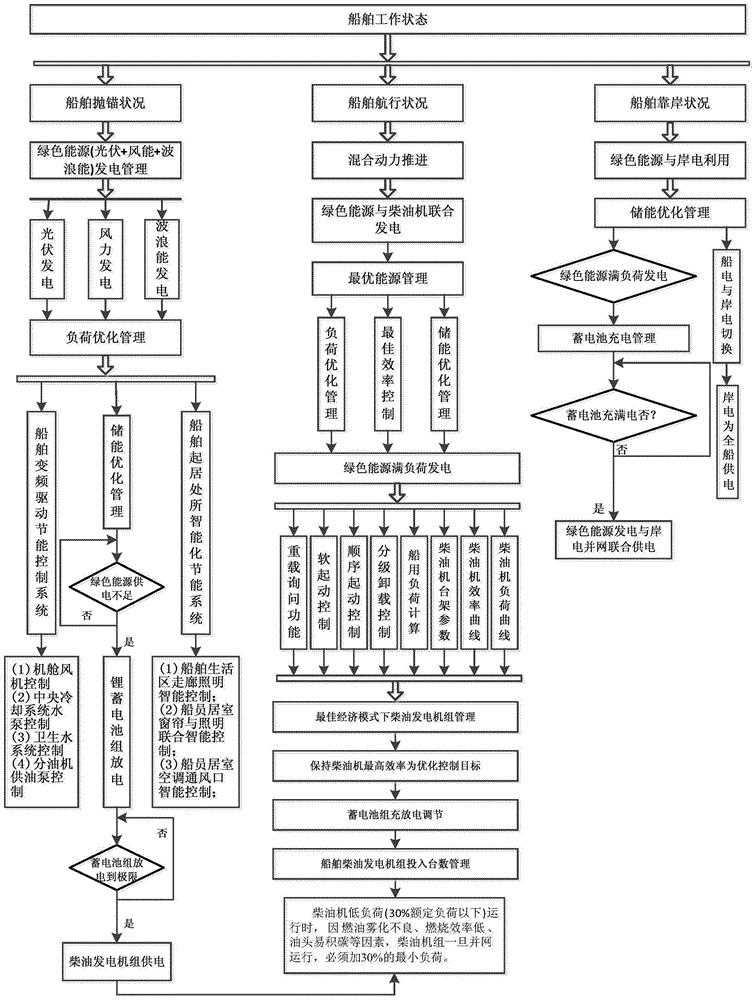

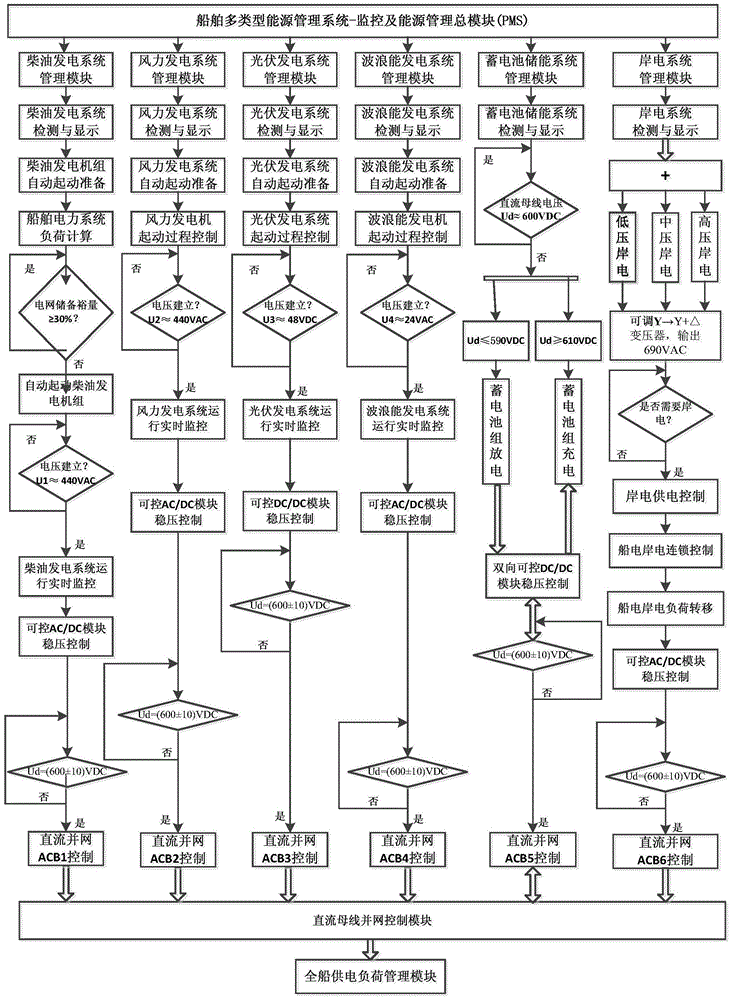

Ship multi-type energy source management system and energy source management method

InactiveCN106809363AControlled emissionsPromote sustainable developmentPropulsion based emission reductionAuxillariesThermal energyShore

The invention provides a ship multi-type energy source management system and an energy source management method. The ship multi-type energy source management system comprises a monitoring and energy source management master module, a diesel power generation system, a wind power generation system, a photovoltaic power generation system, a wave energy power generation system, a storage battery energy storage system, a shore power system, a direct current bus bar and a plurality of paths of power transmission systems. The ship multi-type energy source management system and the energy source management method have the advantages that the ship multi-type energy source management system provided by the invention fills the technological blank of integrating various types of green energy source power generation into ship heat energy power generation systems; the energy conservation and emission reduction are met; the global warming is responded; the greenhouse gas emission is controlled; the atmospheric environment is protected and the sustainable development of low-carbon economy is promoted.

Owner:SHANGHAI GUANTU ELECTRICAL TECH CO LTD

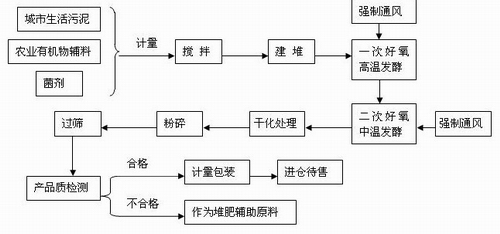

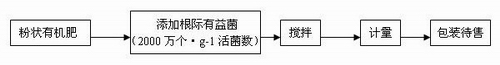

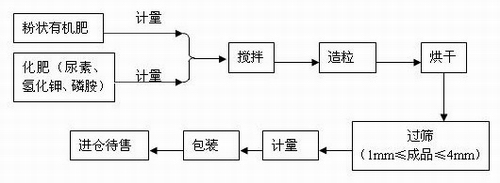

Method for producing organic fertilizer by using municipal sewage sludge

InactiveCN101983952ASimple and fast operationEasy to handleBio-organic fraction processingOrganic fertiliser preparationMunicipal sewageOrganic fertilizer

The invention relates to a method for producing organic fertilizer by using municipal sewage sludge. In the method, the municipal sewage sludge is fermented for the second time to be prepared into agricultural organic fertilizer or is further processed to be prepared into biological organic fertilizer or organic-inorganic compound fertilizer, the municipal sewage sludge is composted to be harmless municipal sewage sludge, and then, the municipal sewage sludge is prepared into the organic fertilizer to be applied to the soil. The invention can effectively improve the soil fertility, improve the crop yield, realize the purpose of recycling resources and relieve the processing cost by using incomes, and has positive significance for treating and recycling municipal sewage sludge and promoting low carbon economy.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI +1

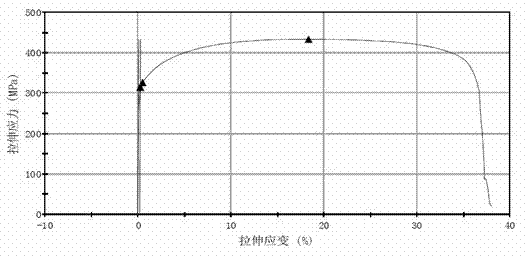

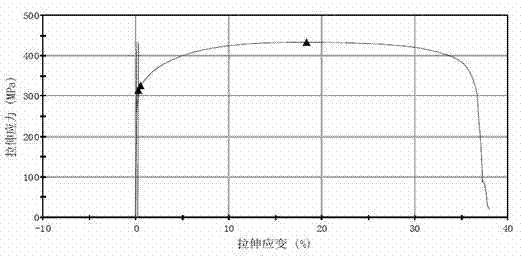

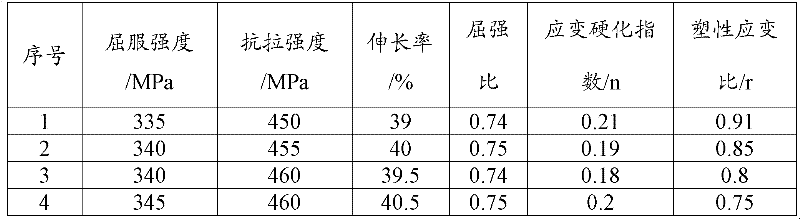

Titanium-containing cold heading steel wire rod for 12.9-grade fastener and production method for titanium-containing cold heading steel wire rod

InactiveCN102321846AEmission reductionReduce pollutionProcess efficiency improvementWire rodTitanium

The invention discloses a titanium-containing cold heading steel wire rod for a 12.9-grade fastener and a production method for the titanium-containing cold heading steel wire rod. The wire rod comprises the following components in percentage by weight: 0.34 to 0.38 percent of C, 0.15 to 0.30 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, 0.90 to 1.10 percent of Cr, 0.17 to 0.24 percent of Mo, 0.005 to 0.05 percent of Ti, 0.01 to 0.04 percent of Al and 40 to 110ppm of N, which are basic components, more than one of 5 to 30ppm of B, 5 to 20ppm of Ca and 0.05 to 0.20 percent of Cu, which is optional components, and the balance of iron and impurities. The preparation method sequentially comprises the following steps of: smelting in an electric furnace; refining outside the furnace; continuously casting small square billets; polishing the square billets; and performing high-speed wire controlled rolling; cooling large-roll coiled wires in piles or Stelmor wire controlled cooling, and the preparation method also can comprise a step of performing vacuum treatment after the step of refining outside the furnace. The titanium-containing cold heading steel wire rod completely meets the production and use requirements of the 12.9-grade fastener, has the advantages of simple production process, low cost, low energy consumption, low carbon emission and light environmental pollution and meets the long-term requirements of low-carbon economy and sustainable development.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for preparing concrete pavement brick by using recycled aggregate of construction waste

InactiveCN106673592ARealize resourcesQuality improvementSolid waste managementEcological environmentBrick

The invention relates to a method for preparing a concrete pavement brick by using recycled aggregate of construction waste. The method is characterized in that a concrete pavement is prepared from the following raw materials in parts by weight: 60-80 parts of recycled aggregate of the construction waste, 25-35 parts of superfine 52.5 Portland cement, 10-15 parts of a gelatinizing agent, 0.5-2 parts of a superplasticizer, 0.5-2 parts of a reinforcing agent, 0.1-0.5 part of a dispersing agent and 0.1-1 part of a retarder. The quality of the concrete pavement brick is ensured by adopting the construction waste as the aggregate and adjusting the ingredients and quality of the cement and an additive; the prepared concrete pavement brick has the characteristics of high strength, good abrasive resistance, stable quality, long service life, low cost and the like; and the concrete pavement brick is prepared by adopting the construction waste as the aggregate, so that the construction waste is comprehensively utilized to turn the waste into treasure, reclamation of the construction waste is achieved, the ecological environment is improved, and the aims of protecting the environment, saving resources and achieving low-carbon economy are achieved.

Owner:盛丹

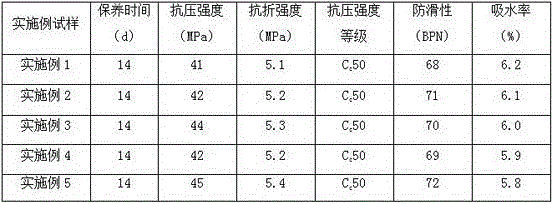

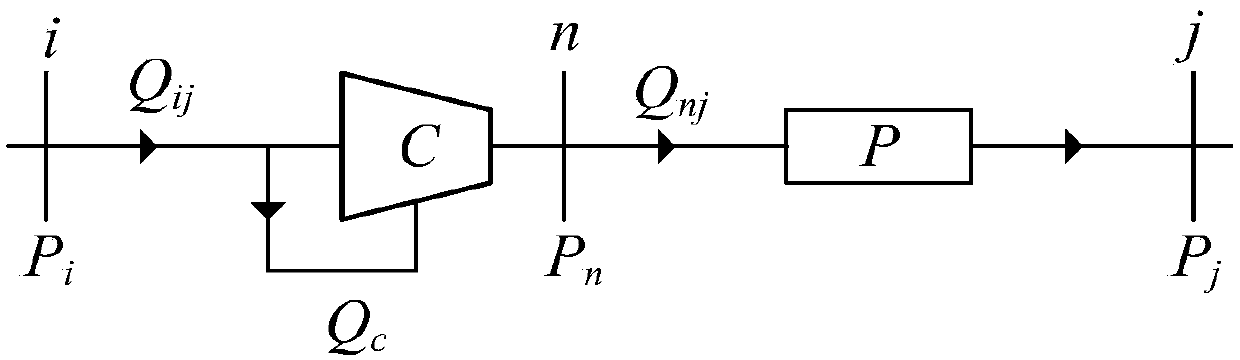

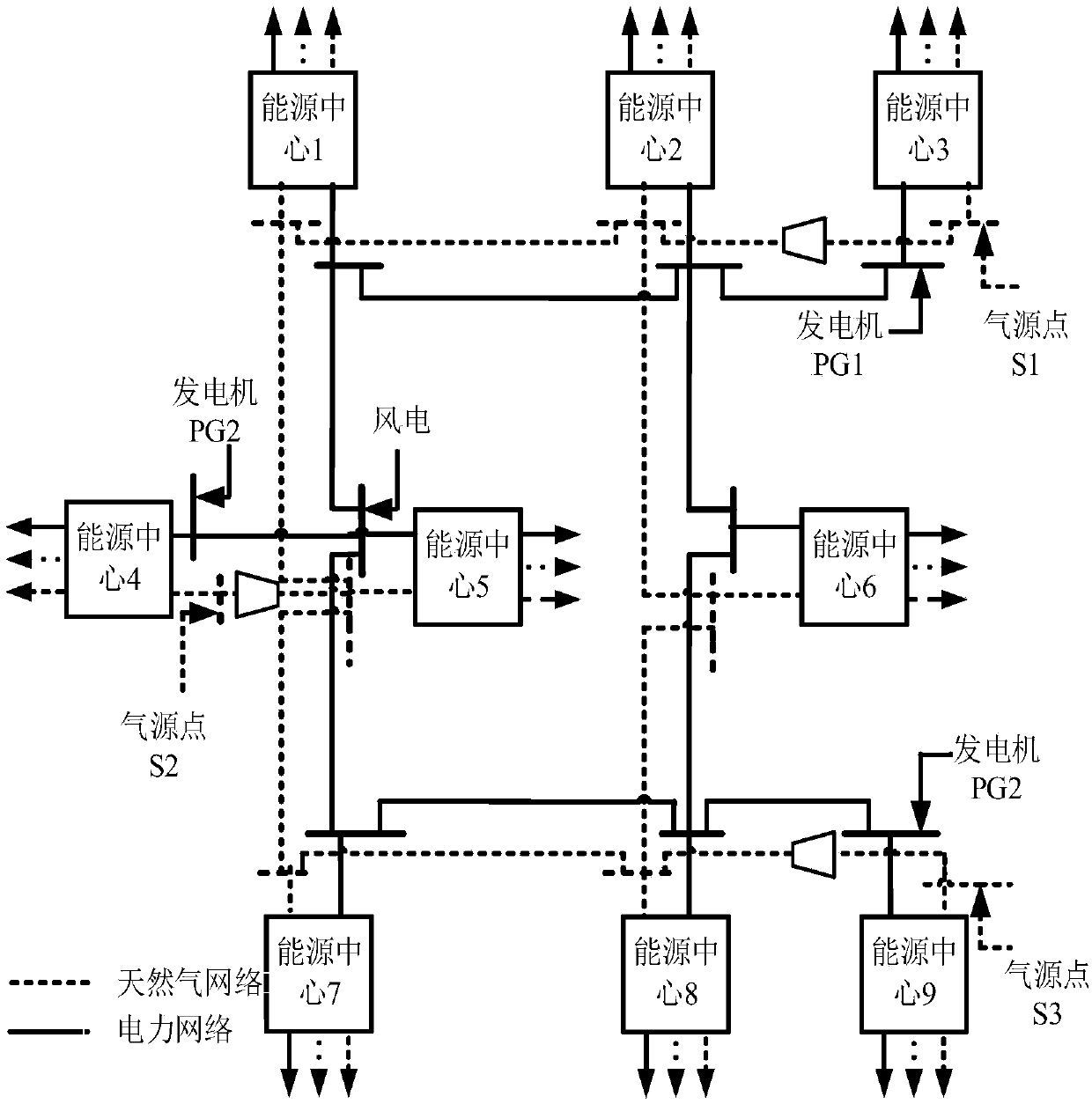

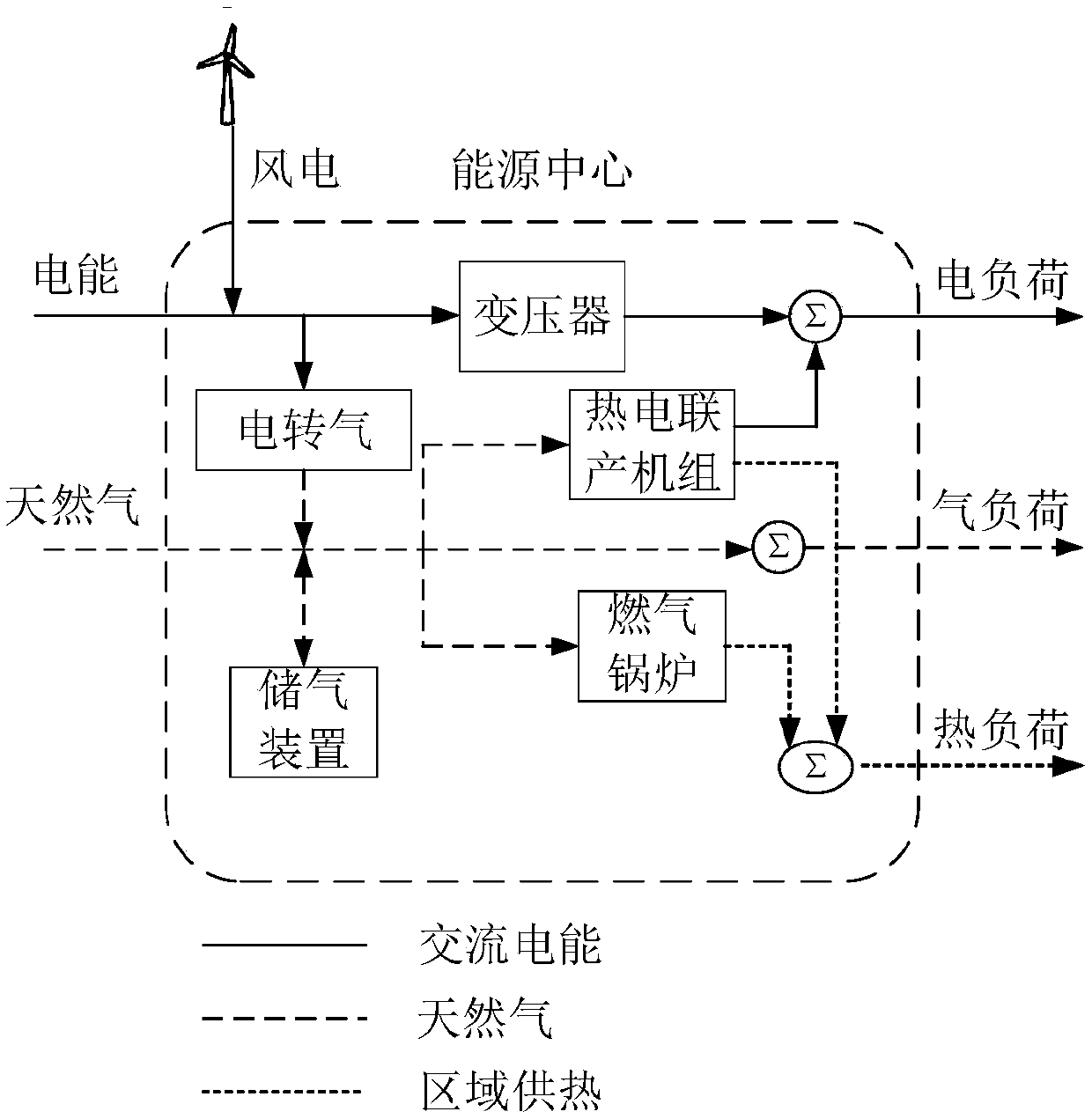

Integrated energy system optimization scheduling method considering carbon trading mechanism and flexible load

ActiveCN109524957AEmission reductionReduce energy consumptionForecastingInformation technology support systemIntegrated energy systemHeat energy

The invention discloses an integrated energy system optimization scheduling method considering a carbon trading mechanism and a flexible load. The technical solution of the invention comprises a stepof modeling a coupling link of an integrated energy system based on an energy center model and outputting electric energy, heat energy and natural gas to supply load demand, wherein input energies areelectric energy and natural gas, a step of introducing the carbon trading mechanism into an integrated energy system scheduling model, comprehensively considering the carbon emissions of an entire energy supply chain, and establishing an over-discharge penalty mechanism, a step of applying the flexible load to the low-carbon economic operation of the integrated energy system, and a step of introducing a power system network constraint, a natural gas system network constraint and an energy center internal constraint on the above basis and establishing an integrated energy system low-carbon economic scheduling model with the goal of carbon trading cost, flexible load scheduling cost and system energy cost. According to the method, the consumption of renewable energy can be promoted, the system energy consumption and carbon emission are reduced, and the comprehensive benefits of the system are significantly improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

Supercritical carbon dioxide dyeing method of ready-made clothes

InactiveCN101812810AAchieve dyeingShorten the production cycleDyeing processHigh pressureNormal state

The invention relates to a supercritical carbon dioxide dyeing method of ready-made clothes, comprising the process flow of: putting dyes and ready-made clothes into a supercritical carbon dioxide dyeing device in sequence; heating to enable the temperature of the device to be 70-150 DEG C; starting a high-pressure system to enable the pressure of the system to be 15-25MPa; dyeing under the condition for 50-120min; then releasing pressure and keeping the pressure at 4-5MPa, and recovering carbon dioxide and the dyes at the temperature of 25-40 DEG C; and releasing pressure and cooling to be in a normal state to obtain dyed fabrics. The method has the characteristics that anhydrous dyeing is carried out on grey ready-made clothes; the dyes and the carbon dioxide which are involved in dyeing can be recovered; the ready-made clothes do not need washing after dyed; the processing is not limited by the size of an order; the production cycle is short; only the ready-made clothes are dyed and no leftovers are left; the method actually saves energy, protects environment and meets the development requirements of low-carbon economy.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for preparing activated carbon from pinecone

InactiveCN102249228AReduce manufacturing costRaw materials are cheap and easy to getSolid waste disposalElectronic waste recyclingActivated carbonMicrowave oven

The invention discloses a method for preparing activated carbon from pinecone, which comprises the following steps of: (1) drying the pinecone at the temperature of between 100 and 120 DEG C for 20 to 30 hours; (2) grinding the dried pinecone in the step (1) into pinecone particles with the size of 1 to 3mm; (3) mixing the pinecone particles in the step (2) and potassium hydroxide in a weight ratio of 1:1-1:4, adding water and soaking for 20 to 30 hours to obtain a mixed material; (4) putting the mixed material in the step (3) into a microwave oven, carbonizing and activating to obtain an activated mixed material, wherein microwave irradiation power is 200 to 700W, and microwave irradiation time is 5 to 10 minutes; and (5) washing the activated mixed material in the step (4) by using acidand water respectively, drying and grinding to obtain the activated carbon. By the method, the raw material is cheap and readily available, the production cost of the activated carbon is reduced, waste is recycled, resources are circulated, and the development of low-carbon economy is promoted.

Owner:南通保来利轴承有限公司 +1

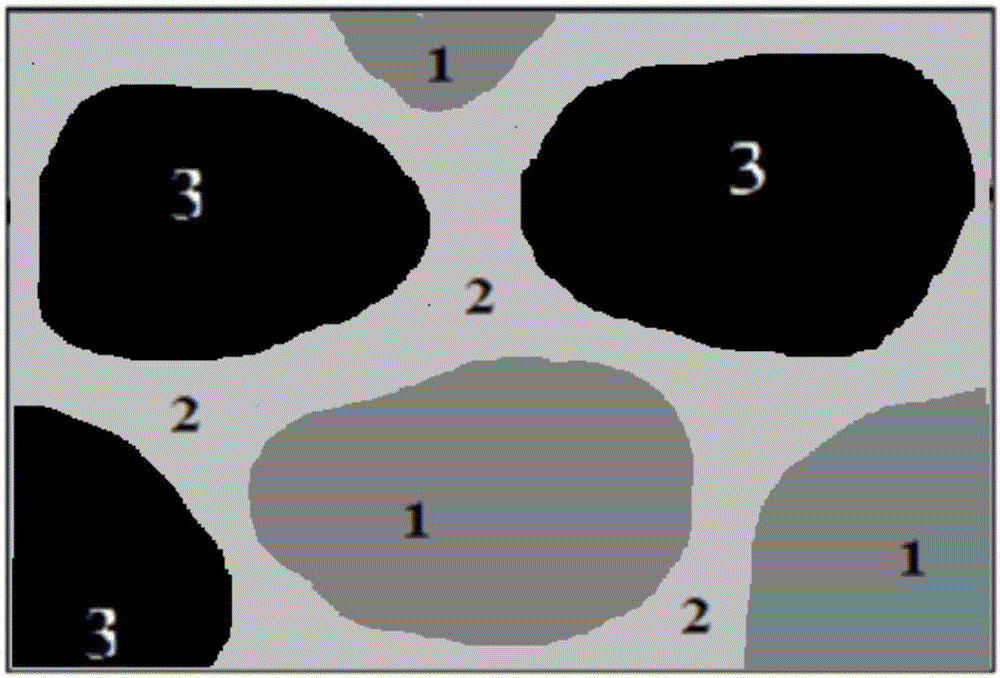

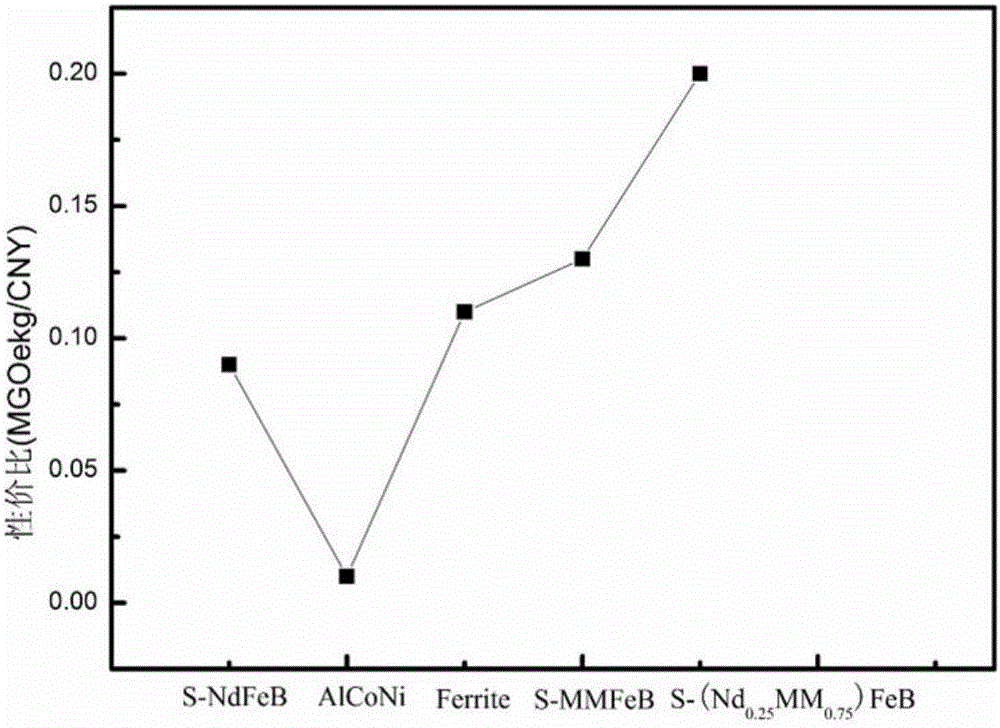

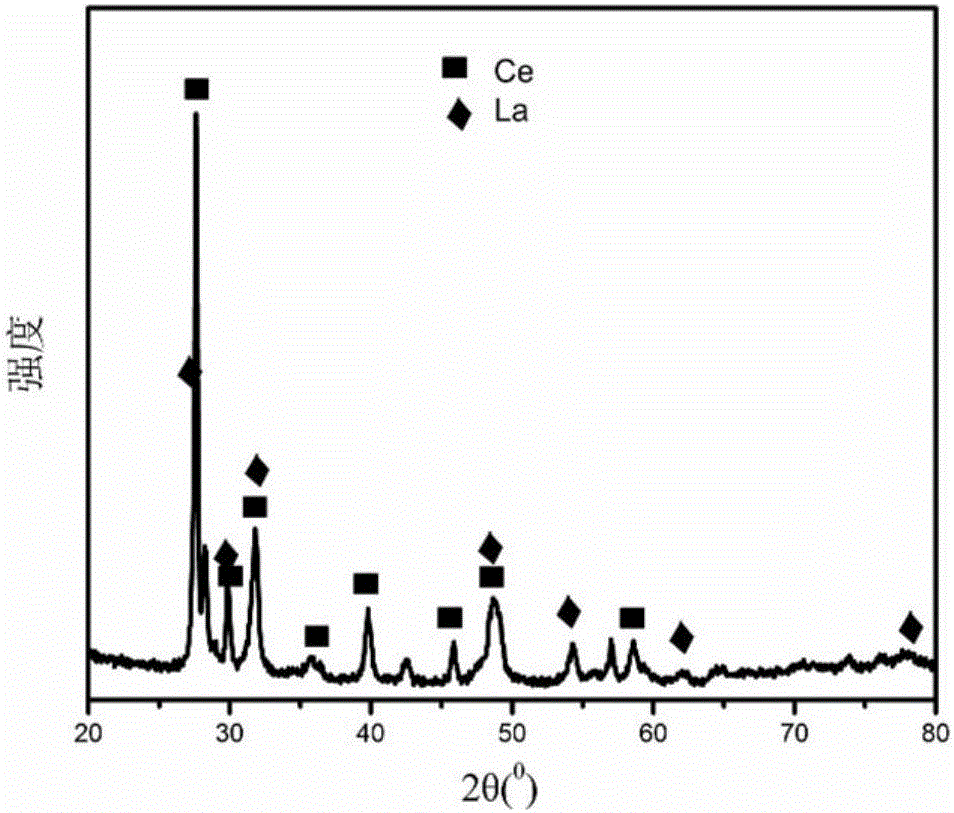

Double-hard magnetic main phase mixed rare-earth permanent magnet and preparation method thereof

ActiveCN106128674ANo wasteNo pollution in the processInductances/transformers/magnets manufactureMagnetic materialsChemical compositionCerium

The invention relates to a double-hard magnetic main phase mixed rare-earth permanent magnet and a preparation method thereof. The permanent magnet comprises double hard magnetic main phases and a rear-earth-rich phase, wherein the double hard magnetic main phases are MM<2>Fe<14>B and (PrNd)<2>Fe<14>B respectively; the permanent magnet is prepared from the following chemical component in percentage by mass: [MM<x1>(PrNd)<1-x1>]<x>Fe<100-x-y-z>B<y>TM<z>; x is smaller than or equal to 31 and greater than or equal to 27; x1 is smaller than or equal to 1 and greater than or equal to 0; y is smaller than or equal to 1 and greater than or equal to 0.9; z is smaller than or equal to 1.5 and greater than 0; TM is a composition of more of the elements Al, Cu, Co, Nb, Ga, Tb and Zr; and MM is a mixed rare-earth alloy which is directly separated from raw ore and contains La, Ce, Pr and Nd. The anisotropic sintered mixed rare-earth permanent magnet with high cost performance within a range of 10-48MGOe can be prepared by adjusting the content of PrNd. A basic rare-earth raw material used by the permanent magnet is cheap mixed rare earth, so that a separation and purification technology for the rare earth can be reduced, efficient utilization of lanthanum-cerium rare earth is achieved and the double-hard magnetic main phase mixed rare-earth permanent magnet meets the requirements of low carbon economy on green production technology innovation of a rare-earth permanent magnet product.

Owner:CENT IRON & STEEL RES INST

Supercritical carbon dioxide dyeing method for bulk fibers

InactiveCN101812809AAchieve direct dyeingImprove dyeing qualityDyeing processCellulose fiberNatural fiber

The invention relates to a supercritical carbon dioxide dyeing method for bulk fibers. The process flow comprises the following steps: placing dyes and bulk fiber materials in a supercritical carbon dioxide dyeing device, and dyeing under the condition of 70-150 DEG C and 20-30 MPa for 50-120 minutes; then releasing the pressure, and reclaiming carbon dioxide and the dyes under the condition of 4-5 MPa; and returning to the normal state to obtain stock-dyed fibers, wherein the bulk fibers are natural cellulose fibers, natural protein fibers and chemical fibers. The outstanding characteristics of the invention are as follows: the dyes directly carry out the supercritical waterless dyeing on the bulk fibers, and enable the fabric to obtain a special effect; the fabric is enabled to have the characteristics of good dyeing quality, cleaning production without waste products and environmental pollution, low comprehensive cost and obvious economic benefits and environmental benefits, especially waterless dyeing which conforms to the current low-carbon economic policy calling for water saving and energy saving; and the product comes up to GB18401-2003, National General Safety Technical Code for Textile Products.

Owner:DALIAN POLYTECHNIC UNIVERSITY

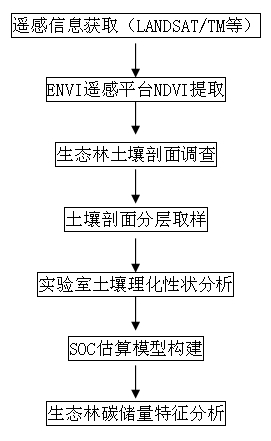

Evaluation method of soil organic carbon storage in ecological forest

The invention discloses an evaluation method of soil organic carbon (SOC) storage in ecological forest, which belongs to the field of environmental monitor technology and low carbon economy and technology in forestry ecology. In the preparation method, the attribute data of the soil landscape type are obtained and subject to characteristic analysis to acquire the landscape pattern information. Soil typical sections are excavated and layered, and soil samples are collected and pre-treated. SOC information of the above soil samples is determined by potassium bichromate volumetric method and SOC estimation model is established thereby. Quantitative estimation of the SOC storage is carried out and multivariate data of the ecological forest are obtained. Temporal and spatial features and change law of soil organic carbon are analyzed. Characteristics and regularities of ecological effect of the ecological forest with carbon as the core are reflected by the method of the invention. The method also reflects the change law and objective characteristics of ecological forests comprehensively and systematically, thereby guiding the objective practice of CO2 emission reduction and the eco-economic development.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Sintered permeable environmental-friendly brick produced by using ceramic waste residue and manufacturing method thereof

ActiveCN101955349AMitigate the heat island effectGuaranteed water circulationSolid waste managementClimate change adaptationTunnel kilnBrick

The invention relates to a sintered permeable environmental-friendly brick produced by using ceramic waste residue and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: stirring ceramic waste residue powder, waste glass powder, waste porcelain fragment powder, municipal foundation waste sludge powder, calcium oxide, calcium sulfate, bentonite, talcpowder, garbage ash residue powder, waste plant powder and water serving as raw materials to form a wet mixture, and performing mechanical vibration and extrusion molding to obtain the lower-layer brick of the permeable brick; uniformly distributing a layer of fine fabric on the upper part of the lower-layer brick of the permeable brick by using a secondary distributing machine, manufacturing a ceramic waste residue sintered permeable environmental-friendly unburned brick under the pressure of 25 to 30Mpa and naturally drying; and feeding the molded and naturally-dried ceramic waste residue permeable environmental-friendly unburned brick into a tunnel kiln for roasting, controlling the temperature to be between 1,150 and 1,200 DEG C and burning the unburned brick to obtain the ceramic waste residue sintered permeable environmental-friendly brick product. Different specifications of vegetation bricks can also be prepared from the raw materials. The product has the advantages of certain water permeability, air permeability and water retentivity, multiple functions of reducing temperature and noise, regulating climate, eliminating urban heat island effect, improving air quality, maintaining surface water circulation and the like, high strength, no pollution, low cost and good benefit, and meets the requirements of energy conservation, emission reduction, environmental protection, and the development of low carbon economy in China.

Owner:清远绿由环保科技有限公司

Sintering expansion type light ceramsite produced by using oily sludge and manufacture method of sintering expansion type light ceramsite

ActiveCN103241970AImprove plasticityImprove yieldSolid waste managementClimate change adaptationSludgeSuperplasticizer

The invention relates to a sintering expansion type light ceramsite produced by using oily sludge and a manufacture method of the sintering expansion type light ceramsite. The manufacture method is characterized by comprising the following steps of: uniformly mixing raw materials including oily sludge, building waste residue, waste energy-saving lamp residue, boiler waste residue, wood material processing waste residue, calcium oxide, calcium sulfate, carboxymethylcellulose, calcium carbonate, ferric sulfide, a polycarboxylate superplasticizer, ferrous sulfate, magnesium sulfate and water by using a dual-shaft mixing and stirring machine, manufacturing into spherical particles with diameters of 5-20mm by using a disc pelletizing machine, drying, roasting by using a dual-cylinder rotary kiln, controlling the temperature to be 1,050-1,200 DEG C and the time to be 10-25 minutes, cooling and discharging from the kiln, then screening and manufacturing to be a sintering expansion type light ceramsite product. The sintering expansion type light ceramsite product has the advantages and effects of being light in weight, preserving and insulating heat, absorbing and insulating sound, comprehensively utilizing and recycling solid waste resources, and being free of pollution, low in cost and good in benefit, and accords with the requirements of saving energy, reducing emission, protecting environment and developing low-carbon economy in China.

Owner:清远绿由环保科技有限公司 +1

Hot-rolled pickled sheet with low yield ratio and production method thereof

ActiveCN102409223AAchieving the requirement of low yield ratioIn line with the concept of green steelChemical compositionTrace element

The invention discloses a hot-rolled pickled sheet with a low yield ratio. The hot-rolled pickled sheet comprises the following chemical components in percentage by mass: 0.04-0.12 of C, 0.005-0.05 of Si, 0.8-1.5 of Mn, less than or equal to 0.020 of P, less than or equal to 0.020 of S, 0.01-0.08 of Al, 0.0005-0.003 of B and the balance of Fe and trace elements. The invention also discloses a method for producing the hot-rolled pickled sheet with the low yield ratio. According to the hot-rolled pickled sheet with the low yield ratio and the production method thereof, a proper element content proportion is given through analog computation of influence of each element on yield strength and tensile strength by utilizing a common C-Mn component system, and the content of the alloy elements isless, thus production cost can be greatly reduced; a hot rolling process window is wide, which is convenient for production and implementation; and the property of a finished product is excellent, and the yield ratio reaches the requirement of a cold plate. The production method provided by the invention is an economical and effective hot-rolled pickled sheet production method and meets the requirements of green steel and low-carbon economy.

Owner:BEIJING SHOUGANG CO LTD

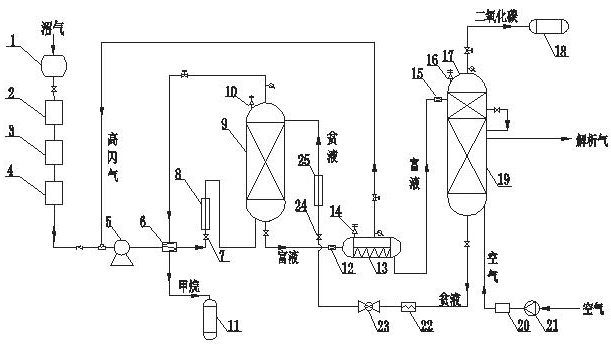

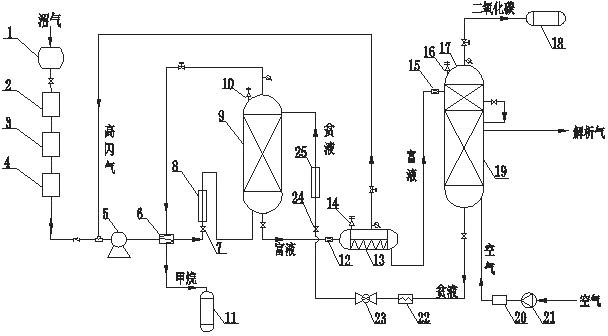

Method for separating and producing methane and carbon dioxide from marsh gas

ActiveCN102329672AImprove the degree of purificationAvoid pollutionCarbon compoundsGaseous fuelsSorbentVaporization

The invention relates to the fields of environment friendliness and renewable energy source recycle. A method for separating and producing methane and carbon dioxide from marsh gas, which is realized through five steps as follows: pretreatment, methane separation, rich liquid flash vaporization, carbon dioxide recycle and adsorbent regeneration. The volume ratio of the separated methane is up to over 96%, and the volume ratio of the carbon dioxide is up to over 98%. The invention has the characters tics of simple process, low energy consumption, nontoxicity, high purity and safety process. Byusing the method, not only is low-carbon circular flow of economy realized, but also pollution to the environment is prevented.

Owner:北京昊业怡生科技有限公司

Aerated concrete building block produced by using ceramic waste and manufacturing method thereof

ActiveCN101948286AStrong enoughSolve processing problemsSolid waste managementSodium sulfatePollution

The invention relates to an aerated concrete building block produced by using ceramic waste and a manufacturing method thereof. The method is characterized in that: the ceramic waste, garbage burnt clinker, river sand, silicate cement, burnt lime, calcium sulfate, aluminum powder, sodium sulfate, polycarboxylate efficient water reducing agent, soap powder, borax, sodium chloride and water are used as raw materials in the method; and the method comprises the following steps of: stirring the raw materials into paste by adopting a double-shaft mixing stirrer, pouring the mixture into a die, performing standing aeration, curing and mechanical cutting and forming, conveying the formed ceramic waste aerated concrete building block to an autoclave to perform steam curing, heating the ceramic waste aerated concrete building block for 2 to 3 hours, keeping the temperature constant for 5 to 8 hours at the temperature of between 95 and 100 DEG C, and then naturally cooling the ceramic waste aerated concrete building block for 1 to 2 hours to form a ceramic waste aerated concrete building block product. The product has the advantages of light weight, high strength, no pollution, low cost and good benefit, and meets the specified requirements of energy conservation, emission reduction, development, low carbon, economy and environmental protection.

Owner:清远绿由环保科技有限公司

Method for rapidly dyeing wool with mordant dyes

ActiveCN101942769AMeet the quality requirements for color fastnessAvoid damageDry-cleaning apparatus for textilesDyeing processFiberYarn

The invention relates to a method for rapidly dyeing wool with mordant dyes, comprising the following steps: preparing dyeing, adding low-temperature rapid dyeing assistants and dyes, raising temperature rapidly, carrying out dyeing at low temperature, adding mordants and formic acid without lowering temperature, carrying out mordanting at low temperature and carrying out aftertreatment and taking the wool out of the tank. In the invention, rapid temperature raising, lower dyeing temperature and the method of adding mordants without lowering temperature realize low-temperature rapid dyeing with mordant dyes by after-chrome dyeing. Compared with the traditional after-chrome dyeing method with mordant dyes, the method has the following advantages: fiber damage is lowered, the handfeel is good, the luster is bright, the yarn spinnability is improved, the color fastness conforms to the quality requirement of wool top dyeing color fastness and the dyeing time is shortened by 30-50%; and the method greatly reduces water, electricity, steam and labor consumption, improves the labor productivity and conforms to the requirement for low carbon economy.

Owner:JIANGSU DANMAO TEXTILE

Method for producing fiberboards by lignocelluloses as raw materials

InactiveCN102650108AEnvironmentally friendlyFunctionalWood working apparatusDomestic articlesCelluloseAdhesive

The invention provides a method for producing fiberboards by lignocelluloses as raw materials. The method comprises the steps as follows: degrading and transforming the lignocelluloses through the biological modification effect of special basidiomycetes; enabling the modified lignocelluloses to have a physical structure with stronger adhesion effect, and chemical properties; and carrying out compression of various density fiberboards on the modified lignocelluloses through a hot press process so as to prepare the density fiberboards free of chemical adhesives. An effective solution is provided for new material preparation, environmental protection and low-carbon economy. According to the method, the chemical adhesives are not added, the fiberboards do not need to be produced by the biological modification-thermocompression bonding process for the basidiomycetes of the added expensive laccases, and the problems of environmental pollution due to formaldehyde released by the chemical adhesives used in the conventional fiberboards, high cost due to treatment of the directly added laccases on the lignocelluloses, or the like is effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

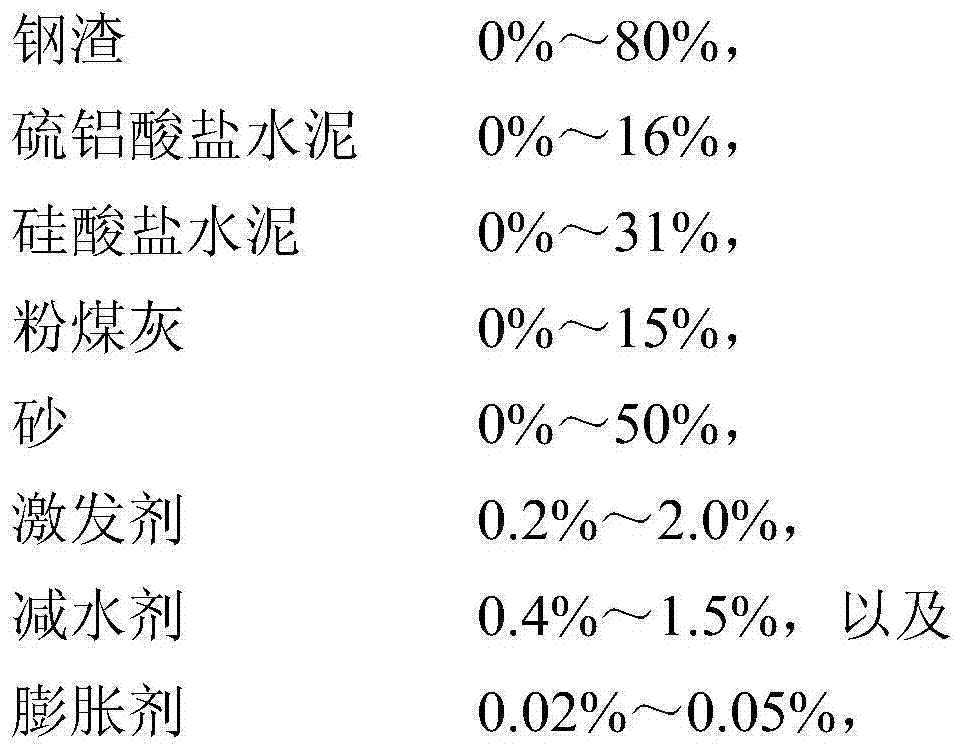

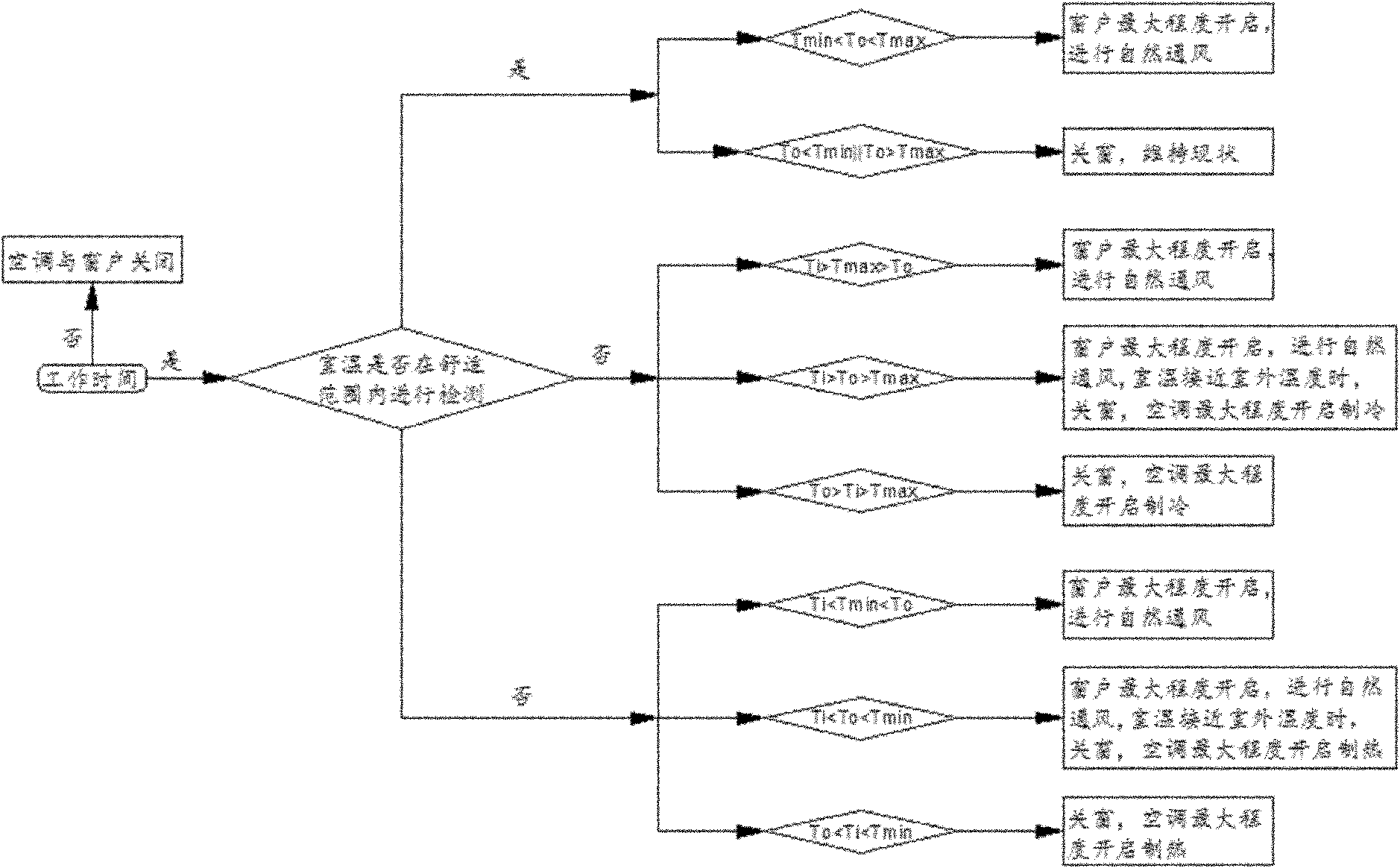

High-content steel slag grouting material

The invention relates to a high-content steel slag grouting material, which is prepared from the following raw materials by weight percent: 0%-8% of steel slag, 0%-16% of sulfoaluminate cement, 0%-31% of portland cement, 0%-15% of coal ash, 0%-50% of sand, 0.2%-2.0% of exciting agent, 0.4%-1.5% of water reducing agent and 0.02%-0.05% of expanding agent. The steel slag grouting material provided by the invention has the advantages of high steel slag content, high strength, no shrinkage and good mobility; the performance indexes of the steel slag grouting material meet the requirements of Technical Regulations of Cement-Based Grouting Material Application GB / T50448-2008; resources can be saved; solid wastes can be utilized; low carbon economy and resource recycling can be realized.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

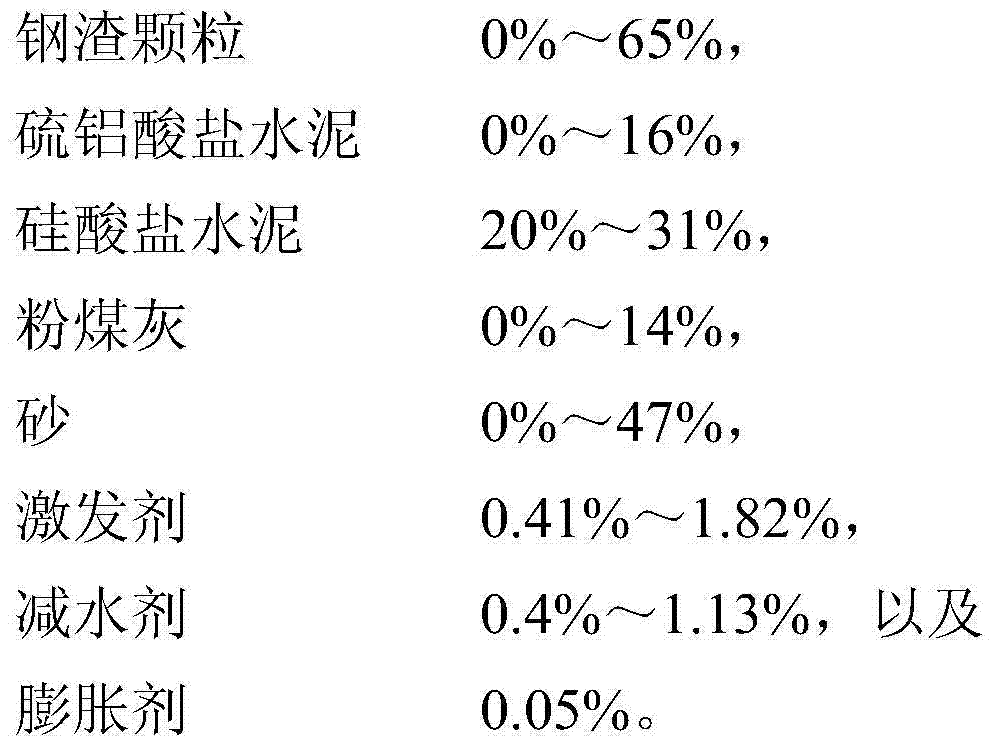

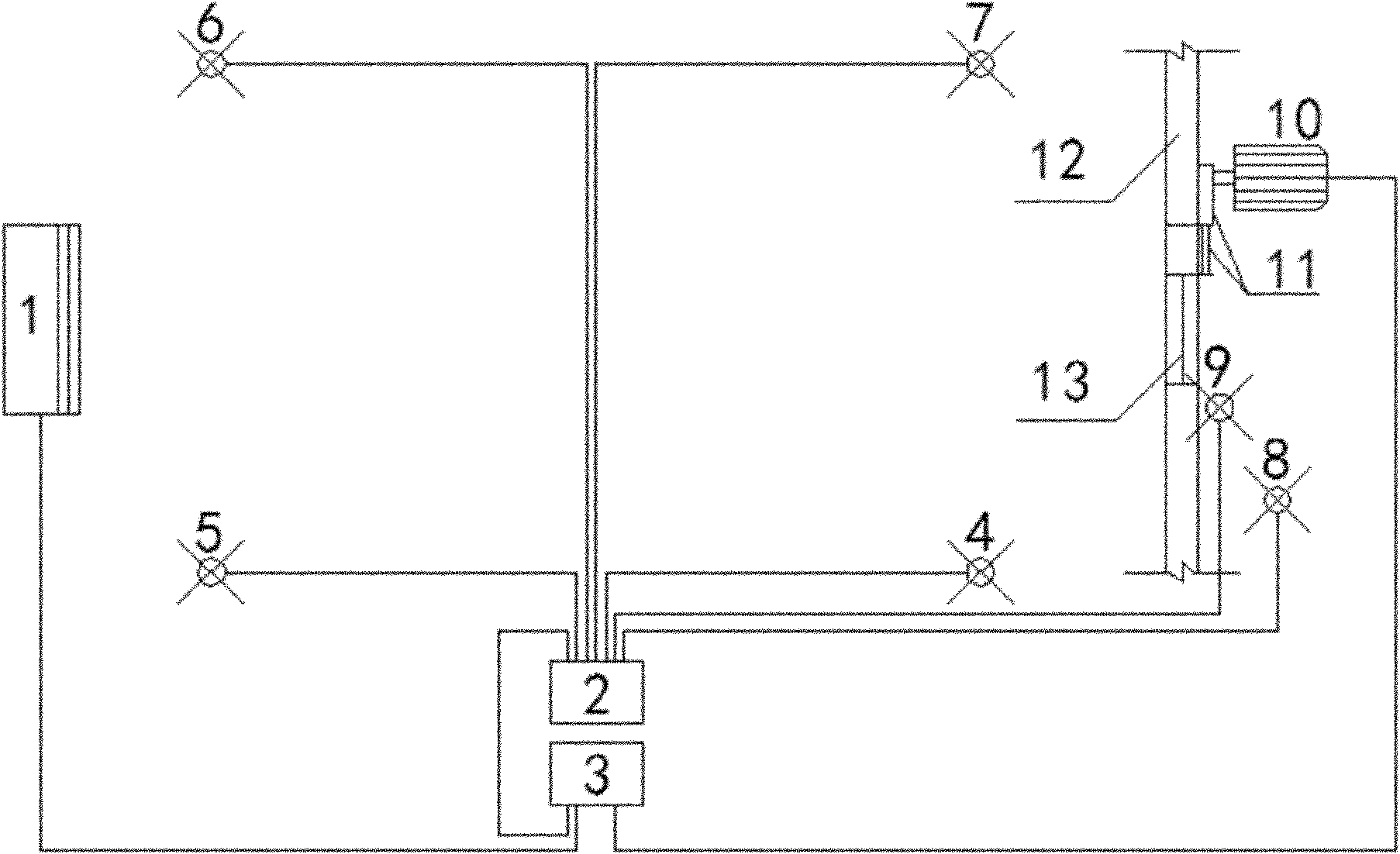

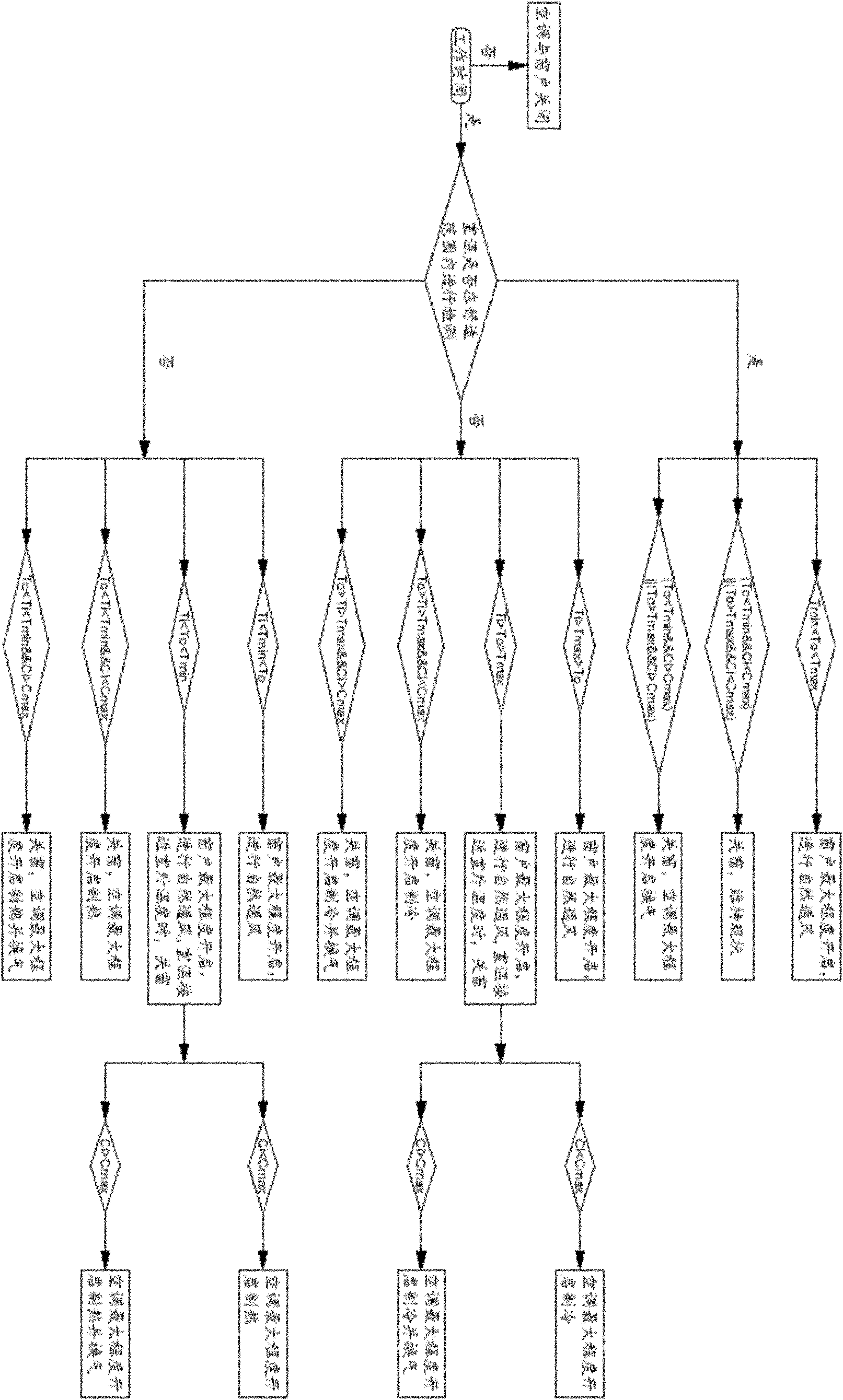

Environmental control method realizing energy stepped utilization by utilizing automatic opening and closing of window

InactiveCN101949575AReduce energy consumptionEnergy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusEnvironmental resource managementMotor drive

The invention discloses an environmental control method realizing energy stepped utilization by utilizing automatic opening and closing of windows. In the method, an air conditioner is arranged in a room; a motor is arranged on an external window of the room; the motor drives the external window to be opened and closed; a temperature sensor and a CO2 concentration detection sensor are arranged in the room; an outdoor temperature and rainfall capacity detection sensor is arranged outside the room; the temperature sensor, the CO2 concentration detection sensor and the rainfall capacity detection sensor are respectively connected with a digital quantity acquisition module; and the air conditioner, the digital quantity acquisition module and the motor are respectively connected with a digital quantity control module, thus achieving the environmental control effect of the architectural space, simultaneously lowering the environmental control energy consumption, reflecting the low-carbon economy concept, combining the automation technique and the environment control, and providing guarantee to accurately control the thermal comfort of the architectural space.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Steamed ecological water permeable environmentally friendly brick produced by waste ceramic residues and manufacturing method thereof

ActiveCN101994283AMitigate the heat island effectGuaranteed water circulationSolid waste managementSingle unit pavingsBrickSodium Bentonite

The invention relates to a steamed ecological water permeable environmentally friendly brick produced by waste ceramic residues and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: adding a lower brick material obtained by uniformly mixing waste ceramic residue powder, waste glass powder, garbage clinker powder, portland cement, calcium oxide, calcium sulfate, sodium chloride, a rosin hot polymer, calcium sulfonate, sodium aluminate and water to a double-axis mixing stirrer to stir into a wet state, and then vibrating, extruding and molding into a lower brick of the ecological water permeable environmentally friendly brick; uniformly coating a layer of fine material of an upper brick material obtained by uniformly mixing waste ceramic fragment powder, bentonite, talcum powder and water on the upper part of the lower brick by using a secondary spreader to manufacture a water permeable environmentally friendly brick blank under the pressure of 25-30Mpa; maintaining with steam; heating at constant temperature; and naturally cooling to manufacture the steamed ecological water permeable environmentally friendly brick product of the waste ceramic residues. The raw materials of the invention also can be manufactured into vegetation bricks of different specifications. The product has certain water permeability, air permeability and water retentivity, also has various functions of cooling, reducing noise, regulating the climate, eliminating the heat island effect of a city, improving the air quality, maintaining the surface water circulation, and the like and the advantages of high product strength, no pollution, low cost and good benefit and conforms to the requirements on saving energy, reducing emission, protecting environment and developing low-carbon economy.

Owner:清远绿由环保科技有限公司

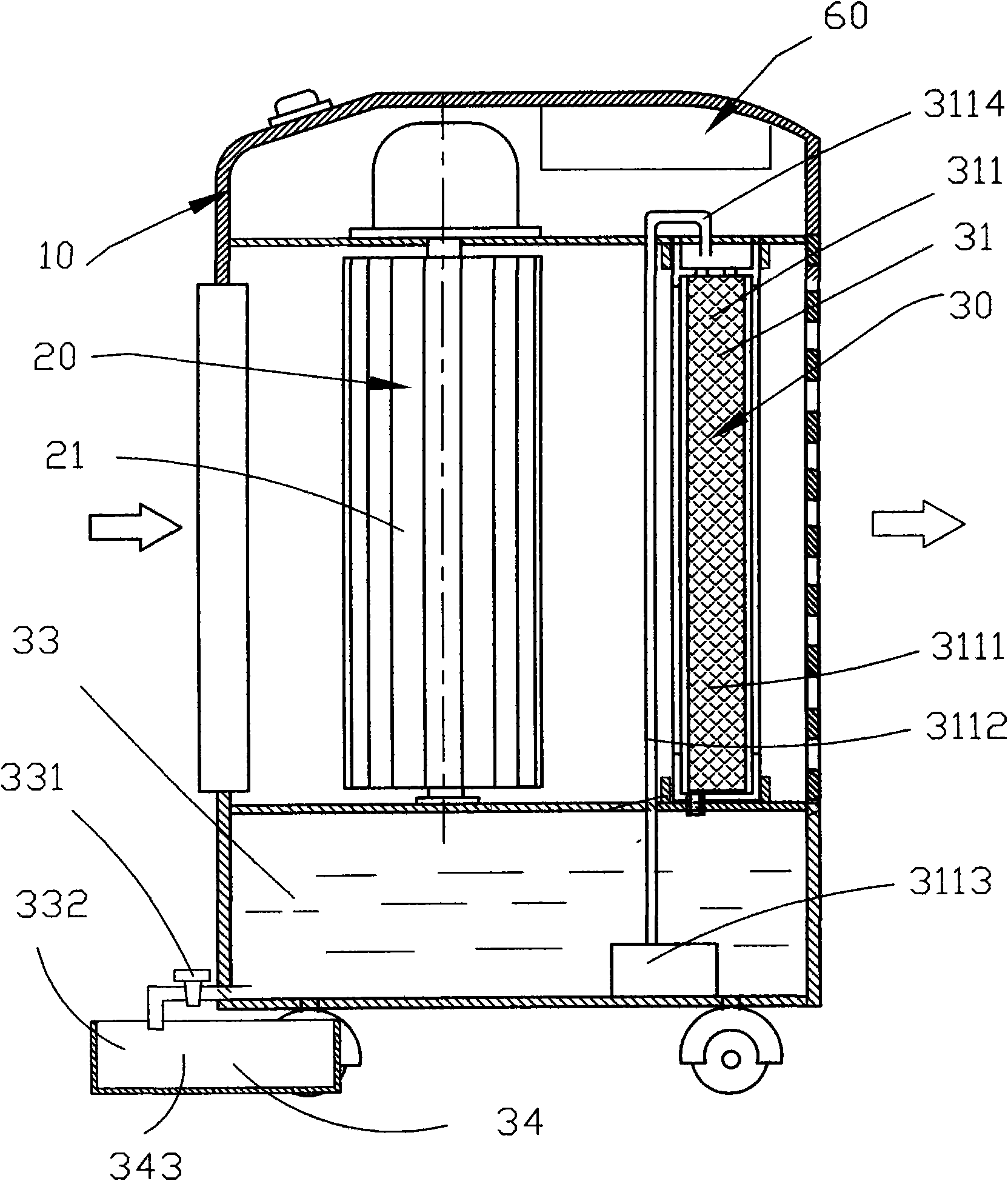

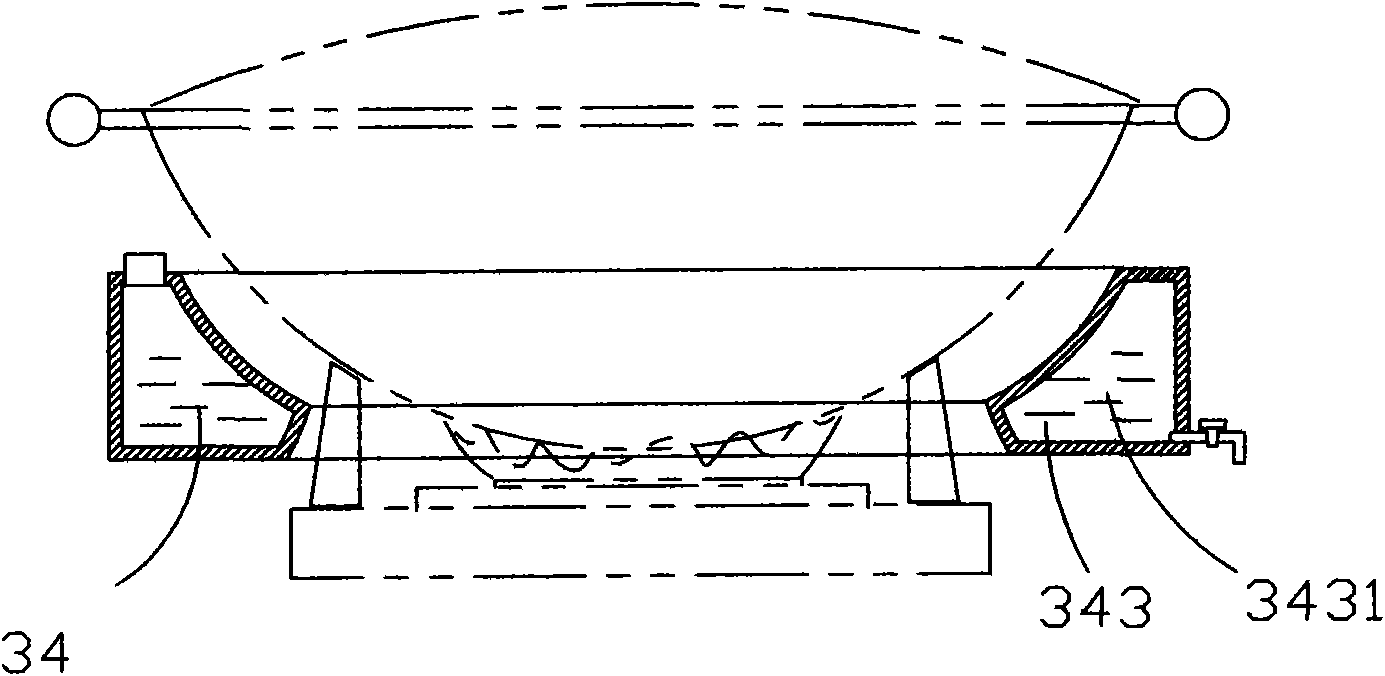

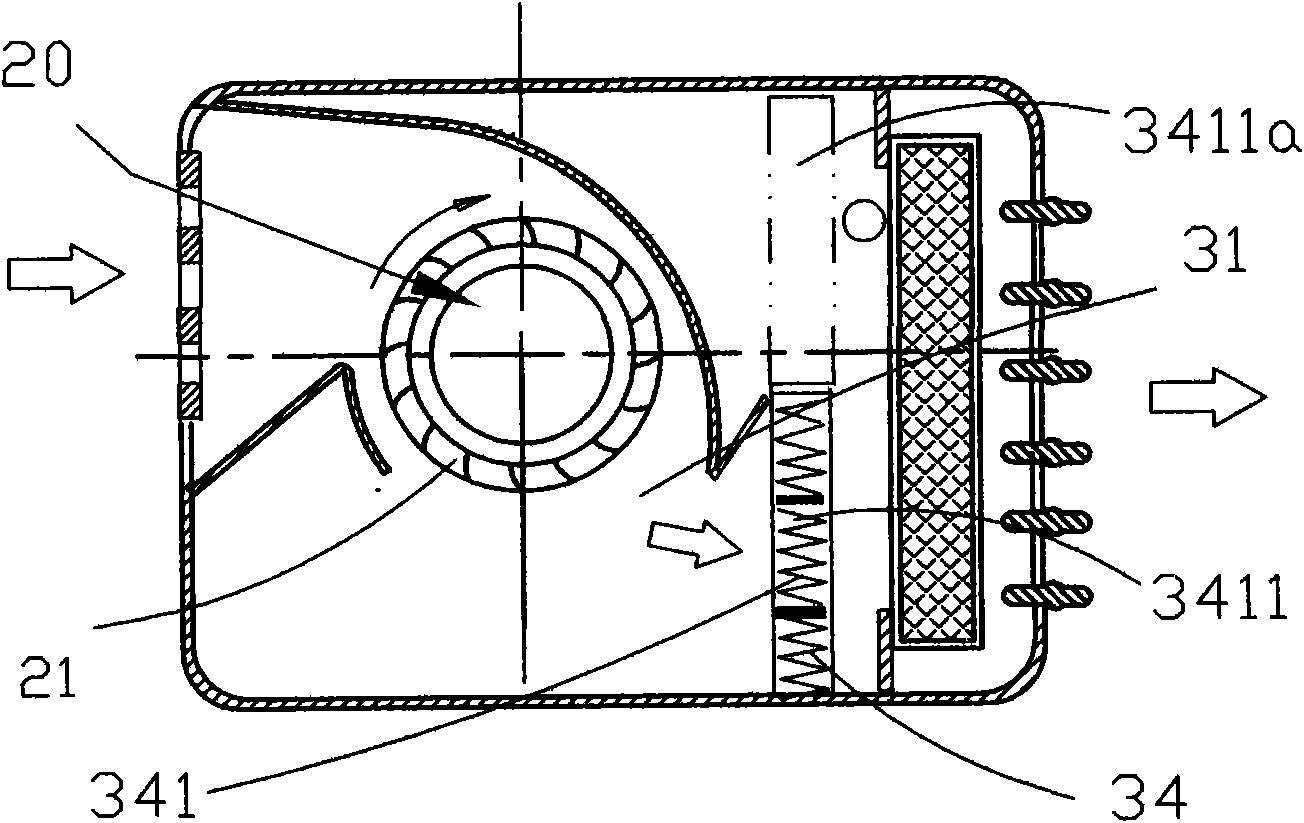

Multifunctional air condition fan capable of dehumidifying air and dehumidifying method thereof

InactiveCN101818930AReduce manufacturing costEliminate waste of resourcesLighting and heating apparatusSpace heating and ventilation detailsEnvironmental resistanceCooling effect

The invention provides a multifunctional air condition fan capable of dehumidifying air and a dehumidifying method thereof, belonging to a device for adjusting the temperature and the humidity of indoor air. The multifunctional air condition fan comprises a shell (10), a fan component (20), an evaporating system (30) and an electric control part (60), wherein the evaporating system comprises a wet curtain (31), a liquid storing box (33) and a hygroscopic agent regenerating device (34); when under the work condition of wetting and temperature reducing, the liquid storing box (33) stores the water; and when under the work condition of dehumidifying, the liquid storing box stores the hygroscopic agent. The regenerating device has an internal type, an external type and a manual type. The invention realizes the multifunctions of wetting and temperature reducing, dehumidifying, cooling and heating with the cost which is similar to that of the existing evaporating type cold fan. The invention integrates the dehumidifying device and the existing air condition fan into a whole, which have complete season complementation and inverse working principle, thereby reducing the manufacture cost of the special dehumidifying device and eliminating the resources waste caused by the seasonal idling. The invention can achieve the cooling effect without a compressor and Freon, and can take the residual heat of the kitchen and the solar energy as cooling energy, thereby being an innovative technology of environment protection and low carbon economy for families and public places, and having higher popularization and use value.

Owner:SHENZHEN LANGSI SCI & TECH

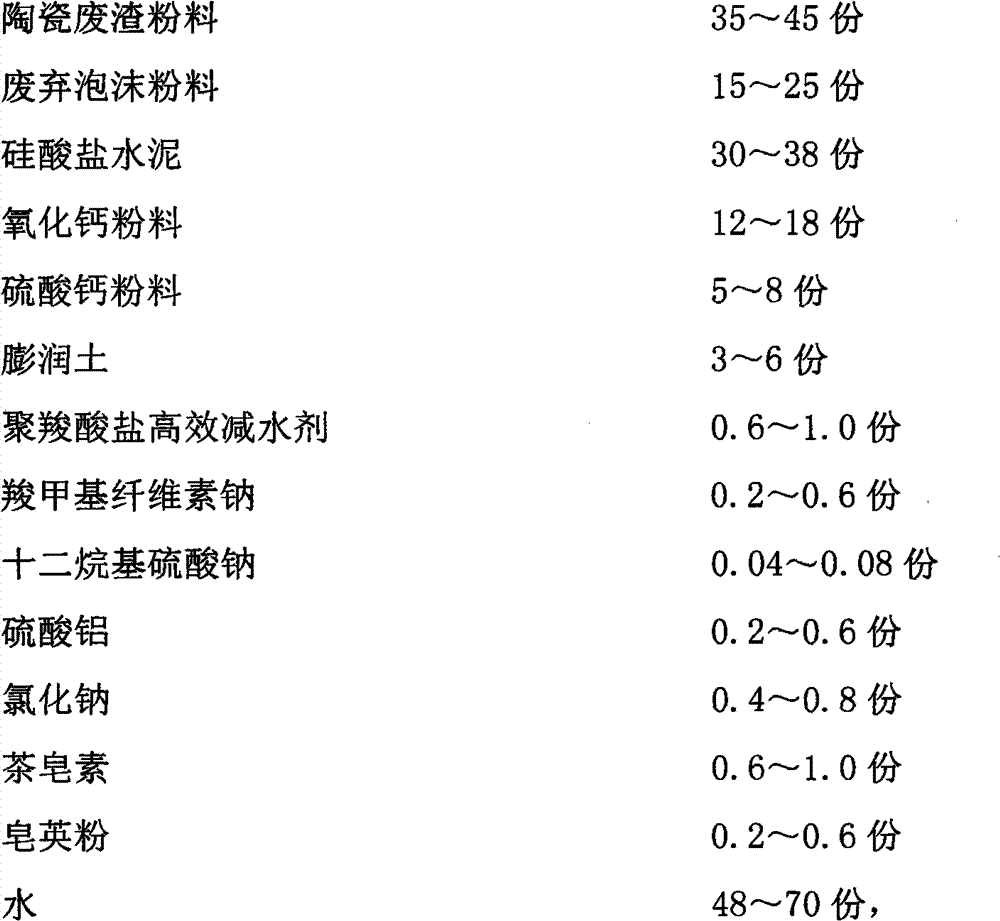

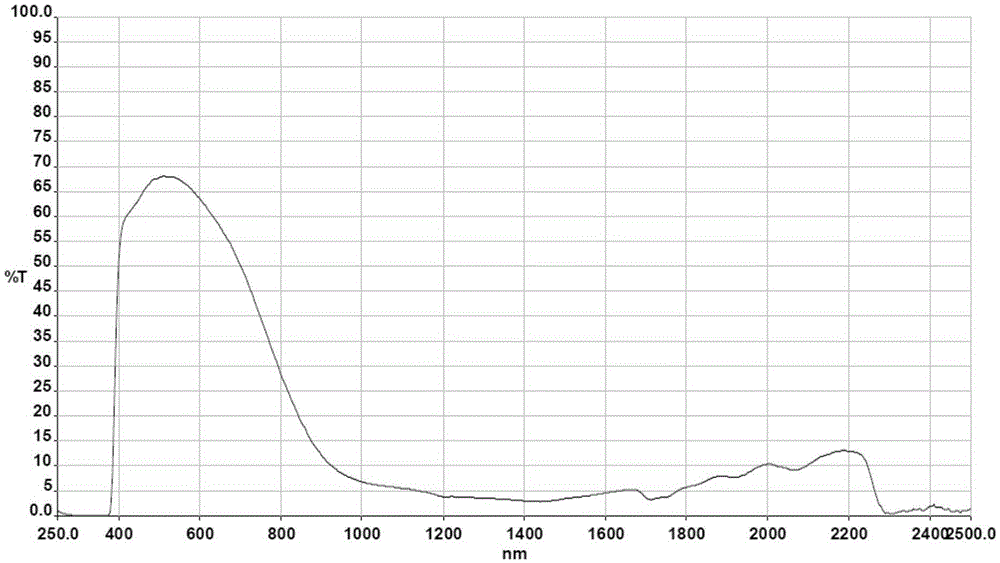

Foamed concrete building block made of waste residues of ceramics and method for manufacturing foamed concrete building block

InactiveCN102807349ALight in massLight weightSolid waste managementCeramicwareCelluloseFoam concrete

The invention relates to a foamed concrete building block made of waste residues of ceramics and a method for manufacturing the foamed concrete building block. The foamed concrete building block is manufactured by the following steps of: uniformly stirring waste residues of ceramics, waste polystyrene foam, Portland cement, calcium oxide, calcium sulphate, bentonite, a polycarboxylate high-efficiency water reducing agent, sodium cellulose glycolate, aluminum sulphate, sodium chloride and water, which serve as raw materials, by using a twin-shaft mixer, and mixing the mixture with tea saponin and saponin powder to form foam; under the full-automatic control of a computer, conveying the mixture to a high-speed mixed foam pulping mixer by using a spiral tube conveyor, uniformly stirring the mixture to obtain pasted foam pulp; and transmitting the foam pulp to a mold, moulding the foam pulp to obtain a concrete building block mould, reshaping, and transmitting the shaped mould to a curing room for solidifying; and demolding, performing automatic stacking, packaging, and storing the packaged concrete building block in a storage yard. The product has the advantages of light weight, high strength, environment friendliness, low cost and high benefits and is in line with the national rules and regulations about energy conservation and emission reduction, development of low-carbon economy and environmental protection.

Owner:李桓宇

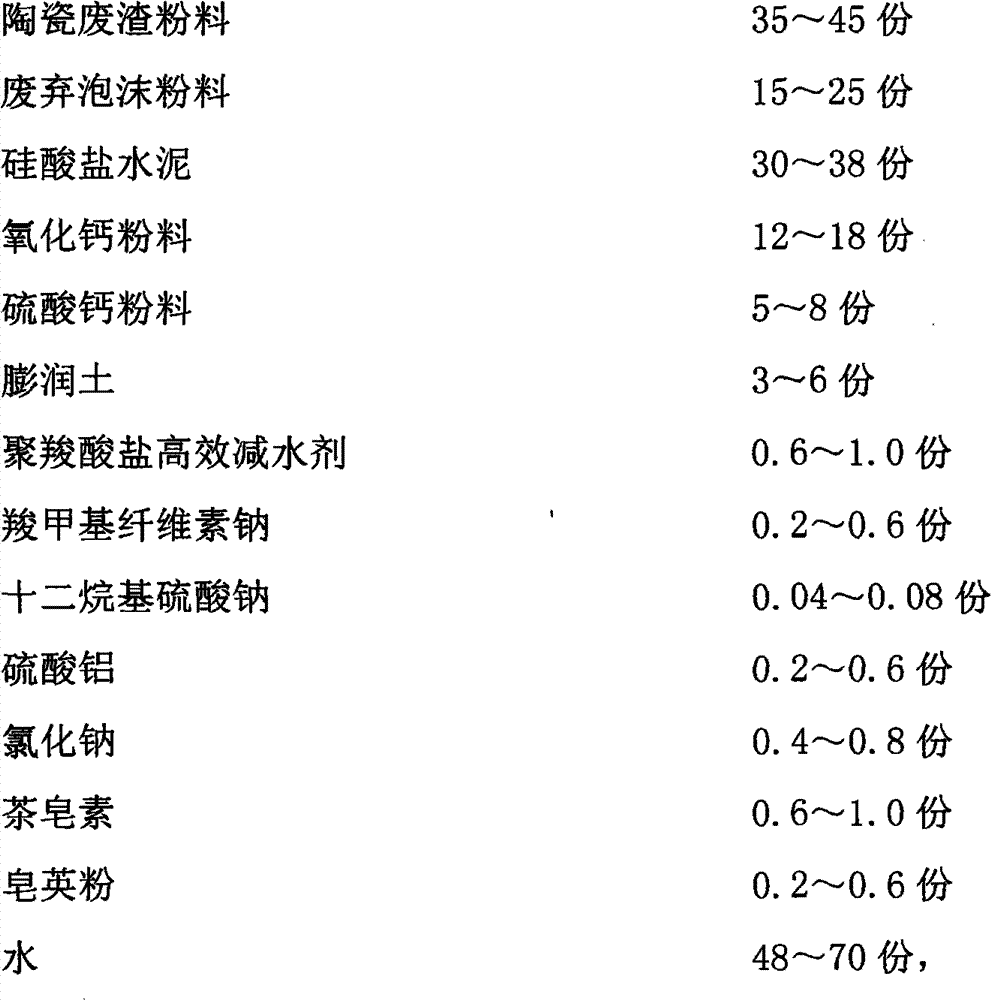

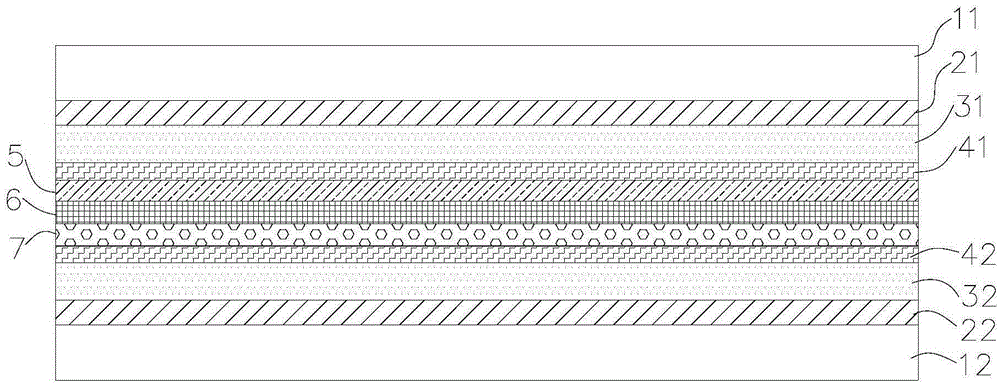

Electrochromic laminated glass and preparation method thereof

ActiveCN105252849AGood ion transmission abilityReduce energy loadGlass/slag layered productsInfraredEnvironmental resistance

The invention specifically relates to an electrochromic laminated glass and a preparation method thereof, belonging to the technical field of energy-saving glass. According to the invention, a solid gel electrolyte is used as an ion transport layer so as to successfully overcome the problems of great inconvenience in packaging and unsuitability for large-area display of conventional electrochromic laminated glass using a liquid electrolyte. Through adjustment of composition and proportion of the solid gel electrolyte, the eventually formed ion transport layer has good ion transport performance. Moreover, the electrochromic laminated glass uses a PC film or a PMMA film as a substrate and cooperatively uses a thermal insulation glue film to highly efficiently shield infrared rays and ultraviolet rays; thus, the prepared electrochromic laminated glass has a heat reflection function, guarantees high-efficiency selectivity to spectra, can automatically carry out color regulation and control, light adjustment and temperature adjustment, has the characteristics of high efficiency, low energy consumption, greenness, environmental protection, intelligentialization, substantially reduces energy load of a building, and accords with the current development requirements for energy conservation, emission reduction and low-carbon economy.

Owner:东莞市友联亨达光电有限公司

Environment-friendly brick produced from combustion slag of oil-bearing sludge reclaimed coal and manufacturing method thereof

ActiveCN101941825AEnhance and improve performanceImprove performanceSolid waste managementBrickSludge

The invention relates to an environment-friendly brick produced from combustion slag of oil-bearing sludge reclaimed coal and a manufacturing method thereof. The invention is characterized in that slag powder, which is obtained by combusting reclaimed coal made of oil-bearing sludge and coal gangue powder, waste clinker powder, fly ash powder, Portland cement, calcium oxide, calcium sulfate, sodium chloride, colophony thermopolymer, calcium sulfonate, sodium sulfate, sodium aluminate, water and the like are used as raw materials. The method comprises the following steps: mixing the raw materials into a moisturized state by using a double-shaft mixer, carrying out extrusion molding in a mechanical vibration mode, steam-curing, and naturally cooling to obtain the environment-friendly brick produced from combustion slag of oil-bearing sludge reclaimed coal. The raw materials of the invention can also be used for making hollow building block, crown wall bricks, square bricks and pavement bricks with different specifications. The product has the advantages of light weight, high strength, no pollution, low cost and good benefit, and conforms to the environment protection development low-carbon economic requirements of energy saving and emission reduction.

Owner:清远绿由环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com