Hot-rolled pickled sheet with low yield ratio and production method thereof

A hot-rolled pickling and low yield ratio technology, applied in the field of steel rolling, can solve the problems of high cost and large amount of alloying elements added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

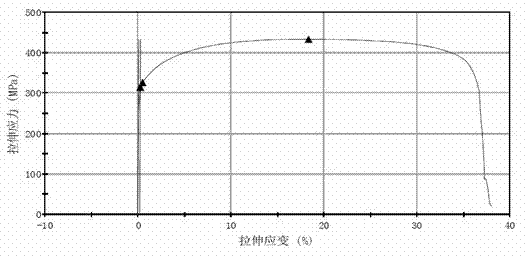

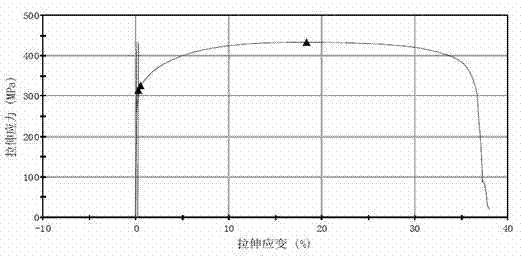

Image

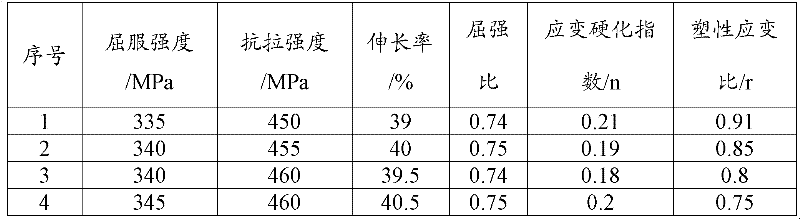

Examples

Embodiment Construction

[0020] The present invention provides a low-yield-ratio hot-rolled pickling plate, the mass percent of its chemical composition is: C: 0.04-0.12, Si: 0.005-0.05, Mn: 0.8-1.5, P≤0.020, S≤0.020, Al : 0.01~0.08, B: 0.0005~0.003, the balance is Fe and trace elements. An appropriate amount of B can coarsen ferrite grains and reduce the yield strength of strip steel, but the addition of B element has a great influence, too little will not achieve the effect of coarsening, too much will easily form bainite or martensitic Tensile phase, affecting the formability of the strip. The present invention determines that its content is 0.0005-0.003.

[0021] The invention provides a method for producing the above-mentioned low yield ratio hot-rolled pickling plate, comprising:

[0022] Step S1: The mass percentage of the chemical composition obtained through converter or electric furnace smelting is: C: 0.04-0.12, Si: 0.005-0.05, Mn: 0.8-1.5, P≤0.020, S≤0.020, Al: 0.01-0.08, B: 0.0005~0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com