Method for separating and producing methane and carbon dioxide from marsh gas

A technology of carbon dioxide and biogas, applied in chemical instruments and methods, inorganic chemistry, gas fuel, etc., can solve the problems of not exerting economic benefits, and achieve the effect of low-carbon economic cycle, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

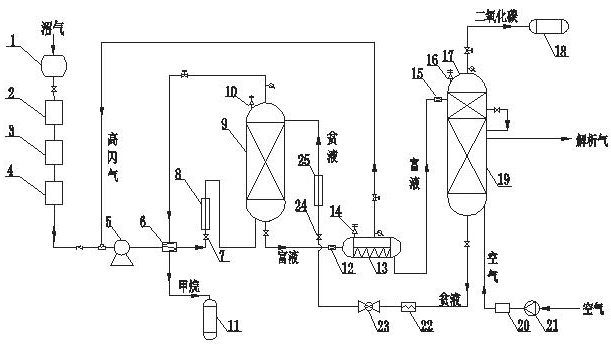

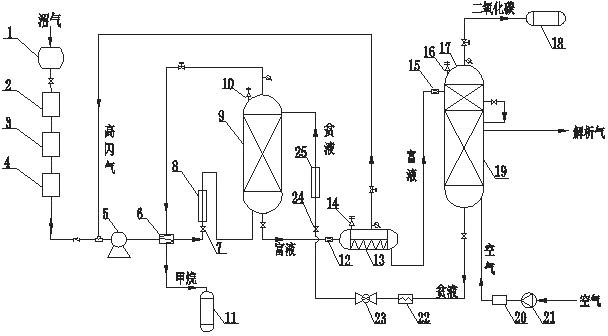

[0015] Referring to accompanying drawing, production method of the present invention is carried out as follows.

[0016] 1. Pretreatment, in order to separate high-purity methane and carbon dioxide from biogas, while protecting the adsorbent from pollution. Before separation, the biogas needs to be pretreated to remove low-level impurities such as hydrogen sulfide, water vapor and dust in the biogas. Make the sum of the volume of methane and carbon dioxide account for more than 97% of the total volume of biogas. The invention adopts iron oxide to remove hydrogen sulfide, adopts sponge to remove dust, and adopts silica gel and molecular sieve to remove water.

[0017] The pretreatment method is: send the biogas generated in the process of landfill, anaerobic digestion of organic waste or anaerobic treatment of high-concentration organic wastewater into the gas storage bag 1 through the pipeline; the biogas in the gas storage bag 1 flows through the valve to Desulfurization to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com