Comprehensive utilization method of slag iron concentrates of wet-type zinc smelting furnace

A technology for hydrometallurgical smelting of zinc and iron concentrate, applied in the field of metallurgy, can solve the problems of high technical difficulty, inability to recover rare and precious metals and other valuable elements, and small market for polymerized ferric sulfate products, and achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

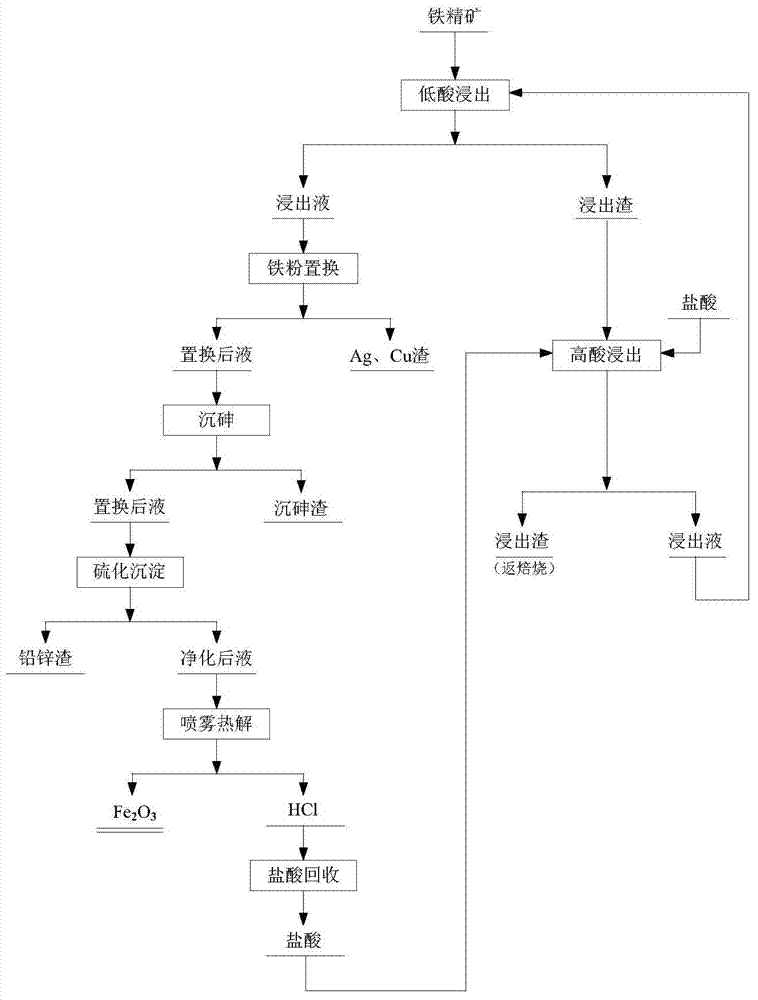

Method used

Image

Examples

Embodiment 1

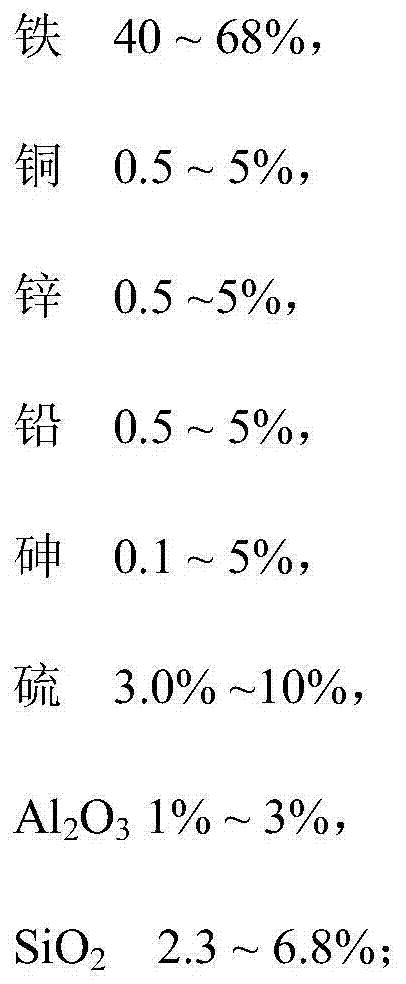

[0047] The raw material is zinc hydrometallurgy kiln slag iron concentrate. The main components of the raw material are: Fe40%, Ag10g / t, Cu5.0%, Zn5.0%, Pb5.0%, As5.0%, Al 2 o 3 1.0%, S10.0%, SiO 2 6.8%;

[0048] The kiln slag iron concentrate is leached at room temperature, the concentration of hydrochloric acid is 0.5mol / L during low-acid leaching, the liquid-solid ratio is 10:1ml / g, and the leaching time is 240min; 3mol / L hydrochloric acid is carried out high-acid leaching for 180min according to the liquid-solid ratio of 20:1ml / g. The leaching slag obtained by acid leaching is used in the roasting process; after low-acid leaching and high-acid leaching, the leaching rate of Fe in the raw material is 92.21%, the leaching rate of Ag is 98.95%, the leaching rate of copper is 95.07%, and the leaching rate of Pb The leaching rate of As was 99.34%, the leaching rate of As was 88.57%, and the leaching rate of Zn was 57.92%;

[0049] At this moment, the pH value of the low-aci...

Embodiment 2

[0054] The raw material is zinc hydrometallurgy kiln slag iron concentrate. The main components of the raw material are: Fe55.0%, Ag1000g / t, Cu0.5%, Zn5.0%, Pb5.0%, As3.5%, Al 2 o 3 2.0%, S5.0%, SiO 2 4.6%, the rest is oxygen in the oxides of various elements; leaching kiln slag iron concentrate at 60°C, the concentration of hydrochloric acid is 2.5mol / L during low-acid leaching, the liquid-solid ratio is 10:1ml / g, and the leaching time is 180min; the obtained low-acid leaching solution is ready for use, and the obtained low-acid leaching residue is subjected to high-acid leaching for 30 minutes with 5mol / L hydrochloric acid at a liquid-solid ratio of 5:1ml / g. In the low-acid leaching process, the leaching continues according to the low-acid leaching conditions, and the leaching residue obtained from high-acid leaching is used in the roasting process; after low-acid leaching and high-acid leaching, the leaching rate of Fe in the raw material is 91.36%, and the leaching rate o...

Embodiment 3

[0060] Using hydrometallurgy zinc kiln slag iron concentrate as raw material, the composition of the raw material is: Fe56.5%, Ag256g / t, Cu2.5%, Zn2.5%, Pb0.99%, As0.49%, Al 2 o 3 1.8%, S4.75%, SiO 2 3.4%, the rest is oxygen in the oxides of various elements; leaching kiln slag iron concentrate at 90°C, the concentration of hydrochloric acid is 3.0mol / L during low-acid leaching, the liquid-solid ratio is 5:1ml / g, and the leaching time is 30min; The gained low-acid leaching liquid is for subsequent use, and the hydrochloric acid of gained low-acid leaching residue is 5:1ml / g to carry out high-acid leaching 30min with the hydrochloric acid of 6.0mol / L by liquid-solid ratio, after the high-acid leaching, the leachate hydrochloric acid concentration is 3.2mol / L, can Return to the low-acid leaching process, continue leaching according to the low-acid leaching conditions, and use the leaching residue obtained from high-acid leaching for the roasting process; after low-acid leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com