Clearing construction method for underground obstacle

A technology of underground obstacles and construction methods, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of high cost, long construction period, and large construction space, and achieve the effect of small impact, saving construction period, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

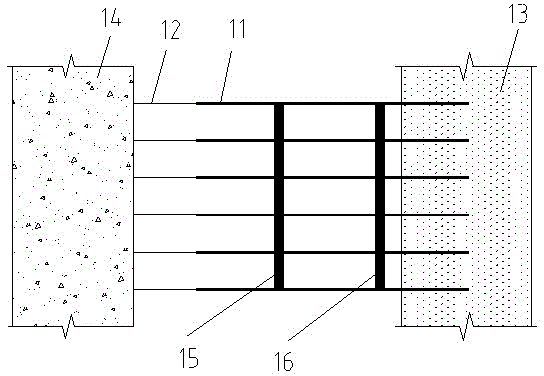

[0040] Such as figure 1 As shown, the reference signs are as follows: 11, the anchorage section of the underground obstacle, 12, the free section of the underground obstacle, 13, the subway operation section, 14, the built building, 15, the first trough forming area, 16, the second trough forming area Groove area.

[0041] The construction interval in the underground obstacle removal construction method of the present invention is specifically taken the subway operation interval as an example, and the construction method includes the following specific steps:

[0042] a. According to the drawings, consult the positional relationship between the underground obstacle anchoring section 11 and the subway operating section 13, and determine that the end of the underground obstacle anchoring section 11 is located inside the subway operating section 13;

[0043] b. Grooving the upper part of the underground obstacle anchoring section 11 to the position of the obstacle through the sl...

Embodiment 2

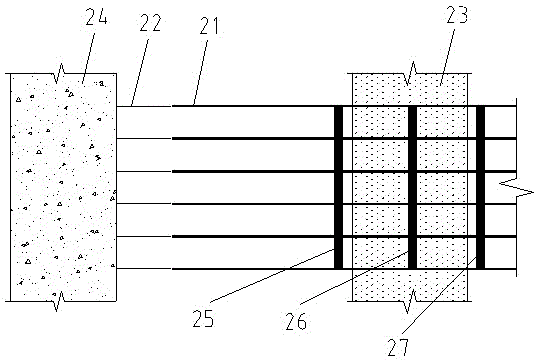

[0049] Such as figure 2 As shown, the reference signs are as follows: 21, the anchorage section of the underground obstacle, 22, the free section of the underground obstacle, 23, the subway operation section, 24, the built building, 25, the first trough forming area, 26, the second trough forming area Grooved area, 27, the third grooved area.

[0050] The construction interval in the underground obstacle removal construction method of the present invention is specifically taken the subway operation interval as an example, and the construction method includes the following specific steps:

[0051] a. According to the drawings, consult the positional relationship between the underground obstacle anchoring section 21 and the subway operating section 23, and determine that the underground obstacle anchoring section 21 runs through the subway operating section 23;

[0052] b. Grooving the upper part of the underground obstacle anchoring section 21 to the position of the obstacle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com