Tunnel construction drainage treatment method and treatment device thereof

A technology for drainage treatment device and tunnel construction, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Reasonable, the sedimentation tank covers a large area, etc., to achieve the effect of reducing on-site construction procedures, reducing material consumption, and reducing the area of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

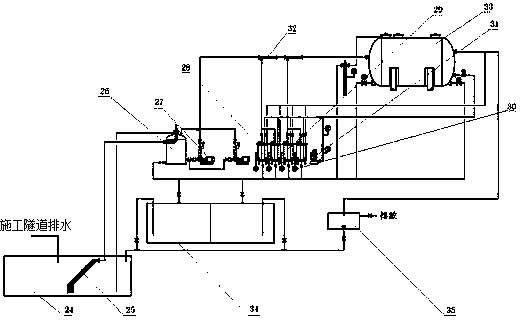

[0031] Such as figure 1 As shown, a tunnel construction drainage treatment device includes a vacuum diverter 26, a lift pump 27, a pipe mixer 32, and a drainage treatment unit 33 connected sequentially through pipelines. The top of the vacuum diverter 26 is provided with an inclined plate desander 25 , the tubular mixer 32 is connected with a liquid medicine dosing unit through a pipeline, and the liquid medicine dosing unit includes a Roots blower 32 and several liquid medicine dissolution tanks 30 connected with metering pumps 28, 29;

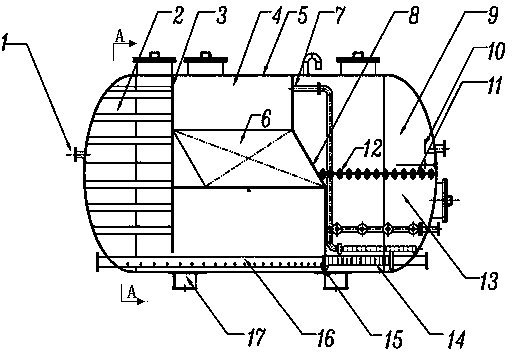

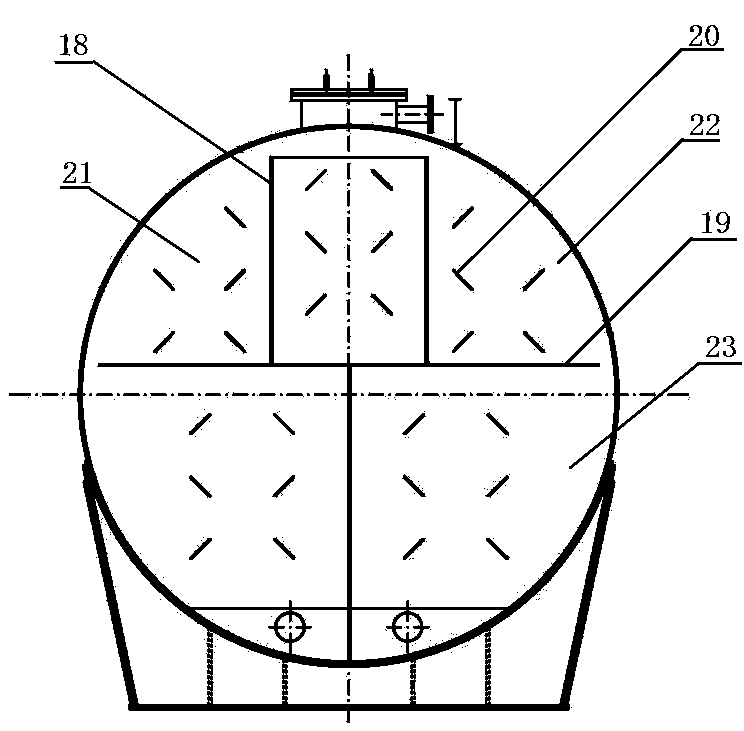

[0032] Such as figure 2 As shown, the drainage treatment unit 33 is a horizontal tank 5, the bottom of the tank 5 is provided with a saddle support 17, one end of the tank 5 is provided with a water inlet weir 1 connected with a tubular mixer 32, and the other end is provided with a water outlet Weir 10; tank 5 is divided into flocculation zone 2, sedimentation zone 4 and filter zone 9 by two vertical partition partitions 3,8; flocculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com