Prefabricated reinforced concrete beam with transverse steel partition boards and construction method

A reinforced concrete beam, prefabricated assembly technology, applied in joists, girders, trusses and other directions, can solve the problems of shortened construction period, poor overall performance, poor impermeability, etc. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

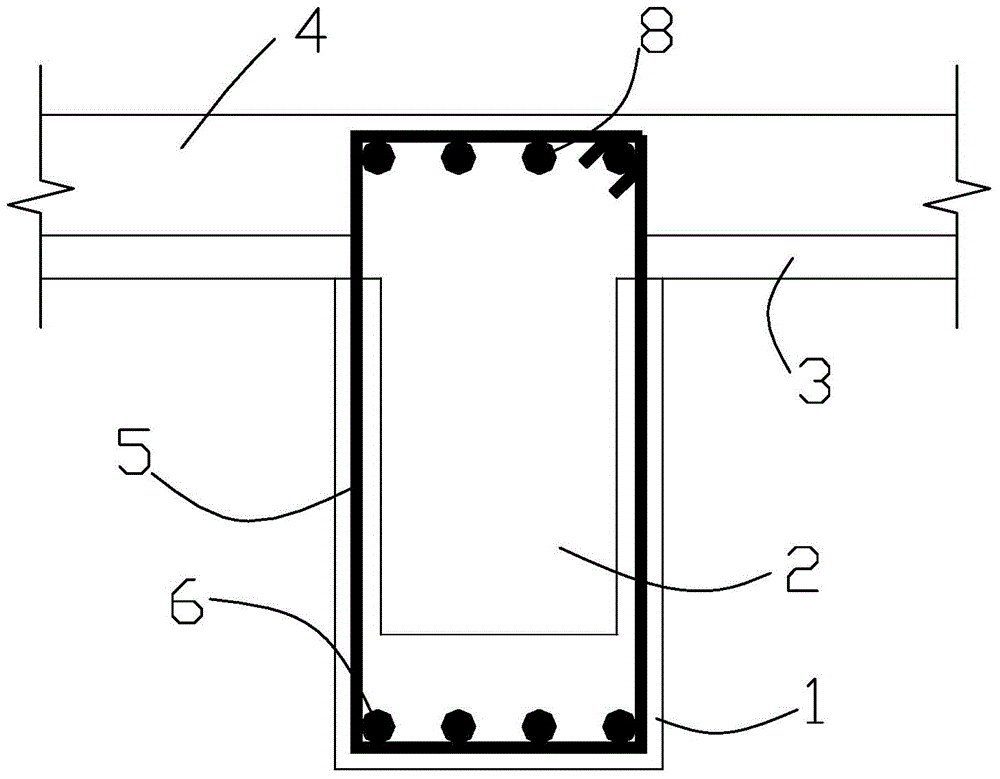

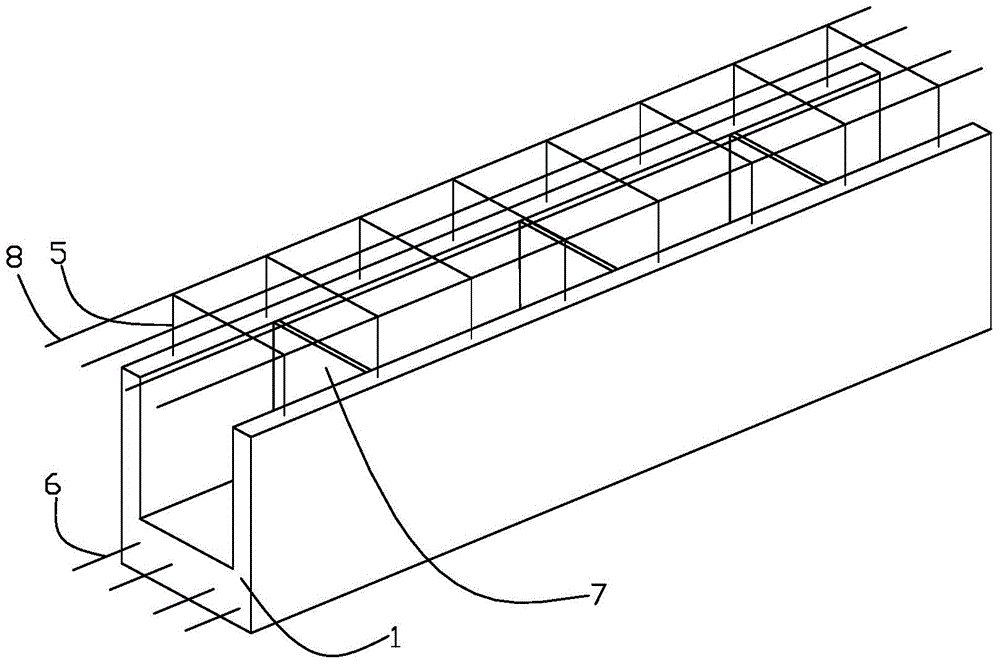

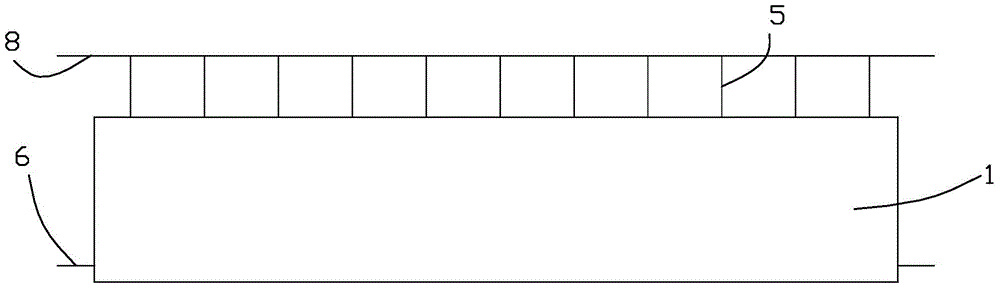

[0050] The present invention is a prefabricated assembled reinforced concrete beam with a transverse steel partition, which adopts the idea of partially prefabricated assembled part cast-in-place, and consists of a prefabricated part and a cast-in-place part, such as Figure 1 to Figure 10 As shown, it includes: prefabricated U-shaped high-strength concrete tank 1; cast-in-place ordinary concrete-2 filled in prefabricated U-shaped high-strength concrete tank 1; Steel partition 7; a number of closed stirrups 5 arranged in the prefabricated U-shaped high-strength concrete groove 1 and perpendicular to the length direction of the groove; a number of longitudinal reinforcements arranged in the bottom of the prefabricated U-shaped high-strength concrete groove 1 and parallel to the groove length direction -6; and the cast-in-place flange plate arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com