Full-prefabricated concrete anti-collision guardrail and construction method

A technology of prefabricated concrete and anti-collision barriers, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of unrealized full prefabrication of concrete anti-collision barriers, speed up the bridge construction cycle, and difficult to guarantee the appearance quality, so as to reduce the Construction process, good applicability, effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

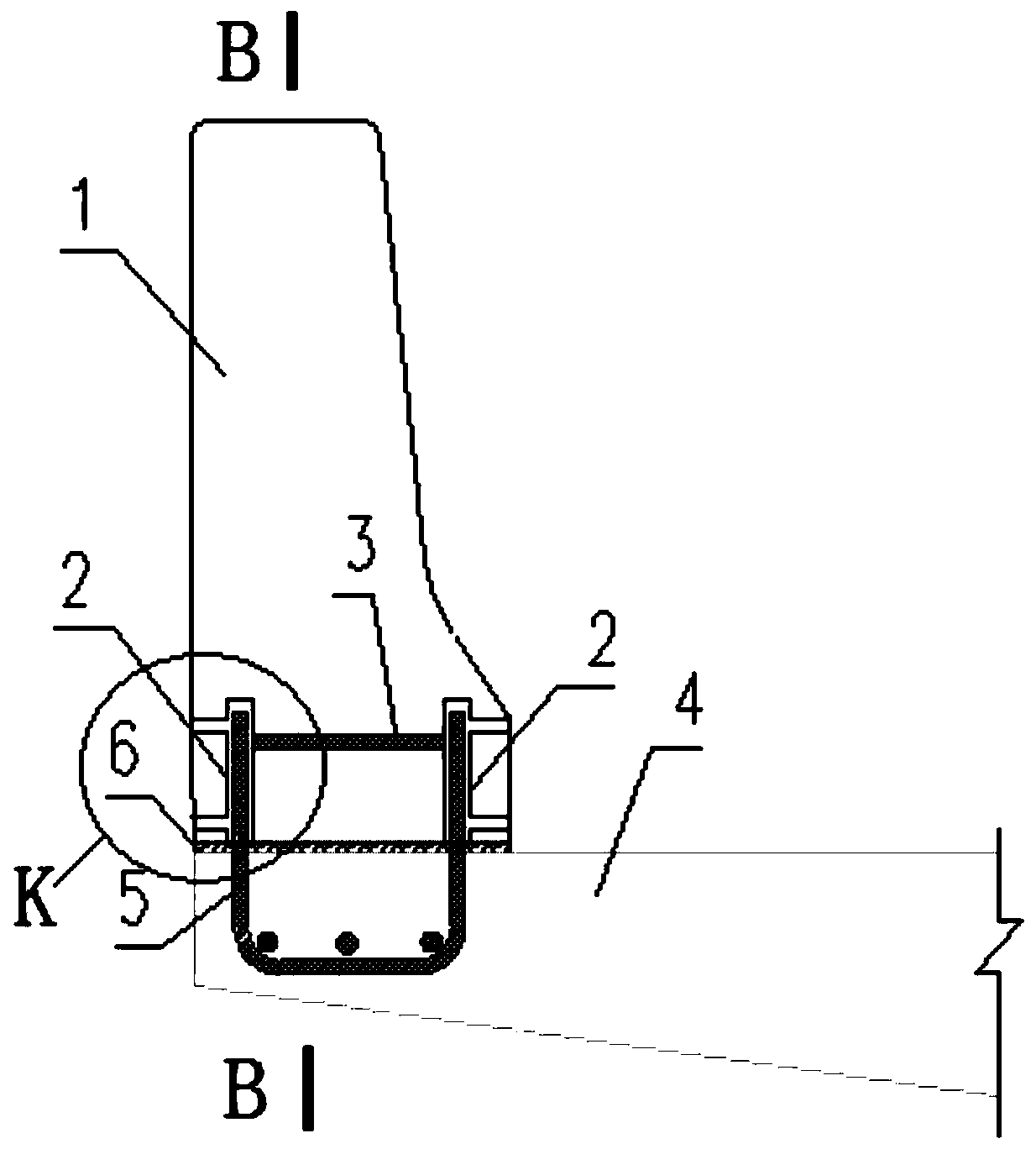

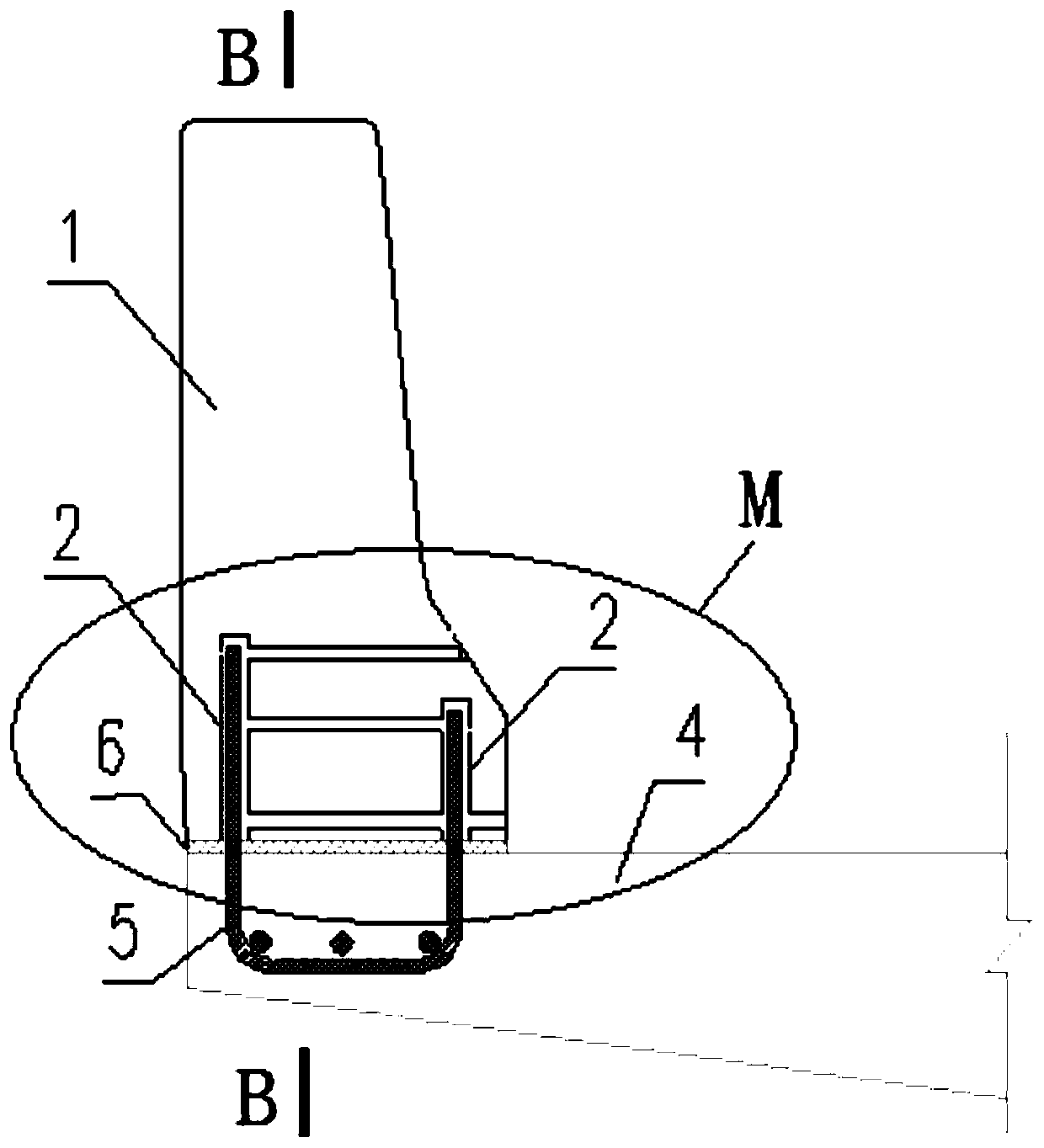

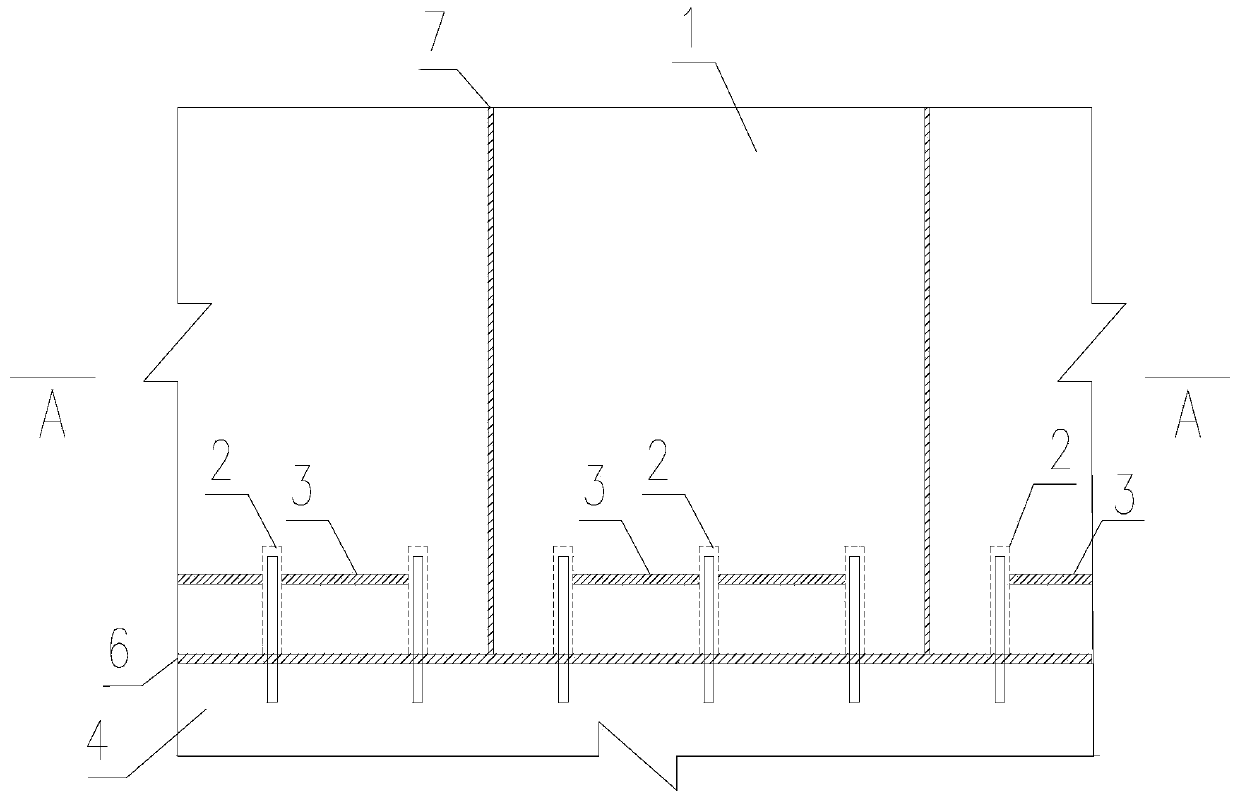

[0032] refer to Figure 1 to Figure 6 As shown, the full prefabricated concrete crash barrier in an embodiment provided by the present invention includes several jointed precast concrete crash barrier segments 1, and each precast concrete crash barrier segment 1 bottom is provided with a connecting device 2. The connecting device 2 is connected to the top plate 4 of the bridge deck;

[0033] The connection device 2 includes a steel casing 21, a slurry inlet pipe 22 and a slurry outlet pipe 23. The steel casing 21 is sleeved on the steel bar 5 reserved for the bridge deck, and the slurry inlet pipe 22 and the slurry outlet pipe 23 are respectively connected to the steel casing 21. .

[0034] Further, the steel sleeves 21 are connected by casing connecting steel bars 3 to enhance the connection force between the sleeve and the concrete; the slurry inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com