Insulating layer and inner wall surface combined type wall body module

A combined technology for interior walls, applied to thermal insulation, walls, building components, etc., can solve the problems of long production cycle and high production cost, and achieve the effects of improving quality, firm installation, and simplifying construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

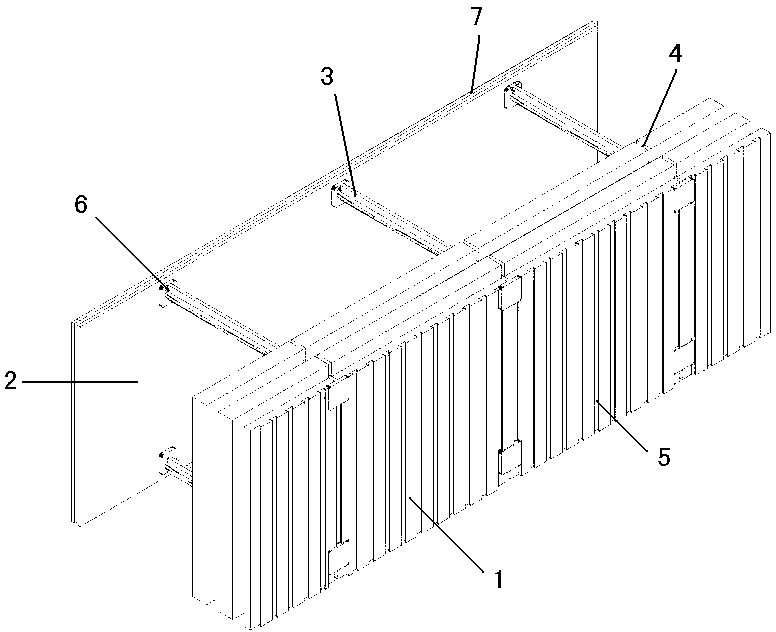

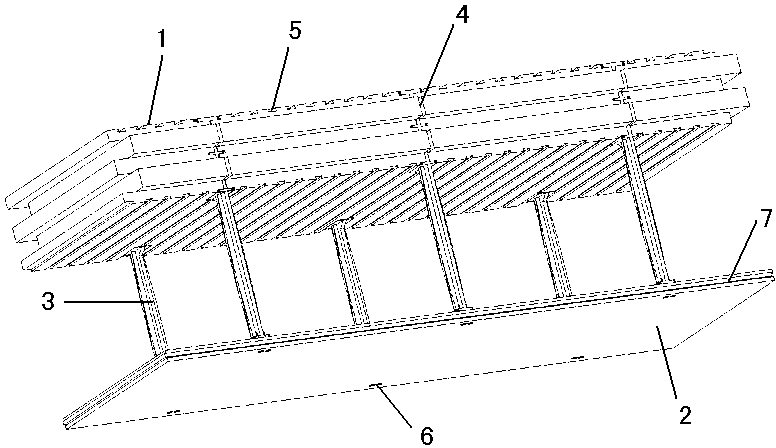

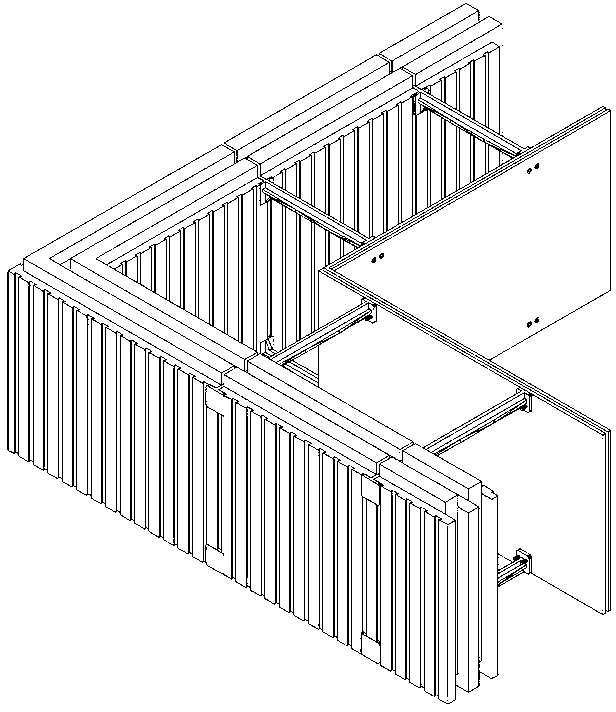

[0022] combine figure 1 and figure 2 , the structure of the first embodiment of the present invention includes an outer formwork 1, an inner formwork 2 and a connecting bridge 3, and each two corresponding sides of the inner formwork and the outer formwork have a mating slot and a socket. The outer formwork is made of thermal insulation material and has grooves 5 on the surface, and the inner formwork is a non-absorbent high-density board with a flat surface, a fiber magnesium board and a fireproof board. It is also equipped with a plug-in groove, one end of the connecting bridge has a plug-in plate, and the other end has a flat end plate, the outer template is provided with a connecting bridge insertion slot 4, and one end of the connecting bridge with a plug-in In the connecting bridge insertion slot, one end of the connecting bridge with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com