Prefabricated reinforced concrete beam with transverse high-strength concrete separation plate and construction method thereof

A technology for reinforced concrete beams and high-strength concrete, applied in joists, girders, truss beams, etc., can solve the problems of shortened construction period, poor overall performance, poor impermeability, etc. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

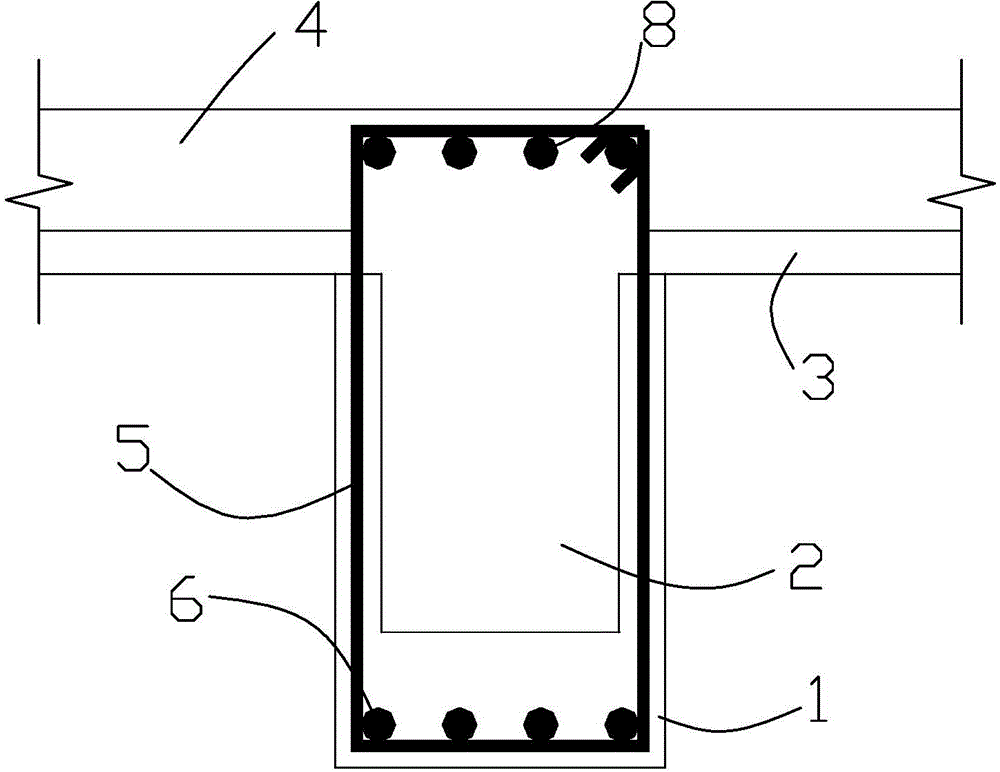

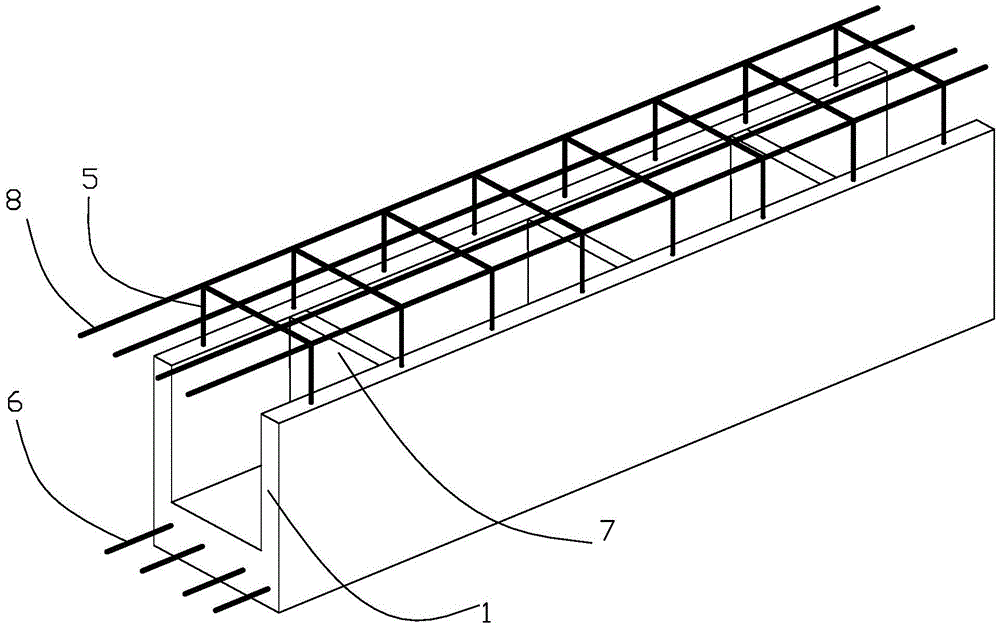

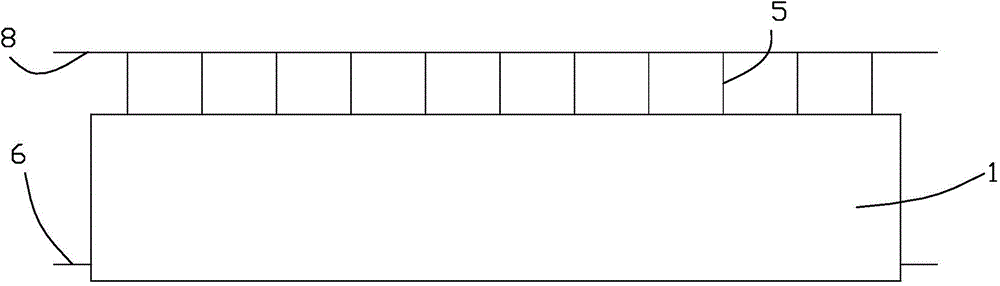

[0050] The present invention is a prefabricated and assembled reinforced concrete beam with a transverse high-strength concrete partition, which adopts the idea of partially prefabricated and assembled partly cast-in-place, and is composed of a prefabricated part and a cast-in-place part, such as Figure 1 to Figure 10 As shown, it includes: prefabricated U-shaped high-strength concrete tank 1; cast-in-place ordinary concrete-2 filled in prefabricated U-shaped high-strength concrete tank 1; High-strength concrete partition 7; a number of closed stirrups 5 arranged in the prefabricated U-shaped high-strength concrete groove 1 and perpendicular to the length direction of the groove; Reinforcement one 6;

[0051] Among them, such as figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the lower part of the stirrup 5 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com